Single-phase capacitor-operated motor

A capacitor and single-phase technology, which is applied in the field of single-phase capacitor running motors, can solve the problems of shortened motor end cover height, low winding distribution coefficient, large cogging torque ripple, etc., to achieve copper saving, high winding coefficient, Effect of small cogging torque pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

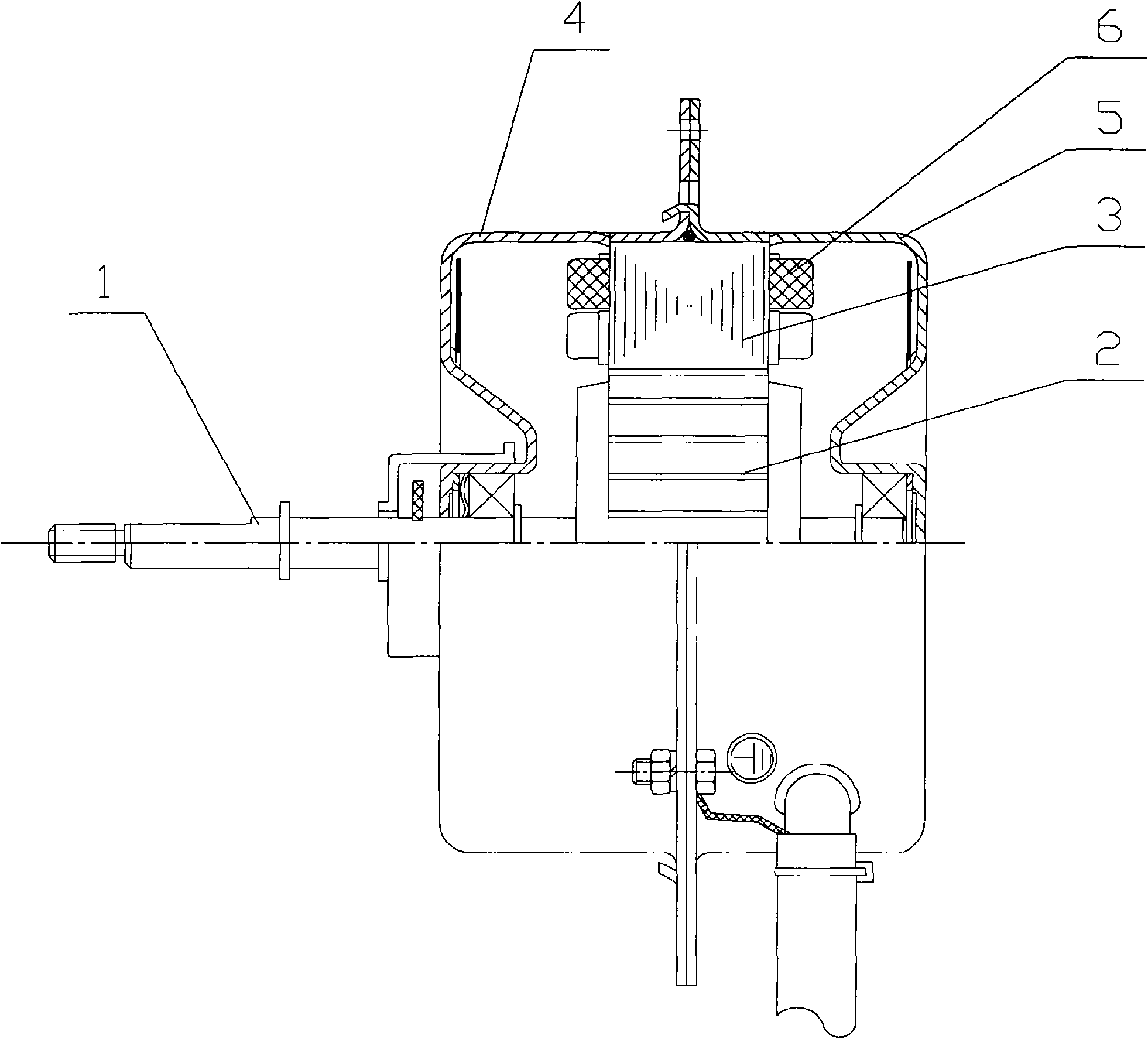

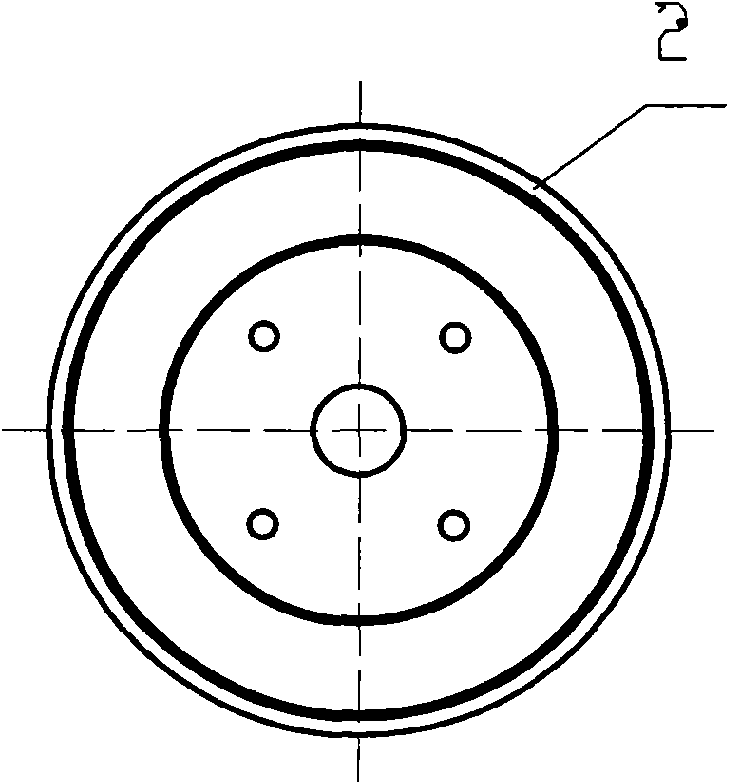

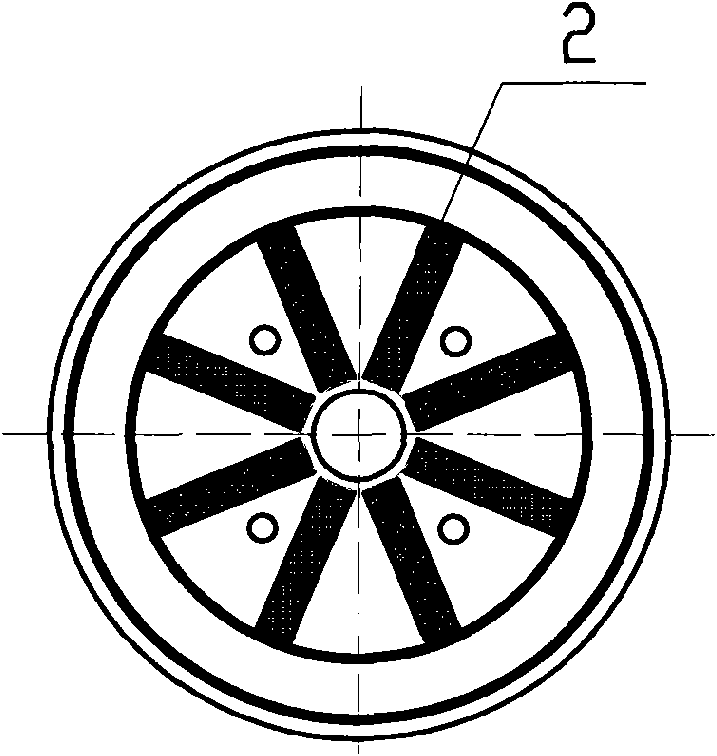

[0024] Embodiment 1 of the present invention discloses an AC motor for a fan, specifically a single-phase concentrated winding permanent magnet synchronous motor for a fan, figure 1 It is a side view half-sectional view of the present invention. The single-phase capacitor running motor of the present invention includes a motor shaft 1, a rotor 2, a stator 3, a front end cover 4 and a rear end cover 5, wherein the rotor 2 is sleeved on the motor shaft 1, The stator 3 is set on the outer side of the rotor 2, and the outer side of the stator 3 is a front end cover 4 and a rear end cover 5 that are interlocked with each other. Both ends of the motor shaft 1 are installed on the front end cover 4 and the rear end cover 5 through bearings, and the stator 3 The stator core 33 is made with deep row slots 331 and shallow row slots 332 double row slots, the winding of the stator 3 is a concentrated winding including the first winding 31 and the second winding 32, the first winding 31 an...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the first winding 31 is connected in parallel with the second winding 2 after the capacitor C is connected in series. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com