Three phase external rotor double salient pole permanent magnet brushless electric generator

A permanent magnet brushless and generator technology, applied in the direction of synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of motor output limitation, increased cost, and control system complexity, and achieve high reliability, good high-speed performance, The effect of increasing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

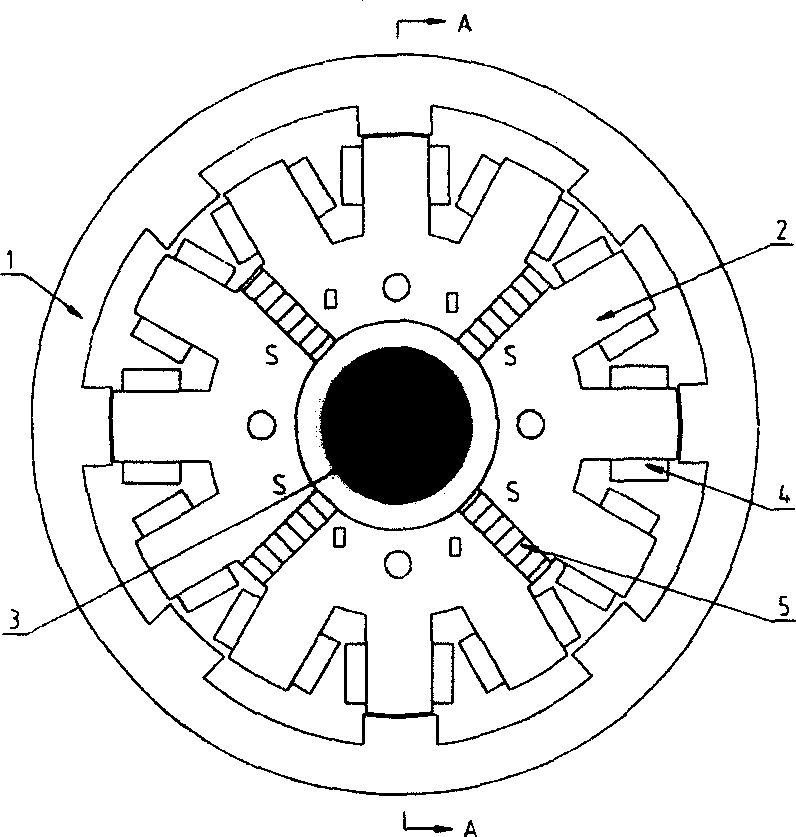

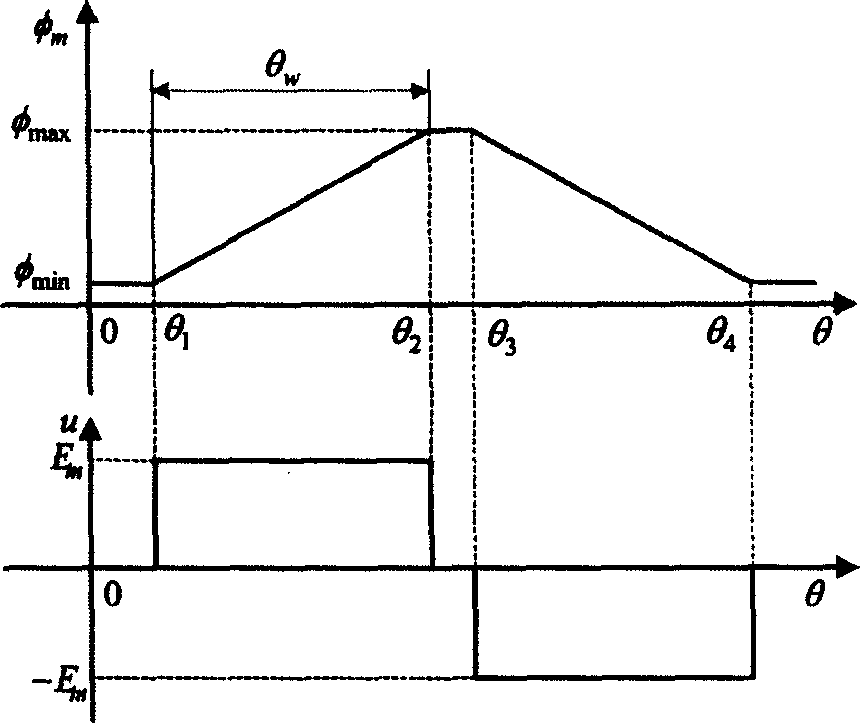

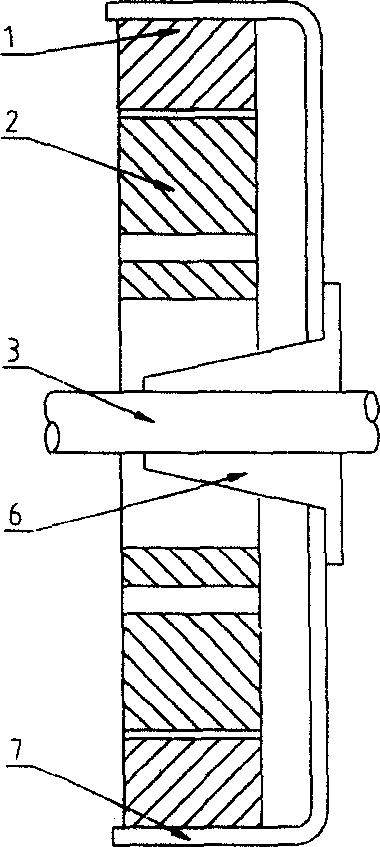

[0019] The generator has a structure in which the stator is inside and the rotor is outside. The permanent magnets and armature windings are located on the stator side. The stator is fixed through four mounting holes. The rotor has no windings, no brushes, and no permanent magnets. The rotor passes through the casing and The shaft sleeve seat is connected with the rotating shaft. On the yoke of the stator, there are 4 (two or more) NdFeB rare earth permanent magnets evenly distributed on the yoke of the stator. The polarities of the 4 permanent magnets 5 are according to N, S, S, N, N, S, S, N forms are distributed, and the excitation magnetic field of the generator is provided by the rare earth permanent magnet. The stator is evenly distributed with 12 salient poles, and the outer rotor is evenly distributed with 8 salient poles. The stator and rotor are all silicon steel sheet laminated structures. The number of salient poles of the rotor is less than the number of salient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com