Five-phase permanent magnet fault-tolerant motor with magnetic congregating effect for electric vehicle

An electric vehicle and permanent magnet fault-tolerant technology, which is applied in the fields of electric vehicles, electricians, and motors, can solve the problems of reducing the fault-tolerant performance of the motor, interphase short circuit, and difficulty in weakening the magnetic speed regulation, so as to save the mechanical connection and save the motor Effect of reducing cost and motor weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

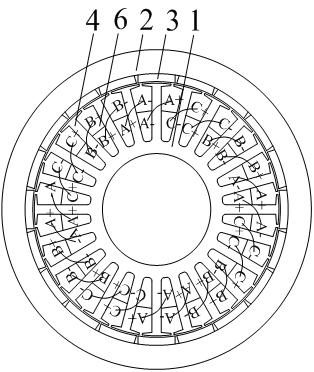

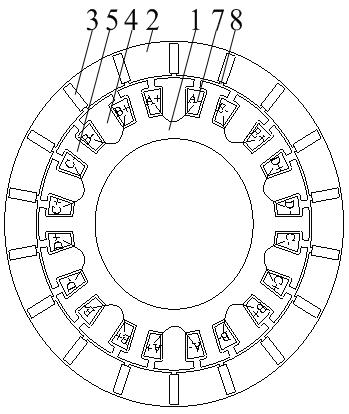

[0018] Such as figure 2 As shown, the present invention is a five-phase, outer rotor, permanent magnet built-in motor structure, which is composed of a stator 1, an outer rotor 2, a permanent magnet 3, an armature tooth 4, a fault-tolerant tooth 5 and a single-layer concentrated winding 7 . The iron cores of the stator 1 and the outer rotor 2 are formed by laminating punched sheets of D23 material commonly used in China.

[0019] The outer rotor 2 is arranged on the outer ring of the stator 1, and the armature teeth 4 and the fault-tolerant teeth 5 are arranged between the outer rotor 2 and the stator 1. The armature teeth 4 and the fault-tolerant teeth 5 are evenly distributed along the outer ring of the stator 1, and the armature The teeth 4 and the tolerance teeth 5 are arranged at intervals one by one, and the width of the armature teeth 4 is twice the width of the tolerance teeth 5 . The permanent magnets 3 are radially embedded in the outer rotor 2 along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com