High-nickel ternary positive electrode material as well as preparation method and application thereof

A cathode material, high-nickel technology, applied in chemical instruments and methods, nickel compounds, electrical components, etc., can solve the problems of rapid growth of DCR gas production, reduction of lithium-nickel mixing, material microcracks, etc., to achieve DCR and gas production. The effect of improved performance, easy operation and control, and excellent particle pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

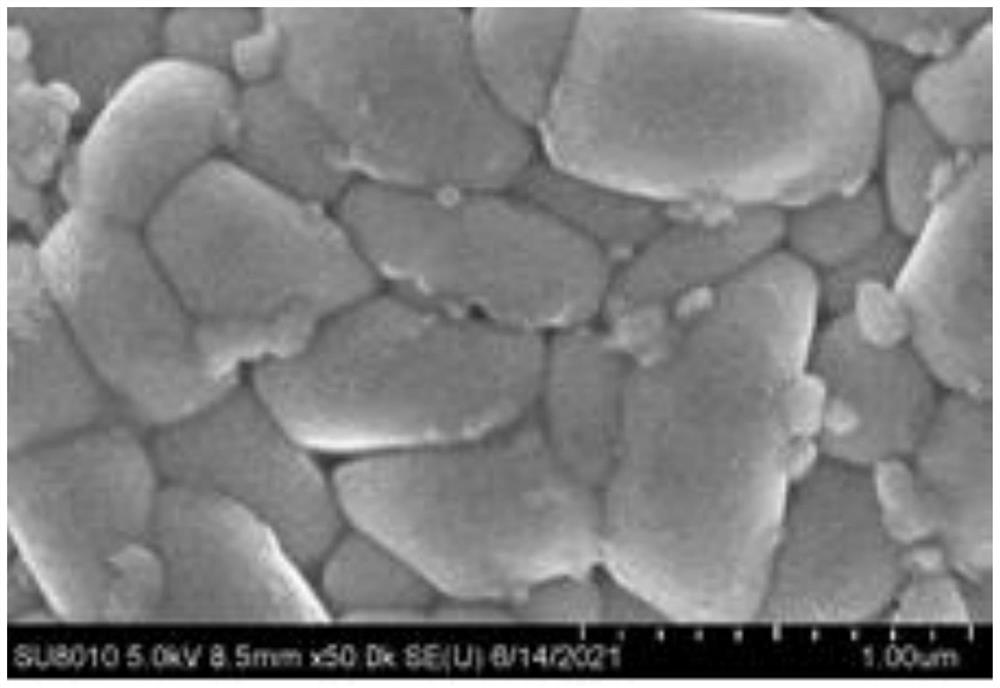

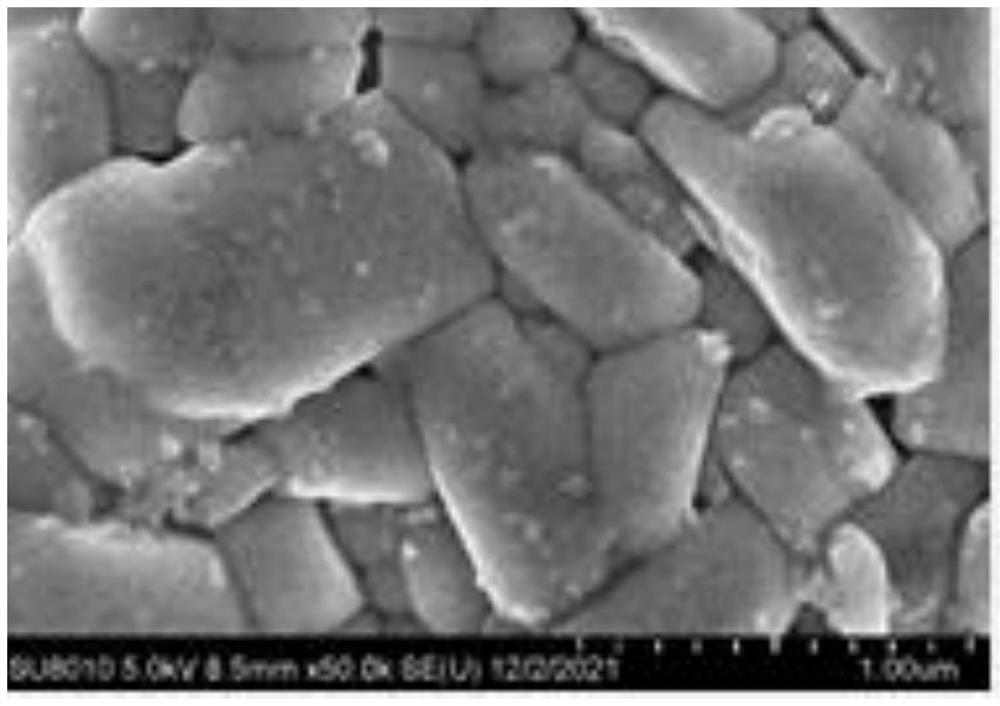

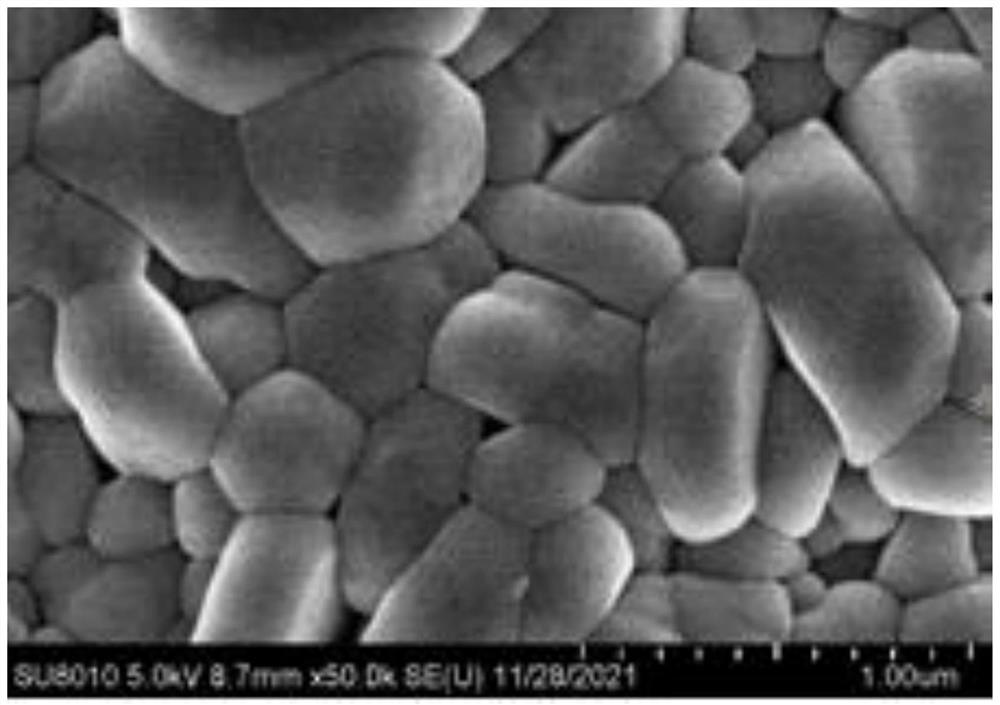

[0040] The invention provides a high-nickel ternary positive electrode material that is doped to improve particle strength. The preparation method includes: mixing a high-nickel ternary precursor and a lithium source uniformly at high speed, and adding additives through low-speed mixing to make the additives at the grain boundaries Enrichment, sintering, washing, drying, and back-burning to prepare the sample; after the sample is heat-treated, the additives are enriched at the grain boundary, and the grain boundary is strengthened (the grain boundary is generally a relatively fragile part of the particle, which is easily Corrosion), particles with better pressure resistance and chemical stability, good thermal stability of the ternary cathode material, so that the cycle, DCR and gas production performance of the cathode material has been significantly improved.

[0041] The present invention also provides a method for preparing a high-nickel ternary positive electrode material,...

Embodiment 1

