Q345B medium-wide band steel and production method thereof

A production method and wide-band steel technology, applied to Q345B wide-band steel and its production field, can solve problems such as anisotropy, severe band structure, and reduced toughness, and achieve the goals of reducing the amount of addition, improving the internal structure, and improving product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

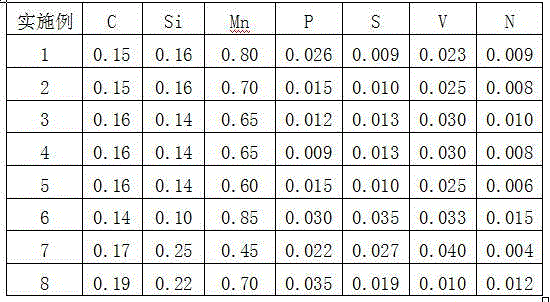

[0020] Embodiment 1: The technological process of the production method of wide-band steel in this Q345B is: steel billet→reheating furnace heating→high-pressure water descaling→rough rolling→hot coil box→finish rolling unit rolling→layer cooling→coiling; the specific process Conditions are described below.

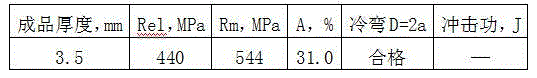

[0021] Put the billet shown in Example 1 in Table 1 into a heating furnace with a furnace temperature of 1200±10°C in the soaking section and heat it for 150 minutes. The rolling temperature is 900°C, the total reduction rate of hot rolling is 92%, the laminar cooling speed range is 20°C / s, and the coiling temperature after layer cooling is 680°C. The test results of the mechanical properties of the medium and wide band steel coils obtained in this example are shown in Table 2 below.

[0022] Table 2: Mechanical properties of the medium and wide band steel coils obtained in Example 1

[0023]

Embodiment 2

[0024] Embodiment 2: The production method of the wide-band steel in this Q345B adopts the following specific processes.

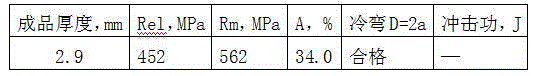

[0025] Put the billet shown in Example 2 in Table 1 into a heating furnace with a furnace temperature of 1200±10°C in the soaking section and heat it for 140 minutes. The rolling temperature is 890°C, the total hot rolling reduction rate is 96%, the laminar cooling speed range is 18°C / s, and the coiling temperature after layer cooling is 660°C. The test results of the mechanical properties of the medium and wide band steel coils obtained in this example are shown in Table 3 below.

[0026] Table 3: The mechanical properties of the wide-band steel coil obtained in embodiment 2

[0027]

Embodiment 3

[0028] Embodiment 3: The production method of the wide-band steel in this Q345B adopts the following specific processes.

[0029] Put the billet shown in Example 3 in Table 1 into a heating furnace with a furnace temperature of 1190±10°C in the soaking section and heat it for 140 minutes. After being released from the furnace, the billet is descaled by high-pressure water and rolled. The rolling temperature is 870°C, the total reduction rate of hot rolling is 91%, the laminar cooling speed range is 25°C / s, and the coiling temperature after layer cooling is 660°C. The test results of the mechanical properties of the medium and wide band steel coil obtained in this embodiment are shown in Table 4 below.

[0030] Table 4: Mechanical properties of the medium and wide band steel coils obtained in Example 3

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com