Patents

Literature

119results about How to "Improve the restraint effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-loss surface plasmon optical waveguide structure

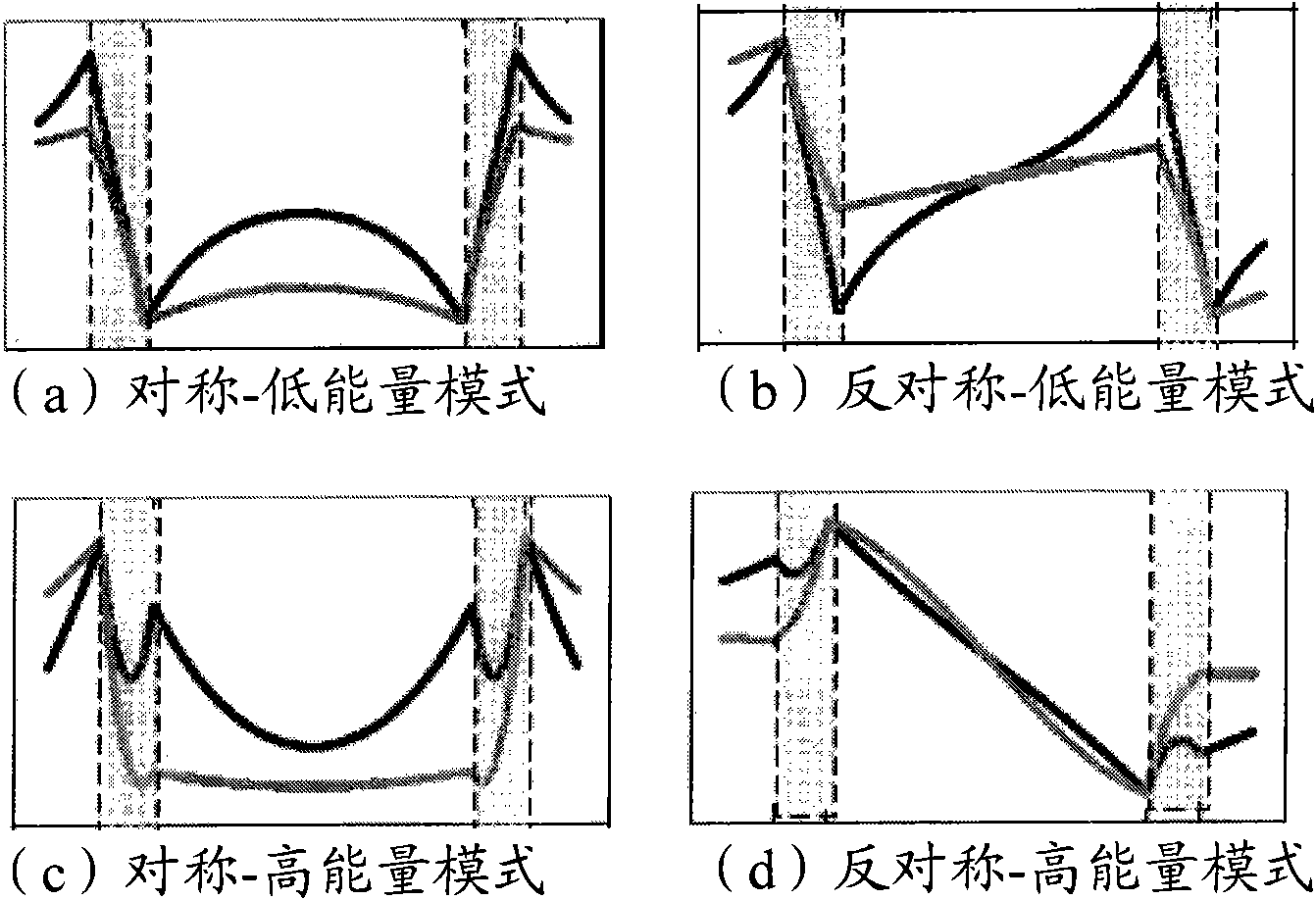

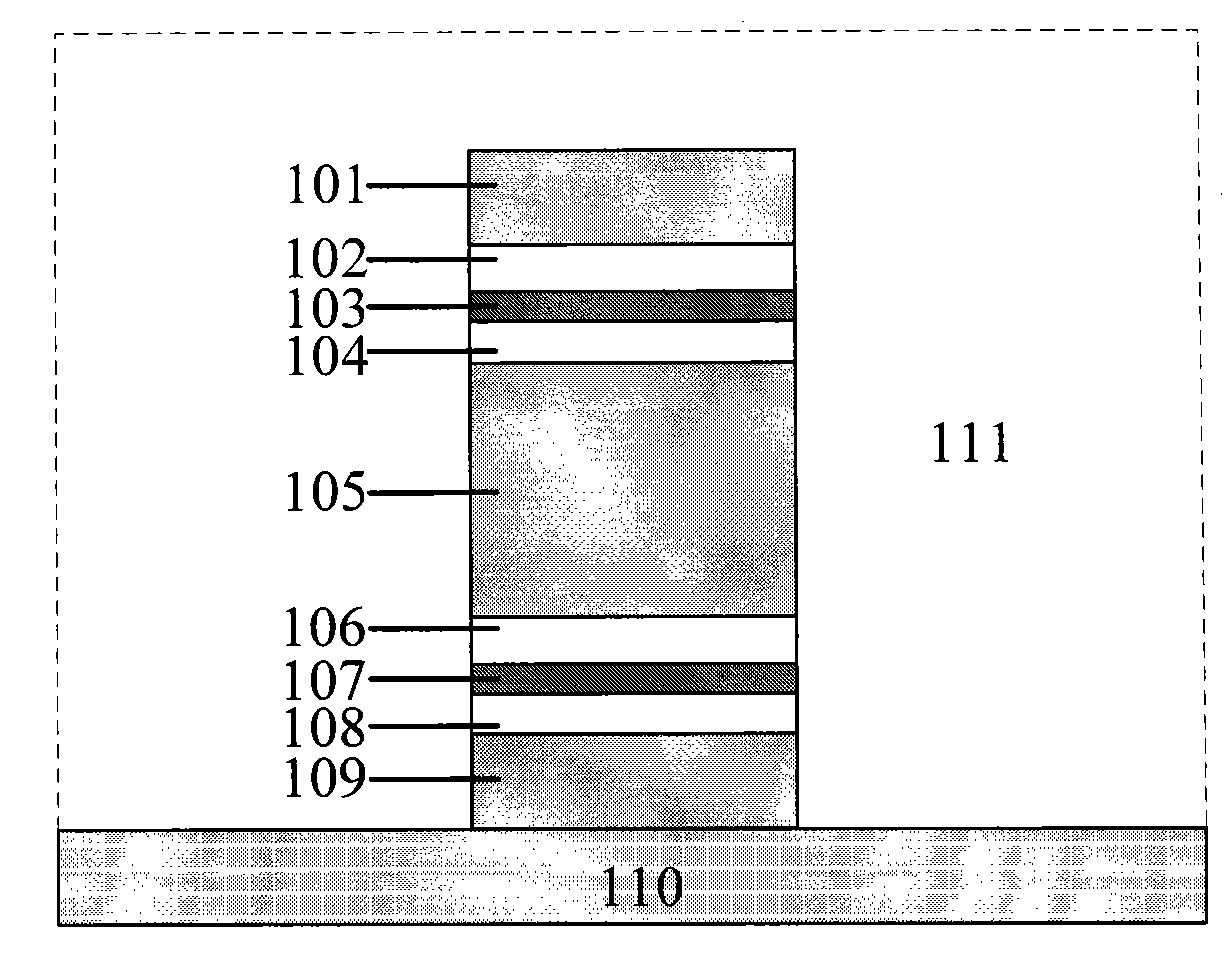

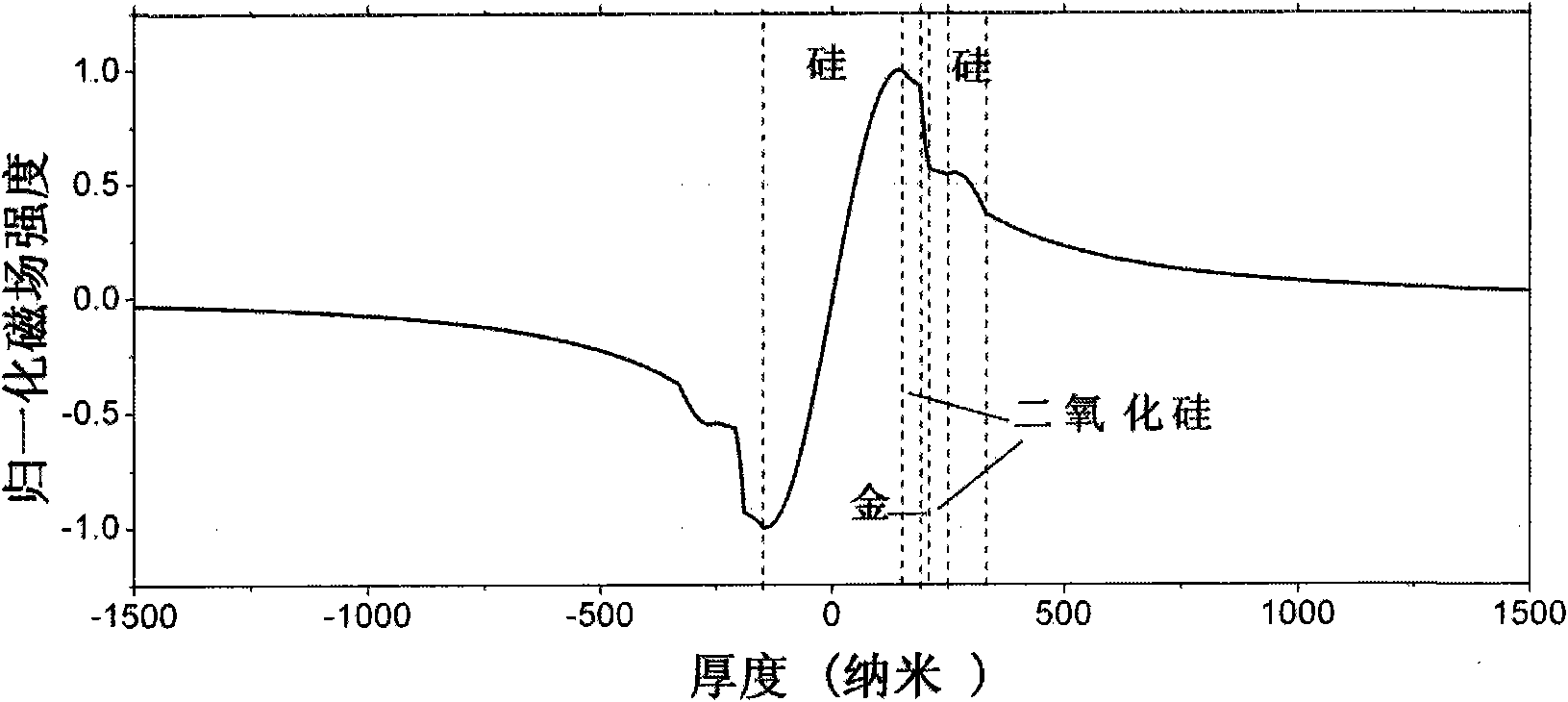

InactiveCN101630038AReduce lossReduce transmission lossOptical waveguide light guideSurface plasmonHigh energy

The invention relates to the technical fields of surface plasmon optical waveguide structures and provides an antisymmetric-high energy mode surface plasmon optical waveguide structure capable of low-loss transmission for overcoming a large loss drawback of the conventional metal / media / metal waveguide transmission. The optical waveguide structure realizes a waveguide structure for supporting transmission in an antisymmetric-high energy mode by combining the refractive index difference between a plurality of high refractive index layers and a low refractive index substrate and a low refractive index covering layer and a surface plasmon effect of a metal layer and uses the low refractive index medium layers on two sides of the metal layer to reduce transmission loss, thereby realizing low-loss surface plasmon optical waveguide. Meanwhile, the optical waveguide structure has the advantages of small effective mode filed area and low loss can be used for manufacturing optical devices of a subwavelength size and ultra high integration level optical circuits.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA +1

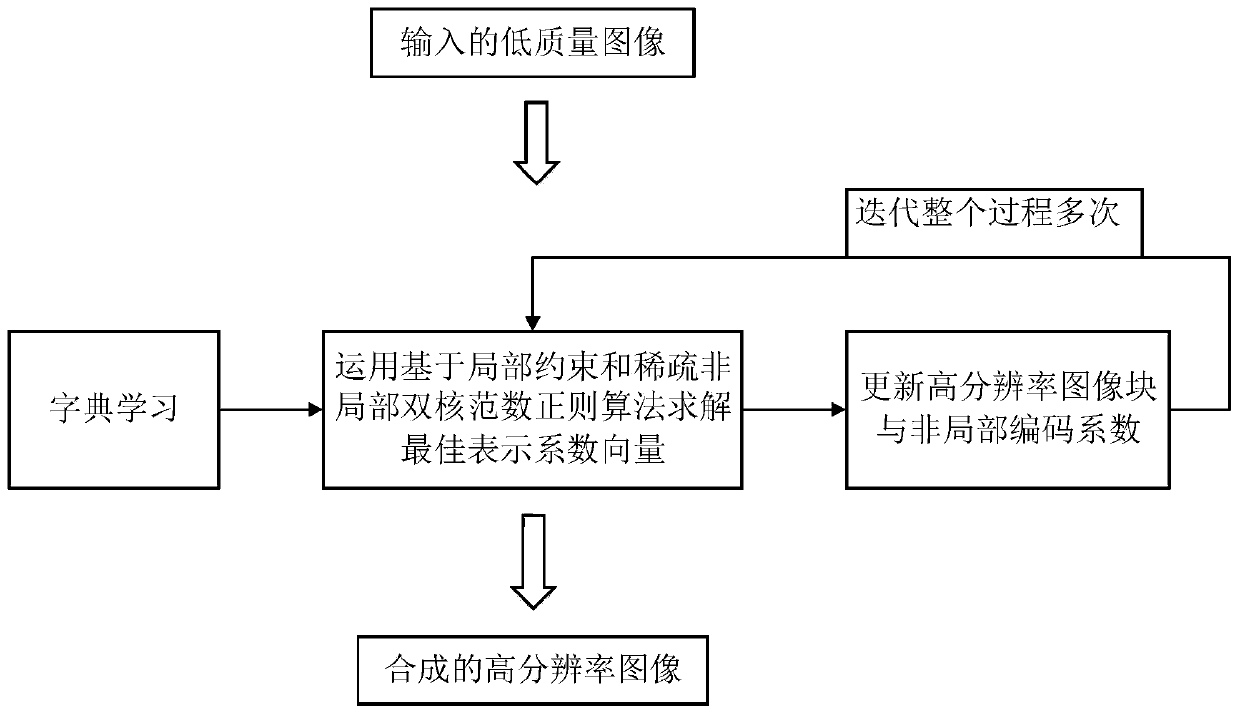

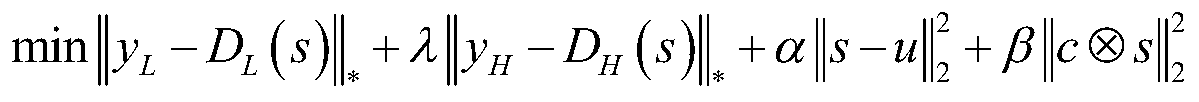

Face image super-resolution method based on local and sparse non-local regularities

ActiveCN109766863AImprove the restraint effectImprove image qualityGeometric image transformationCharacter and pattern recognitionDictionary learningCluster algorithm

The invention discloses a face image super-resolution method based on local and sparse non-local regularities. The face image super-resolution method comprises the following steps of 1, obtaining image blocks of all pixel positions of a test image and a training sample image; 2, using a local PCA dictionary learning method, using a K-means clustering algorithm to divide and cluster the image blocks of the training sample image blocks, and learning a local PCA dictionary by each cluster; 3, for a low-quality image block, solving an optimal representation coefficient vector by applying a local constraint and sparse non-local dual-core norm regularization algorithm; 4, synthesizing a high-resolution image block on the high-resolution dictionary by using the optimal representation coefficientvector, updating a non-local coding coefficient, and putting the updated coefficient and the high-resolution image block into the step 3 for next iteration; A high-resolution image block is obtained through multiple times of iterative updating; And step 5, outputting a high-resolution image. The method has the advantage of improving the image quality.

Owner:NANJING UNIV OF POSTS & TELECOMM

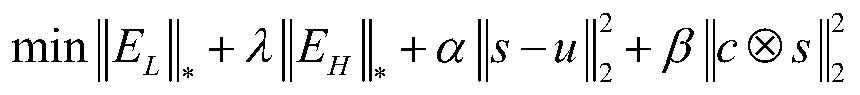

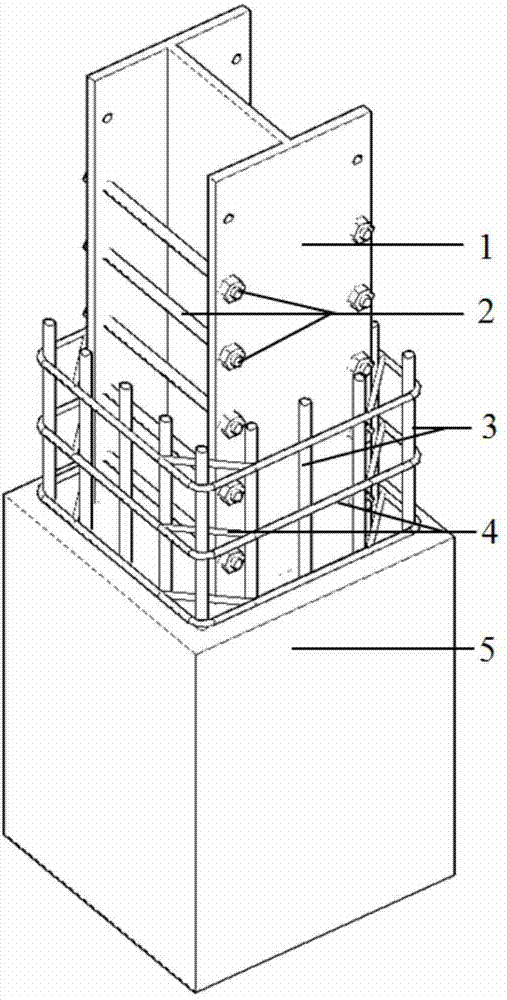

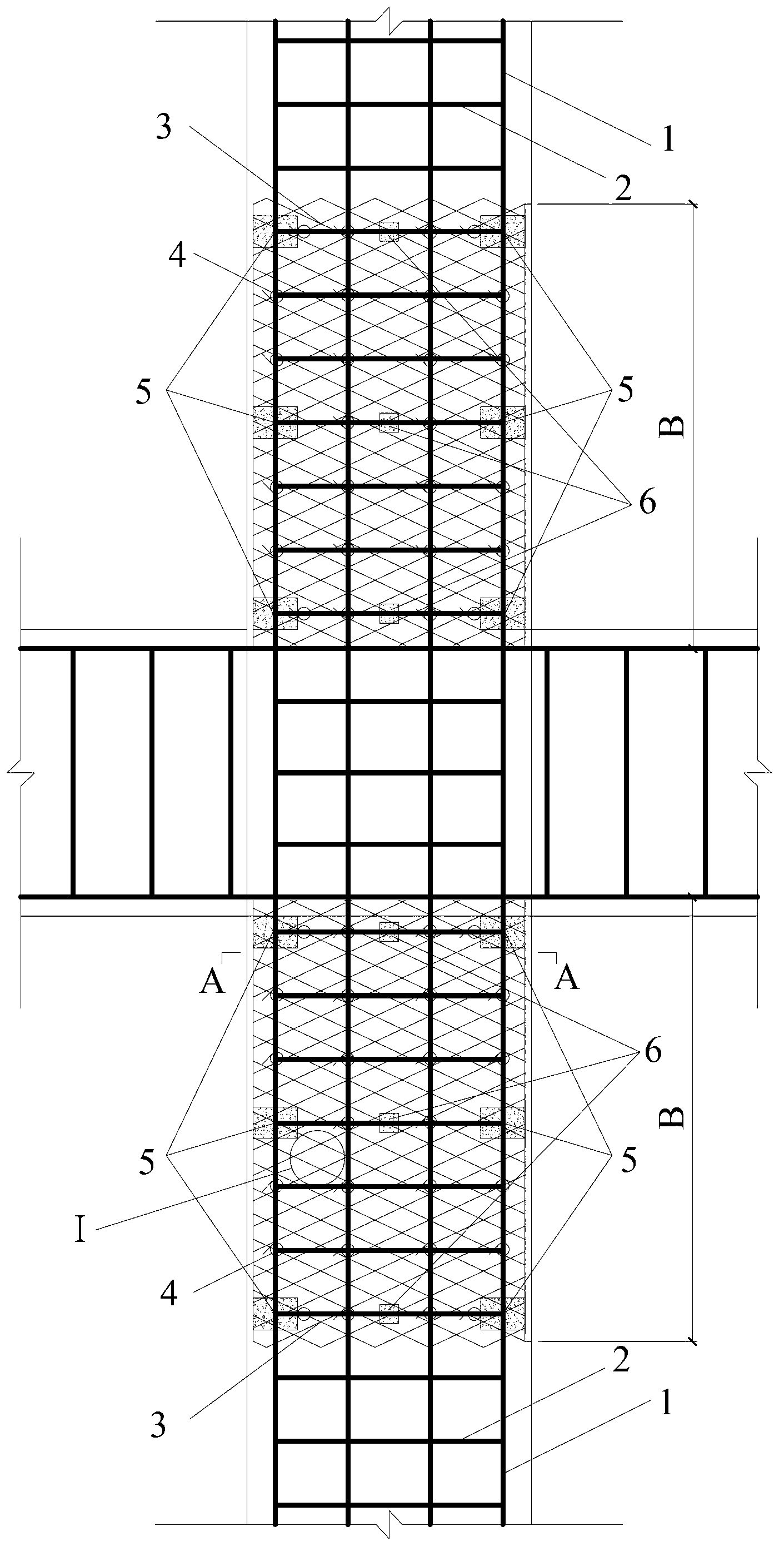

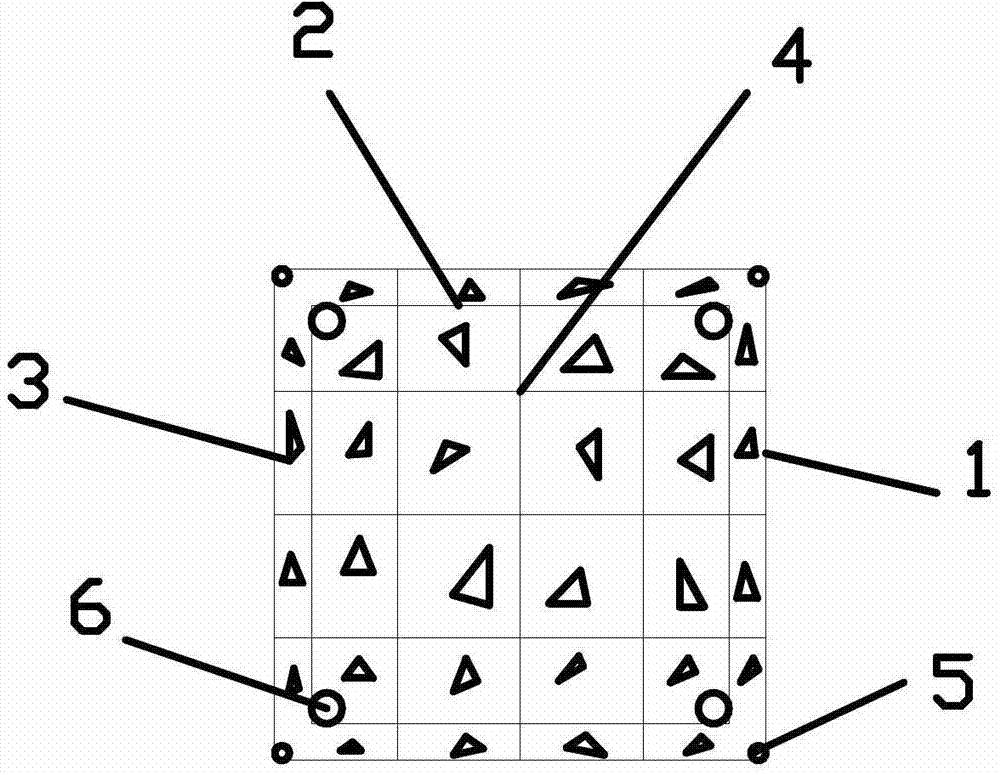

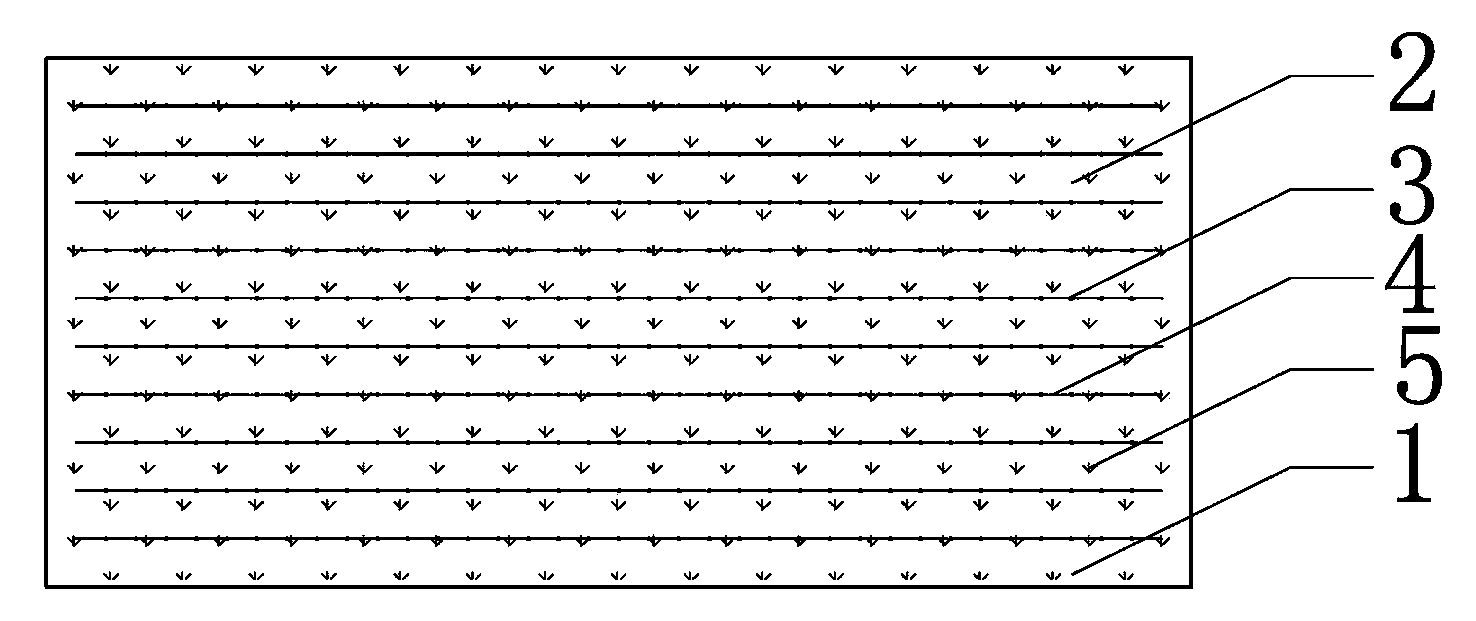

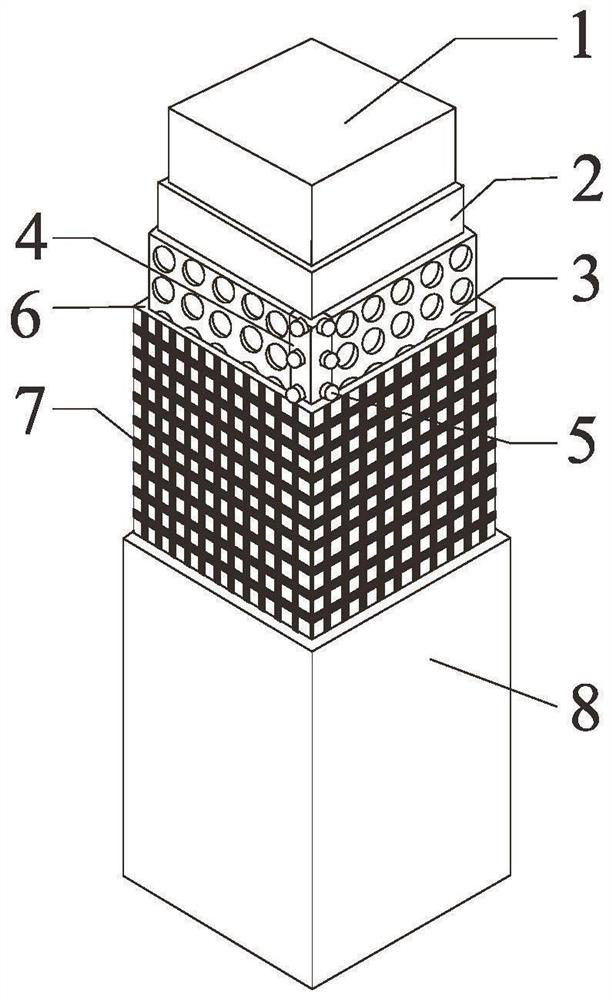

H-shaped steel bone-confined concrete column with round steel draw bars and fabrication method of column

InactiveCN103924740AReduce own overhangConstrained buckling deformationStrutsPillarsUltimate tensile strengthElastic plastic deformation

The invention relates to a steel bone concrete column, and particularly relates to an H-shaped steel bone-confined concrete column with round steel draw bars. The H-shaped steel bone-confined concrete column with the round steel draw bars comprises an H-shaped steel bone, the round steel draw bars, longitudinal reinforcement, a composite stirrup and concrete, wherein the round steel draw bars are connected with two flanges, at the outer sides of the flanges and near the free edges, of the H-shaped steel bone through bolts, so that the free extension length of each flange is effectively reduced, buckling deformation of the flanges is constrained, and meanwhile, the inspection capability of internal concrete of the steel bone is enhanced by existence of the round steel draw bars. The round steel draw bars are arranged at intervals, and the internal part of the steel bone is communicated with external concrete in series, so that the pouring quality of the concrete is ensured. Therefore, the concrete disclosed by the invention has the relatively high strength and the good elastic-plastic deformation capacity, and the formed steel bone concrete column has the relatively high bearing capacity, ductility and energy-dissipating capacity.

