Mixed excitation permanent magnet flux switching motor

A magnetic flux switching motor and mixed excitation technology, which is applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the limitation of the magnetic field adjustment range and limit the wide speed regulation drive system Research and application of occasions, difficult to adjust the air gap magnetic field and other problems, to achieve the effect of low flux linkage harmonic content, simple structure, and small loss of electric excitation copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

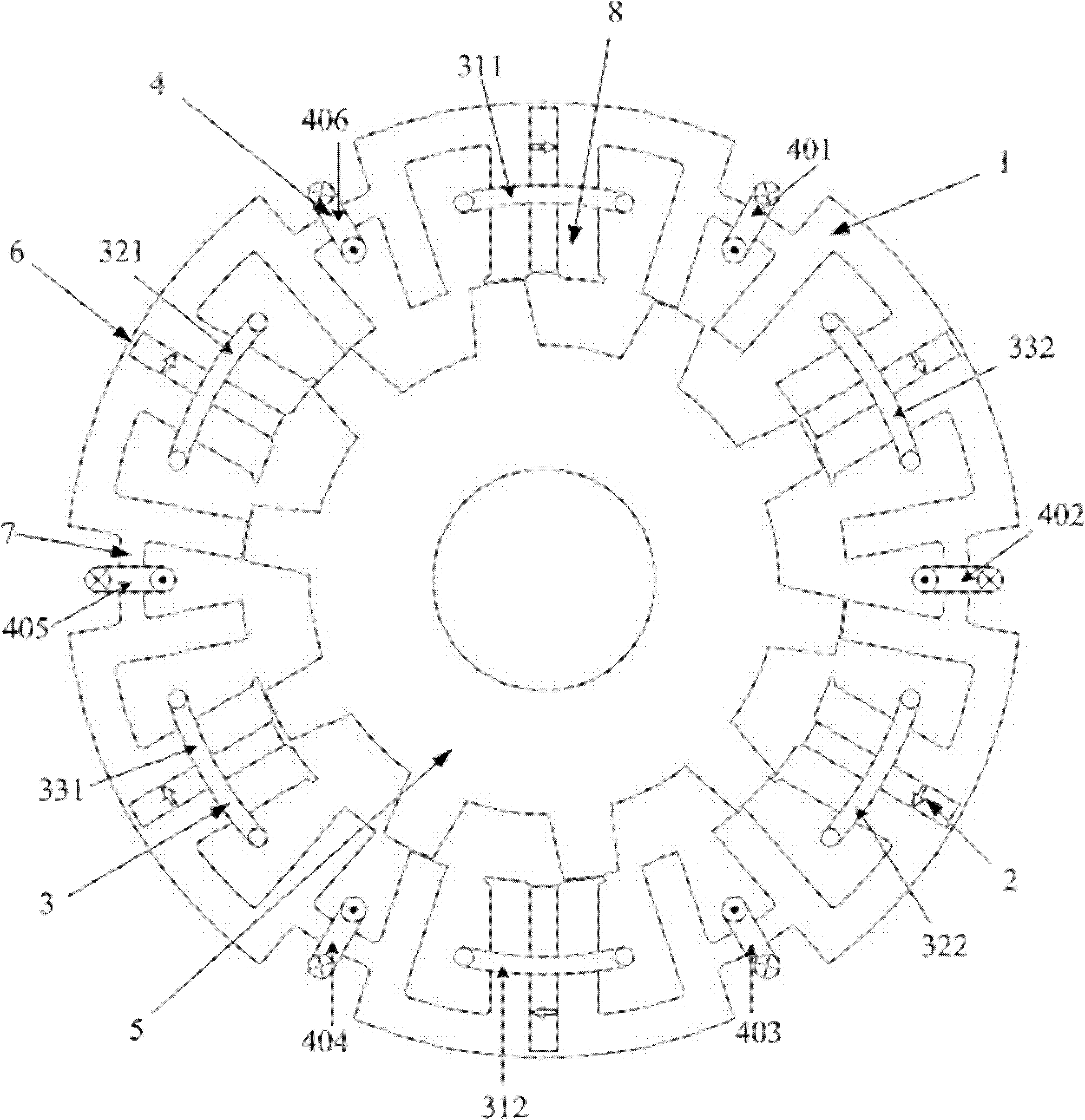

[0018] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, the hybrid excitation permanent magnet flux switching motor of the present invention includes a stator 1 and a rotor 5, and the rotor 5 with 10 salient poles is located inside the stator 1; Permanent magnets: Three-phase armature windings 3, single-phase field windings 4 and six permanent magnets 2 are arranged on the stator 1.

[0019] The stator 1 includes: 12 U-shaped stator cores, and the first iron core connecting magnetic bridge 6 and the second iron core connecting magnetic bridge 7 which are connected circularly to each U-shaped iron core in turn; the two U-shaped arms of each U-shaped iron core are stator teeth 8 , so the number of stator teeth 8 is four times the number of permanent magnet blocks; the U-shaped iron core of the stator is connected to the magnetic bridge through the iron core to form a whole, which is convenient for processing. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com