High-performance silicon carbide ceramic material and preparation method thereof

A high-performance technology of silicon carbide ceramics, applied in the field of high-performance silicon carbide ceramic materials and its preparation, can solve the problems of low strength and toughness, low density, and low toughness of silicon carbide ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

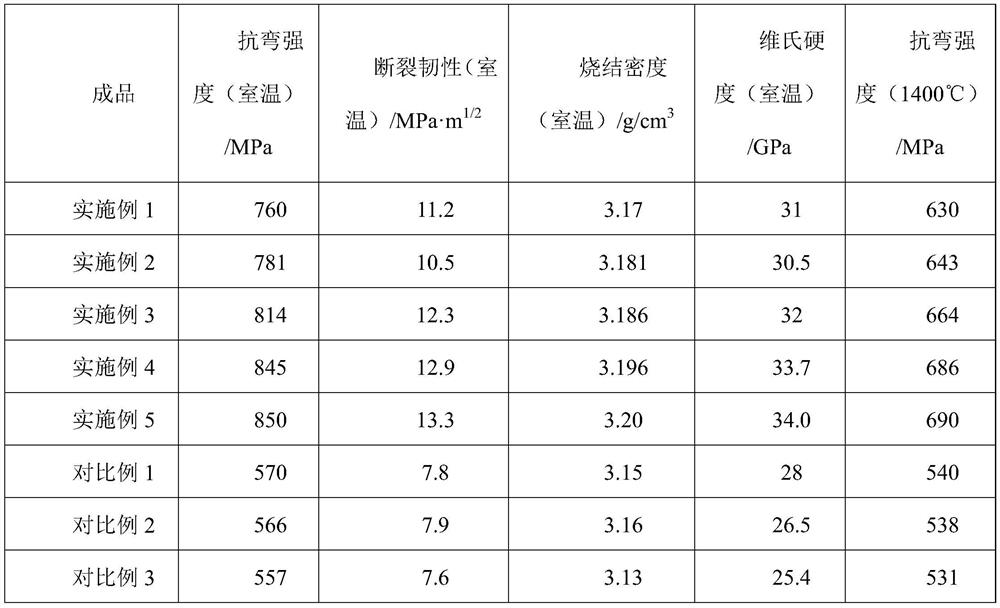

Examples

Embodiment 1

[0028] Embodiment 1, a kind of preparation method of high-performance silicon carbide ceramic material is characterized in that, comprises the steps:

[0029] (1) Prepare raw materials: in terms of mass percentage, in the raw materials, the content of silicon carbide powder is 75%, the content of sintering aid is 20%, and the content of binder is 5%; in the silicon carbide powder, Silicon carbide powder is composed of α-silicon carbide powder and β-silicon carbide powder. Based on the total amount of silicon carbide powder, the mass percentage of α-silicon carbide powder is 60%, and the rest is β-silicon carbide powder; The average particle size is 20nm, and the average particle size of β-silicon carbide powder is 230nm; the sintering aid is composed of B 4 Composition of C, C and AlN; B 4 The mass ratio of C, C and AlN is 1:2:3; the binder is phenolic resin;

[0030] (2) Ball milling and mixing: Carry out ball milling and mixing of silicon carbide powder, sintering aid and ...

Embodiment 2

[0034] Embodiment 2, a kind of preparation method of high-performance silicon carbide ceramic material is characterized in that, comprises the steps:

[0035] (1) Prepare raw materials: in terms of mass percentage, in the raw materials, the content of silicon carbide powder is 90%, the content of sintering aid is 5%, and the content of binder is 5%; in the silicon carbide powder, Silicon carbide powder is composed of α-silicon carbide powder and β-silicon carbide powder. Based on the total amount of silicon carbide powder, the mass percentage of α-silicon carbide powder is 70%, and the rest is β-silicon carbide powder; The average particle size is 200nm, and the average particle size of β-silicon carbide powder is 30nm; the sintering aid is composed of B 4 Composition of C, C and AlN; B 4 The mass ratio of C, C and AlN is 1:2:1; the binder is phenolic resin;

[0036] (2) Ball milling and mixing: Carry out ball milling and mixing of silicon carbide powder, sintering aid and b...

Embodiment 3

[0040] Embodiment 3, a kind of preparation method of high-performance silicon carbide ceramic material is characterized in that, comprises the steps:

[0041] (1) Prepare raw materials: in terms of mass percentage, in the raw materials, the content of silicon carbide powder is 75%, the content of sintering aid is 20%, and the content of binder is 5%; in the silicon carbide powder, Silicon carbide powder is composed of α-silicon carbide powder and β-silicon carbide powder. Based on the total amount of silicon carbide powder, the mass percentage of α-silicon carbide powder is 66%, and the rest is β-silicon carbide powder; The average particle size is 20nm, and the average particle size of β-silicon carbide powder is 230nm; the sintering aid is composed of B 4 Composition of C, C and AlN; B 4 The mass ratio of C, C and AlN is 1:2:3; the binder is phenolic resin;

[0042] (2) Ball milling and mixing: Carry out ball milling and mixing of silicon carbide powder, sintering aid and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Sintered density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com