Owner:BEIJING UNIV OF TECH

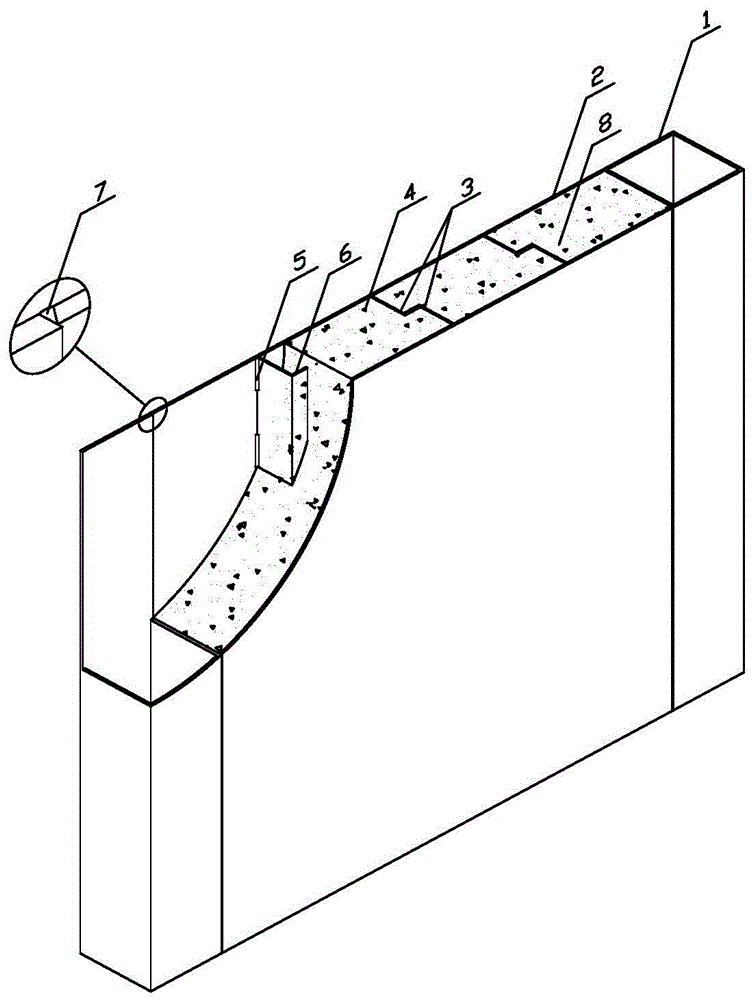

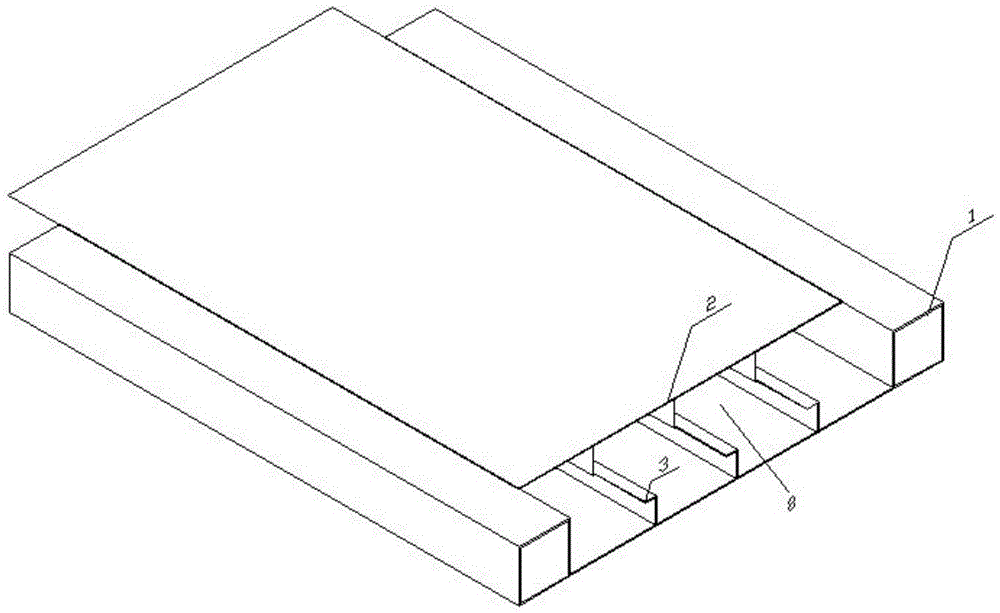

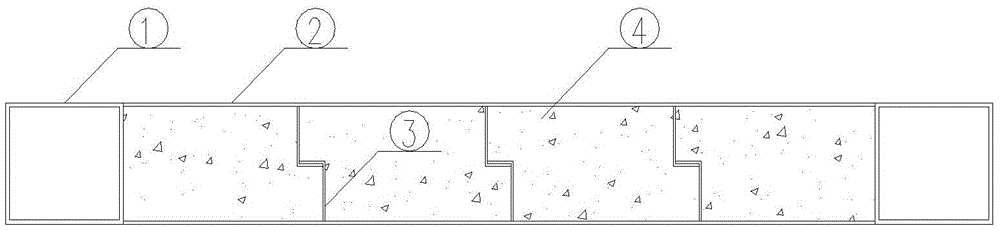

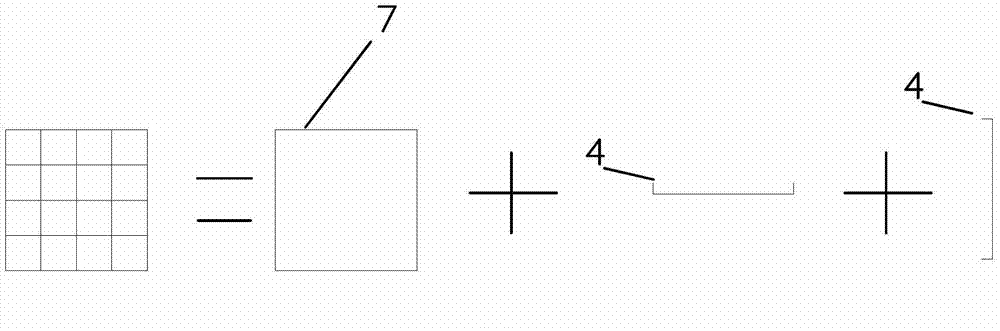

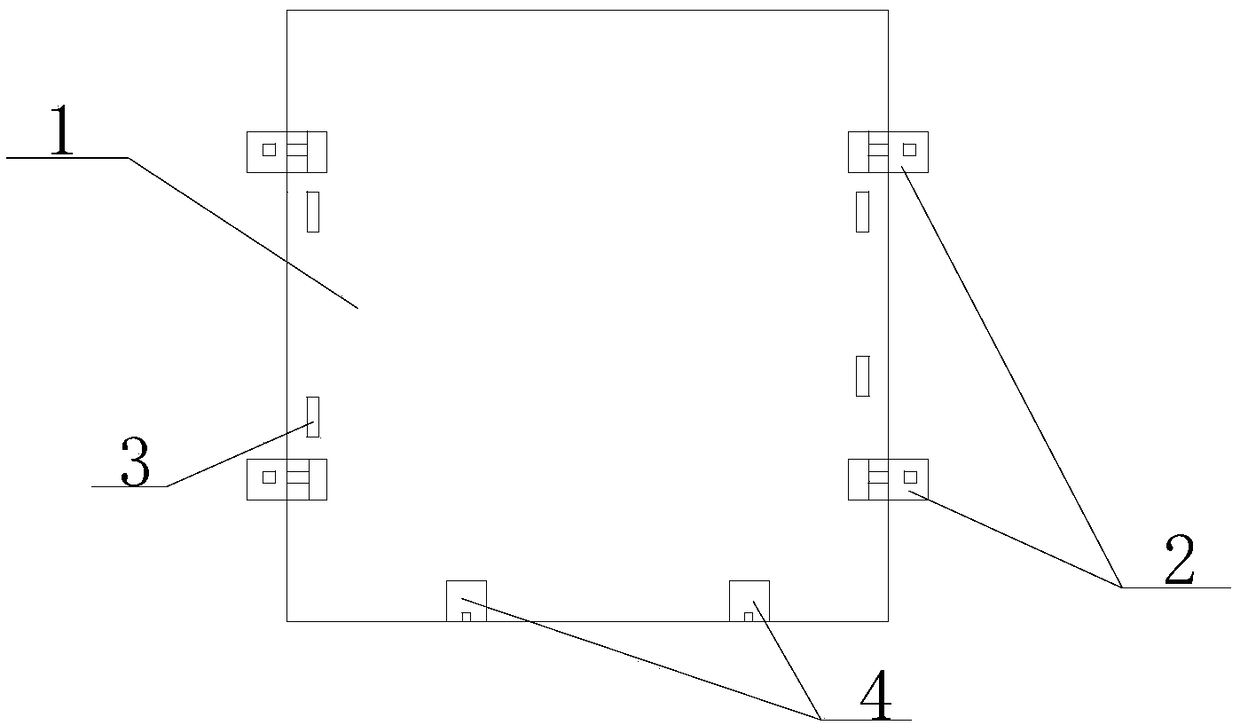

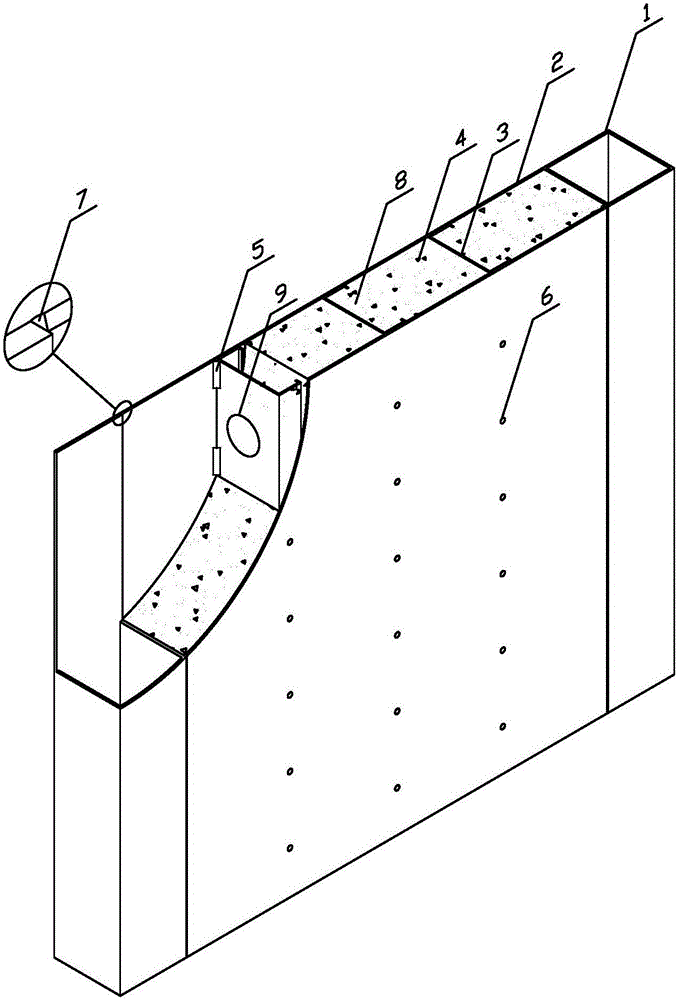

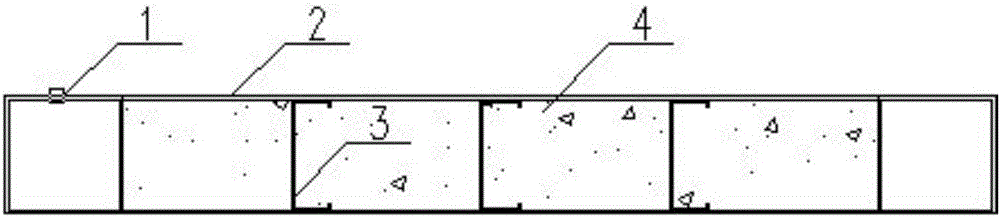

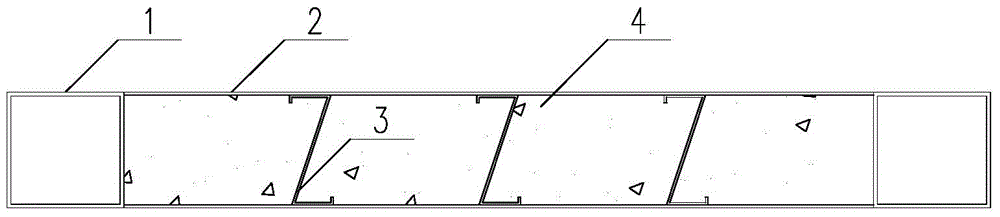

Pull-joint type double-steel-plate composite shear wall

The invention discloses a pull-joint type double-steel-plate composite shear wall, comprising steel pipe columns (steel pipe columns or concrete-filled steel tube columns) respectively arranged at the two ends, a pair of steel plates and at least one pull-joint type connecting piece. The pull-joint type connecting piece is firstly connected with the steel plates by staggered and intermittent one-side fillet welds in a welding way, and then a whole is assembled; the pull-joint type double-steel-plate composite shear wall has the advantages that the composite shear wall is simple in pull-joint structure, has a flat wall surface, and is less in welding workload, easy to operate and convenient to assemble; the stress performance of the composite shear wall is seldom affected by the welding quality since weld joints are positioned at construction parts; the composite shear wall is economical and safe; the steel plates and concrete are strong in cooperative work capability. A straight hook L shape, a sickle hook shape or hump hook shape can be adopted as the pull-joint way of the connecting piece, the pull-joint position can be positioned at the middle or side part of the thickness of the composite wall, and the pull-joint way is flexible and changeable, so that different engineering stress and use requirements are met. Riffled plates can be used as the wallboard steel plates and the pull-joint type connecting piece, so that the binding action between the wall steel plates and the concrete is effectively improved, and the co-working between steel components and the concrete is guaranteed.

Owner:HEFEI UNIV OF TECH +1

Steel screen restricted column plastic hinge region concrete structure and making method thereof

InactiveCN103225368AGood restraint effectSlow down the rate of stiffness decayStrutsBuilding reinforcementsRebarEngineering

The invention discloses a steel screen restricted column plastic hinge region concrete structure and a making method thereof, and belongs to the technical field of building engineering construction. In the invention, the binding of steel screens outside the steel reinforcement cage of a column plastic hinge region provides a good restriction effect for concrete, can prevent the early shedding of concrete and improves the column ductility. The making method concretely comprises the following operation steps: steel reinforcement cage binding, steel screen cutting, steel screen bending, steel screen installation, and column formwork and concrete pouring and vibration. The steel screen restricted column plastic hinge region concrete structure effectively raises the rotation capability of the column plastic hinge region, improves the column ductility and improves the concrete work state.

Owner:BEIJING UNIV OF TECH

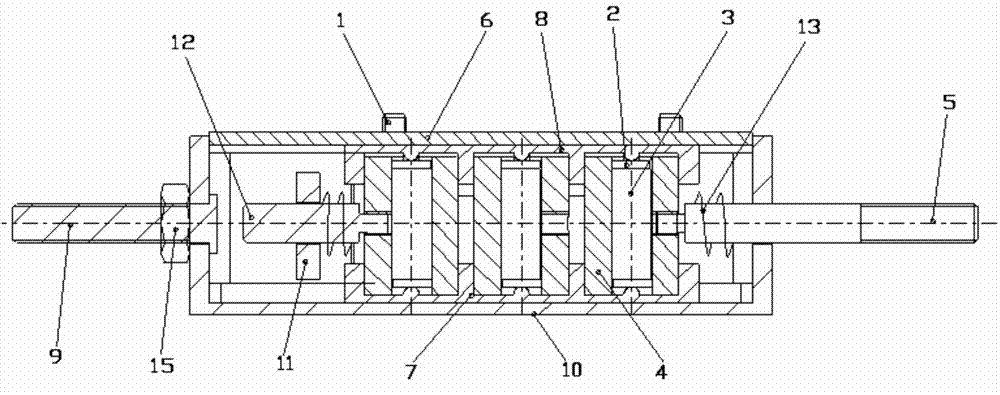

Self-resetting piezoelectric semi-active friction damper

InactiveCN103485436AAvoid the risk of breakingWith reset functionShock proofingElectricitySemi active

A self-resetting piezoelectric semi-active friction damper comprises a shell and sleeves, wherein the shell comprises a top cover and a small box. One end of each sleeve is arranged on a base at the bottom of the small box, the other end of each sleeve is arranged on a top seat below the bottom of the top cover, a certain gap is reserved between the top seat and the other end of the corresponding sleeve, piezoelectric ceramic drivers are placed in the sleeves, leads of the piezoelectric ceramic drivers extend out of the damper through small grooves in the side faces of the sleeves and long and narrow hole grooves in the side walls of the small box and are connected with an external power supply, gaskets are arranged at two ends of each piezoelectric ceramic driver, a baffle is fixed to one side wall of the small box through a fixing screw, pre-pressure is applied by pre-tightening screws on the top cover, a balancing pull rod penetrates the baffle and is connected with the outer wall of the left sleeve, a connecting pull rod is fixed to the left side wall of the small box through a hexagonal nut, an actuating pull rod penetrates one side wall of the small box and is connected with the right sleeve, and reset springs are arranged on the balancing pull rod and the actuating pull rod respectively. A control system of the self-resetting piezoelectric semi-active friction damper is simple, the performance of the piezoelectric ceramic drivers is stable, the pre-pressure is conveniently applied, output energy is less, power output is high, and a piston can automatically reset.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

