Powder metallurgy stainless steel and preparation method thereof

A technology of powder metallurgy and stainless steel, applied in the field of powder metallurgy stainless steel and its preparation, can solve the problems of reduced density, low mechanical properties and low corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

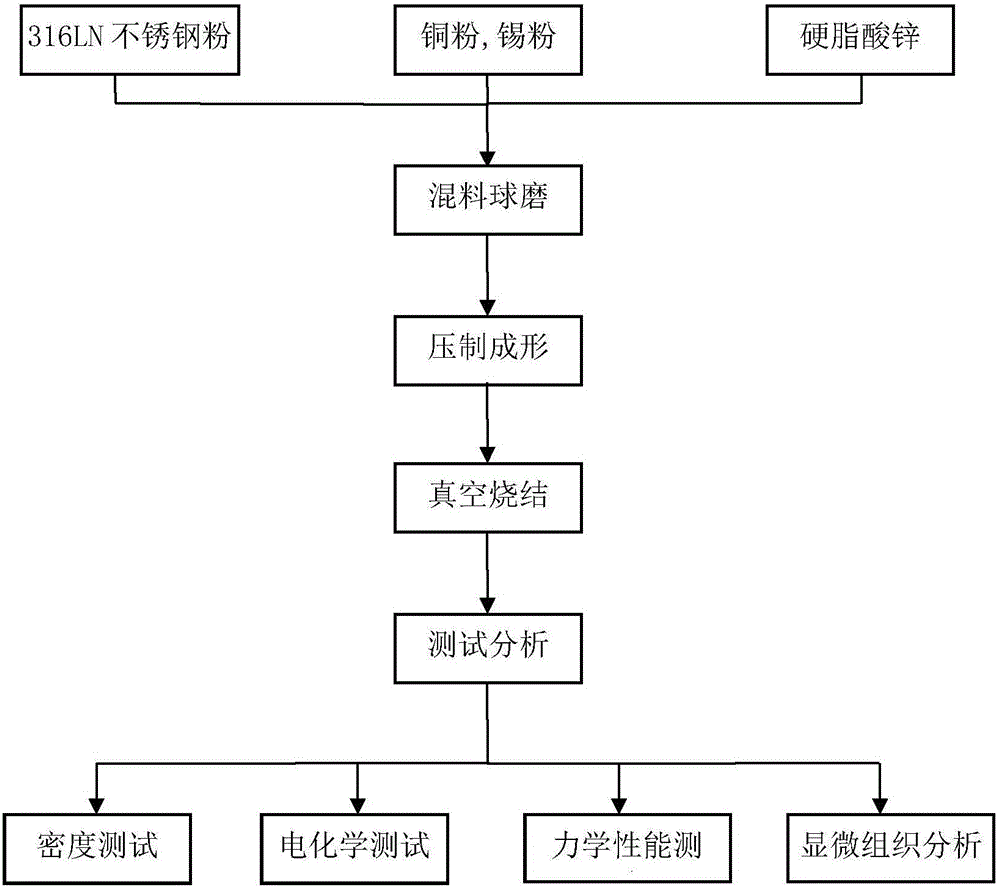

[0030] The invention provides a method for preparing powder metallurgy stainless steel, which uses components including the following mass content as raw materials: 95-98 wt% stainless steel powder, 1.5-2.5 wt% Cu powder and 0.5-2.5 wt% Sn powder;

[0031] Specifically include the following steps:

[0032] (1) stainless steel powder, Cu powder, Sn powder and lubricant are mixed, obtain mixed powder;

[0033] (2) Compressing the mixed powder obtained in the step (1) to obtain a green body;

[0034] (3) Pre-sintering the green body obtained in the step (2) to obtain a pre-sintered body;

[0035] (4) Sintering the pre-sintered green body obtained in the step (3) to obtain powder metallurgy stainless steel.

[0036] In the embodiment of the present invention, the preparation process of powder metallurgy stainless steel is preferably as follows figure 1 As shown, 316LN stainless steel powder, copper powder, tin powder and zinc stearate are mixed and ball milled to obtain a mix...

