Image fixing apparatus image forming apparatus using the same

A technology for fixing belts and detection devices, which is applied to electrical recording technology using charge graphics, equipment and instruments using electrical recording technology using charge graphics, and can solve problems such as poor bonding accuracy, peeling, and the inability of the core to be close to the fixing part and other problems to achieve the effect of suppressing temperature rise and reducing variable errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

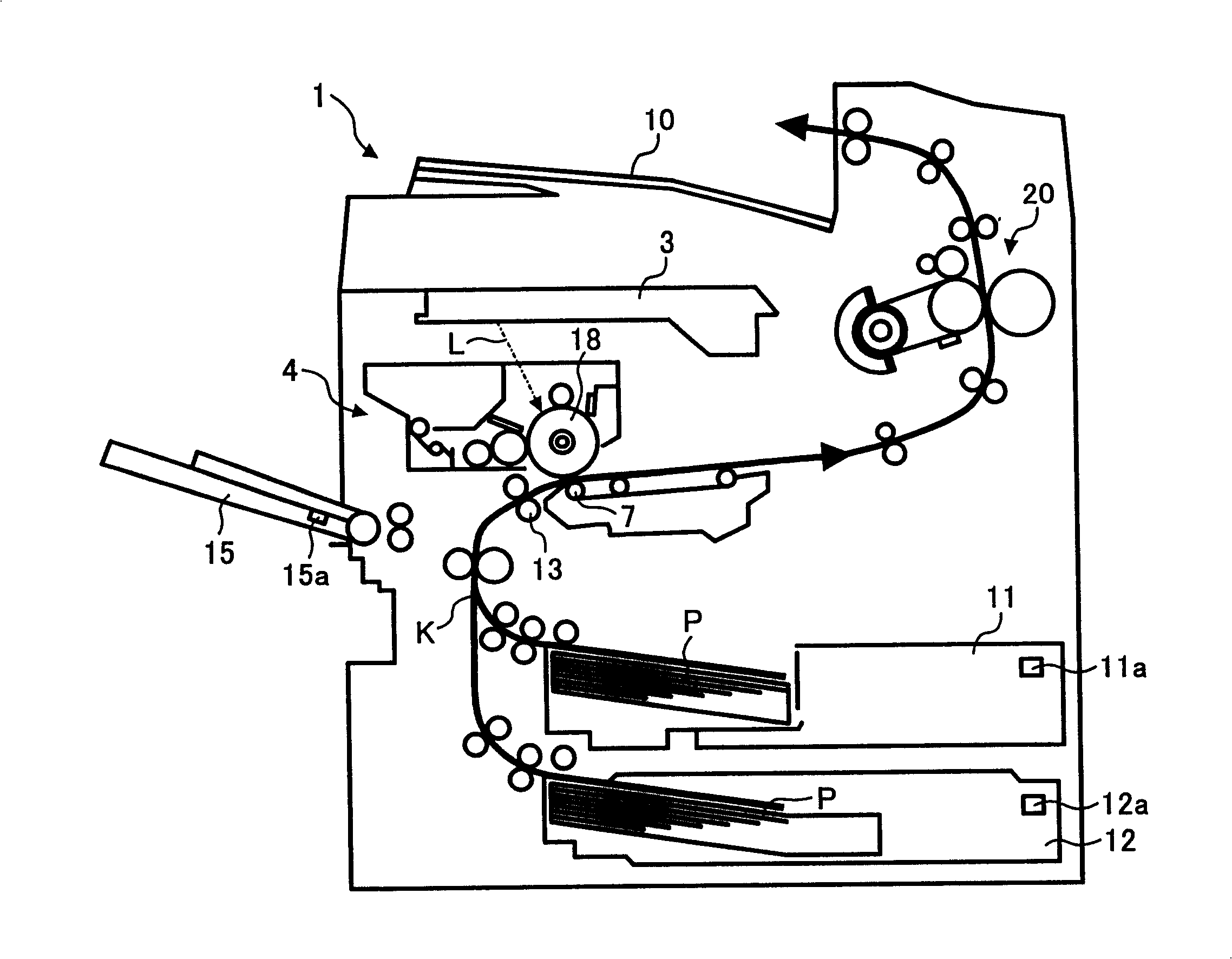

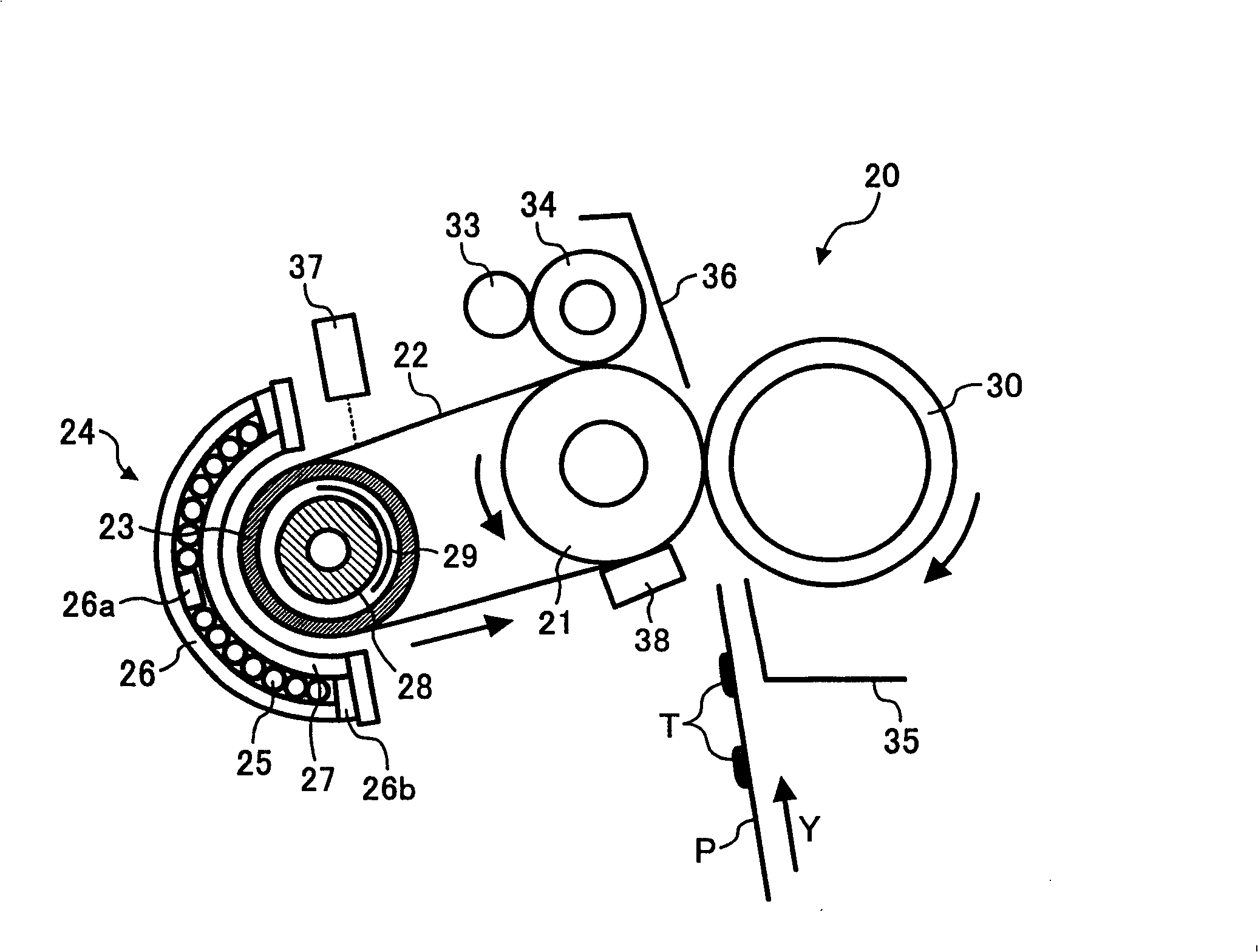

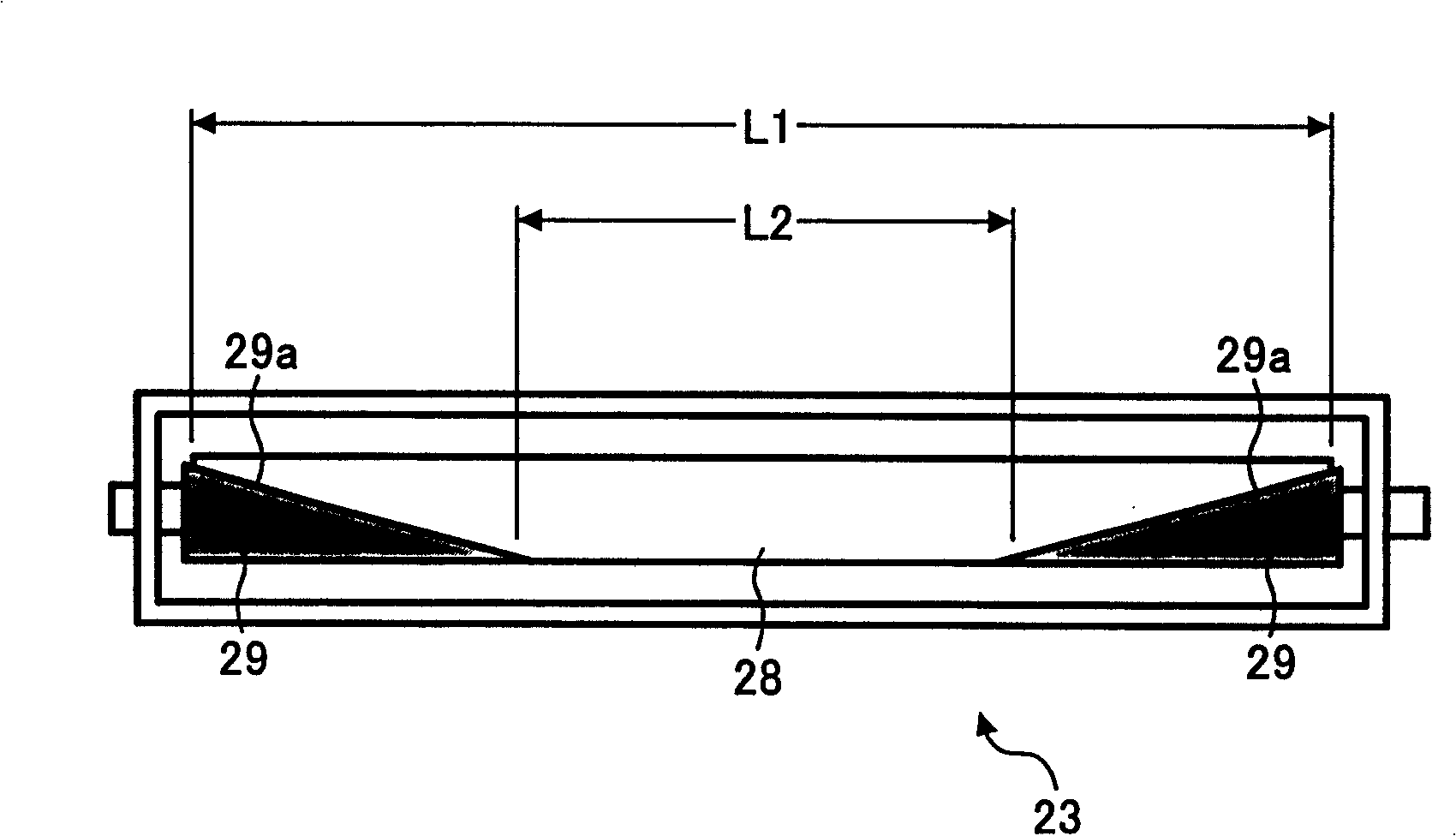

[0107] refer to Figure 1-Figure 8 , to describe Embodiment 1 of the present invention in detail.

[0108] exist figure 1 In , the overall configuration and operation of the image forming apparatus will be described.

[0109] exist figure 1 Among them, symbol 1 represents the device body of a laser printer as an image forming device; symbol 3 represents an exposure unit, which irradiates the photosensitive drum 18 with an exposure light beam L based on image information;

