Permanent magnet synchronous motor with magnetism concentration effect

A permanent magnet synchronous motor, effect technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuits, electric components, etc., can solve problems such as increased maintenance difficulty, long distributed winding ends, and increased number of stator slots , to achieve the effect of improving torque density and operating efficiency, improving fault tolerance, and avoiding short circuit between phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

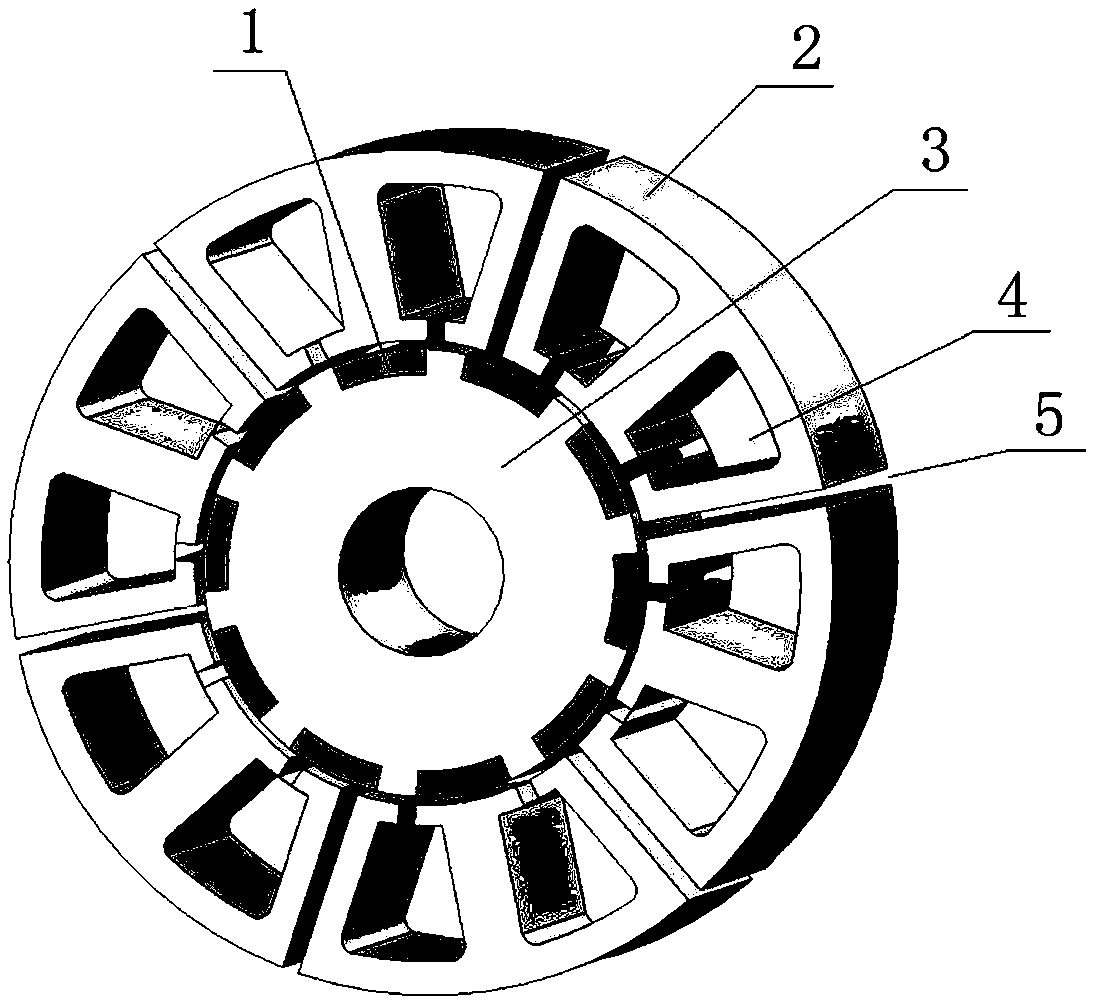

[0025] The invention proposes a portable permanent magnet synchronous motor with "magnetism gathering" effect. The motor adopts a block-type stator core, which can improve the torque density and operating efficiency of the motor, and at the same time make the motor easy to transport, install and manufacture. and maintenance purposes.

