Method for designing variable speed pumped storage motor with double speed regulation mechanisms

A technology of pumped storage and design methods, which can be used in computing, electrical digital data processing, special data processing applications, etc., and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

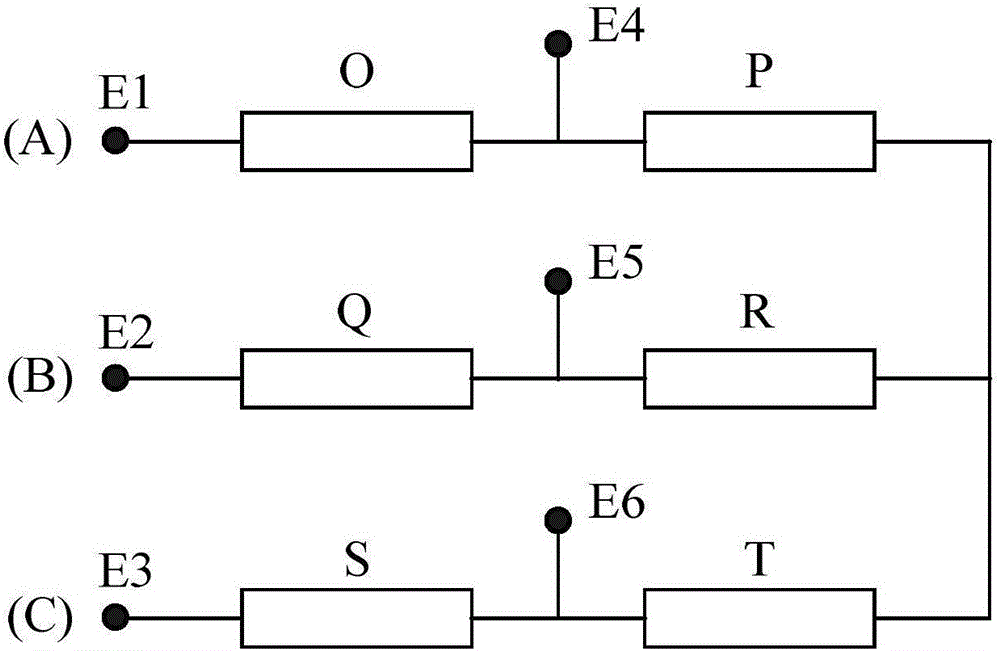

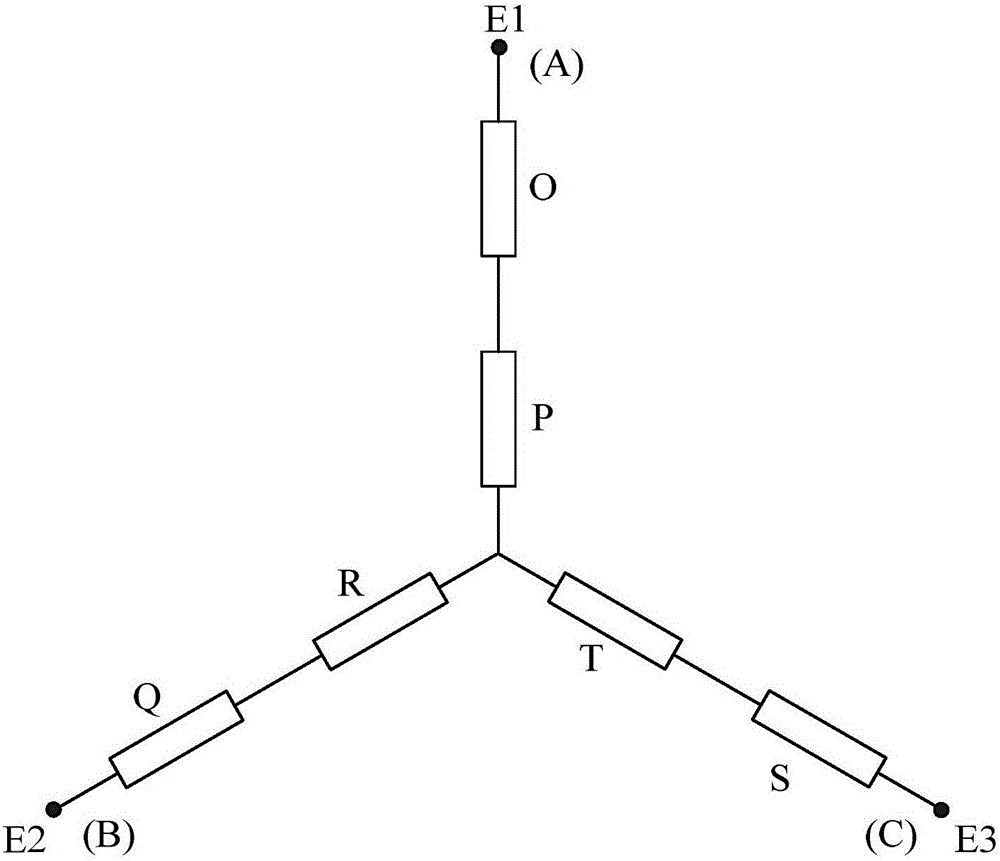

[0038] In this embodiment, the 480MV pumped storage motor is taken as an example. It is necessary to use the YY connection mode when running at high speed, and the E 1 E. 2 E. 3 ends shorted together and the E 4 E. 5 E. 6 The terminal is connected to the three-phase AC power supply; when running at low speed, the Y connection method is required, and the E 1 E. 2 E. 3 The terminal is directly connected to the three-phase AC power supply and the E 4 E. 5 E. 6 The end is suspended, the A-phase winding is divided into O-segment winding and P-segment winding, the B-phase winding is divided into Q-segment winding and R-segment winding, and the C-phase winding is divided into S-segment winding and T-segment winding.

