Novel high torque density high power factor fault tolerant permanent magnet vernier machine and its modulation method

A technology of power factor and vernier motors, applied in synchronous motors with stationary armatures and rotating magnets, motor generator control, electronic commutation motor control, etc., can solve the problem of low winding factor, inappropriateness, and low magnetic field utilization And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

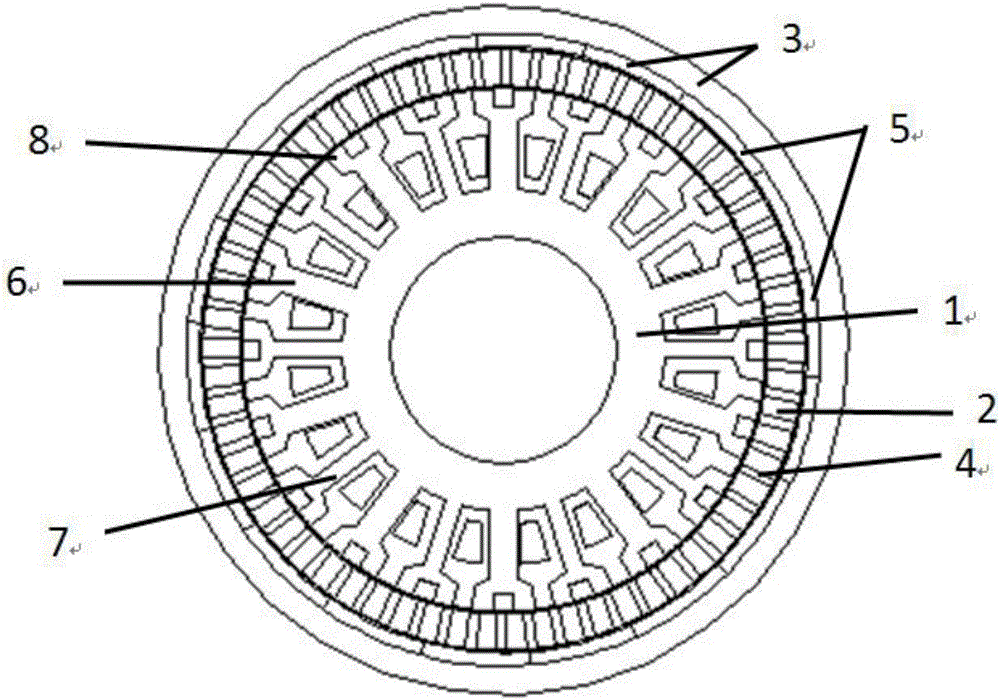

[0042] A new type of high torque density high power factor fault-tolerant permanent magnet vernier motor of the present invention, the motor includes an inner stator 1, an inner rotor 2 and an outer rotor 3 in sequence from the inside to the outside, between the inner stator 1 and the inner rotor 2, the inner rotor 2 and the outer rotor 3 have air gaps; the inner rotor 2 is embedded with radial permanent magnets 4, which adopt tangential excitation, and the N poles and S poles of the radial permanent magnets 4 are arranged alternately along the circumference; the inner rotor 2 A plurality of surface-embedded permanent magnets 5 are embedded between the surface and the outer rotor 3. The surface-embedded permanent magnets 5 are unipolar, and they are all excited in the direction of the center of the circle; the inner stator 1 is alternately arranged with armature teeth. 6 and fault-tolerant teeth 7; the armature teeth 6 and fault-tolerant teeth 7 are evenly arranged with modulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com