Double-winding modular bearingless magnetic flux switching permanent magnet motor

A magnetic flux switching, permanent magnet motor technology, applied in the shape/style/structure of the winding conductor, the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, etc., can solve the problems of heat dissipation and mechanical firmness that cannot be ignored, efficiency, The power factor is not as good as that of permanent magnet motors, and the utilization rate of permanent magnets is reduced, achieving the effects of compact structure, low loss, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

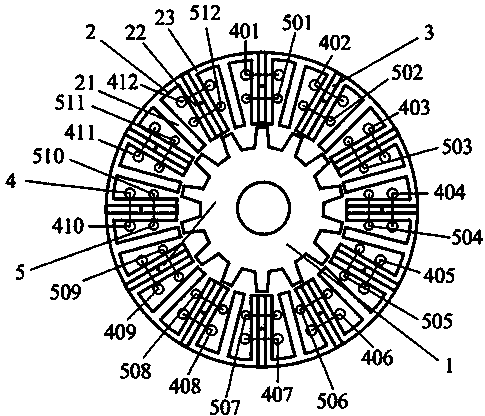

[0026] Such as figure 1 Shown is a modular double-winding bearingless flux switching permanent magnet motor, specifically a three-phase stator 12 / 14 pole modular motor, the number of phases of the motor is m, where m=3.

[0027] The motor includes a rotor core 1 and a stator core 2. The rotor core 1 is located inside the stator core 2. Both the rotor core 1 and the stator core 2 are salient pole structures. The stator core 2 has 4m E-shaped core units and 4m Two permanent magnets 3 are staggered and spliced, wherein the magnetization direction of the permanent magnet 3 is tangential, and the magnetization direction of the adjacent permanent magnets 3 is opposite, and the protruding teeth in the middle of the E-shaped core unit are stator fault-tolerant teeth 21, Protruding from both sides are permanent magnet teeth 22, a permanent magnet 3 and two permanent magnet te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com