Carbon fiber strip reinforced structure component and implementation method thereof

A realization method and a technology for strengthening structures, which are applied in building maintenance, building construction, construction, etc., to achieve the effects of green environmental protection, saving input costs, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

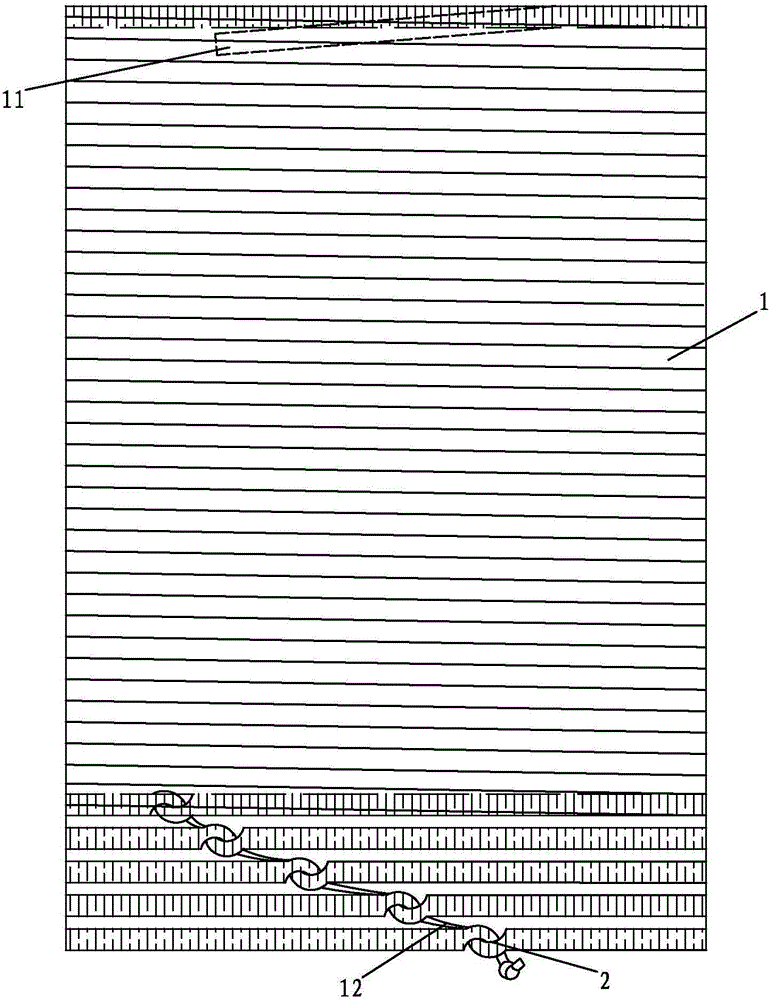

[0032] Such as figure 1 As shown, this embodiment relates to a carbon fiber strip reinforced structural member, which is characterized in that: it includes a structural member and a carbon fiber strip 1 coated on the outer surface of the structural member, and the carbon fiber strip 1 is spirally wound and tightly pressed on the on the outer surface of the structural member. The structural members are beams or columns.

[0033] In the present invention, the self-locking fixing structure of the carbon fiber strip 1 is used to coat the structural member to achieve the purpose of strengthening the structural member, without using flammable and combustible adhesives as the link, so that the carbon fiber strip 1 is damaged under high temperature. Belt 1 can still have a good restraint effect on structural parts, which solves the problem that the adhesive and fiber matrix material bonding carbon fiber and structural parts fail under high temperature such as fire, which may easily l...

Embodiment 2

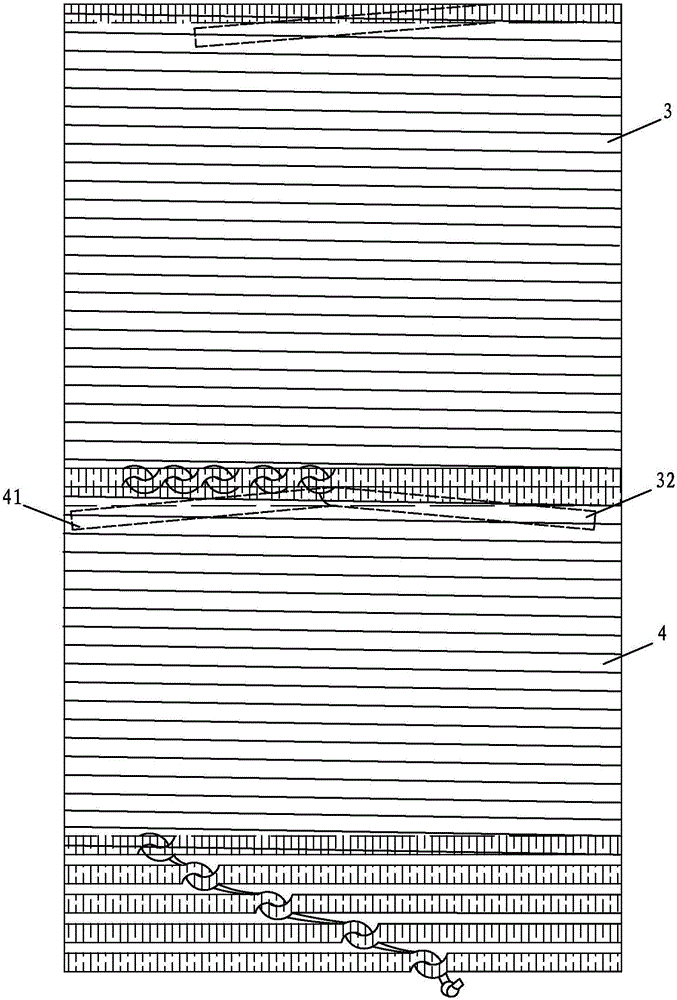

[0050] This embodiment is based on Embodiment 1, such as figure 2 As shown, in the process of thread winding structural parts, when the carbon fiber strip 1 is not long enough, as an improvement to the carbon fiber strip 1, such as figure 2 As shown, after the tail end 32 of the first carbon fiber strip 3 is processed in step 3), the tail end 32 of the first carbon fiber strip 3 is overlapped with the head end 41 of the second carbon fiber strip 4, After the head end of the second carbon fiber strip 4 is tilted, it is overlapped and wound no less than 3 times along the circumferential direction of the structural member, and the tail end 32 of the first carbon fiber strip 3 and the tail end 32 of the second carbon fiber strip 4 The head end 41 is pressed tightly into the second carbon fiber strip 4 . The length of the tail end 32 of the first carbon fiber strip 3 and the head end 41 of the second carbon fiber strip 4 pressed into the second carbon fiber strip 4 is not less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com