Heat-resistant magnesium alloy

A magnesium alloy, heat resistance technology, applied in the field of heat resistant magnesium alloy, can solve problems such as insufficient strength or heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The best mode for carrying out the heat-resistant magnesium alloy (hereinafter referred to as "magnesium alloy") of the present invention will be described below.

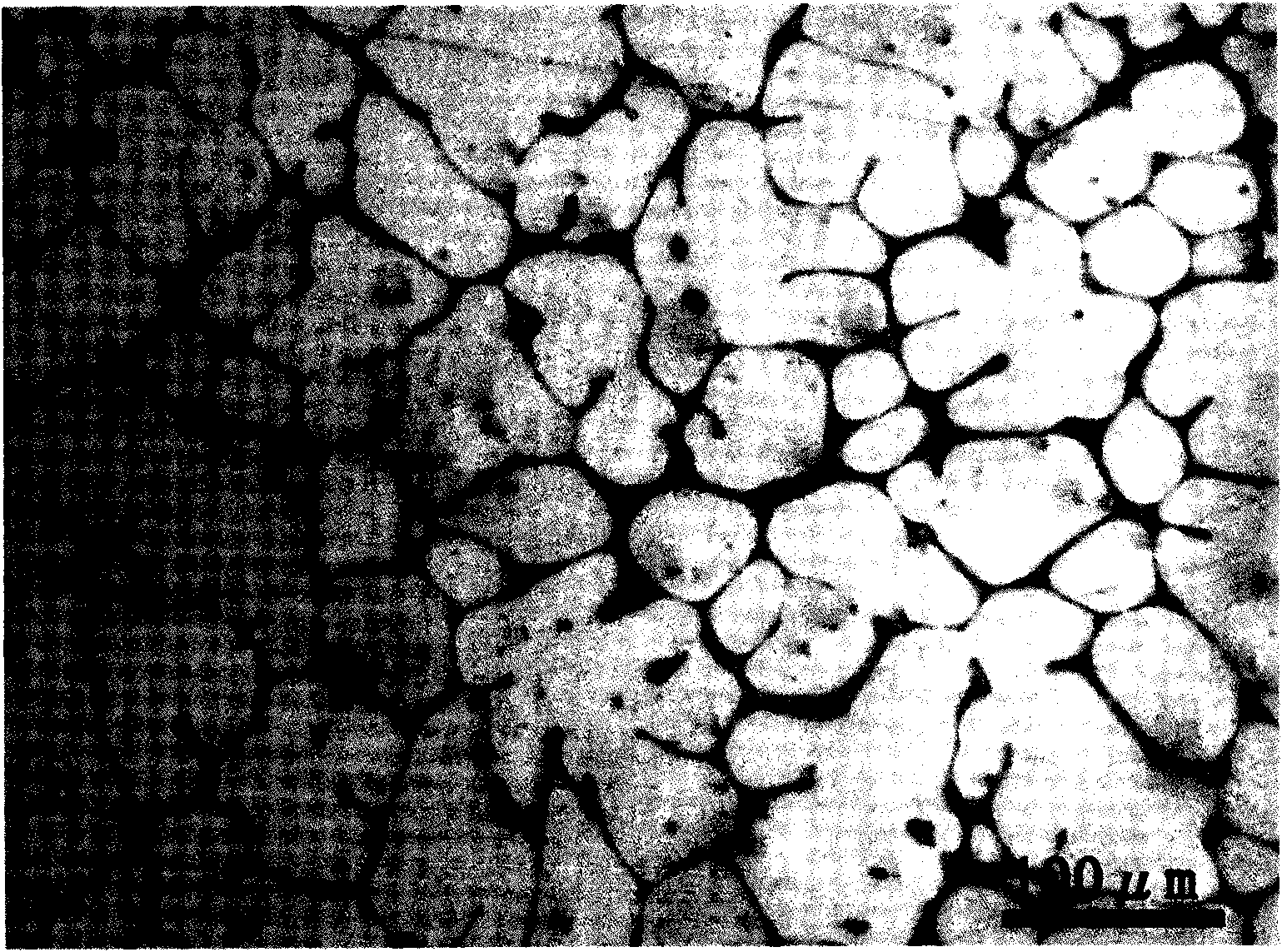

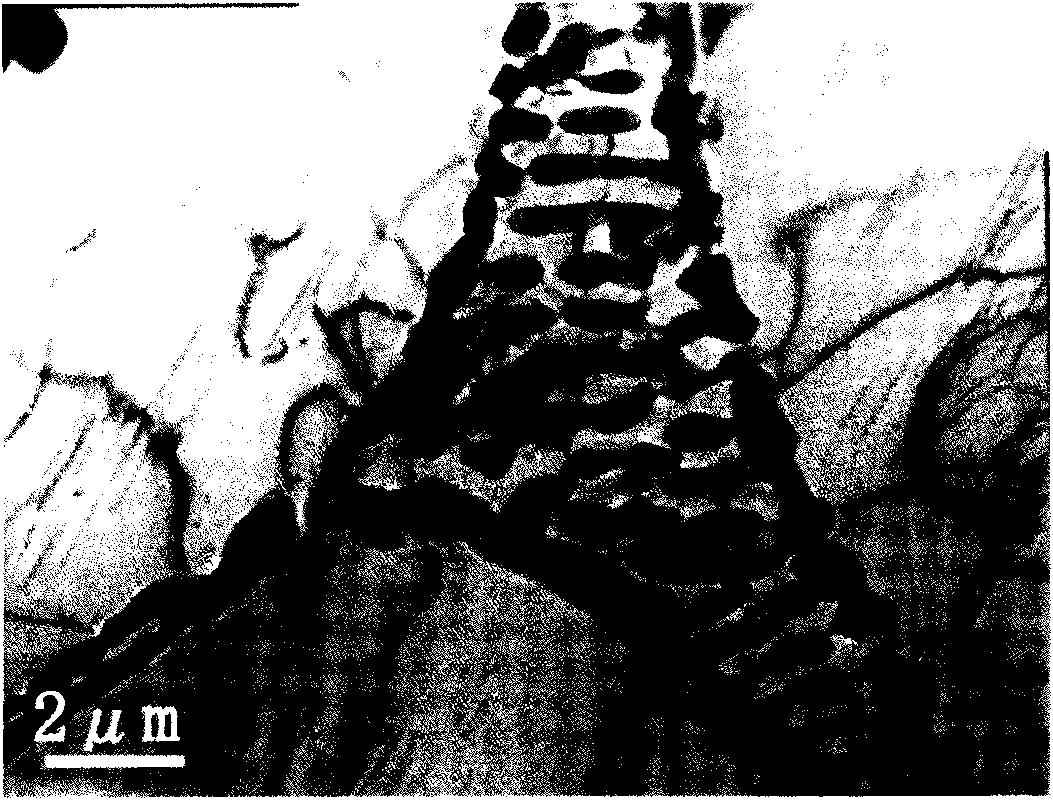

[0029] The magnesium alloy of the present invention contains magnesium (Mg), the first alloy element M1, the second alloy element M2, and calcium (Ca) as main components, and has plate-shaped precipitates containing Mg crystal grains and precipitated into the particles of the Mg crystal grains , the metallic structure of grain boundary crystallized matter crystallized at the grain boundaries of the Mg crystal grains and forming a microscopically continuous network.

[0030] In the magnesium alloy of the present invention, plate-like precipitates exist in Mg crystal grains. Plate-shaped precipitates hinder dislocation movement in Mg crystal grains. The deformation of the crystal occurs by the movement of dislocations on the sliding plane. Therefore, it may be a plate-shaped precipitate parallel to the c-pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com