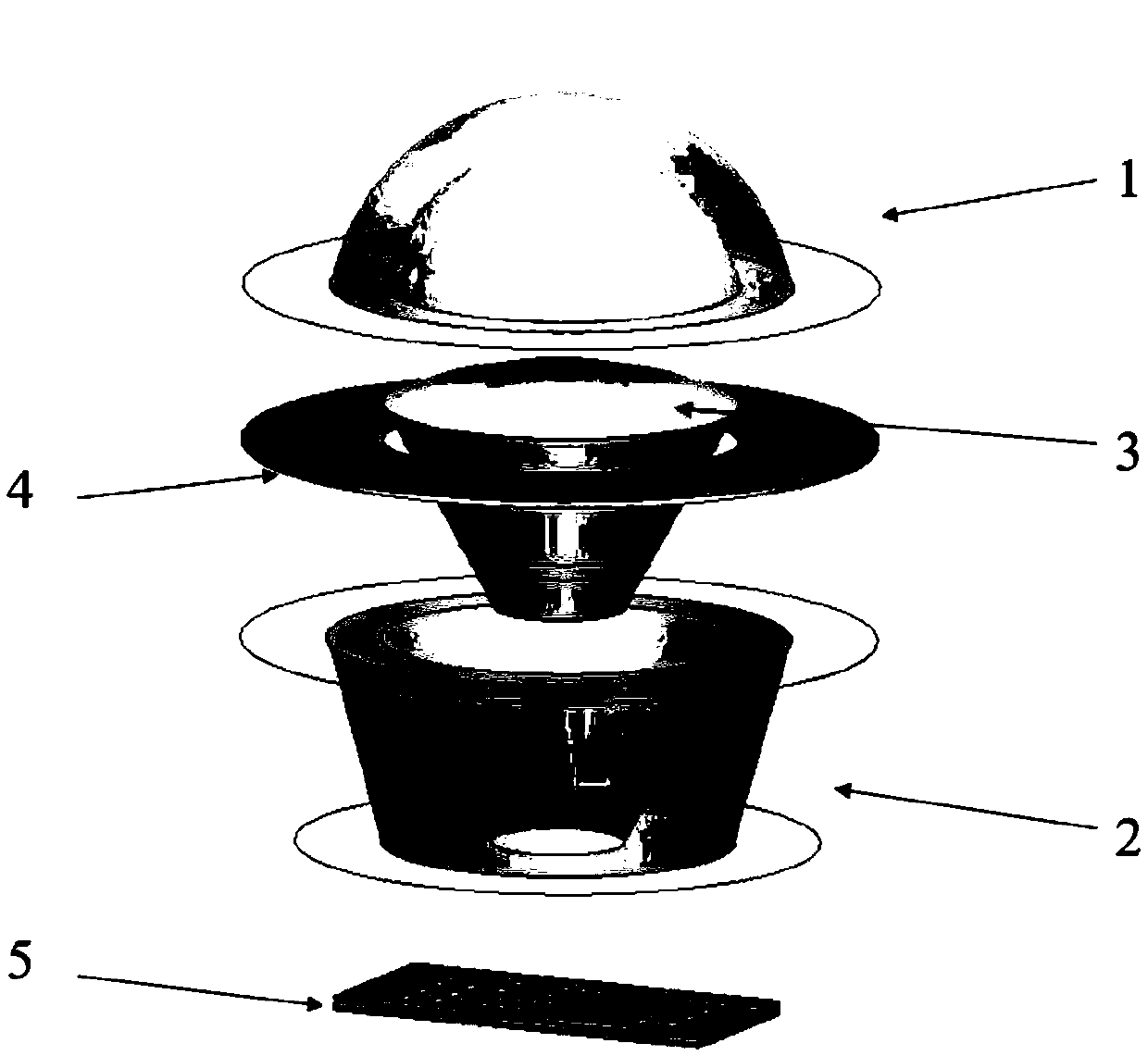

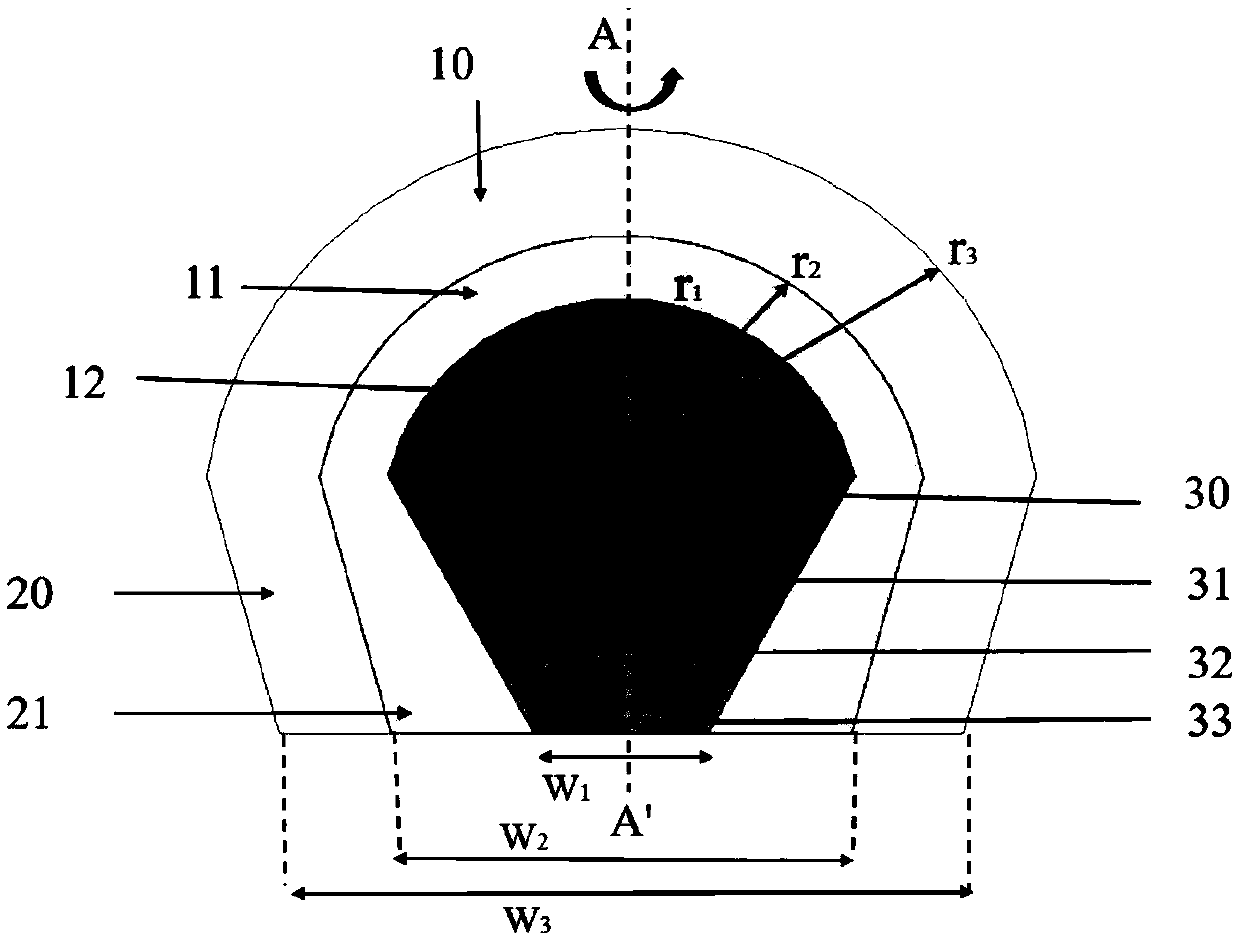

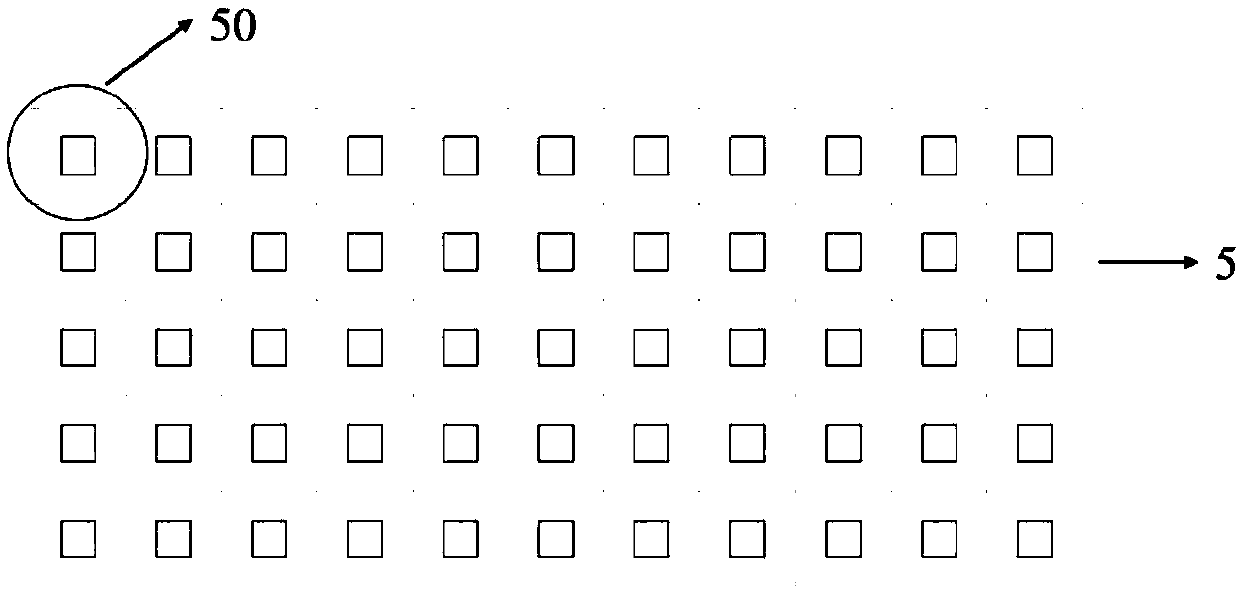

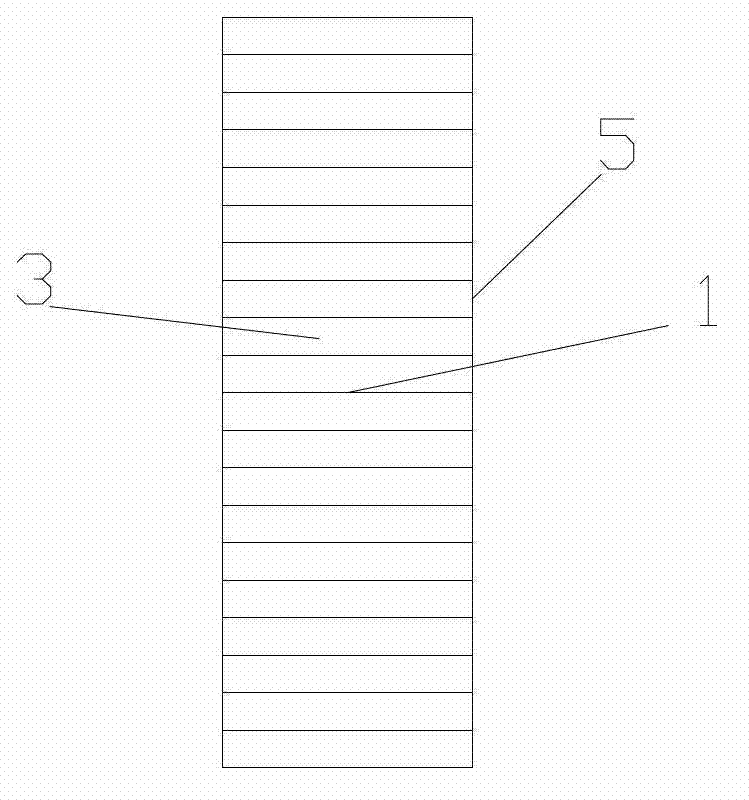

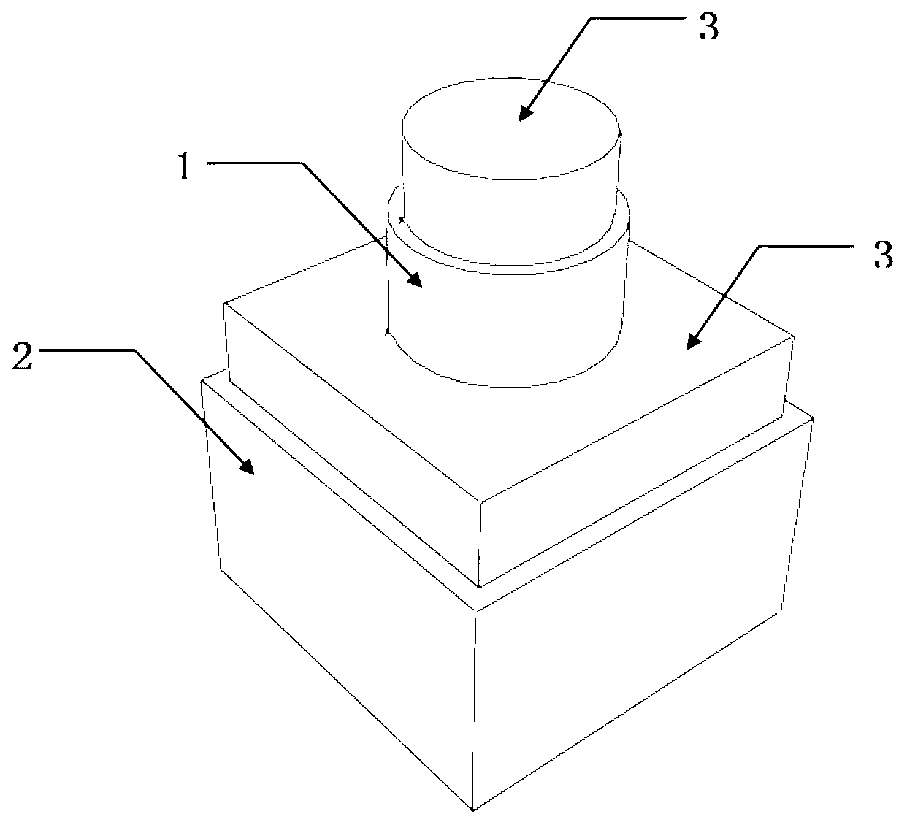

A high-gain, wide-angle scanning lens antenna based on a stepped medium

ActiveCN109103604AHigh gainHigh angle scanIndividually energised antenna arraysMillimeter wave communication systemsMicrowave

The invention discloses a novel high-gain, wide-angle scanning lens antenna based on a stepped medium, belonging to the technical field of microwave and millimeter wave antennas. The antenna includesa lens antenna and a patch antenna feed array horizontally positioned below the lens antenna. The lens antenna includes an upper spherical shell portion, a lower circular table portion, and an inner sector spherical portion which are fitted tightly. The different thickness and dielectric constant of each part of the lens antenna can effectively collect electromagnetic wave, readjust the amplitudeand phase of electromagnetic wave, and achieve high gain. The contour of the lower circular table can refract electromagnetic wave effectively. Based on the placement position of the feed array of thepatch antenna, the large-angle scanning can be realized effectively. The invention can be used in millimeter wave communication system and radar communication, and has the advantages of ensuring highgain and scanning in a large range at the same time, simple power feeding, small number of feed sources, convenient installation and low cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Frame-supporting column with high strength steel bars and super high strength concrete

InactiveCN103046692AReduce section sizeIncrease ultimate strainStrutsPillarsHigh strength concreteReinforced concrete

The invention relates to a reinforced concrete frame-supporting column, in particular to a frame-supporting column with high strength steel bars and super high strength concrete. The frame-supporting column overcomes defects that axial compression ratio limits of ordinary reinforced concrete frame-supporting columns and steel reinforced concrete frame-supporting columns are low, protective covers fall easily under earthquake force, longitudinal bars and steel flanges are easy to bend, the columns are difficult to repair after an earthquake, and high strength steel bars and super high strength concrete cannot be applied, and defects that node constructions of steel reinforced concrete and steel pipe concrete frame-supporting columns are complex, the steel pipe concrete frame-supporting columns do not constrain concrete fully, and steel pipes are easy to bend. The frame-supporting column comprises longitudinal high strength steel bars, high strength closed stirrups and self-compaction super high strength concrete; and constraints include that stirrup spacing of concrete protective covers in whole concrete ranges from 30mm to 35mm, outer surfaces are aligned to outer surfaces of concrete frame-supporting columns, and the stirrup spacing of longitudinal high strength steel bars is constrained to range from 60 mm to 120 mm. By aid of constraining of closely-matched high strength welding closed stirrups on the whole concrete, mechanical properties of super high strength concrete are improved, anti-seismic properties of the column are improved, and the frame-supporting column has a wide application prospect in high-rise or super high-rise structures.

Owner:贵州中建伟业建设(集团)有限责任公司

Carbon fiber strip reinforced structure component and implementation method thereof

The invention relates to a carbon fiber strip reinforced structure component. The carbon fiber strip reinforced structure component comprises a structure component and a carbon fiber strip coated on the outer surface of the structure component, wherein the carbon fiber strip is spirally wound and pressed on the outer surface of the structure component. The invention also provides an implementation method of the carbon fiber strip reinforced structure component. The implementation method is characterized by comprising the following steps: (1) winding the head end of the carbon fiber strip; (2) axially and spirally winding and pressing the carbon fiber strip along the structure component; (3) winding the tail end of the carbon fiber strip. The carbon fiber strip is used for coating the structure component, so that the purpose of reinforcing the structure component is achieved; the head end and the tail end of the carbon fiber strip are respectively subjected to press-in winding and tying treatment, so that the purpose of self locking and anchoring is achieved; the carbon fiber strip is not required to be bound by a flammable adhesive, so that the carbon fiber strip still has high restraint effect on the structure component under the high-temperature breakage; the carbon fiber strip has the advantages of high temperature resistance, long service life and environment friendliness.

Owner:GUANGDONG UNIV OF TECH

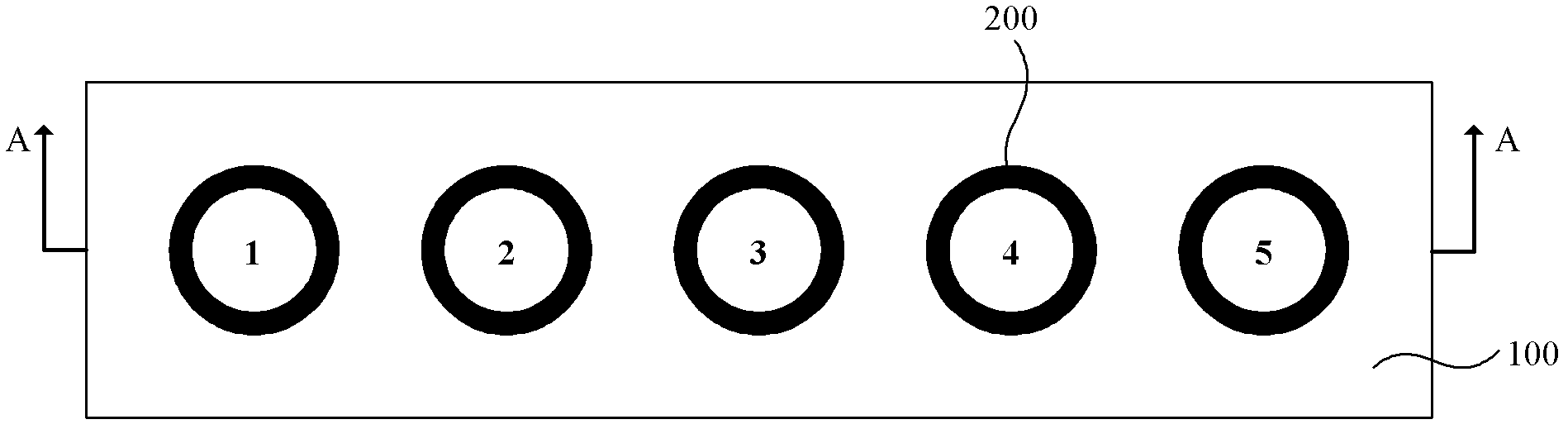

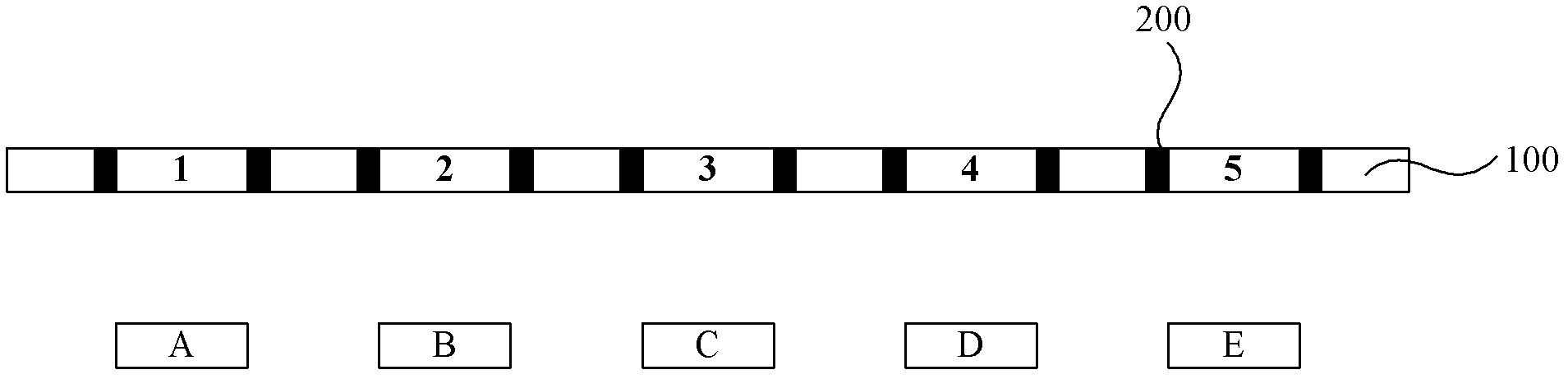

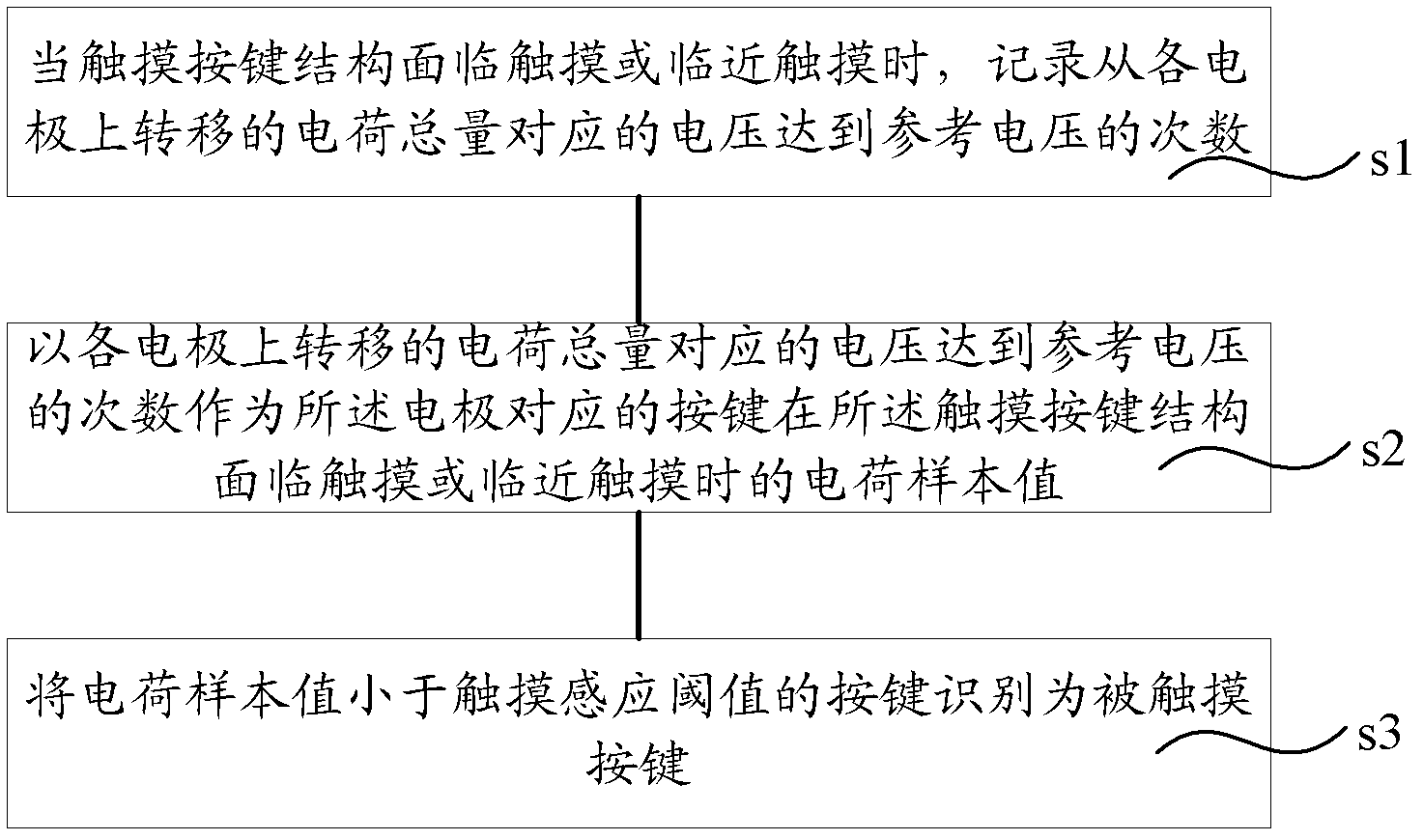

Touch key structure and touch device

InactiveCN102571058AImprove the restraint effectAvoid interferenceElectronic switchingKey pressingCapacitance

The invention discloses a touch key structure and a touch device. The touch key structure comprises a metal touch panel, wherein a plurality of metal keys are arranged on the touch panel, the keys and the touch panel are isolated through an insulation layer, and the touch panel is ground; a detection board is arranged below the touch panel, a plurality of electrodes corresponding to the keys are arranged on the detection board, and the detection board and the touch panel are in insulation isolation; and areas between the plurality of keys and the electrodes form flat capacitors. The touch key structure and the touch device have better restraint effect of an induction range, and avoid the interference of adjacent keys during touch identification.

Owner:JIANGSU HUITONG GRP

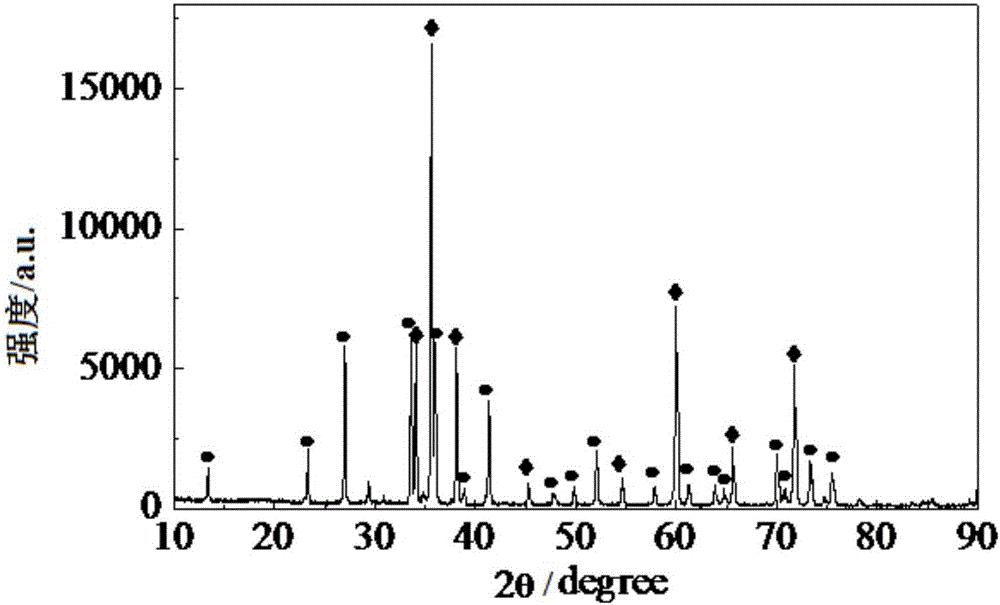

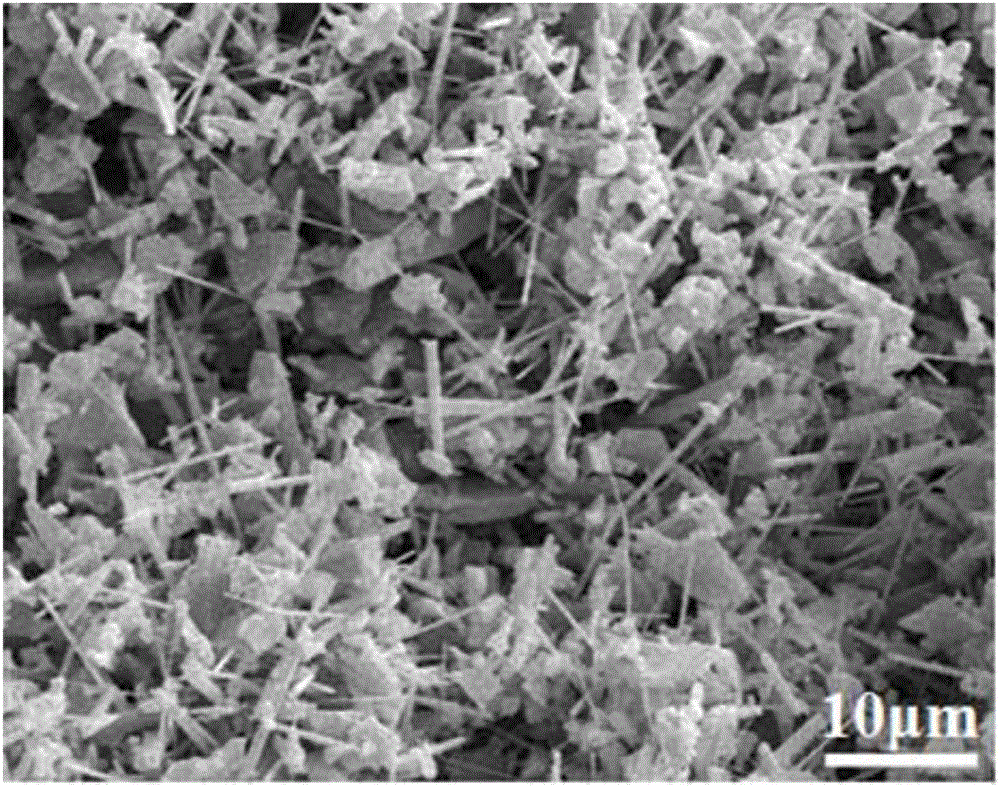

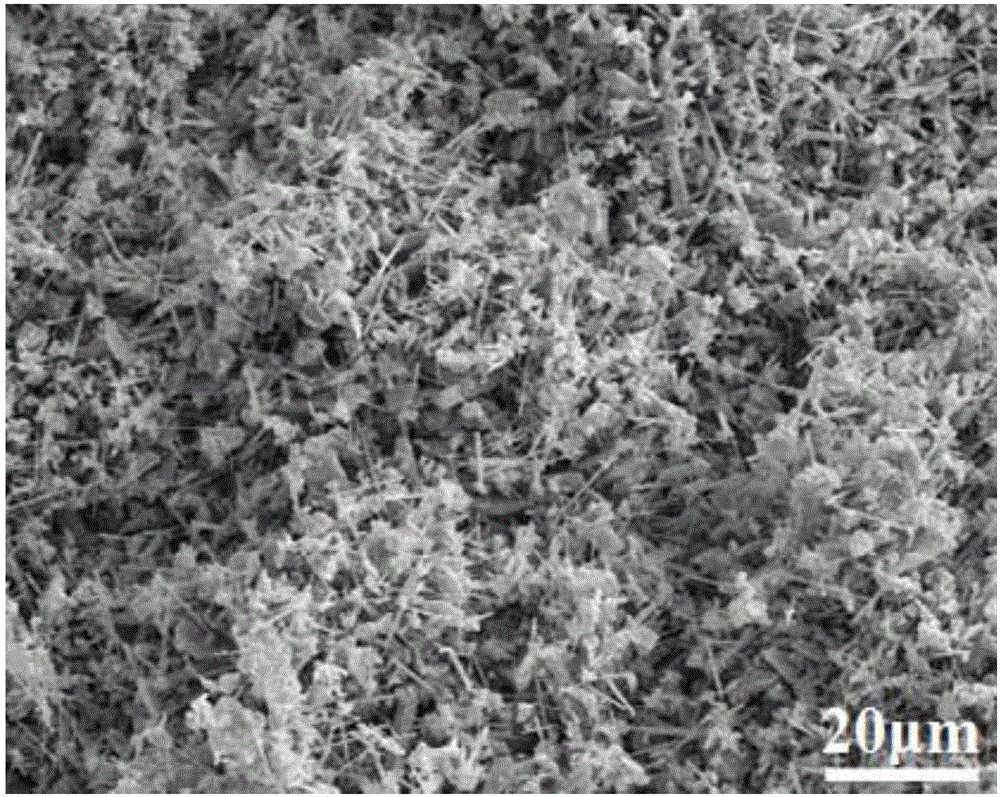

Preparation method for metal-matrix composite enhanced by porous Si3N4/SiC multiphase ceramic

The invention provides a preparation method for a metal-matrix composite enhanced by porous Si3N4 / SiC multiphase ceramic, and relates to a preparation method for a ceramic-enhanced metal-matrix composite. By adoption of the preparation method for the metal-matrix composite enhanced by the porous Si3N4 / SiC multiphase ceramic, the technical problems that an existing ceramic-enhanced metal-matrix composite is high in thermal expansion coefficient, and reinforcement bodies are prone to agglomeration and cannot be dispersed evenly are solved. The preparation method for the metal-matrix composite enhanced by the porous Si3N4 / SiC multiphase ceramic comprises the steps that firstly, slurry is prepared; secondly, the porous Si3N4 / SiC multiphase ceramic is prepared; thirdly, surface modification of the porous multiphase ceramic is conducted; and fourthly, the composite is prepared. According to the preparation method for the metal-matrix composite enhanced by the porous Si3N4 / SiC multiphase ceramic, the pore diameter of the porous multiphase ceramic is small, growth of metal grains in the composite is restrained, and the comprehensive mechanical property of the composite is effectively improved through fine crystal enhancement; Si3N4 / SiC nanowires in the porous multiphase ceramic are evenly distributed; ceramic enhancement bodies in the metal-matrix composite are distributed continuously, so that the metal-matrix composite has a low thermal expansion coefficient; and the metal content is high, so that the composite has high thermal conductivity.

