Rapid response permanent magnet control mechanism

A technology of permanent magnet operation and quick response, applied in the direction of the power device inside the switch, etc., can solve the problem that the power supply requires a lower control speed. The curve is difficult to be consistent, etc., to reduce the refusal of the switch, prevent the coil from burning, and simplify the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

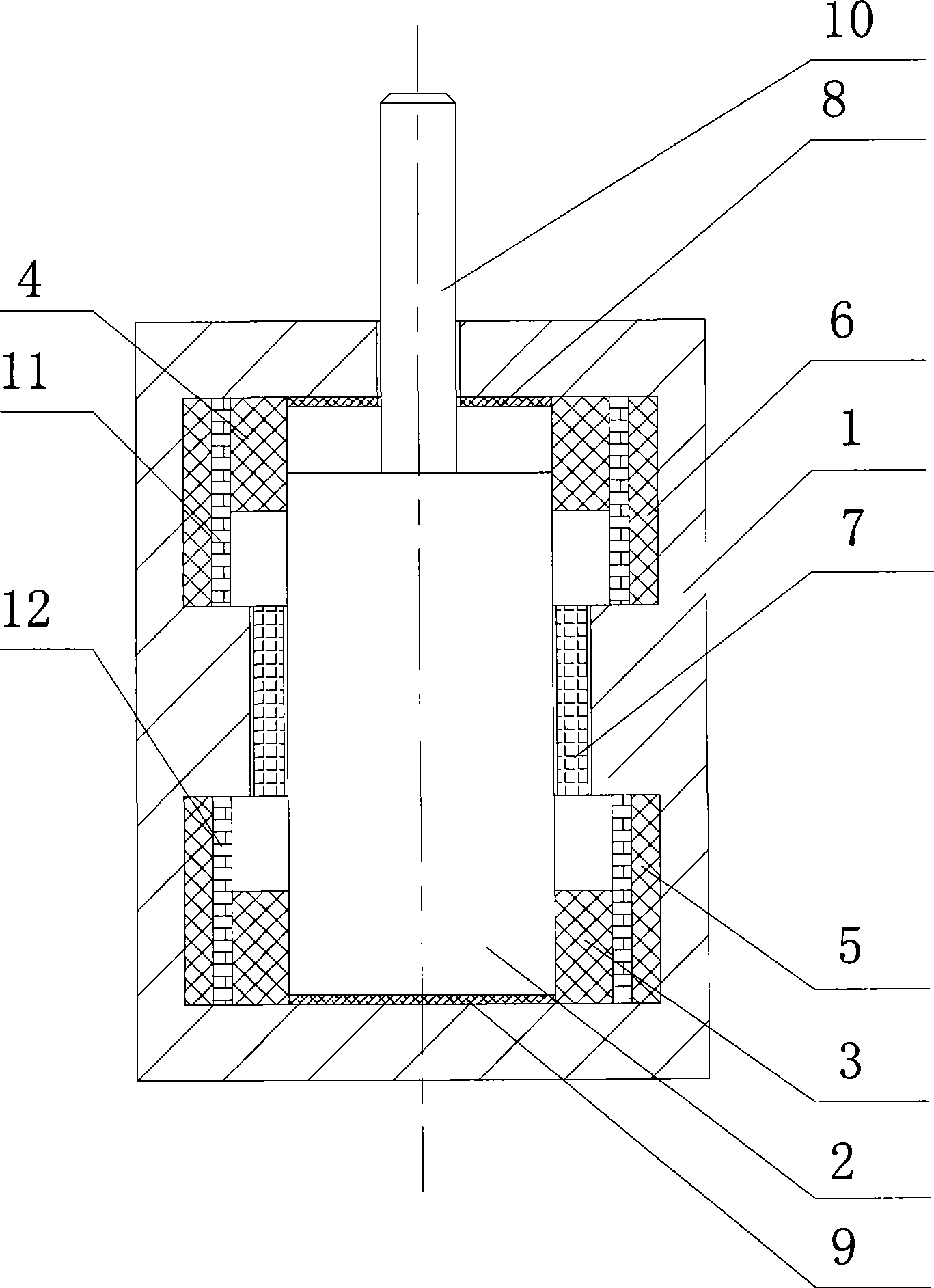

[0028] refer to figure 1 , a fast-response permanent magnet operating mechanism for switch control, including: a yoke 1, a moving iron core 2 and a push rod 10, the top of the moving iron core 2 is provided with a push rod 10, and the moving iron core 2 is set on the magnetic Inside the yoke 1, the opening coil 3, the closing coil 4, the opening starting coil 5, the closing starting coil 6, the annular permanent magnet 7, the upper buffer pad 8, and the lower buffer pad 9 are also arranged in the yoke 1 , the upper insulating layer 11 and the lower insulating layer 12, and the closing coil 3 is located on the top of the inner wall of the yoke 1 and sleeved on the moving iron core 2, and the upper buffer cushion 8 is fastened on the top of the inner wall of the yoke 1 and sleeved On the push rod 10, the opening coil 4 is located at the bottom of the inner wall of the yoke 1 and sleeved on the moving iron core 2, the lower buffer cushion 9 is fastened at the bottom of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com