Axial magnetic field consequent pole brushless hybrid excitation motor

A hybrid excitation motor and axial magnetic field technology, which is applied to motors, synchronous motors for single-phase current, magnetic circuits, etc., can solve the problems of difficult adjustment of motor air gap magnetic field, high cost, and poor magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

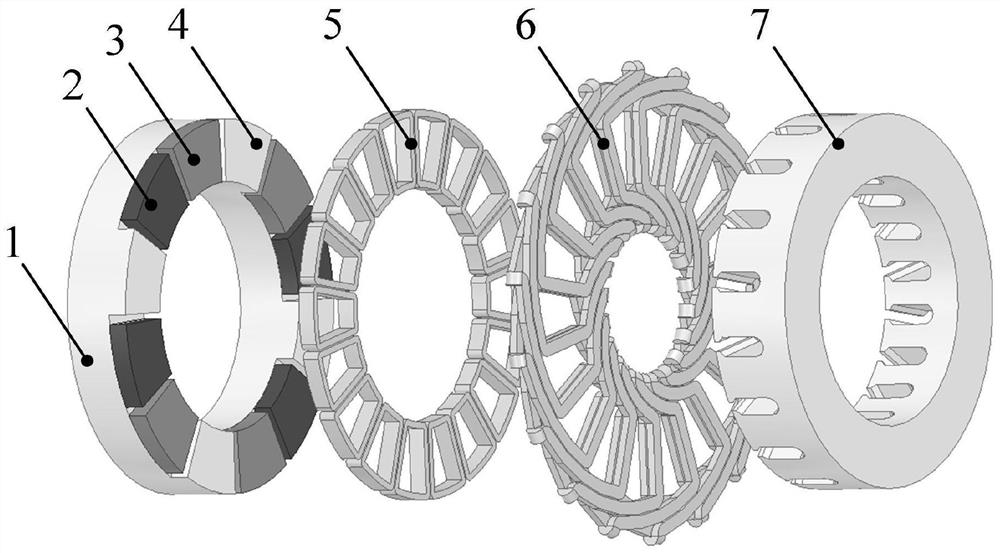

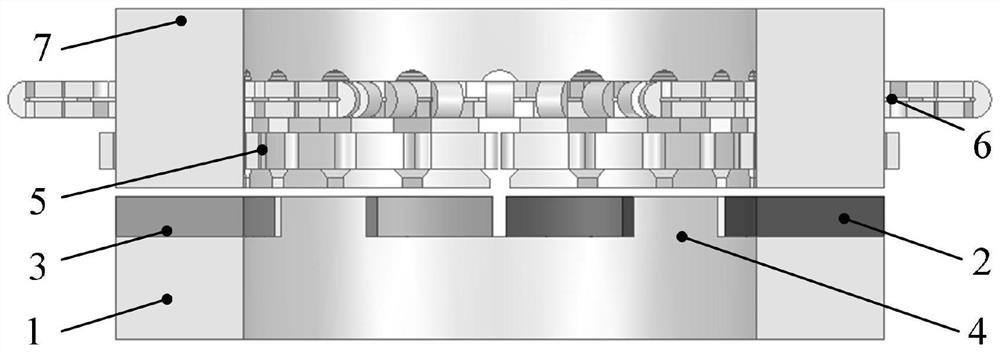

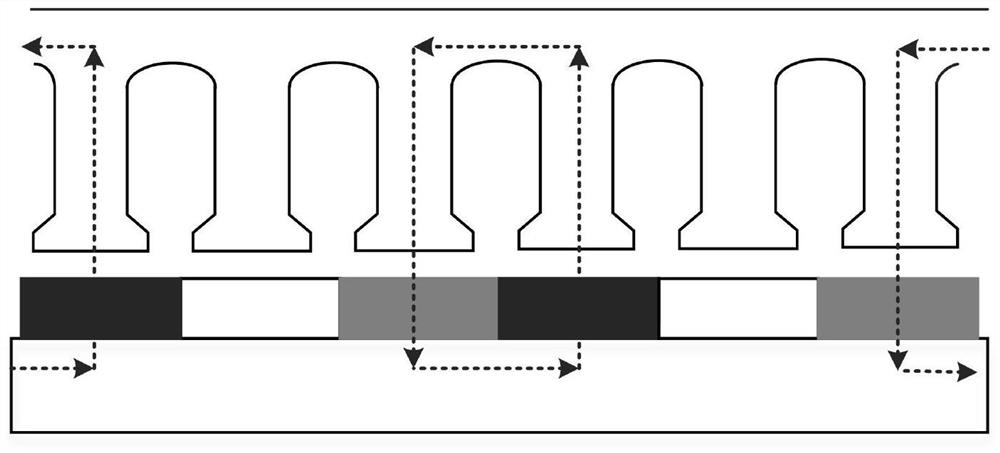

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the axial magnetic field alternating pole brushless hybrid excitation motor adopts three phases, the armature winding 5 adopts 12 poles and 18 slots, and the AC excitation winding 6 adopts 4 poles and 18 slots, which is also applicable to other slot pole coordination. The number of 5 pole pairs of the armature winding is equal to the number of 1 pole pairs of the axial rotor, the number of 6 pole pairs of the AC excitation winding is equal to the number of 4 pole pairs of the core poles, the number of 1 pole pairs of the axial rotor is equal to the number of pole pairs of the permanent magnet poles and the iron core The sum of the 4 pole pairs is equal.

[0037] The axial rotor 1 adopts the alternating structure of permanent magnet N pole 2 and permanent magnet S pole 3, so that the polarity of the adjacent iron core pole 4 is reversed, so as to ensure the formation of a path for the excitatio...

Embodiment 2

[0039] The AC excitation winding 6 can adjust the air gap magnetic field. When the armature winding 5 fails, the AC excitation winding 6 serves as the hot backup of the armature winding 5 and contributes the output torque, which is fault-tolerant. When the motor is running below the base speed, the excitation current is used to increase the magnetization to increase the output torque of the motor; when the motor is running above the base speed, the excitation current is used to weaken the field to expand the operating speed range of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com