Owner:HARBIN INST OF TECH

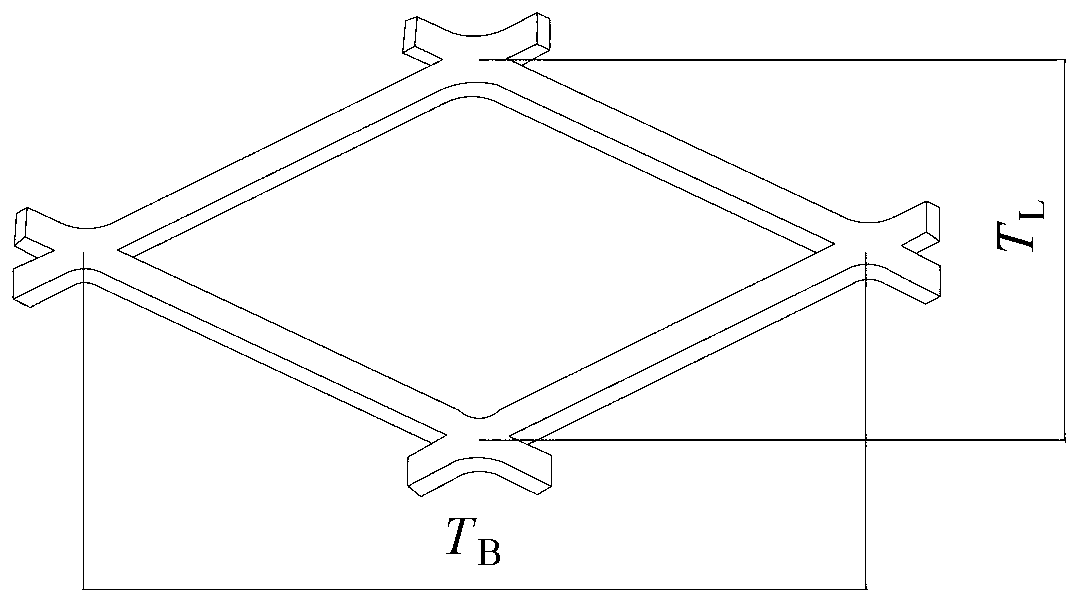

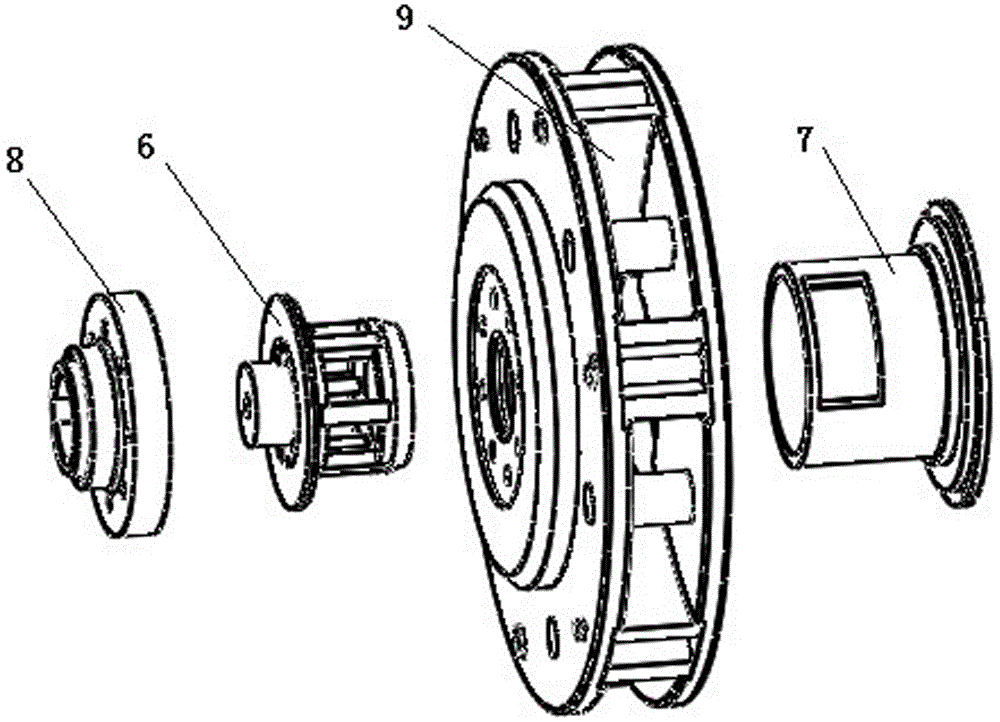

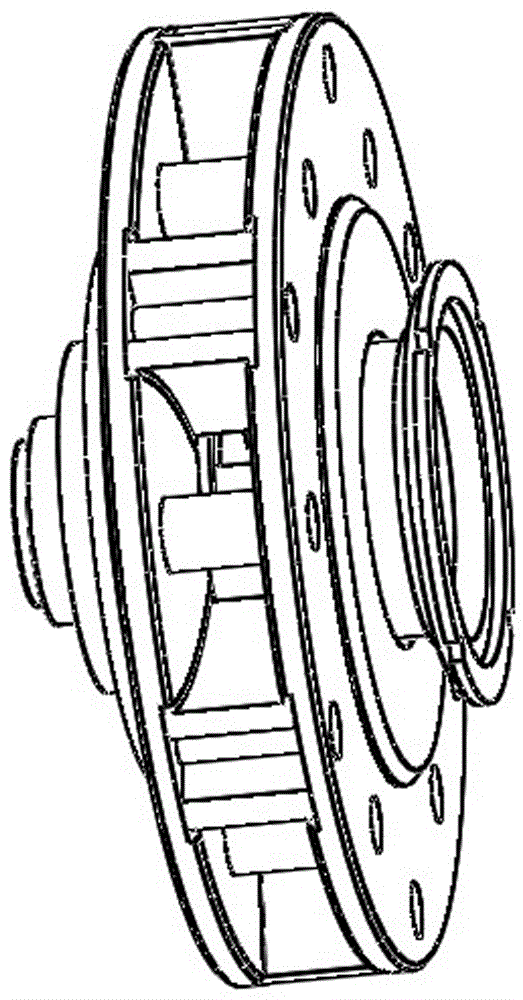

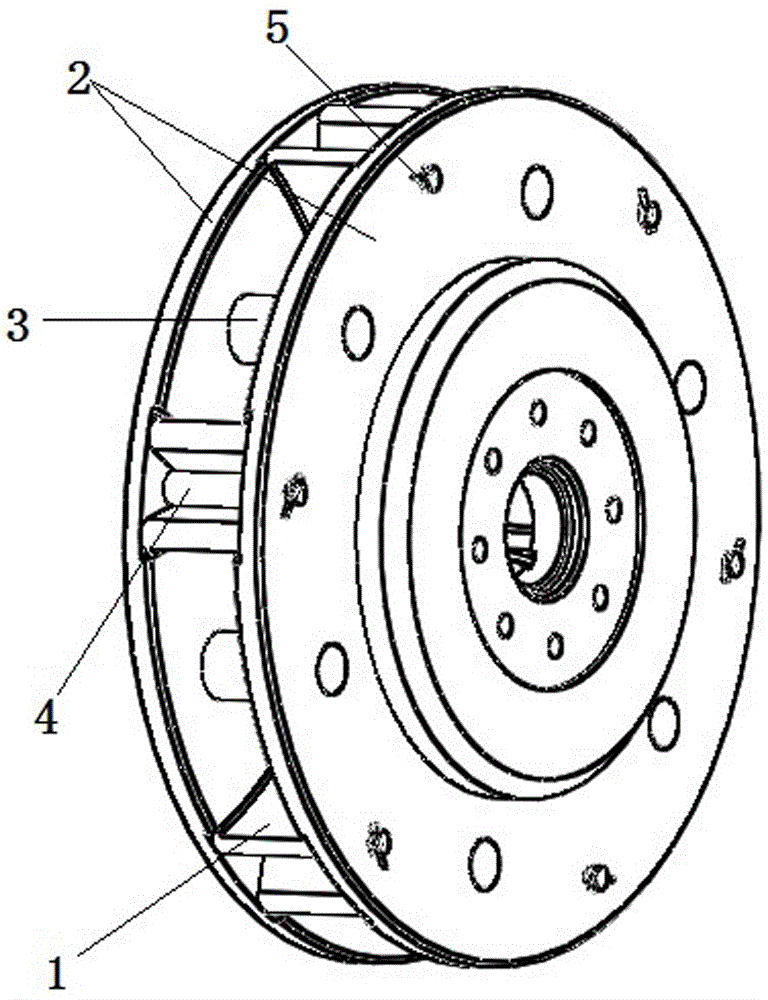

Y-shaped blade shot blaster

The invention discloses a Y-shaped blade shot blaster. The Y-shaped blade shot blaster comprises an impeller combination with a hub hole, and a shot distributing device arranged in the hub hole and used for providing shots. The impeller combination comprises two end discs and Y-shaped blades, the inner side faces of the two end discs are opposite and are assembled into an impeller body through a hub. A plurality of Y-shaped grooves with left-right symmetric structures are formed in the corresponding inner side faces of the two end discs in an alignment manner. The heads of the Y-shaped grooves are arranged in a centripetal manner. The corresponding Y-shaped blades are positioned at the two axial ends of each end disc, the Y-shaped blades are fixed in the Y-shaped grooves formed in the two end discs, and the two outer side faces, in the circumferential direction of the impeller combination, of each Y-shaped blade are shot blasting work faces. The service life of the Y-shaped blade shot blaster is long.

Owner:UNIV OF JINAN

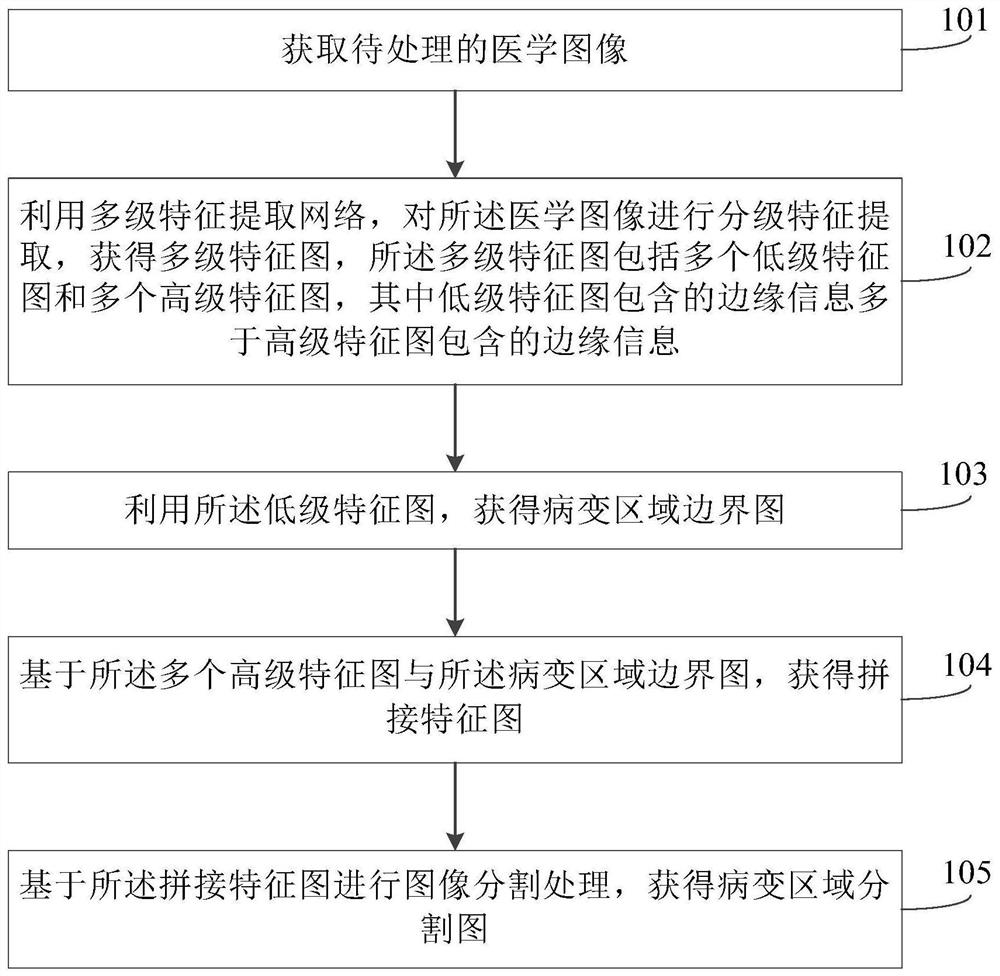

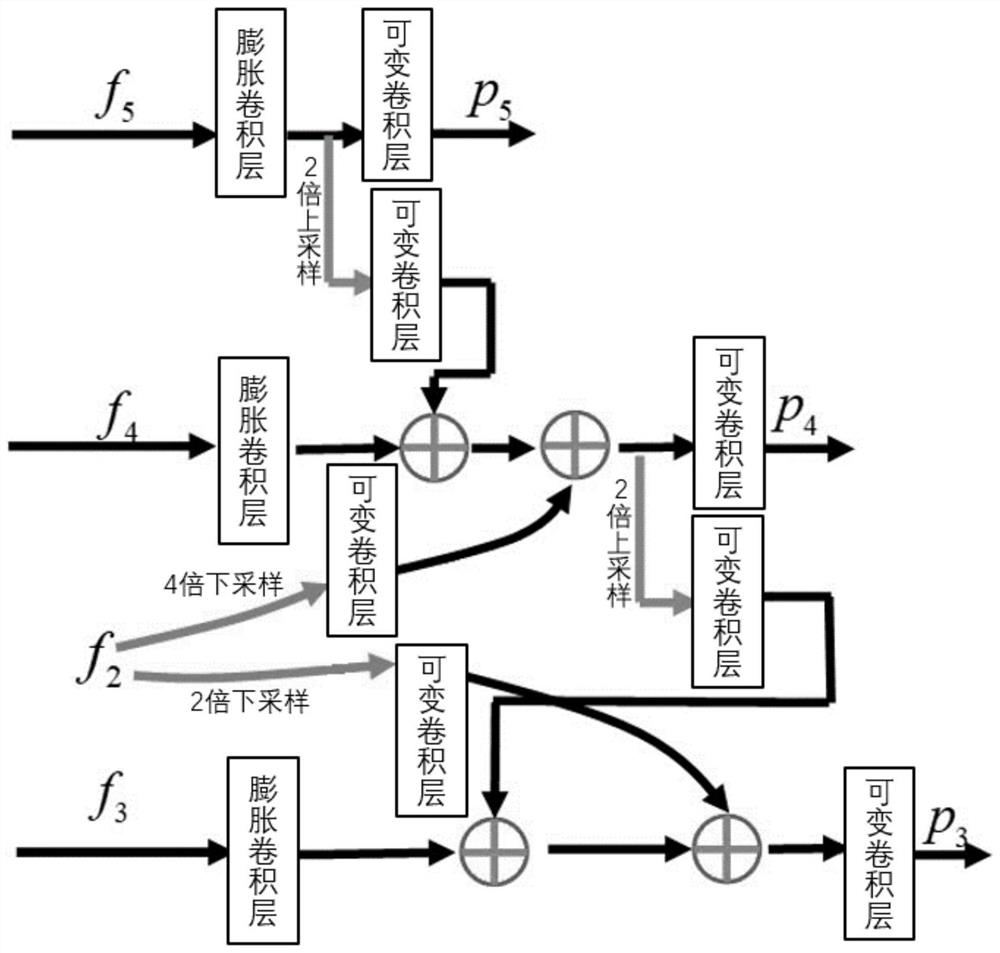

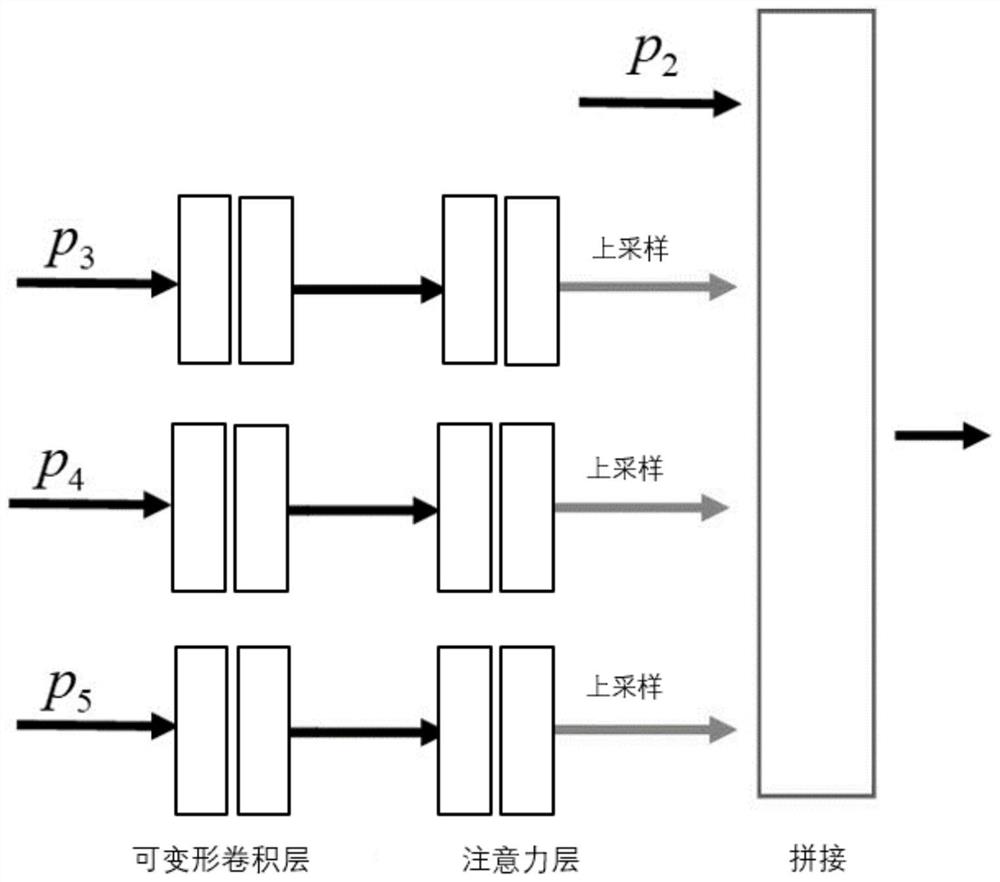

Medical image processing method and device, electronic equipment and storage medium

ActiveCN113506310AEffective segmentationImprove accuracyImage enhancementImage analysisImaging processingFeature extraction

The invention discloses a medical image processing method and device, electronic equipment and a storage medium. The method comprises the steps of obtaining a to-be-processed medical image; performing hierarchical feature extraction on the medical image by using a multi-level feature extraction network to obtain a multi-level feature map, the multi-level feature map including a plurality of low-level feature maps and a plurality of high-level feature maps, the edge information included in the low-level feature maps being more than the edge information included in the high-level feature maps; obtaining a lesion region boundary diagram by using the low-level feature map; obtaining a spliced feature map based on the plurality of advanced feature maps and the lesion region boundary map; and carrying out image segmentation processing based on the spliced feature map to obtain a lesion region segmentation map. According to the technical scheme provided by the embodiment of the invention, the accuracy of lesion region segmentation of the medical image can be improved.

Owner:BEIJING TIANTAN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

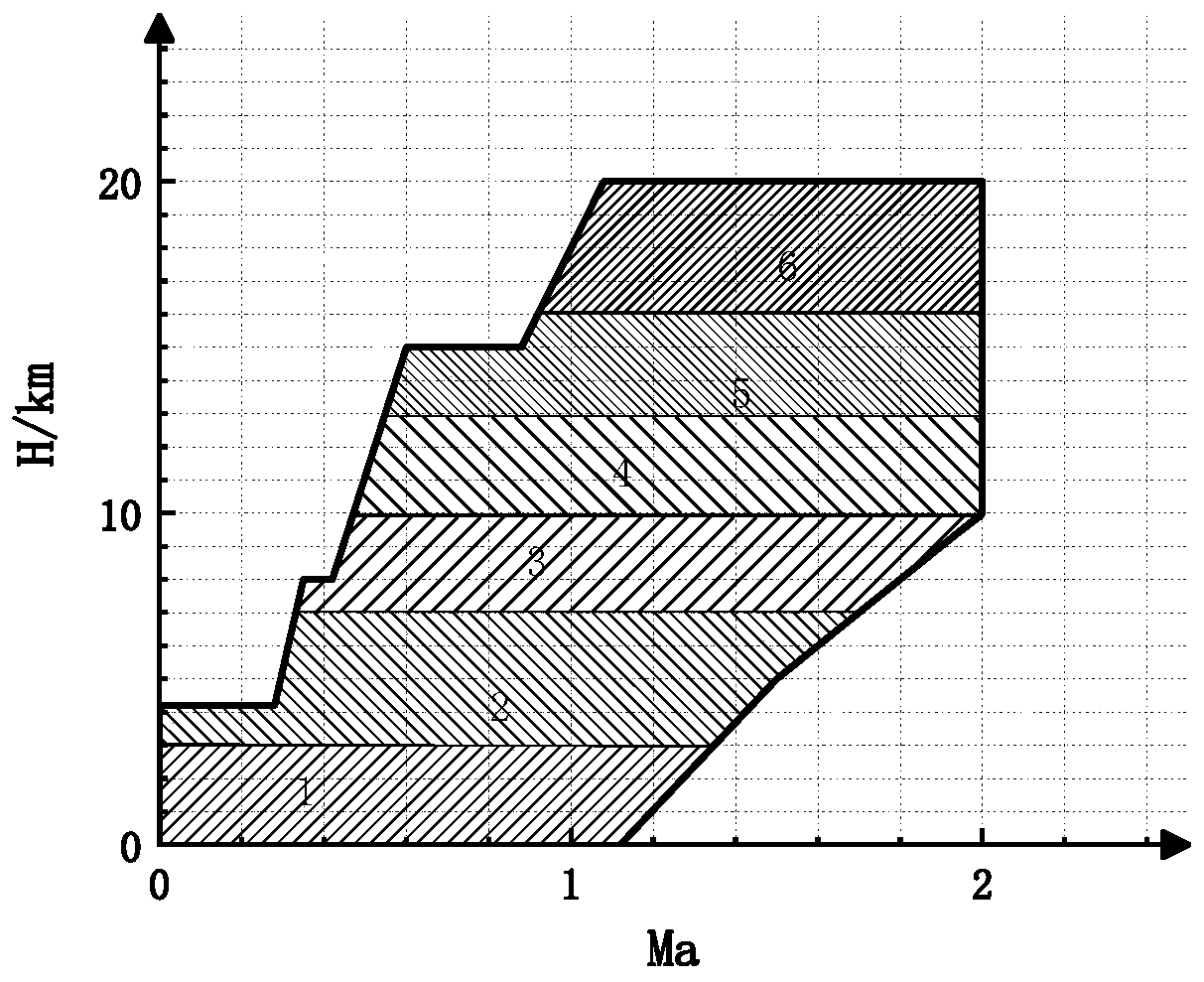

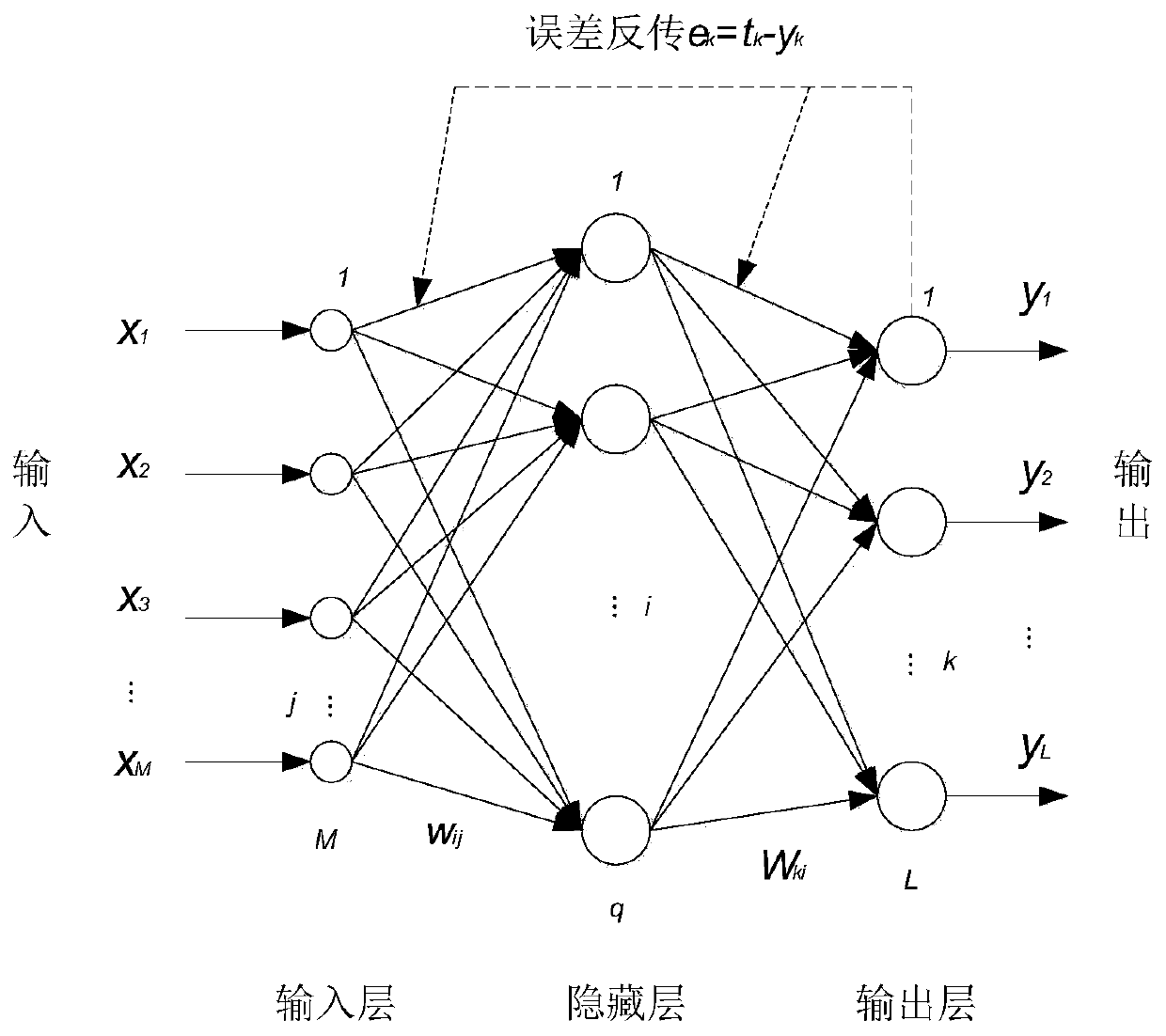

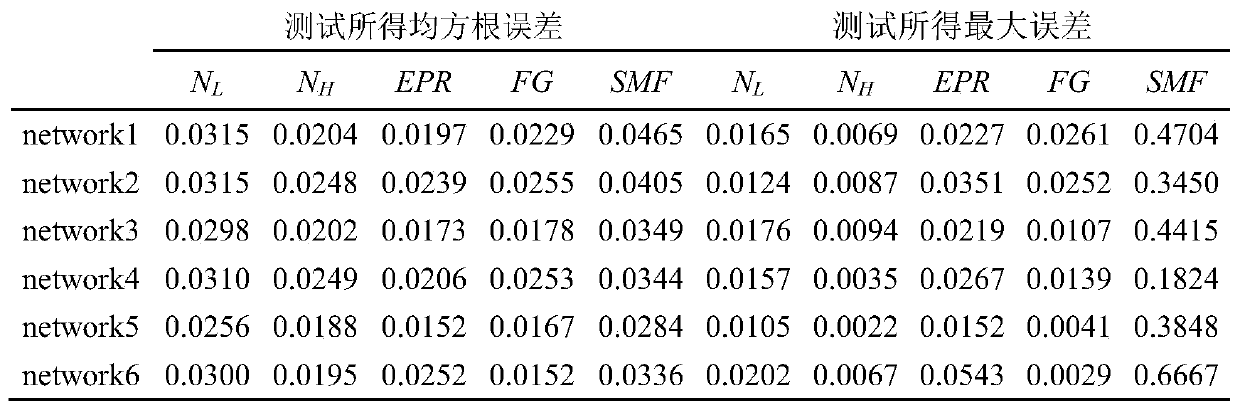

Turbofan engine thrust prediction method and controller based on neural network

ActiveCN110579962AGood tracking performance and constraint performanceShort response timeAdaptive controlNetwork modelTurbofan