[0110] Symbol 4 represents a process cartridge as an image forming unit, which can be attached and detached to the image forming apparatus main body 1; Symbol 7 represents a transfer unit, which transfers the toner image formed on the photosensitive drum 18 to the recording medium P; 10 denotes a discharge table on which an output image is placed; symbols 11 and 12 represent a paper feeding section for storing recording media P such as transfer paper; symbol 13 denotes a registration roller for sending th...

Embodiment 2

[0168] Embodiment 2 of the present invention will be described in detail with reference to FIG. 9 .

[0169] FIG. 9 shows a flowchart of control executed by the fixing device 20 of the second embodiment. In the second embodiment, the magnetic flux shielding member 29 is controlled and driven according to the temperature detected by the pyroelectric element 37 as the temperature detecting means, which is different from that in the first embodiment, where the magnetic flux shielding member 29 is controlled and driven according to the count value of the counting means.

[0170] In the flow of FIG. 9 , the control flow of steps S1 to S10 is the same as that of FIG. 5 of the first embodiment described above.

[0171] In step S10 , after the continuous paper feeding starts, the process proceeds to step S21 , where the temperature on the fixing belt 22 during the continuous paper feeding is detected by the thermoelectric element 37 . Here, the thermoelectric element 37 faces substan...

Embodiment 3

[0180] Referring to Figure 10 and Figure 11 Embodiment 3 of the present invention will be described in detail.

[0181] FIG. 10 shows a flow chart of control executed by the fixing device 20 of the third embodiment. In the present embodiment 3, the driving of the magnetic flux shielding member 29 is controlled according to the temperature change of the widthwise end portion of the fixing belt 22 , which is different from that of the embodiment 2 in which the driving of the magnetic flux shielding member is controlled according to the temperature change of the widthwise central portion of the fixing belt 22 . 29 different.

[0182] In the flow of FIG. 10 , the control flow of steps S1 to S10 is the same as that of FIG. 9 of the second embodiment described above.

[0183] In step S10 , after the continuous paper feeding is started, the process proceeds to step S31 , where the temperature on the fixing belt 22 during the continuous paper feeding is detected by the thermistor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com