Large-size high-density non-binding-phase tungsten carbide target material and preparing method thereof

A high-density, non-bonding technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of limited sample size, high sintering temperature, low density, etc., to reduce sintering cost, increase sintered density, increase the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

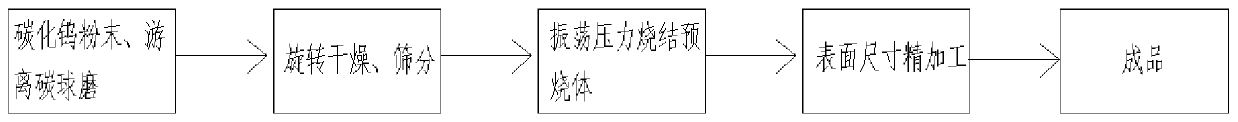

[0046] This embodiment provides a method for preparing a large-size, high-density tungsten carbide target without a binder phase, including the following steps:

[0047] S1. Ingredients: weigh the raw materials according to a certain mass fraction ratio, and set aside; wherein, the raw materials are composed of the following components in the mass fraction ratio: tungsten carbide powder 99.6%, graphite 0.4%, the purity of tungsten carbide powder > 99.9%, The particle size is 0.4~4μm;

[0048] S2. Ball milling and sieving treatment: place the raw materials weighed in step S1 in a vacuum polyurethane mixing tank, add grinding media absolute ethanol and tungsten carbide balls, and carry out vacuum ball milling treatment at a speed of 600r / min for 20h. Then the uniformly mixed slurry is rotated and dried, and finally sieved through an 80-mesh sieve to obtain a mixed powder with uniform particle size;

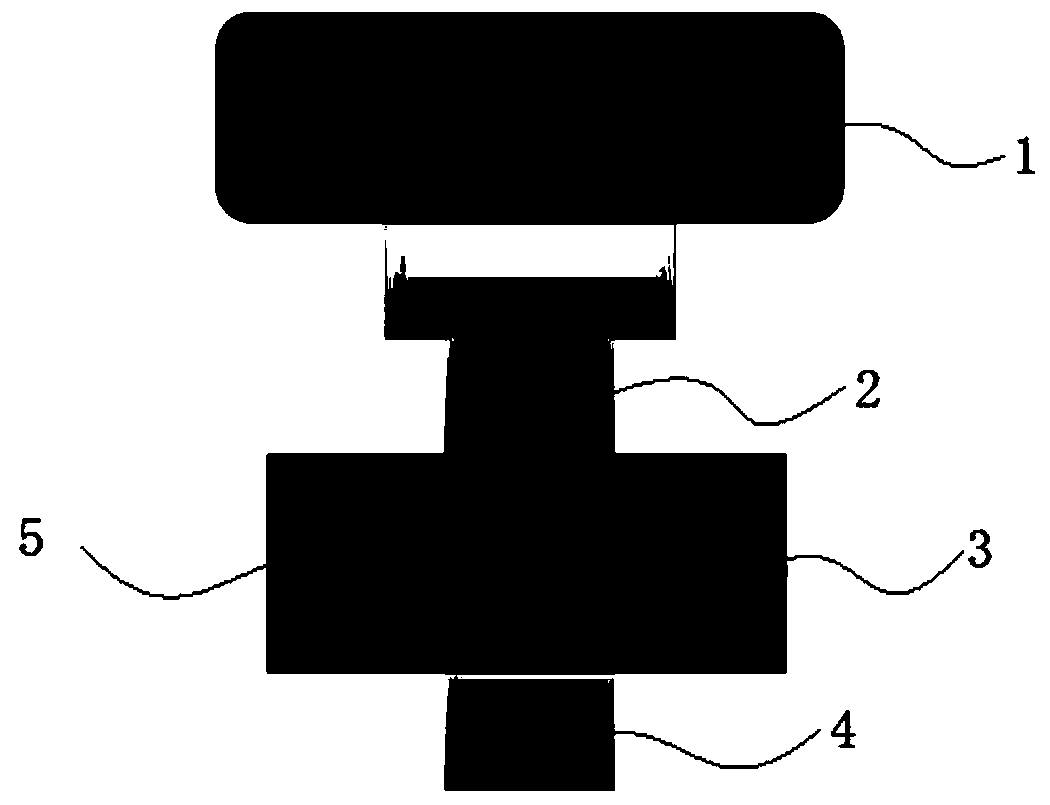

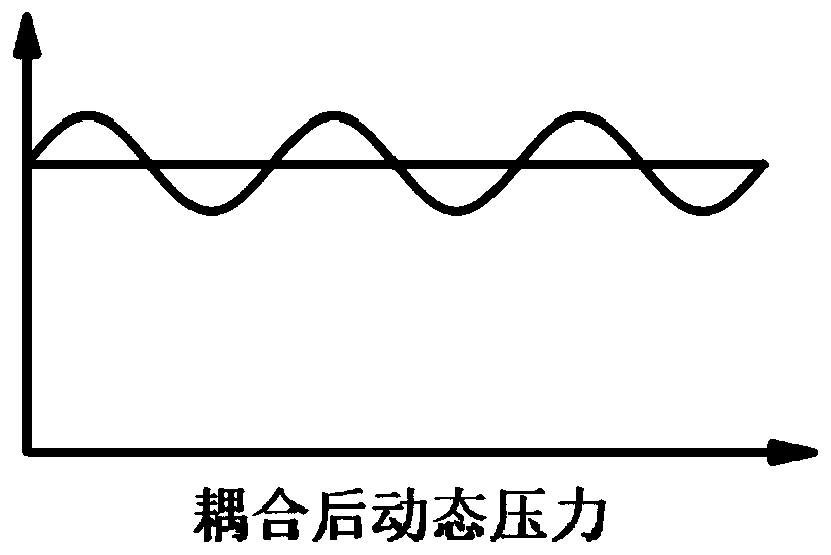

[0049] S3. Sintering treatment: Weigh 40kg of the mixed powder in step S2 and ...

Embodiment 2

[0056] This example provides a method for preparing a large-size, high-density binder-free tungsten carbide target, referring to the operation steps in Example 1, the difference from Example 1 is that in step S2, the sintering temperature is 1750 ℃.

Embodiment 3

[0058] This example provides a method for preparing a large-size, high-density binder-free tungsten carbide target, referring to the operation steps in Example 1, the difference from Example 1 is that in step S2, the sintering temperature is 1800 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com