The invention discloses a turbofan engine thrust prediction method and a turbofan engine thrust prediction controller based on a neural network. The turbofan engine thrust prediction method comprisesthe steps of: establishing a steady-state multiple-input multiple-output neural network model of turbofan engine key gas path measurement parameters; using the neural network model as a prediction model for designing a thrust model prediction controller; designing a certain type of turbofan engine closed-loop control system by using the model prediction controller, and studying tracking performance and constraint performance of a thrust control system. On the basis of considering the existing control constraint conditions of an engine, the turbofan engine thrust prediction method utilizes thesteady-state neural network model combined with an SQP optimization algorithm, regards the minimum error of unmeasurable thrust performance parameters of the engine as a target, designs the thrust prediction controller, calculates a control quantity of the engine, is simple in structure, and has a positive promoting effect on reduction of the workload of designing the controller and suppression ofthrust performance degradation of the controller.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

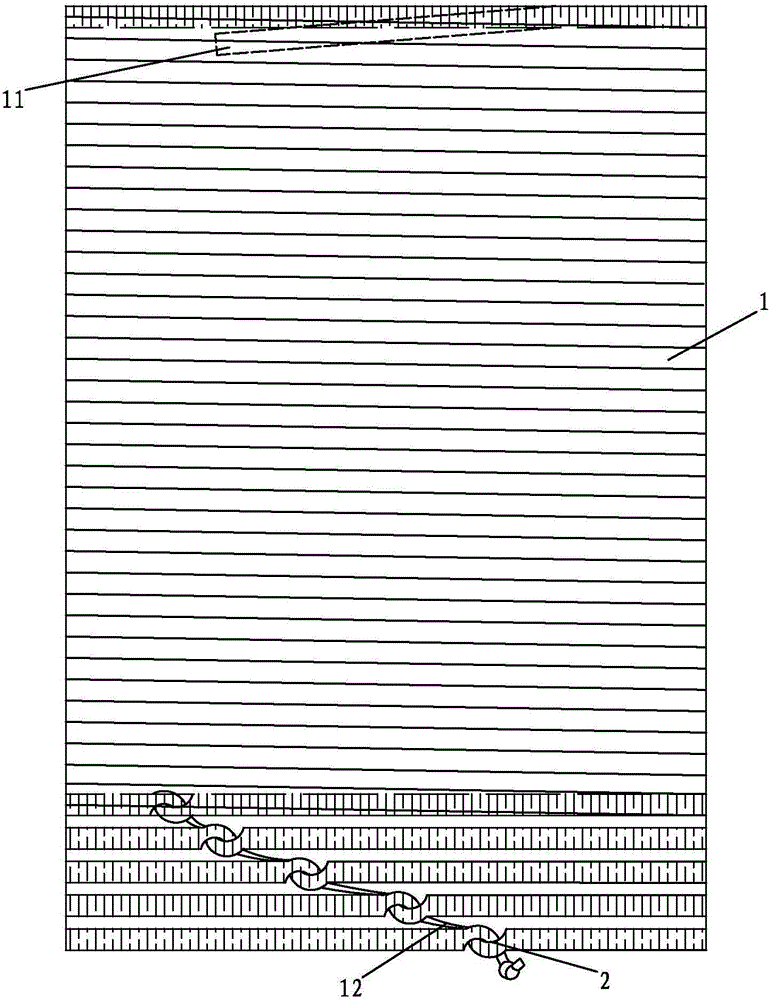

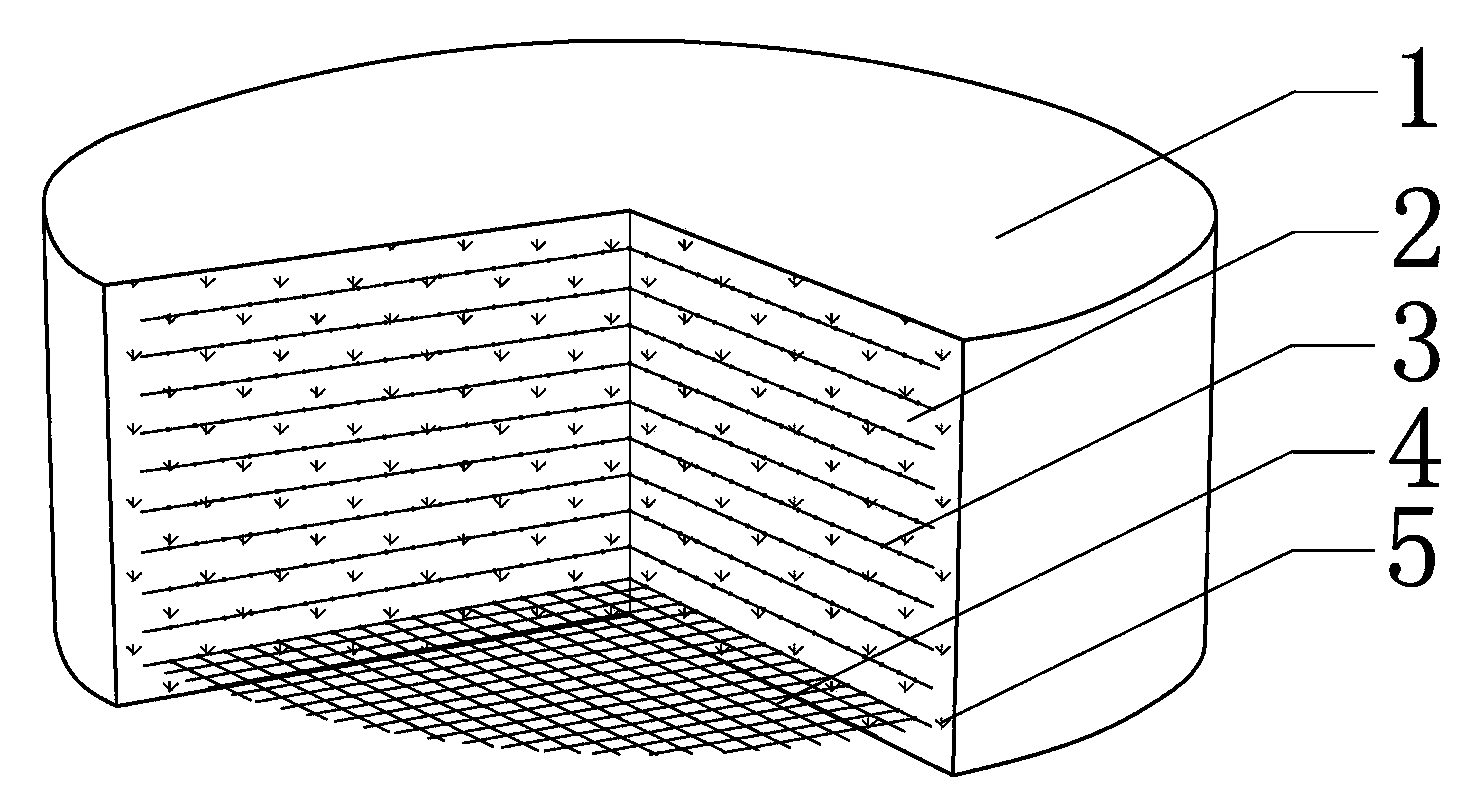

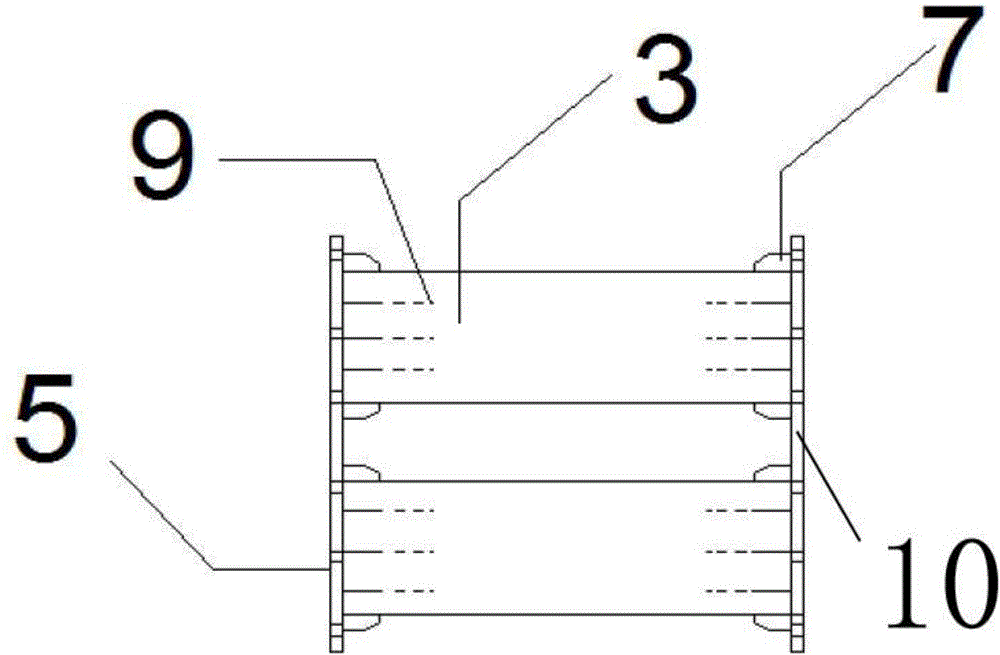

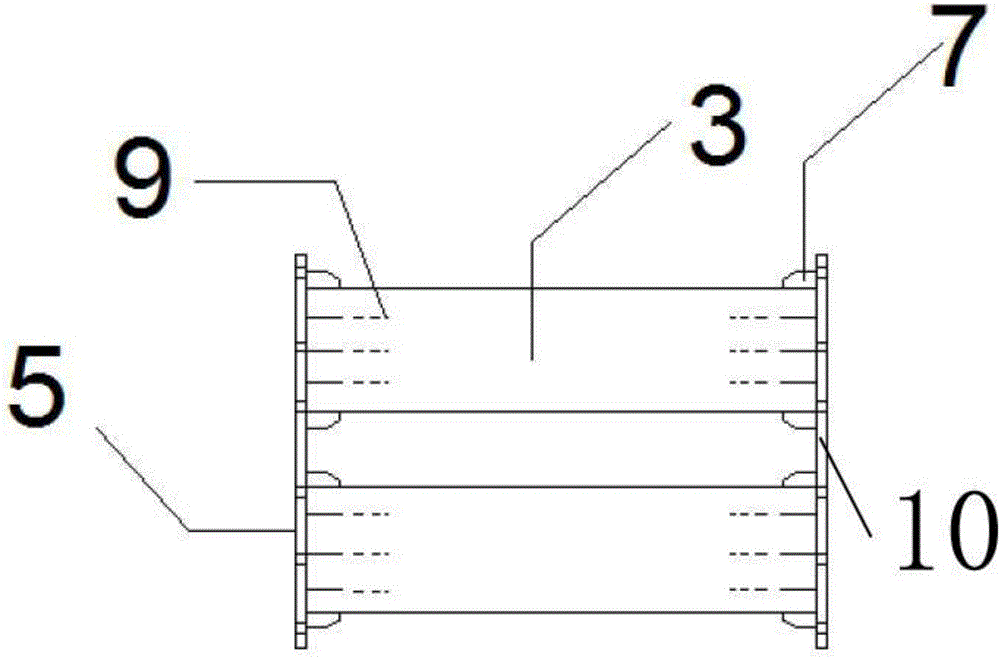

Laminated rubber support reinforced by combining fine high-strength steel wire meshes and steel fibers

InactiveCN104032673AEasy to transportEasy to installBridge structural detailsShock proofingFiberRubber material

The invention relates to a laminated rubber support reinforced by combining fine high-strength steel wire meshes with steel fibers. The laminated rubber support consists of rubber bodies, fine high-strength steel wire meshes, outer-layer protecting rubber and steel fibers, wherein the fine high-strength steel wire meshes are thick meshes woven by high-strength steel wires, and the fine high-strength steel wire meshes are closely distributed in the rubber bodies layer by layer to restrain the side deformation of the rubber bodies, so that the support has rigidity and load-bearing capacity required by normal use; steel fiber materials are distributed in rubber in disorder, so that the mechanical property of the rubber bodies is improved, the connection of the fine high-strength steel wire meshes and composite rubber materials is closer, and the restraining effect is enhanced; favorable deformation capacity of the fine high-strength steel wire meshes and the connection action of the steel fibers ensure that the rubber bodies and the high-strength steel wire meshes can still synergistically work under the condition of extreme deformation, and the problems of adhesive failure and the like cannot occur. Under the action of earthquake, the laminated rubber support allows larger shearing deformation until upper and lower surfaces completely break away from a contact surface to present an overturning state and even generate horizontal scrolling, the earthquake force of an upper structure is prevented from being transmitted to a lower structure, the effect of earthquake insulation is exerted, and the safety of a bridge structure is ensured.

Owner:TONGJI UNIV +1

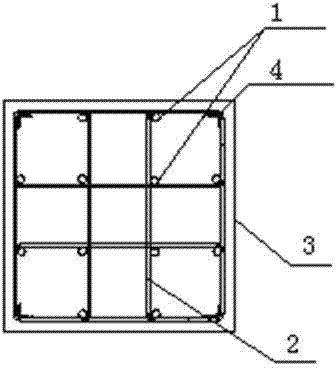

A type of steel area confined concrete rectangular column and its manufacturing method

InactiveCN102261165AImprove restraintImprove the restraint effectStrutsPillarsConcrete beamsSteel bar

The invention discloses a rectangular column of shaped steel area restrained concrete and a manufacturing method thereof. The invention comprises the use of longitudinal steel bars and stirrups to manufacture the skeleton of a rectangular columnar structure. When manufacturing the skeleton of a rectangular columnar structure, the Set up profiled steel, and make the profiled steels on the four corners parallel to each other, then arrange the longitudinal reinforcement between the profiled steels in parallel, and connect the profiled steel and the longitudinal reinforcement as a whole with stirrups perpendicular to the longitudinal reinforcement, thus forming a three-dimensional network Rectangular columnar structure of rectangular column structure, and then the concrete and rectangular columnar structure of steel reinforcement are poured as a whole according to the traditional concrete pouring method, so that the rectangular column of concrete with section steel area restraint can be obtained. Compared with the prior art, the invention not only has the advantages of better restraint effect and higher overall strength of the column, but also has the advantages of lower steel consumption, lower manufacturing cost and higher reliability.

