Hub-type axial excitation permanent magnetic motor

An axial excitation, permanent magnet motor technology, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of complex structure, no in-wheel motor search, etc., and achieve the effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be described in further detail below in conjunction with the accompanying drawings.

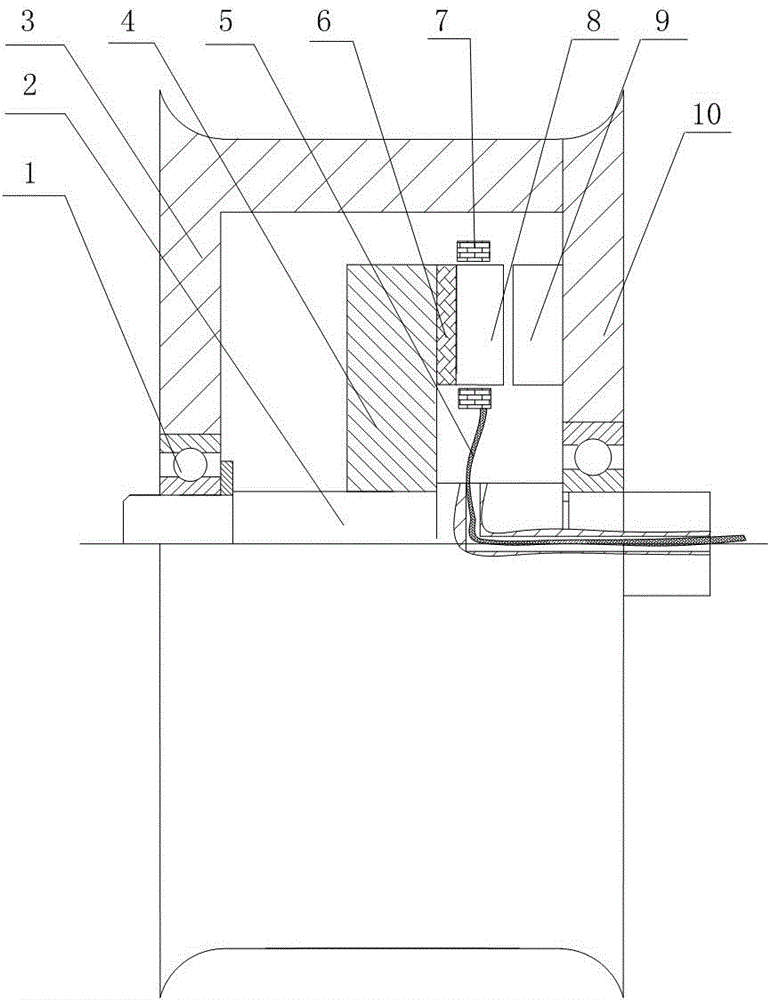

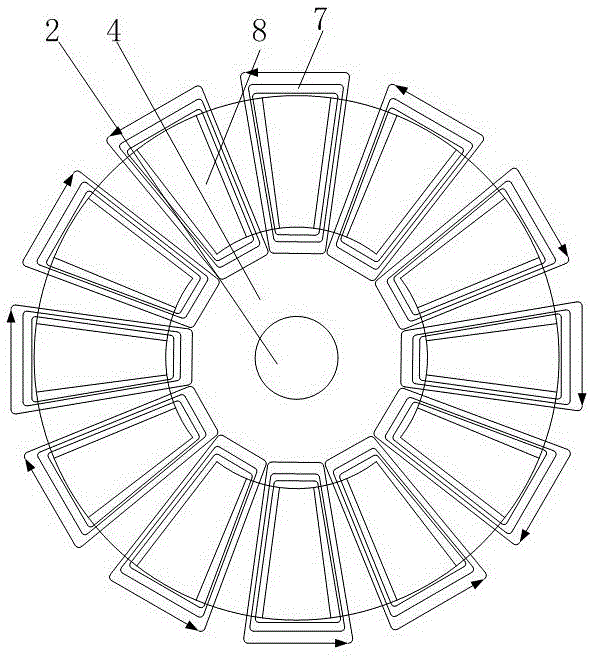

[0034] figure 1 It is a longitudinal sectional view of a hub type axial excitation permanent magnet motor of the present invention.

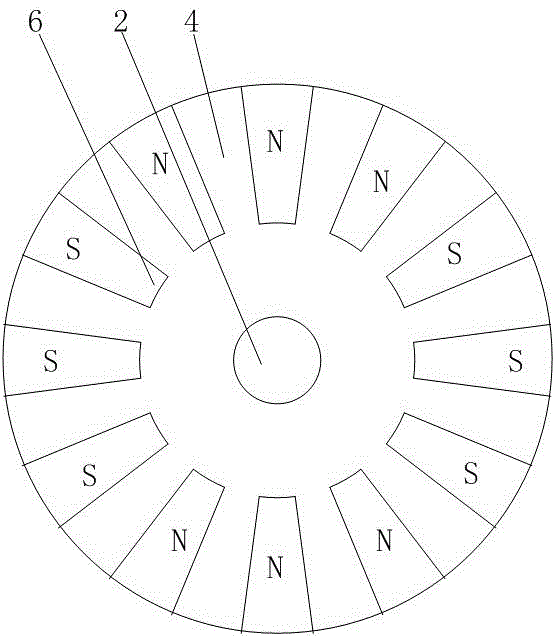

[0035] It consists of bearing (1), shaft (2), hub (3), stator core (4), permanent magnet (6), armature winding (7), stator pole (8), rotor pole (9) and hub cover ( 10) Composition;

[0036] The disc-shaped stator core (4) is fixed in the middle of the shaft (2), the inner rings of the two bearings (1) are respectively fixed at both ends of the shaft (2), and the outer rings of the two bearings (1) are respectively fixed In the central hole of the hub (3) and the hub cover (10), under the action of the bearing (1), the hub (3) and the hub cover (10) can rotate around the axis (2), thereby driving the wheel to rotate;

[0037] A permanent magnet (6) and a stator pole (8) are sequentially fixed on the opposite end surface of the stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com