Modular stator structural low-speed DC brushless motor

A brushless DC, stator-forming technology, applied in the magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of small stator winding coefficient, reduction of permanent magnet tooth permeance torque, reduction of motor efficiency, etc. , to achieve the effect of simple winding process, reducing harmonic torque of permanent magnet permeability and high motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

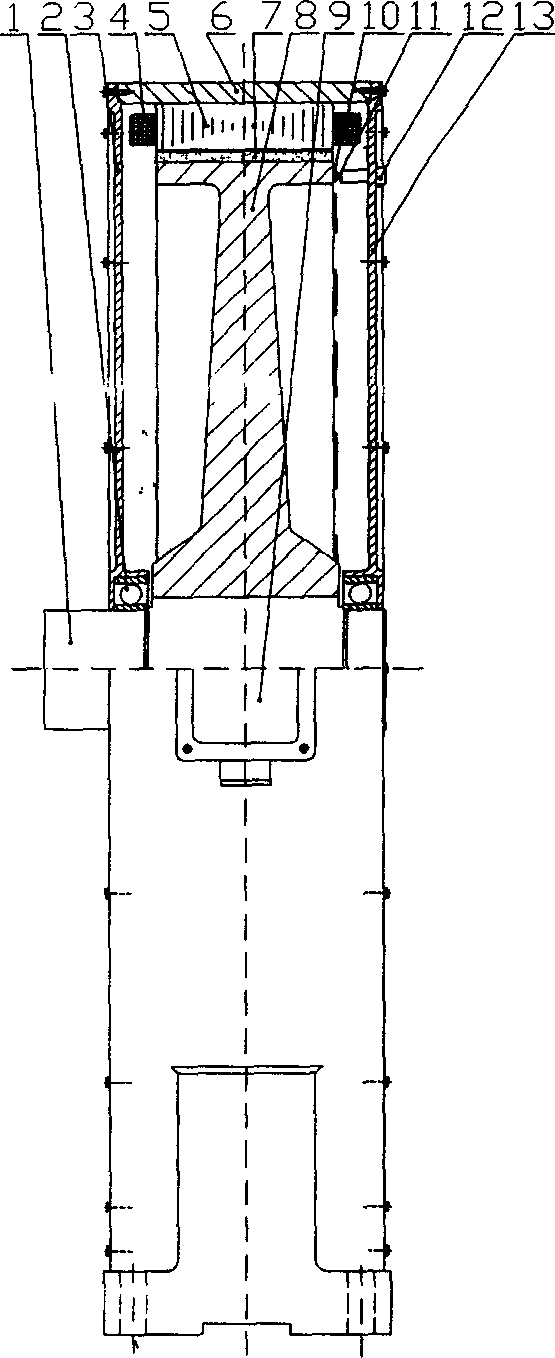

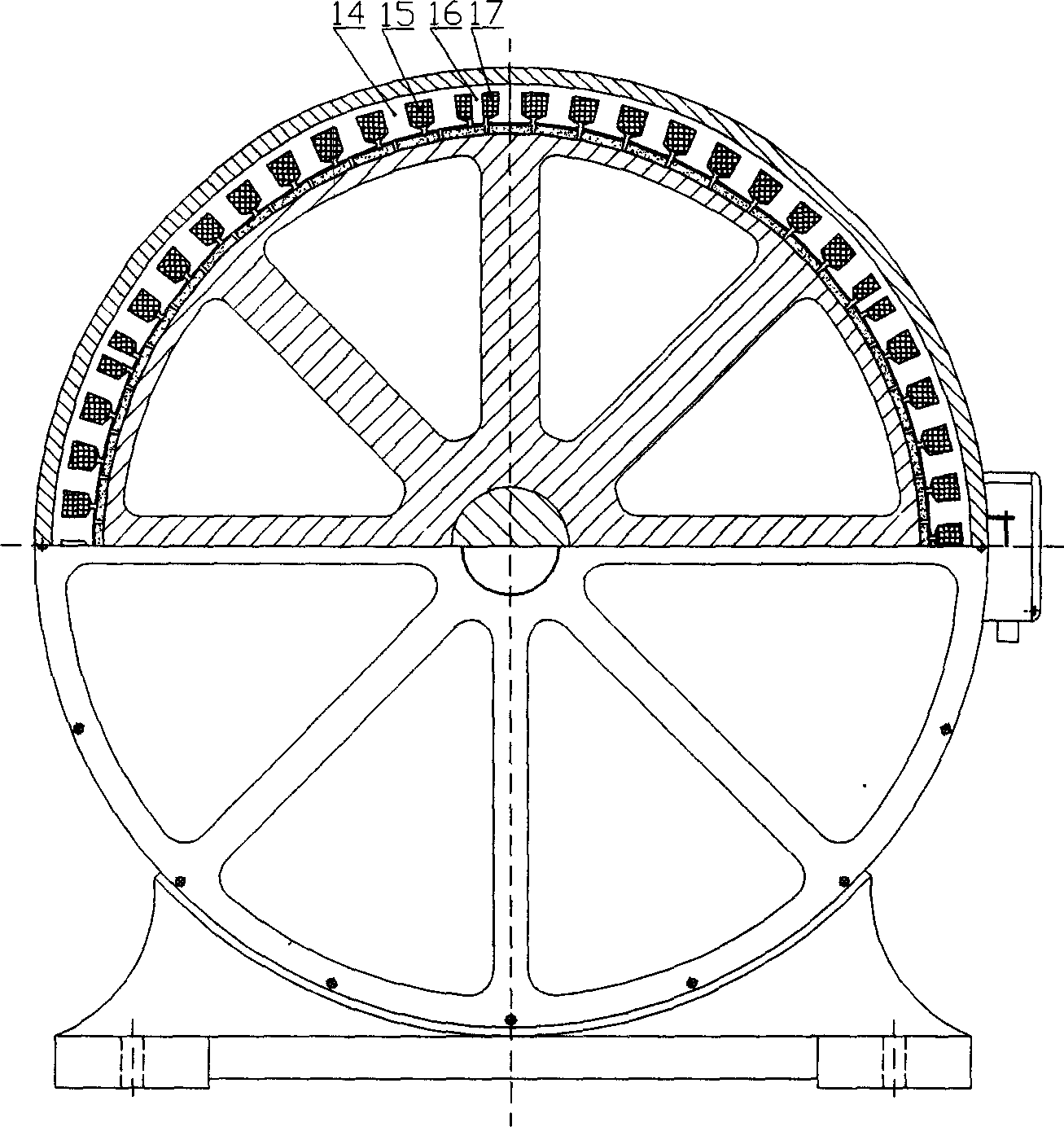

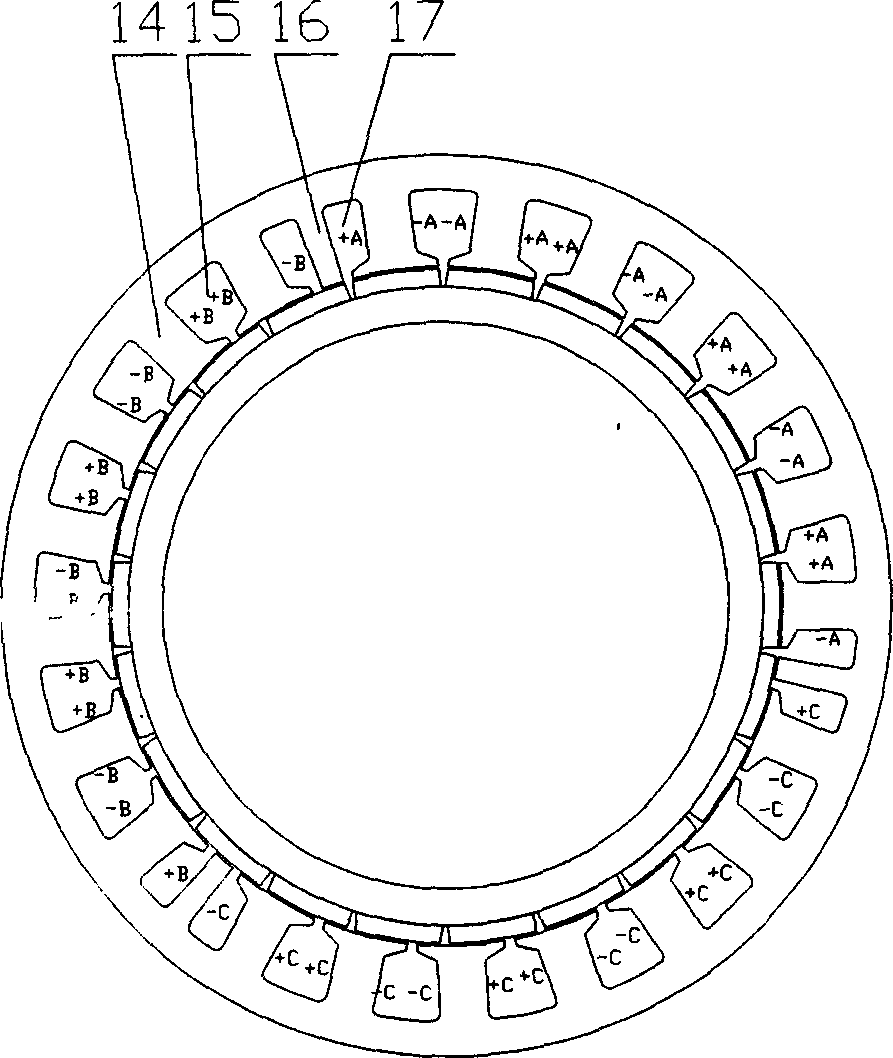

[0010] Such as figure 1 , 2 Shown is a schematic diagram of the structure of a low-speed brushless DC motor with a modular stator structure of the present invention. The motor includes a frame 6, front 3 on both sides of the frame, a rear end cover 13, a rotor shaft 1, a junction box 9, a position sensor, and a position sensor. Sensor junction box 12, Y-connected three-phase winding, modular stator core 5 fixed in the base, rotor installed on the rotor shaft, main magnetic pole NdFeB permanent magnets are arranged on the circumference of the rotor 7. Divide the inner diameter of the stator core evenly into k 1 Sector group, in each sector group A, B, C three-phase each occupying one sector with the same area, one sector belongs to one phase, and the stator core of each sector is evenly opened with k 2 A large tooth 15, a large slot 14 is arranged between the two adjacent large teeth, the tooth pitch of the adjacent large teeth is a pole pitch, and the distance between the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com