Owner:GUIZHOU CONSTR SCI RES & DESIGN INST OF CSCEC

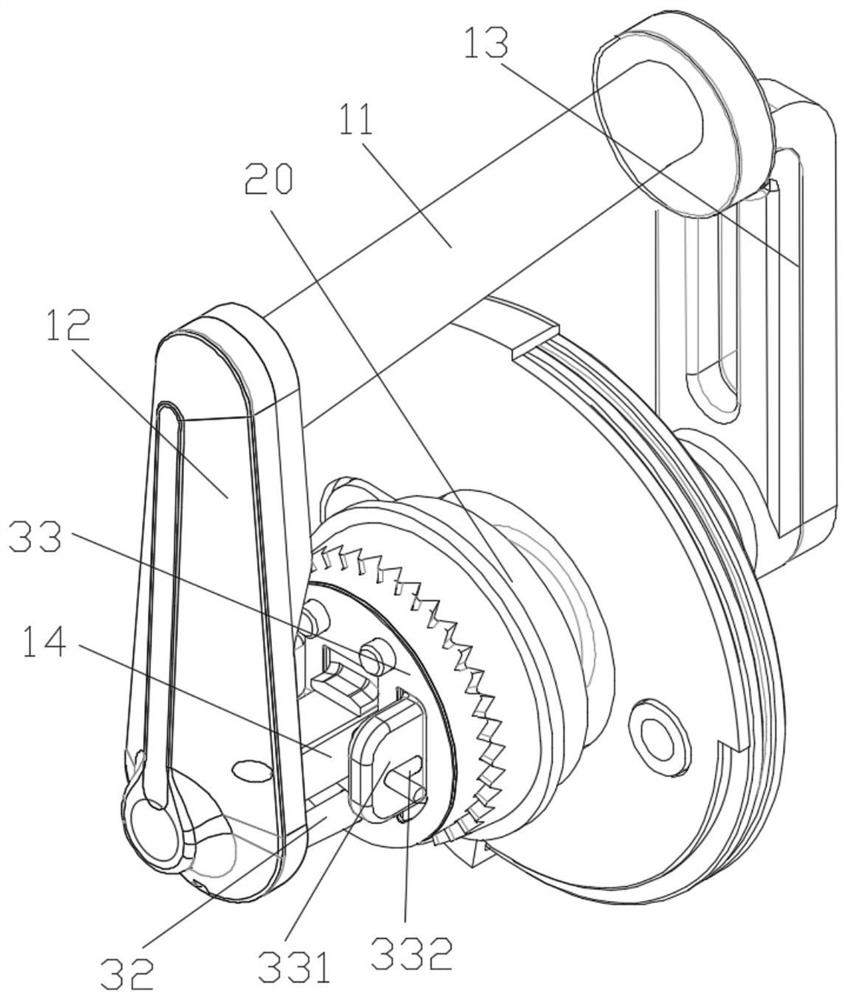

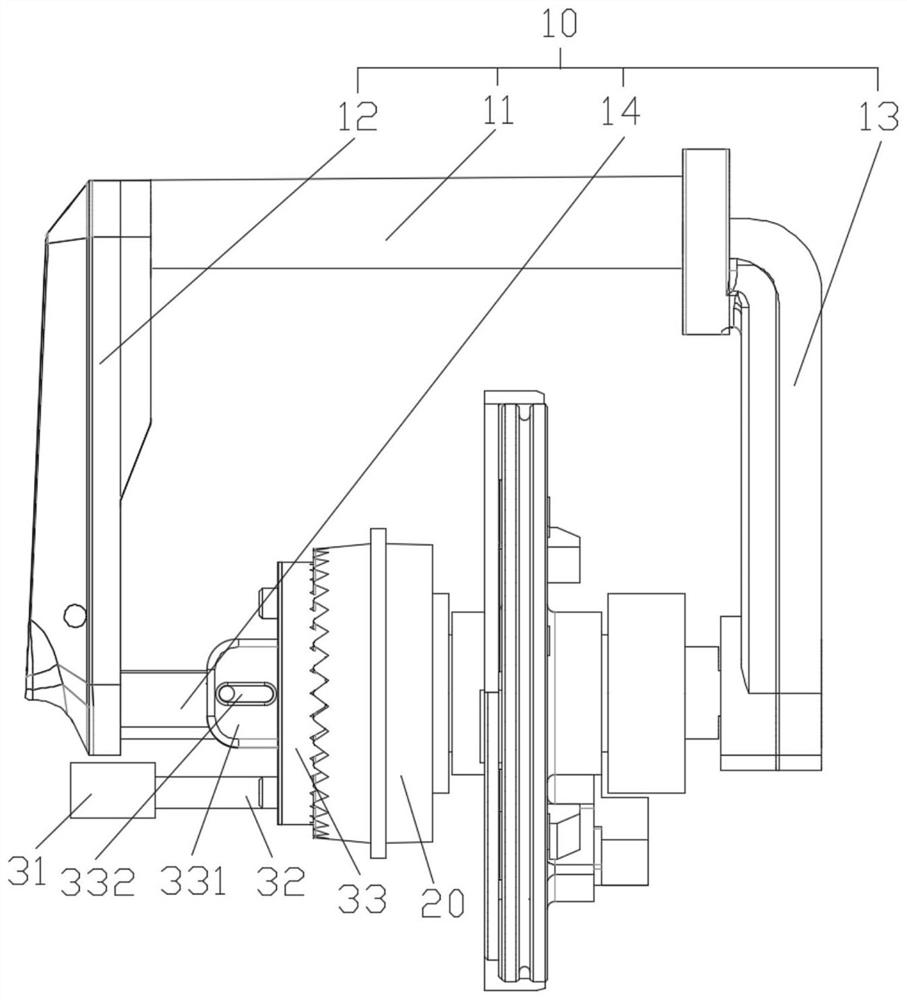

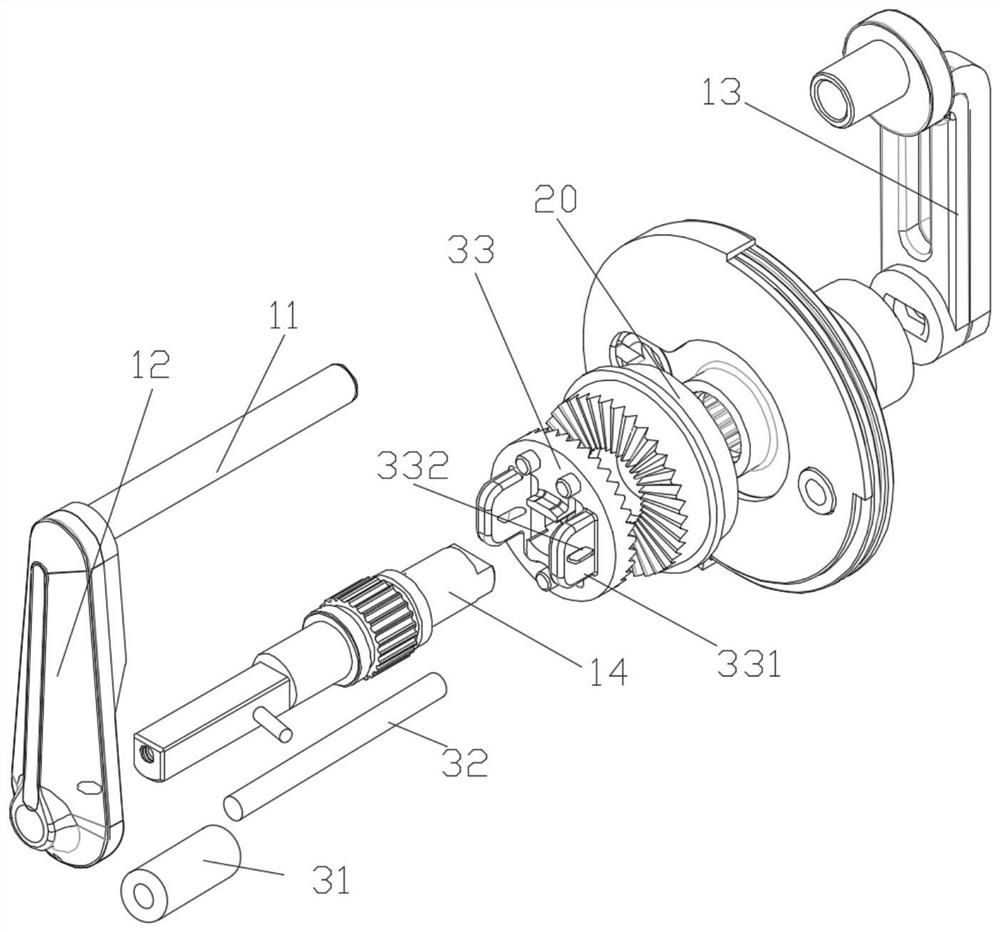

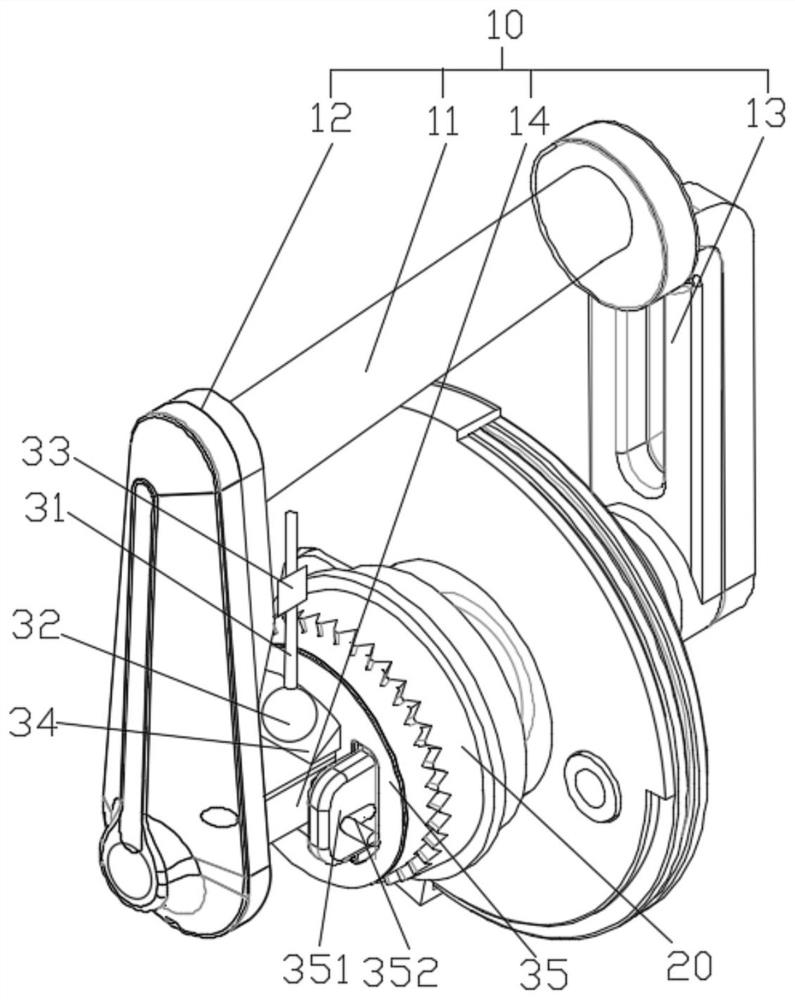

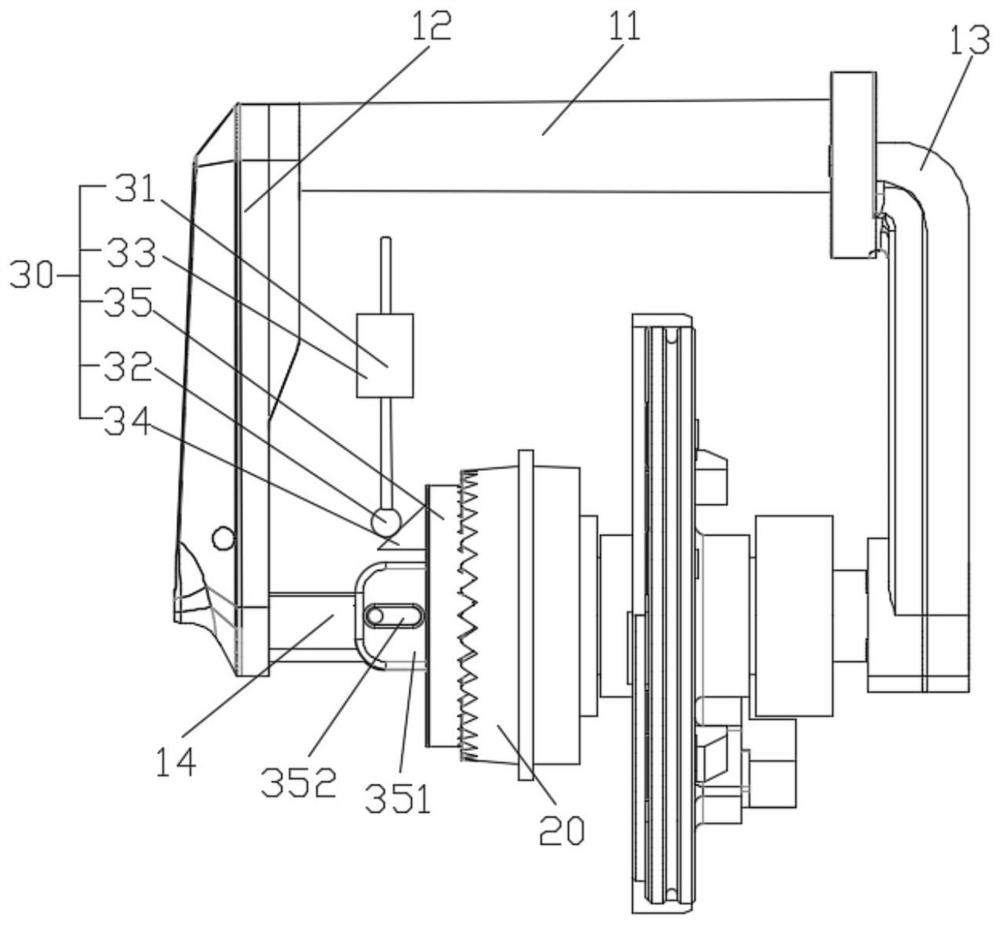

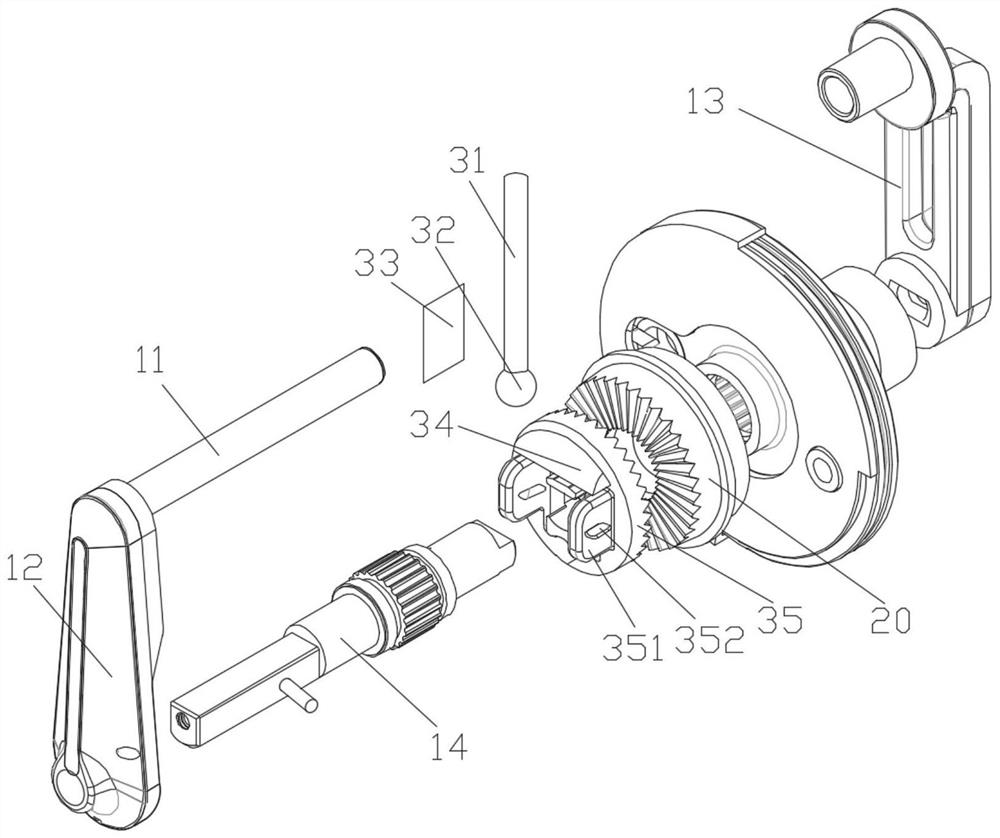

Endoscope self-locking device and endoscope

PendingCN111803008AAchieve lockingGuaranteed stabilitySurgeryEndoscopesEngineeringMechanical engineering

The invention relates to the technical field of endoscopes, in particular to an endoscope self-locking device and an endoscope. The self-locking device comprises a shell and a rotating handle, a firstlocking piece is fixedly arranged in the shell, a rotating shaft is rotatably connected in the first locking piece, and a locking mechanism used for being matched with the first locking piece is movably connected to the rotating shaft; the locking mechanism comprises a base, a push rod and a second locking piece, the base is fixedly connected to the shell, the interior of the base is connected tothe push rod through a thread, the push rod penetrates through the base and the shell, the push rod is used for pushing the second locking piece, the second locking piece is movably connected to therotating shaft, and the second locking piece moves in the axial direction of the rotating shaft; and the push rod controls the second locking piece to be matched with the first locking piece to realize self-locking. Self-locking can be achieved by the rotating handle, locking of an insertion tube is achieved, the imaging stability of the insertion tube is guaranteed, and meanwhile the fatigue strength of an operator is reduced.

Owner:HUNAN VATHIN MEDICAL INSTR CO LTD

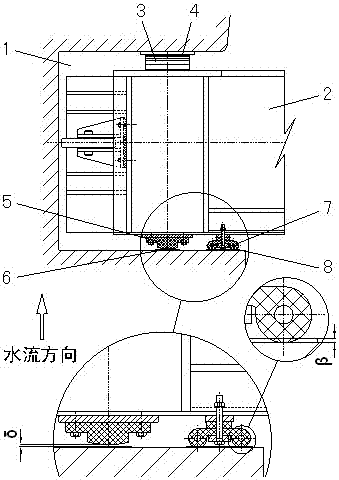

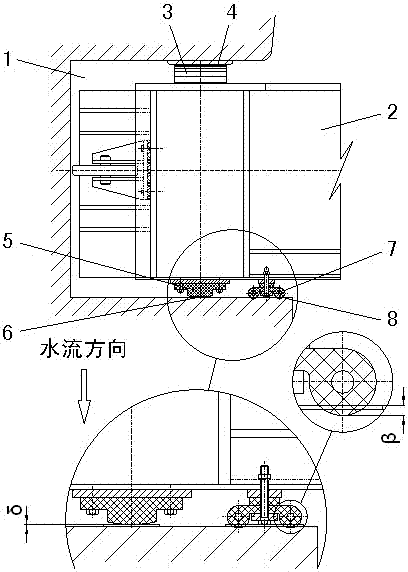

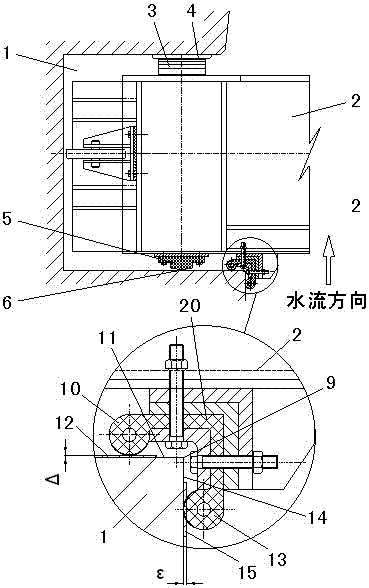

Improving method and device for two-way plane gate water sealing device

ActiveCN107326875ASmall sizeImprove hydraulic conditionsBarrages/weirsHydro energy generationWater flowEngineering

The invention discloses an improving method and device for a two-way plane gate water sealing device, and aims at improving an existing straight-line double-P-type water seal into an L-shaped double-P-type water seal and installing the L-shaped double-P-type water seal at an outer corner of a gate groove. A vertical water flow P type head of the L-shaped double-P-type water seal stretches into a gap formed between the gate groove and a gate flap and corresponds to a vertical water flow water seal base plate installed on a vertical water flow plane of the gate groove; and a downstream water flow P type head of the L-shaped double-P-type water seal corresponds to a downstream water flow water seal base plate installed on a downstream water flow plane of the gate groove. According to the improving method and device, compressive deformation of the water seal of the gate water sealing device always can not exceed a normal valve on the condition that the water flow direction is changed, and then the life of the water seal is effectively prolonged; meanwhile, the size of the gate groove can be effectively decreased, therefore, the hydraulic conditions of the gate groove are good, and the gate running safety is effectively guaranteed.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

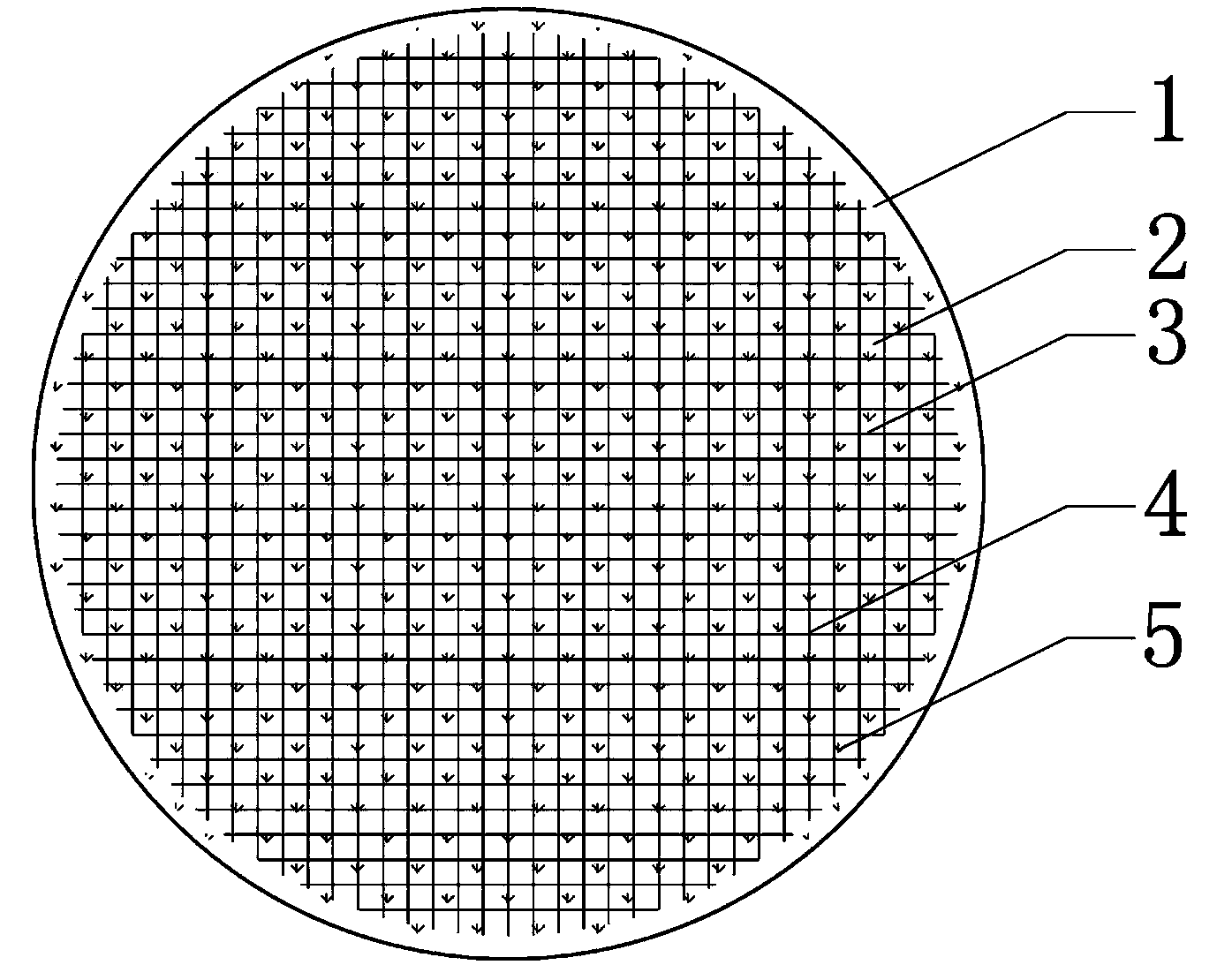

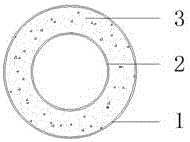

Built-in polyvinyl chloride (PVC) pipe enhanced square steel pipe concrete combined column

InactiveCN103015631AImprove the restraint effectEnhanced Axial Compression CapabilityStrutsPillarsAxial compressionPolyvinyl chloride

The invention discloses a built-in polyvinyl chloride (PVC) pipe enhanced square steel pipe concrete combined column, which comprises a PVC circular plastic pipe, a square steel pipe and concrete, wherein the PVC circular plastic pipe in which the concrete is grouted is embedded in the center of the section of the square steel pipe; and the concrete is grouted in a residual space on the section of the combined column to form a double-sleeve multi-constraint concrete combined column in which one pipe is embedded into another pipe. The combined column has the advantage of improving the comprehensive performance of the square steel pipe concrete column; by the PVC circular pipe, and due to the multiple constraint effect, a constraint effect of the concrete in the column is improved, so that the axial compression strength of the column is improved; furthermore, under the condition that requirements on the bearing capacity and the vibration resistance are met, the sectional area of the column can be greatly reduced by using the cheap PVC plastic pipe, so that the usability of a building space is improved; and the consumption of steel and comprehensive manufacturing cost are reduced.

Owner:GUANGXI UNIV

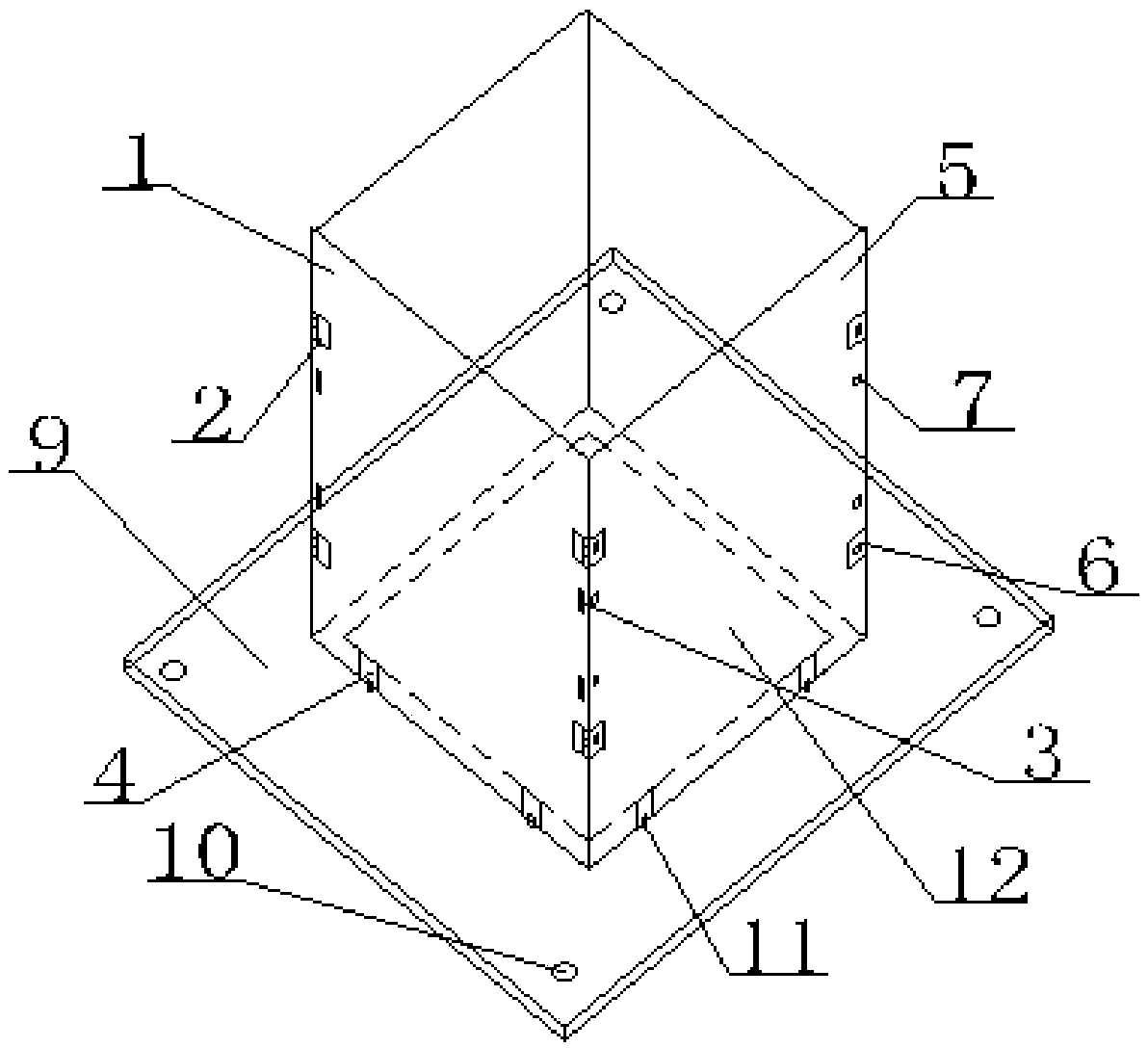

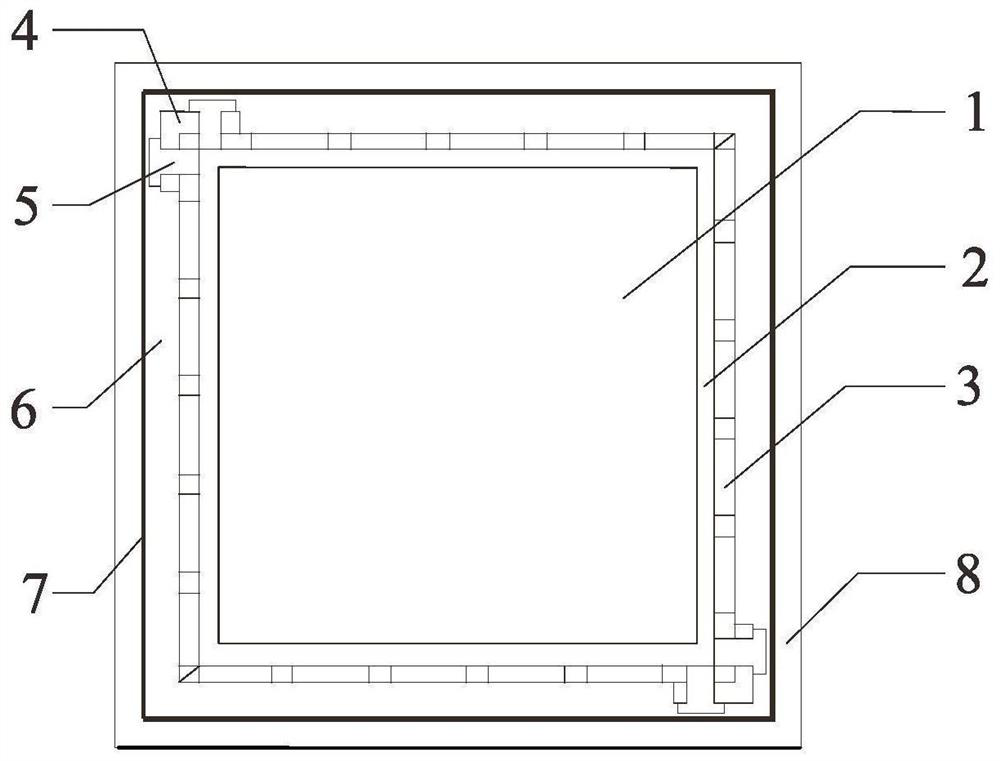

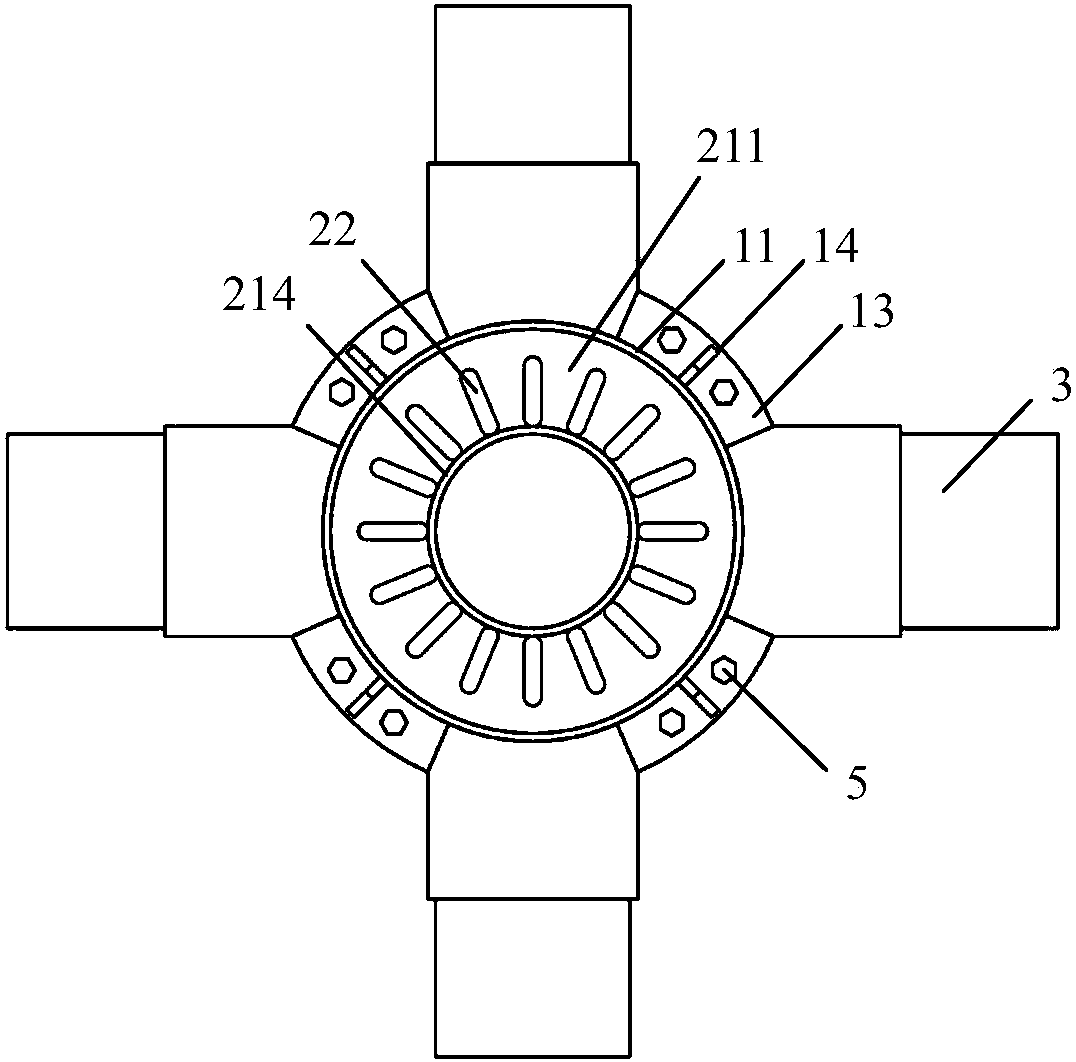

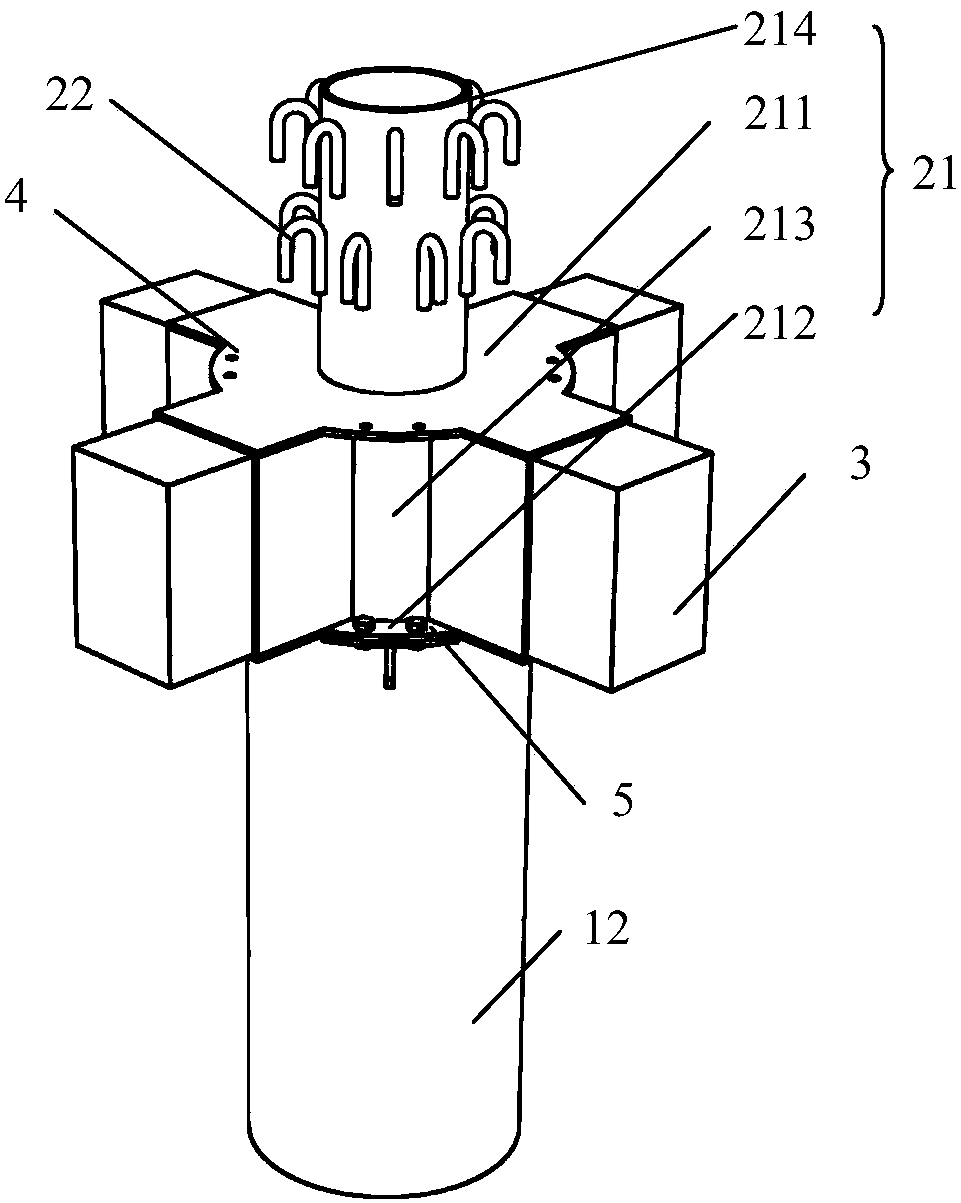

Constraint handling device for biaxial tension and compression concrete test piece

InactiveCN108844809ALess restraintImprove the restraint effectStrength propertiesBiaxial tensionStructural unit

The invention discloses a constraint handling device for a biaxial tension and compression concrete test piece. The device comprises two first structural unit sheets, two second structural unit sheetsand a first third structural unit sheet. The third structural unit sheet is arranged horizontally as a bottom structure of the device, and a reserved test piece position line is arranged in the middle for positioning and placing the concrete test piece; snap joints connected to the third structural unit sheet are arranged on the bottom edges of the first structural unit sheets and the second structural unit sheets; two side edges of the first structural unit sheets are detachably connected to one side edges of the two second structural unit sheets, separately, to form a square side frame structure, and sticky gypsum pouring space is formed among the concrete test piece, the first structural unit sheets and the second structural unit sheets. By attaching a protecting layer to the tensionedand compressed surface of the concrete test piece, the anti-attrition constraint action of a loading plate on concrete can be improved effectively, so that the testing accuracy of a test is improved.