[0039] In order to achieve two speeds of 83.33rpm and 111.1rpm for the 480MV pumped storage motor, the number of stator and rotor poles is 72 / 54, and the number of stator slots is 648. This scheme actually has 8 / 6 poles in the stator and rotor, and 9 repetitio...

Embodiment 2

[0084] In this embodiment, a 145MW pumped storage motor is taken as an example. In order to achieve two speeds of 100rpm and 120rpm, the number of stator and rotor poles is 60 / 50, and the number of stator slots is 540. This scheme actually has 12 / 10 poles in the stator and rotor, and 5 repetitions of 108 slots in the stator.

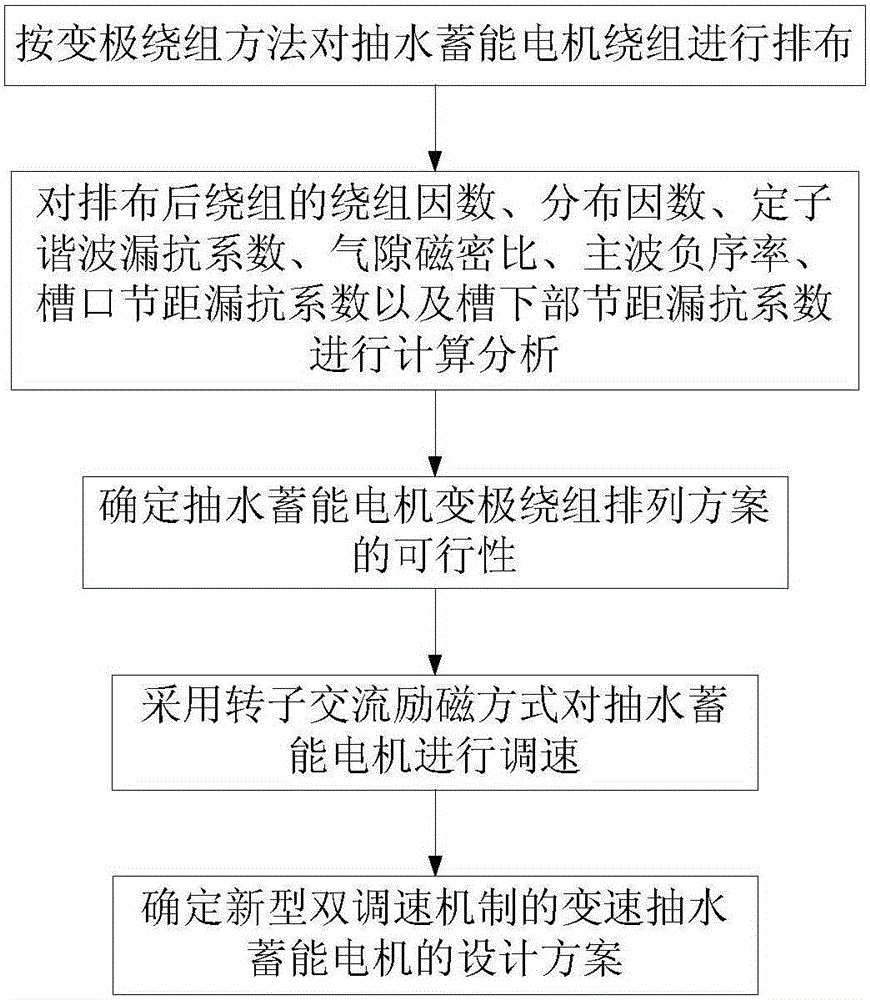

[0085] Arrange the windings of the pumped storage motor according to the pole-changing winding method, and analyze the winding factor, distribution factor, stator harmonic leakage reactance coefficient, air gap magnetic density ratio, main wave negative sequence ratio, and slot pitch after the arrangement The leakage reactance coefficient and the pitch leakage reactance coefficient at the bottom of the slot are calculated and analyzed, and the feasibility of the pole-changing winding arrangement scheme is determined. Adopt the rotor AC excitation method to adjust the speed of the pumped energy storage motor. At the position of the rotor speed of 100rpm (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com