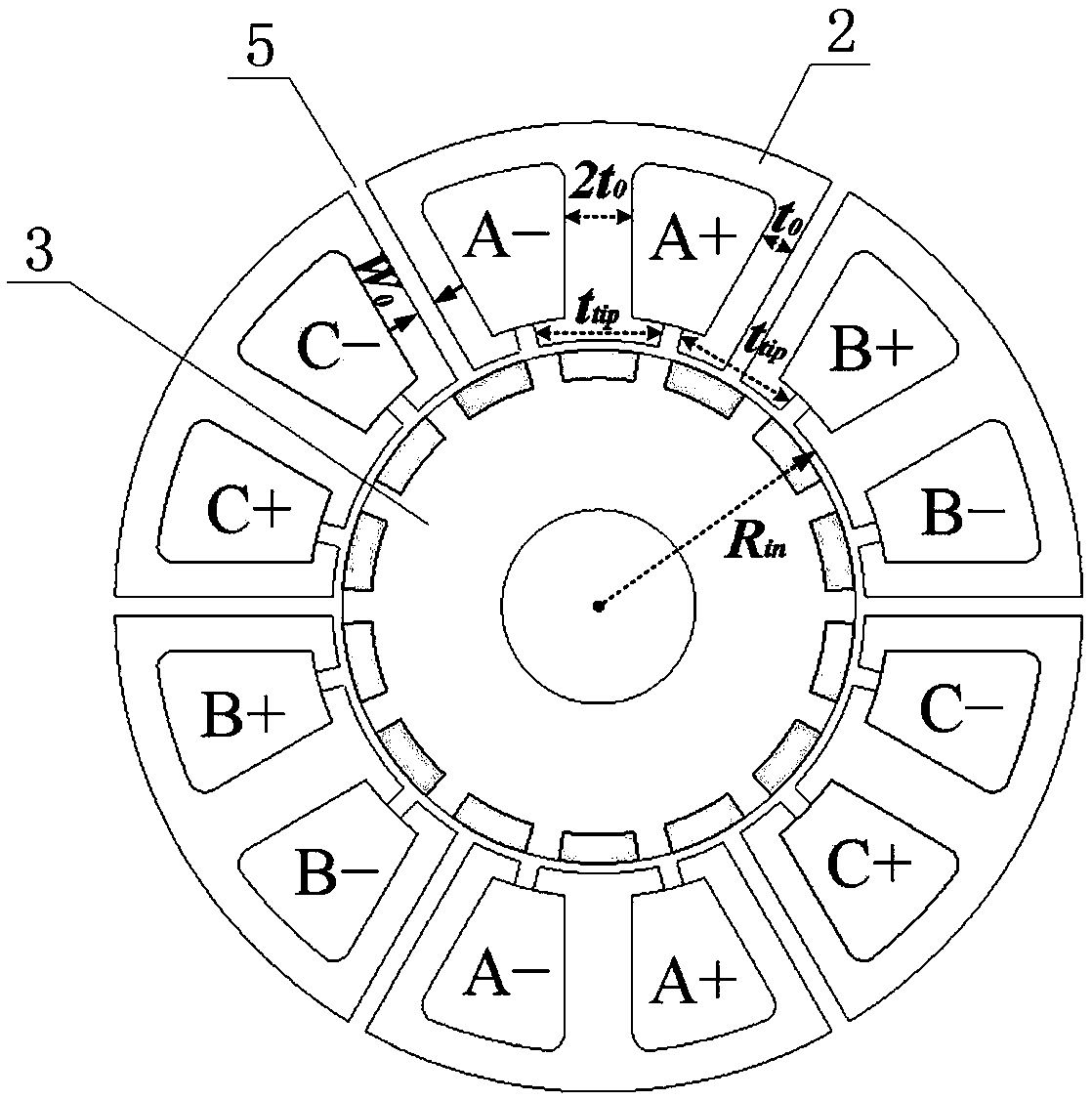

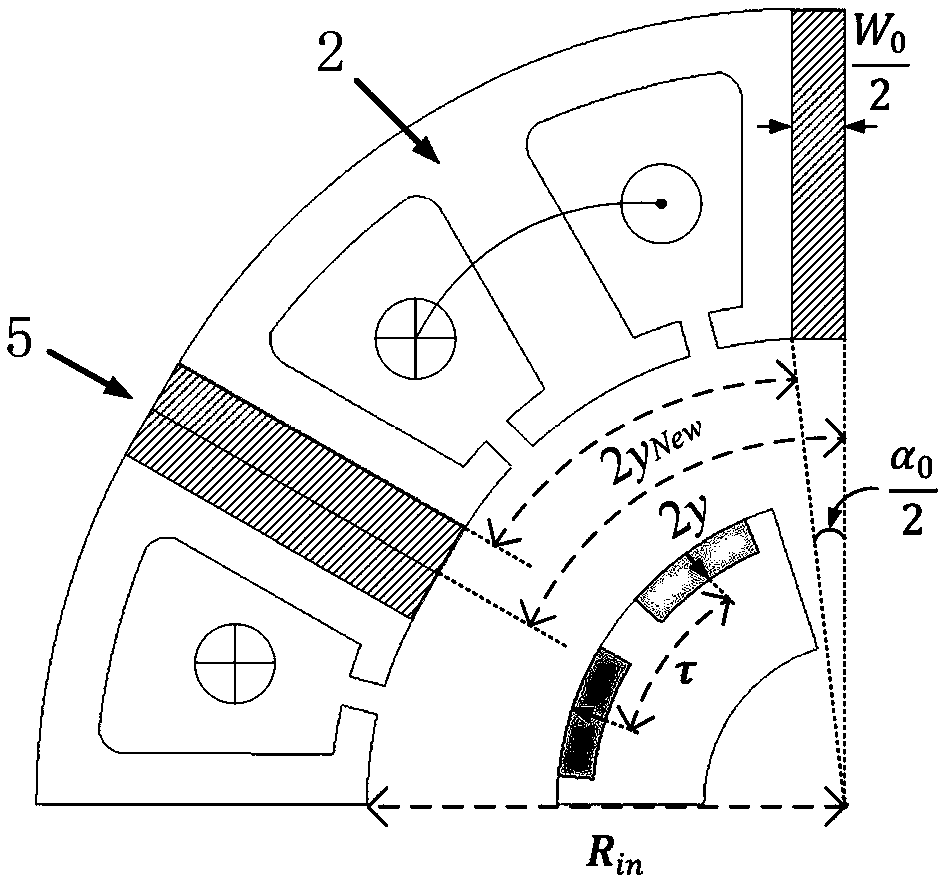

[0026] The present invention provides a novel permanent magnet synchronous motor aiming at few slots and multiple poles, such as figure 1 As shown, the motor completes the transformation of the traditional one-piece fractional slot concentrated winding motor stator by inserting the stator gap into the non-winding teeth. The block stator core and winding configuration are as follows figure 2 shown. Taking the 12-slot and 14-pole segmented stator core motor as an example, keep the width of the winding teeth and their tooth tops unchanged, where the width of the winding teeth is 2t 0 , the winding tooth tip width is t tip , the insertion width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com