Owner:HOHAI UNIV

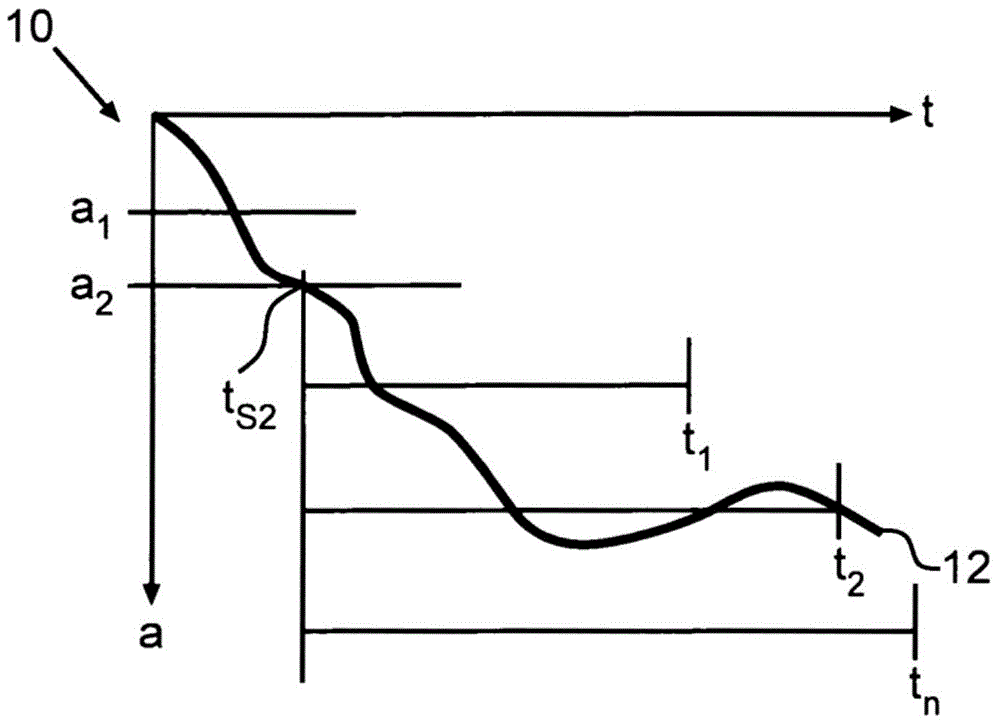

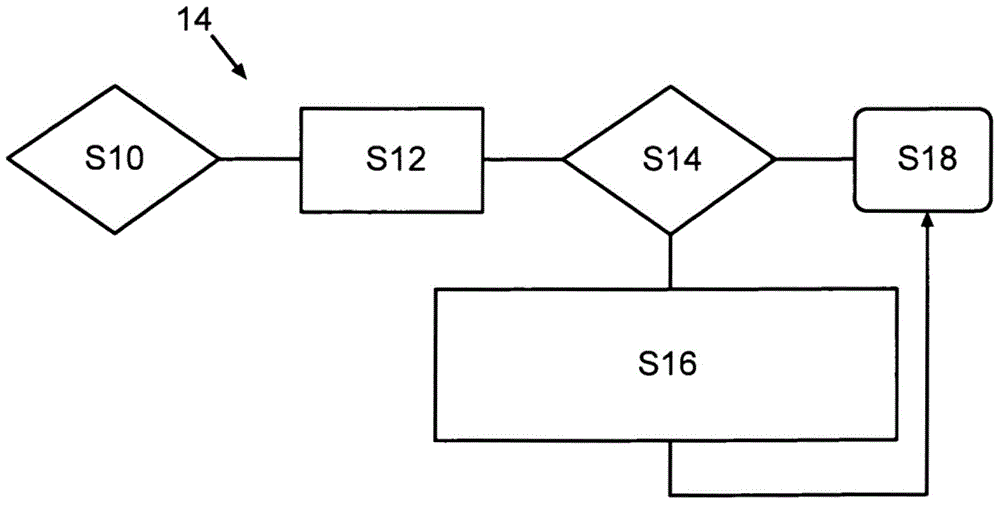

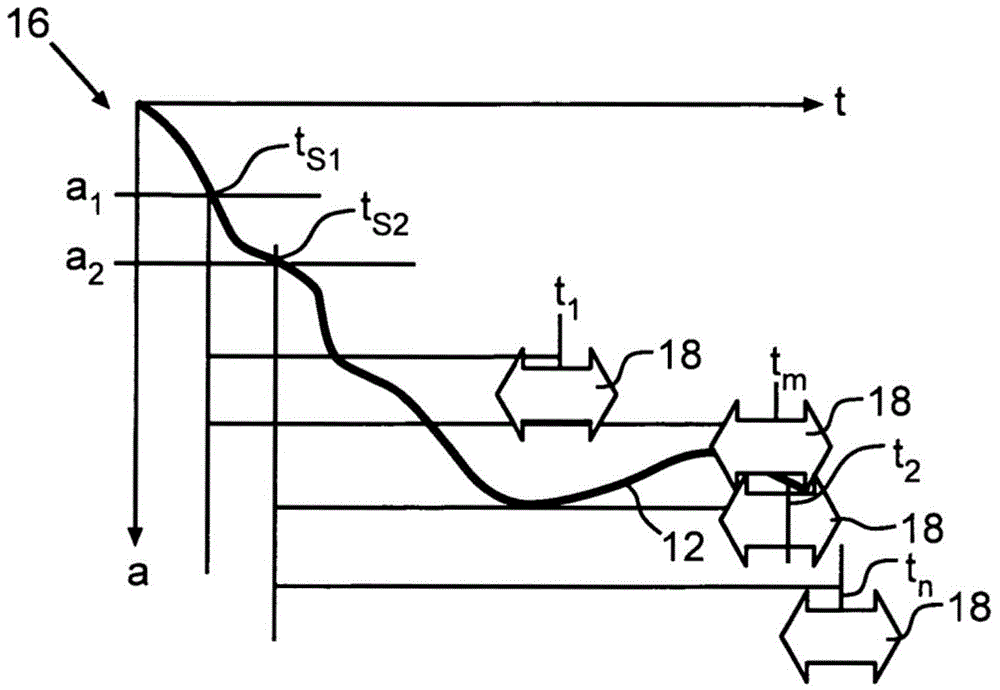

Method for controlling restraint devices of a motor vehicle

ActiveCN103562013AImprove the restraint effectPedestrian/occupant safety arrangementVehicle safety beltsControl theory

Restraint devices for motor vehicles should be triggered more reliably. For this purpose, the invention provides a method for controlling restraint devices of a motor vehicle by measuring a movement variable (a) of the motor vehicle (S20), triggering a first restraint device on the basis of a first predefined threshold value (a1) for the measured movement variable (a) being exceeded (S22), triggering a second restraint device on the basis of a second predefined threshold value (a2) for the measured movement variable (a) being exceeded (S24), and activating a first device influencing the restraining force of the first restraint device and a second device influencing the restraining force of the second restraint device on the basis of the first predefined threshold value (a1) and / or the second predefined threshold value (a2) being exceeded (S22, S24). The invention further relates to a restraint system for a motor vehicle. Finally, the invention relates to a motor vehicle having such a restraint system.

Owner:AUDI AG

Concrete column reinforcement structure and construction method thereof

PendingCN111809908AMake the most of the interconnectionIncrease profitStrutsBuilding repairsReinforced concrete columnStructural engineering

The invention discloses a concrete column reinforcement structure and a construction method thereof. The concrete column reinforcement structure comprises a UHPC substrate layer, a porous steel plate,a UHPC bonding layer, a fiber woven net and a UHPC protective layer which sequentially coats the side wall of a to-be-reinforced concrete column from inside to outside, wherein the porous steel plateis provided with through holes; and the UHPC bonding layer is bonded with the UHPC substrate layer through the through holes of the porous steel plate. Through the adoption of the UHPC substrate layer, the higher compatibility between a reinforcement layer and an original concrete structure can be achieved, as well as the aging-resistant, high-temperature-resistant and moisture-resistant properties can be good; through the fiber net connection mode, the fiber material interconnection effect of a fiber composite material can be sufficiently exerted, and the fiber material utilization ratio canbe improved; the UHPC substrate and the UHPC bonding layer are tightly bonded through the through holes of the porous steel plate, so that not only can the internal and external UHPC bonding capability be enhanced, but also the corrosion-resistant property and the fire-resistant property can be improved; and all the components of the concrete column reinforcement structure can be combined to forma whole subjected to common stress and deformation, and the mechanical properties of the to-be-reinforced concrete column can be improved.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

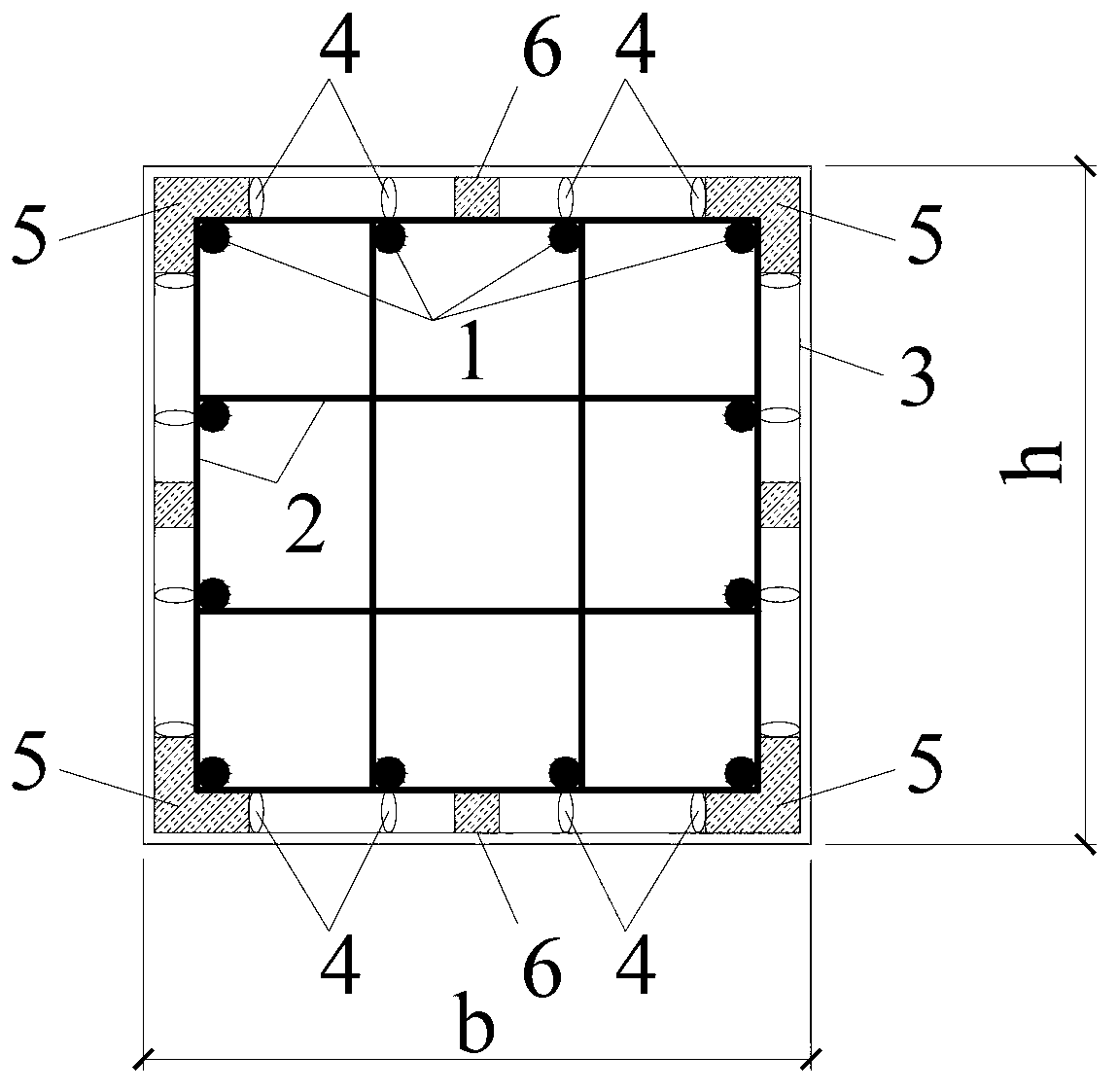

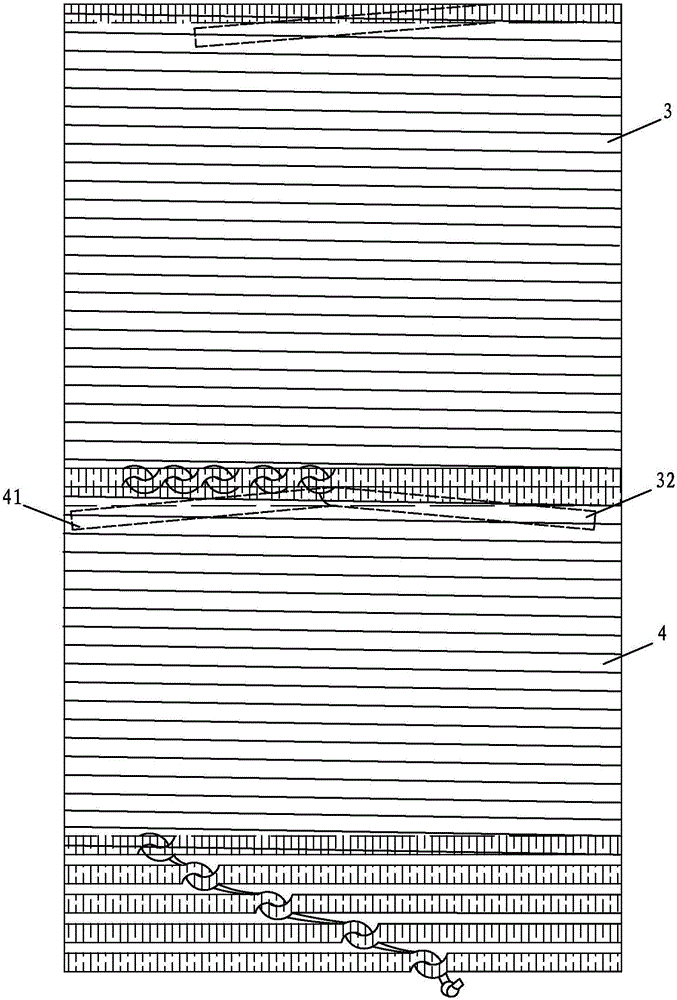

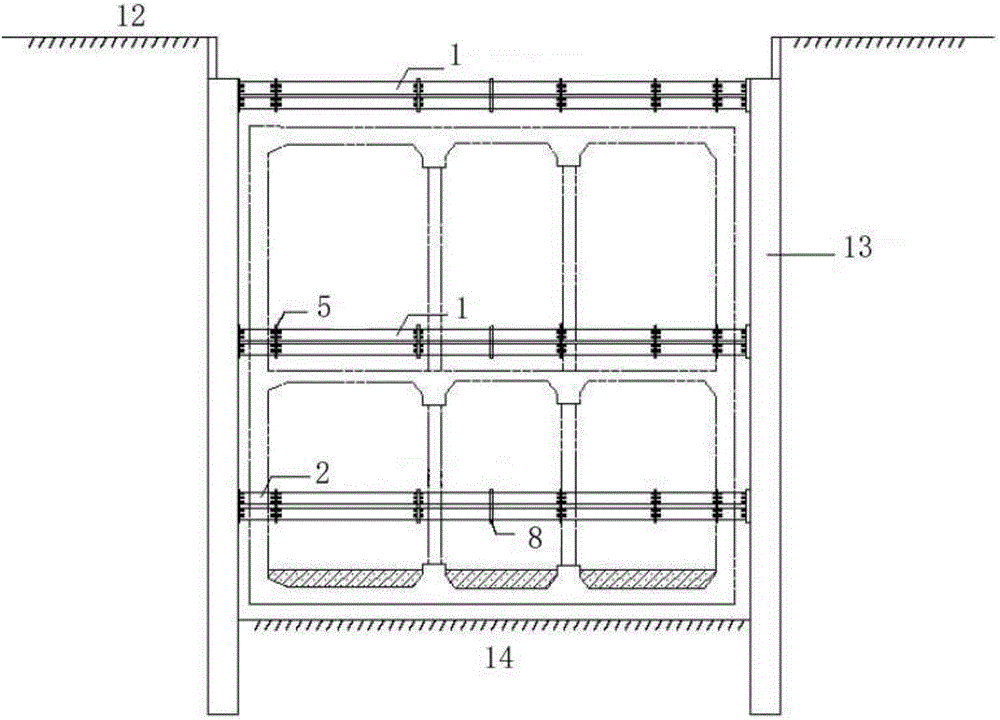

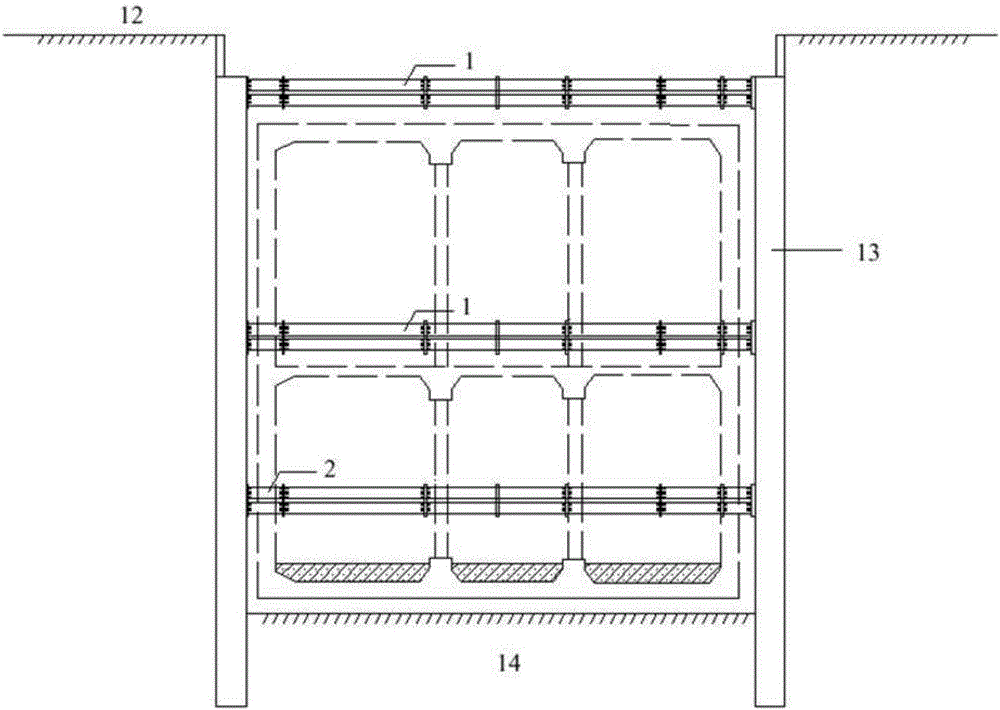

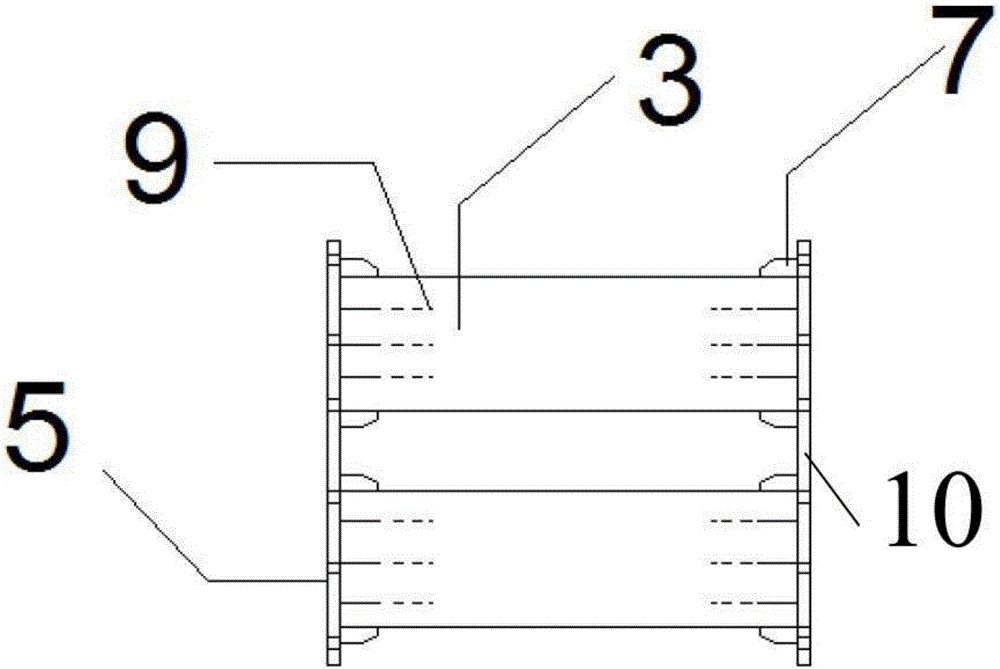

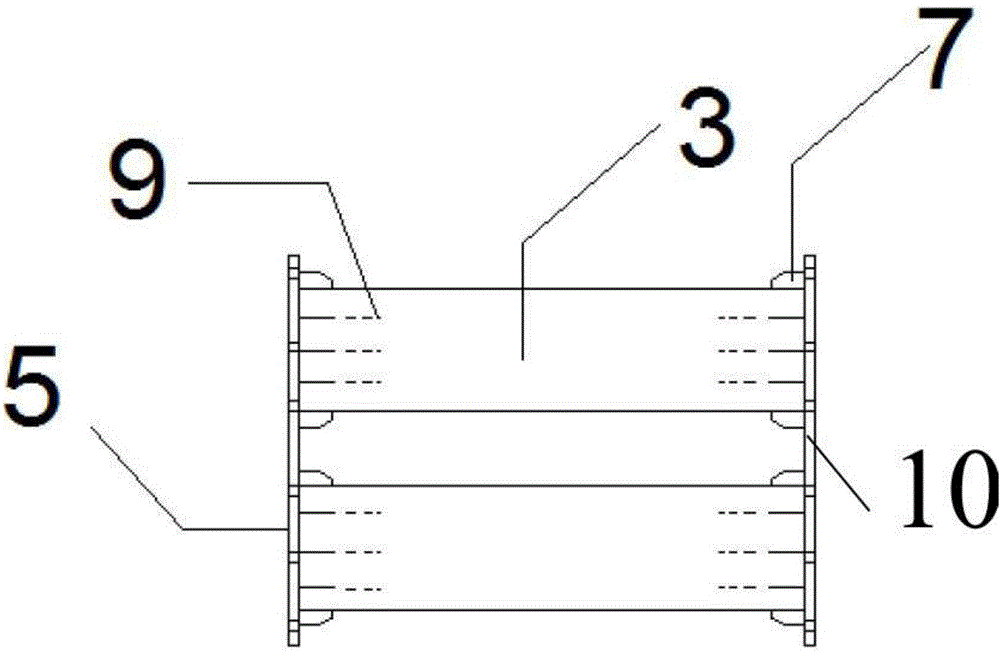

Assembled type four-combined-round-steel-pipe concrete inner support structure and manufacturing method

InactiveCN106351235AGuarantee processing qualityReliable mechanical propertiesExcavationsMetro stationHigh intensity

The invention relates to an assembled four-piece combined circular steel pipe concrete inner support structure and a manufacturing method, and belongs to the technical field of support and support in foundation pits of subway stations. The prefabricated four combined circular steel pipe concrete inner support structure includes different types of circular steel pipe concrete straight supports. Including short straight stay and standard straight stay. The straight supports are connected to each other by high-strength bolts. All components are composed of ultra-high-strength concrete filled round steel pipes, and the cross-sections of four round steel pipes are arranged in a square. The present invention satisfies the splicing needs of supports in foundation pits of different lengths by combining different forms of component lengths, and provides an assembled combined circle with high rigidity, reusability and low cost, which can be used as internal supports in the foundation pit or shaft enclosure structure system The inner support structure of concrete filled steel tube can effectively solve the problems of complex construction and high cost of concrete support. The comprehensive benefit is remarkable, and it has important engineering application value and development prospect.