[0077] Add 1 kg of precursor Ni obtained by co-precipitation method into a 2L ball mill jar 0.85 co 0.06 mn 0.09 (OH) 2, add 475g of lithium hydroxide monohydrate according to the molar ratio of lithiation coefficient 1:1.05, stir and mix at 300rpm for 120min, wait until the material is evenly mixed, then add 1.23g of tungsten trioxide, stir at a low speed of 150rpm for 30min; Into an oxygen atmosphere (oxygen concentration ≥ 80%), pre-sinter at 600°C, then heat up to 750°C for sintering for 12 hours, cool to room temperature, then wash with 1:1 water for 10 minutes, and then place it under a centrifuge at 1000rpm Carry out centrifugation for 15 minutes, then dry in an oven at 140°C for 5 hours, put the dried material into a sagger, introduce an oxygen atmosphere (oxygen concentration ≥ 80%), and sinter at 350°C for 12 hours; obtain grains with excellent particle strength The secondary particles, ultra-long cycle cathode material Li(Ni 0.85 co 0.06 mn 0.09 ) 0.99 W 0.0...

Embodiment 2

[0084] Add 1 kg of precursor Ni obtained by co-precipitation method into a 2L ball mill jar 0.85 co 0.06 mn 0.09 (OH) 2 , according to the molar ratio of lithiation coefficient 1:1.05, add 475g of lithium hydroxide monohydrate, stir and mix at 300rpm for 120min, wait until the materials are evenly mixed, then add 3.03g of nano-aluminum fluoride, stir at a low speed of 150rpm for 30min; put it into a sagger, Introduce an oxygen atmosphere (oxygen concentration ≥ 80%), pre-sinter at 600°C, then heat up to 750°C for sintering for 12 hours, cool to room temperature, then wash with 1:1 water for 10 minutes, and then in a centrifuge at 1000rpm Carry out centrifugal 15min below, then dry 5 hours under 140 ℃ of ovens, put drying material into sagger, pass into oxygen atmosphere (oxygen concentration ≥ 80%), sinter 12h at 350 ℃; Granular secondary particles, ultra-long cycle cathode material Li(Ni 0.85 co 0.06 mn 0.09 ) 0.99 Al 0.01 o 2 .

[0085] After testing, the SEM (mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com