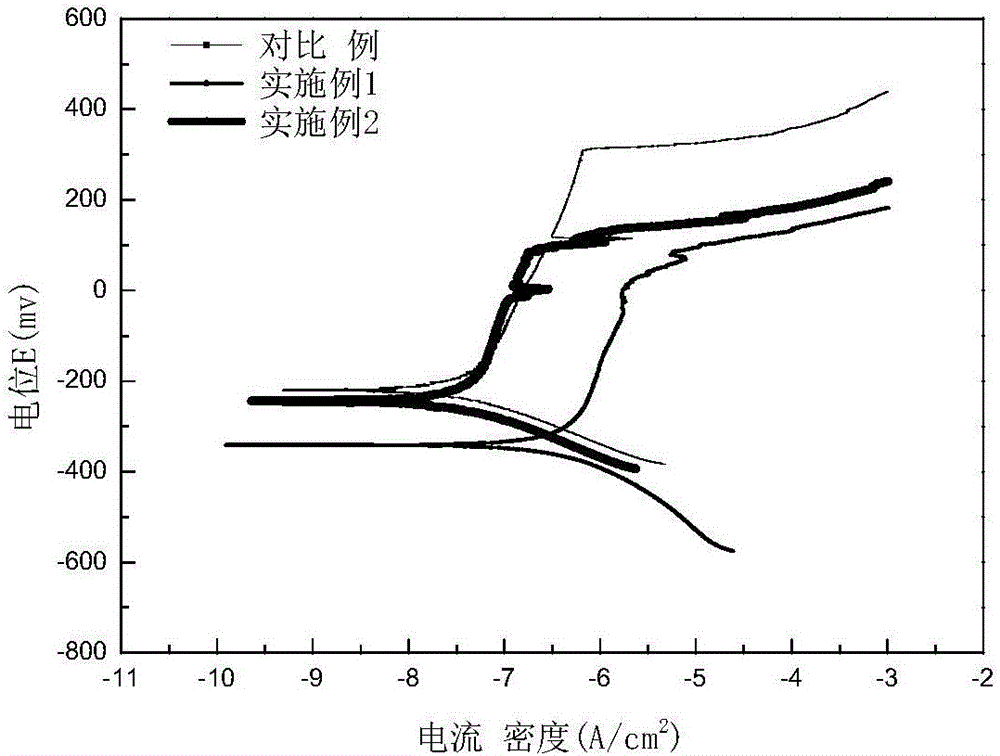

Embodiment 1

[0080] Using 97wt% of 400-mesh stainless steel powder, 2wt% of 400-mesh copper powder, and 1wt% of 400-mesh tin powder as raw materials, the metal powder was mixed, and 0.6% zinc stearate was added to the metal powder mass, and dried by a planetary high-energy ball mill. The grinding mixture, the tank body and the grinding balls are all made of stainless steel, the ball-to-material ratio is 2:1, the rotating speed is 180r / min, and the ball milling time is 1h.

[0081] The uniformly mixed powder was pressed into shape at 700MPa. The sintered sample used for the electrochemical test was a disc with a diameter of 23mm and a thickness of 5mm; the tensile sample used for the mechanical property test was 140mm×10mm×5mm.

[0082] Under the condition of vacuum degree of 0.1Pa, the pressed samples were heated up to 350°C at a rate of 4°C / min, kept at a temperature of 30min, then raised to 750°C at a rate of 5°C / min, kept at a temperature of 60min for pre-sintering, and then Raise the t...

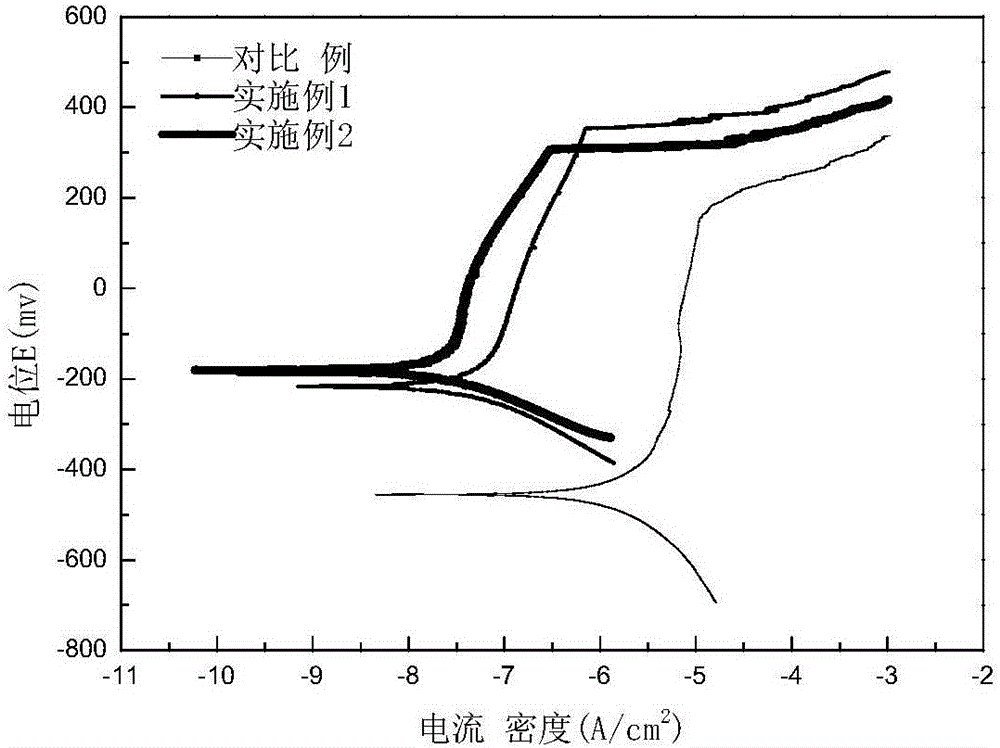

Embodiment 2

[0085] Using 96wt% of 400-mesh stainless steel powder, 2wt% of 400-mesh copper powder, and 2wt% of 400-mesh tin powder as raw materials, the metal powder is mixed, and 0.6% zinc stearate is added to the metal powder, and it is dried by a planetary high-energy ball mill. The grinding mixture, the tank body and the grinding balls are all made of stainless steel, the ball-to-material ratio is 2:1, the rotating speed is 180r / min, and the ball milling time is 1h.

[0086]The uniformly mixed powder was pressed into shape at 700MPa. The sintered sample used for the electrochemical test was a disc with a diameter of 23mm and a thickness of 5mm; the tensile sample used for the mechanical property test was 140×10×5mm.

[0087] Under the condition of vacuum degree of 0.1Pa, the pressed sample was heated to 350°C at a rate of 5°C / min, kept for 30min, and then heated to 750°C at a rate of 5°C / min for pre-sintering for 60min, and then pre-sintered at a rate of 6.5 The rate of °C / min is rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com