Owner:BEIJING UNIV OF TECH

Assembled type three-combined-round-steel-pipe concrete inner support structure and manufacturing method

InactiveCN106351234AGuarantee processing qualityReliable mechanical propertiesExcavationsSteel tubeMetro station

The invention relates to an assembled three-piece combined circular steel pipe concrete inner support structure and a manufacturing method, which belong to the technical field of support and support in foundation pits of subway stations. The prefabricated three combined circular steel pipe concrete inner support structure includes different types of circular steel pipe concrete straight supports. Including short straight stay and standard straight stay. The straight supports are connected to each other by high-strength bolts. All components are composed of ultra-high-strength concrete filled round steel pipes, and the cross-sections of the three round steel pipes are arranged in an inverted triangle. The present invention satisfies the splicing needs of supports in foundation pits of different lengths through the combination of different forms of component lengths, and provides a high rigidity, reusable, cost-reduced assembly-type combined circle used as internal supports in the foundation pit or shaft enclosure structure system The inner support structure of concrete filled steel tube can effectively solve the problems of complex construction and high cost of concrete support. The comprehensive benefit is remarkable, and it has important engineering application value and development prospect.

Owner:BEIJING UNIV OF TECH

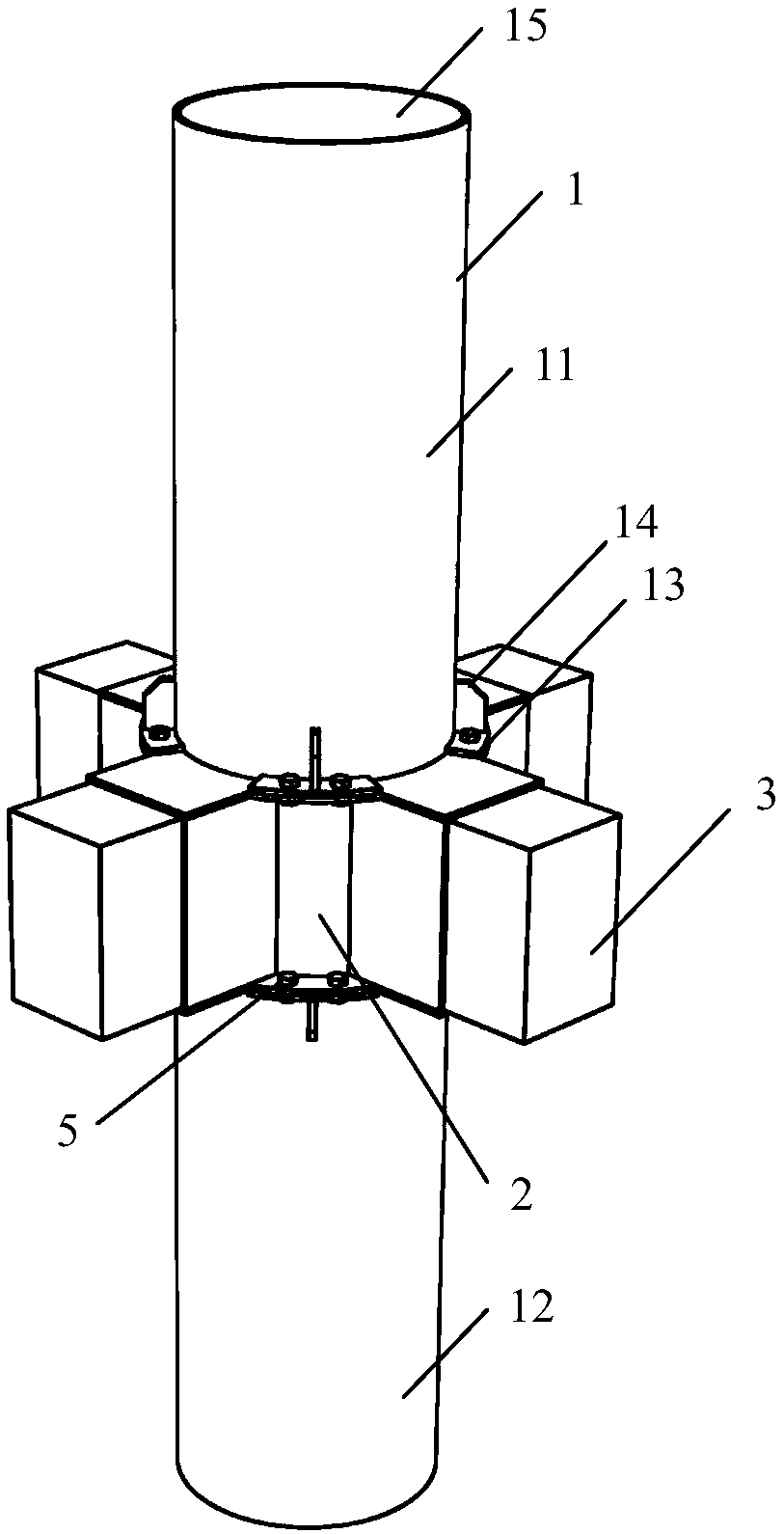

Precast steel tube concrete ring beam structure and construction method

PendingCN108571070AConvenient constructionNovel structureBuilding constructionsSteel platesSteel tube

The invention provides a precast steel tube concrete ring beam structure and a construction method. The structure comprises a steel tube concrete column, a steel tube concrete ring beam and a precastreinforced concrete beam, wherein the steel tube concrete column comprises an upper steel tube column, a lower steel tube column, connecting plates, stiffening ribs and column concrete; the pluralityof connecting plates and stiffening ribs are welded at the lower end of the upper steel tube column and the upper end of the lower steel tube column; the stiffening ribs are vertically arranged on corresponding connecting plates; the column concrete is poured inside the upper steel tube column and the lower steel tube column; the steel tube concrete ring beam comprises ring beam steel tubes, anchor bars and ring beam interior reinforced concrete; the ring beam steel tubes comprise upper steel plates, lower steel plates, side steel plates and inner steel tubes; and the upper steel plates and the lower steel plates are respectively arranged at the upper and lower ends of the side steel plates. The precast steel tube concrete ring beam structure disclosed by the invention is high in bearing capacity, high in stiffness, excellent in seismic ductility, excellent in integrity, convenient and rapid in construction, high in construction quality and capable of realizing shift-away of plastic hinge, and meets the requirements of 'strong column and weak beam, strong joints'.

Owner:FUJIAN UNIV OF TECH

Endoscope self-locking device and endoscope

PendingCN111803009AAchieve lockingGuaranteed stabilitySurgeryEndoscopesEngineeringMechanical engineering

The invention relates to the technical field of endoscopes, in particular to an endoscope self-locking device. The device comprises a shell and a rotating handle, a first locking piece is fixedly arranged in the shell, a rotating shaft is rotatably connected into the first locking piece, and a locking mechanism used for being matched with the first locking piece is movably connected to the rotating shaft; the locking mechanism comprises an operating rod, a rolling wheel, a locking piece, a wedge-shaped block and a second locking piece, the locking piece is connected to the operating rod, the operating rod is matched with the wedge-shaped block, the wedge-shaped block is arranged on the second locking piece, the second locking piece is movably connected to the rotating shaft, and the secondlocking piece can only move in the axial direction of the rotating shaft; and the operating rod controls the second locking piece to be matched with the first locking piece to achieve self-locking, and meanwhile the locking piece locks the operating rod. Self-locking can be achieved by rotating the handle, locking of an insertion tube is achieved, the imaging stability of the insertion tube is guaranteed, and meanwhile the fatigue strength of an operator is reduced.

Owner:HUNAN VATHIN MEDICAL INSTR CO LTD

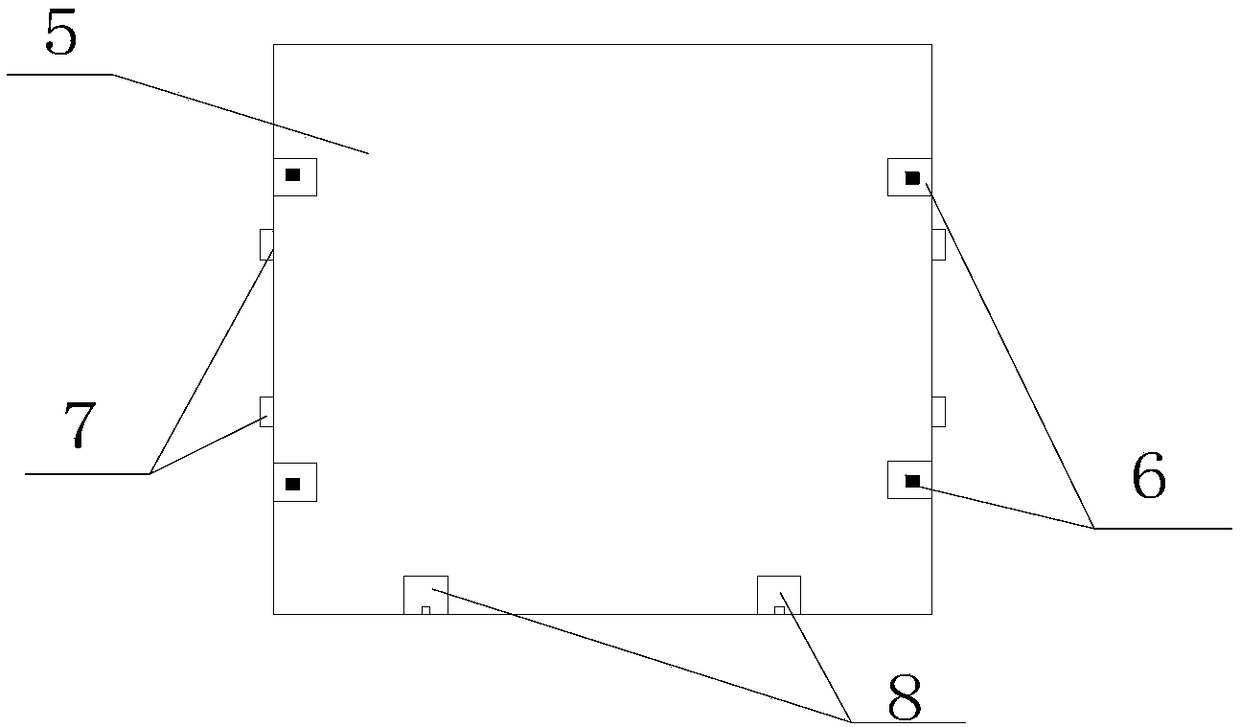

Plug welding type double-steel plate composite shear wall

The invention discloses a plug-welded double-steel plate combined shear wall, which comprises a steel pipe column (steel pipe column, steel pipe concrete column) located at both ends, a pair of steel plates and a plug-welded connector, and the two steel plates are plug-welded The knot of the type connector forms a whole. The plug-welded double steel plate composite shear wall has flat wall surface, less welding workload, the weld is located in the structural part, the mechanical performance of the shear wall is less affected by the quality of the weld, economical and safe, and the steel plate and concrete have a strong ability to work together, etc. advantage. The cross-section of the plug-welded connector is [-shaped or Z-shaped, and the ends of the [-shaped and Z-shaped connectors can be folded inward, and holes can also be arranged on the web of the connector to ensure the overall work of concrete and steel plates. and the compactness of concrete pouring. The wall plate steel plate and tie connectors can use checkered steel plates, which can effectively increase the bonding effect between the wall steel plate and concrete, and ensure the joint work between steel components and concrete.

Owner:HEFEI UNIV OF TECH +1

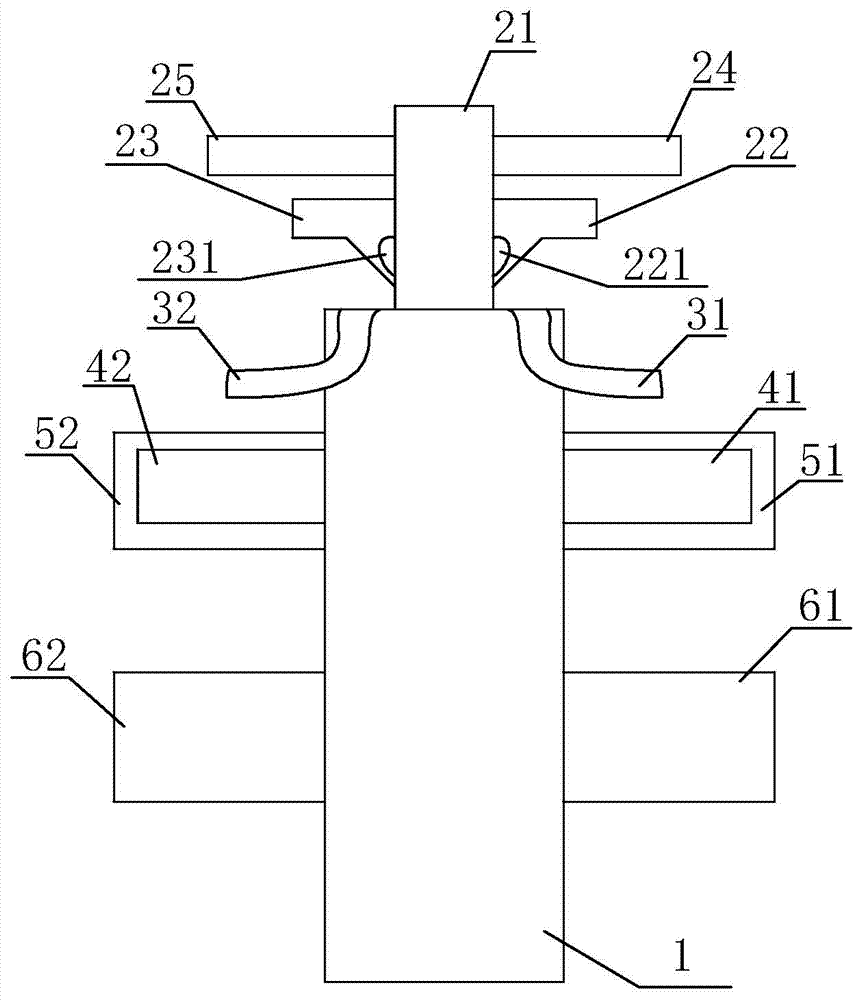

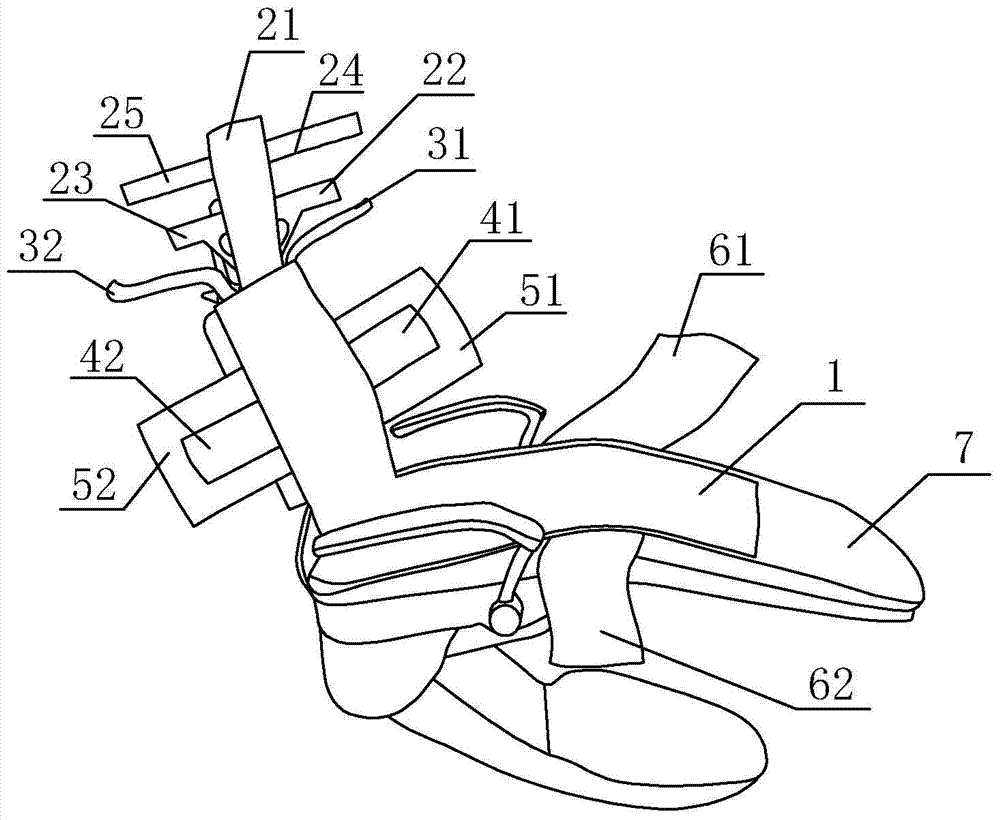

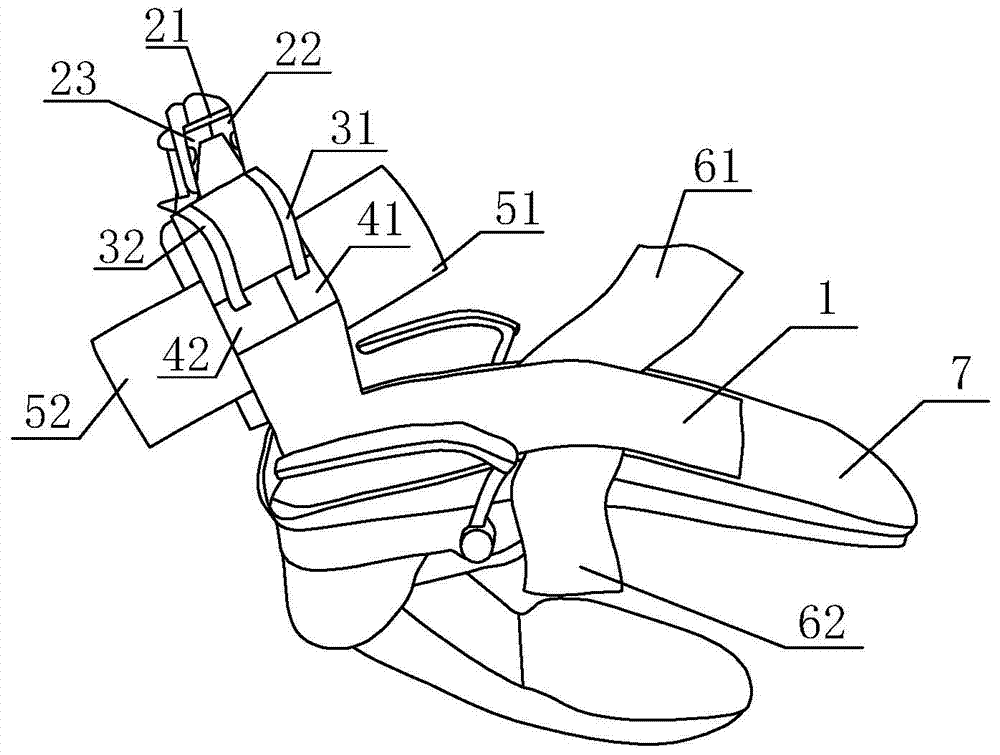

Children's operation restraining strap in stomatological department

InactiveCN104758110AEasy to usePracticalOperating chairsRestraining devicesDental chairArm restraint

The invention relates to a children's operation restraining strap in stomatological department. The children's operation restraining strap comprises a cloth liner, wherein a head restraining strap I, a shoulder restraining strap I and a shoulder restraining strap II are arranged at one end of the cloth liner; a chest and abdomen retraining strap I and an arm retraining strap I are arranged at one side of the cloth liner; a chest and abdomen retraining strap II and an arm retraining strap II are arranged at the other side of the cloth liner; a head retraining strap II and a head retraining strap III are arranged on the head retraining strap I and are respectively arranged at two sides of the head retraining strap I close to the cloth liner; the cloth liner is detachably installed on a dental chair. The children's operation restraining strap is capable of well retraining a child; occurrence of accidents of a children patient caused by swinging of his head and twisting of his body during operation can be prevented, thus safety of the children patient is guaranteed. The children's operation restraining strap is simple in structure and convenient to use, has good retraining effect and is particularly applicable to clinical use.

Owner:LIUZHOU CITY HEALTHCARE HOSPITAL FOR WOMEN & CHILDREN

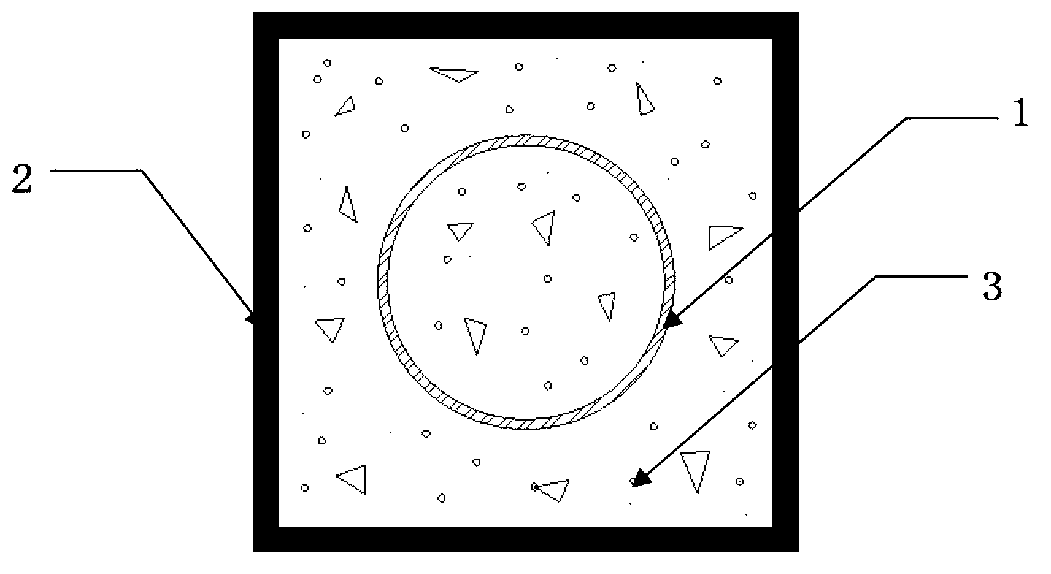

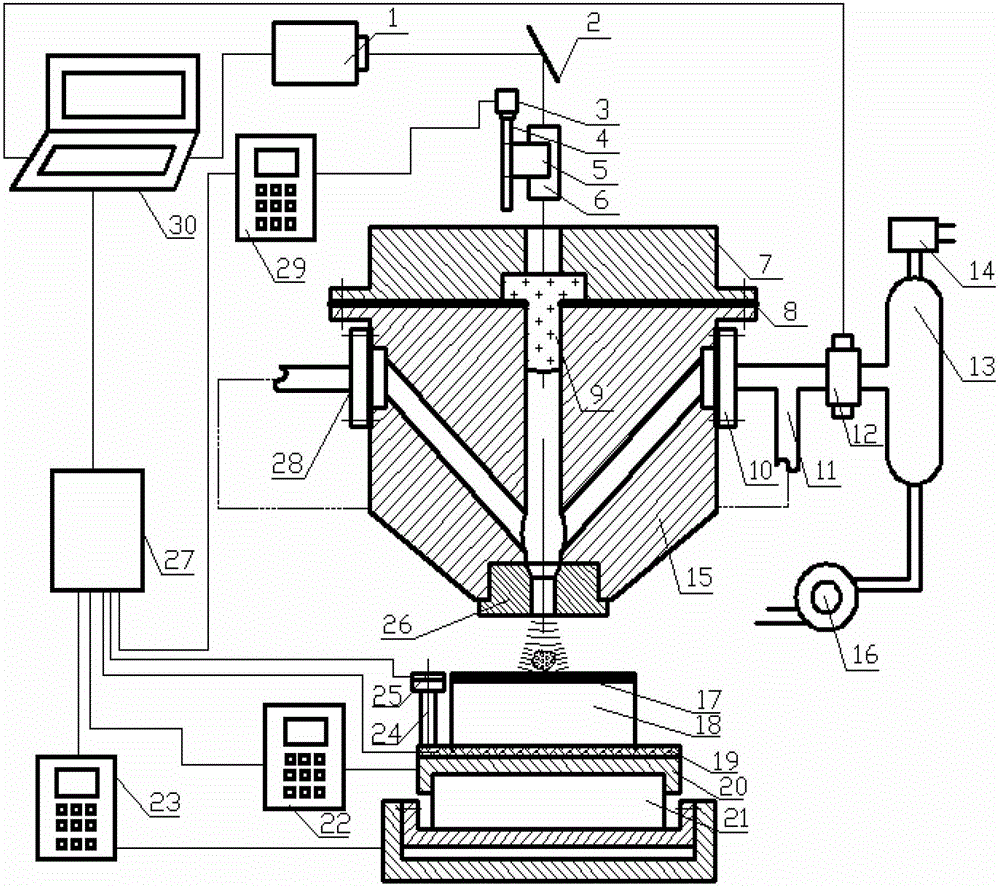

Method and device for improving constraint effect of laser high temperature shot blasting

ActiveCN103266204BDoes not reduce induced shock pressureDoes not affect plasma condensationThermodynamicsWater flow

The invention discloses a method and a device for improving a constraint effect of laser high temperature shot blasting. The method is characterized in that surge pressure generated by high voltage pulse gas is utilized for carrying out constraint on the pressure generated by explosion of laser induced plasma, and the method can be used for solving the problem that a restraint layer such as water flow is not suitable for laser high temperature shot blasting under the condition that plasma coagulation is not influenced, overcoming the defect of local cracking or integral fracture generated on high-temperature-resistant glass due to local press, and substantially improving the effectiveness and reliability of the restraint layer for laser high temperature shot blasting. The device comprises a laser, a heating platform, a pneumatic pump, an accumulator, an electromagnetic switch, a computer system and the like. The method and the device provided by the invention have the advantages that the application range is wide, and the constraint effect is good.

Owner:JIANGSU UNIV

Method for solidifying steel pipe column through external sleeveing of circular steel pipe concrete

The invention provides a method for solidifying a steel pipe column through external sleeveing of circular steel pipe concrete. The method is characterized by comprising the following steps that (1), polishing and derusting are conducted on the surface of an original steel pipe column; (2), an externally-sleeved circular steel pipe is installed on the periphery of the original steel pipe column, and the original steel pipe column is wrapped with the externally-sleeved circular steel pipe; and (3), filling materials are poured between the original steel pipe column and the externally-sleeved circular steel pipe. According to the method for solidifying the steel pipe column through external sleeveing of the circular steel pipe concrete, a steel pipe concrete structure is applied to the solidifying process of the steel pipe column, and a method for local solidifying or overall solidifying of a damaged steel pipe column through externally-coated steel pipe concrete is provided; when local solidifying is conducted, the externally-sleeved steel pipe mainly has a hooping effect, and when overall solidifying is conducted, the externally-sleeved steel pipe can jointly bear the pressure and has the hooping effect, so that a new thought is provided for the solidifying method of the steel pipe column.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com