Method and device for improving constraint effect of laser high temperature shot blasting

A high-temperature shot peening and laser technology, applied in the field of laser shock forming, can solve the problems of not being able to adapt to high temperature and complex surface impact forming, confinement medium damage, laser beam dispersion, etc., to achieve excellent confinement effect, uniform residual stress field, and device operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

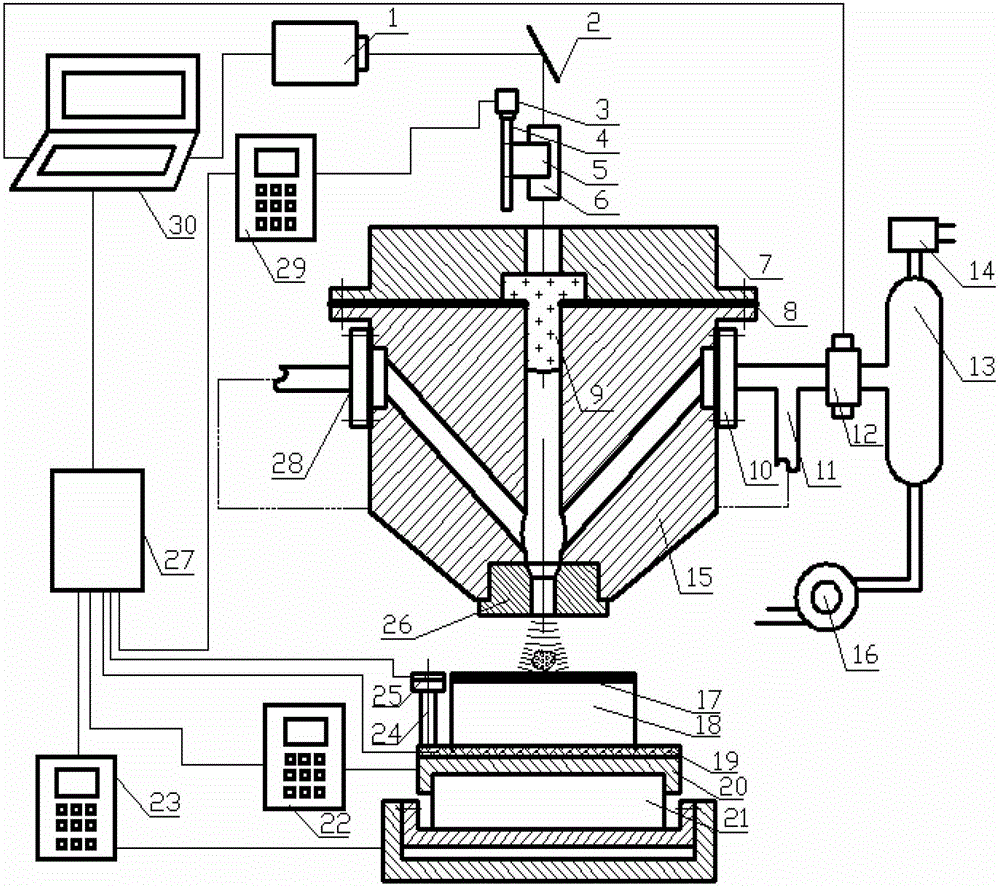

[0039] Such as Figure 1-4 shown.

[0040] A method to improve the confinement effect of laser high-temperature shot peening, the essence of which is to use the impact pressure generated by high-pressure pulsed gas to confine the pressure generated by the plasma explosion induced by laser high-temperature shot peening. This confinement method can be used without affecting the plasma condensation At the same time, it can get rid of the shackles of temperature and is applied to laser peening at higher temperatures. At the same time, this confinement method is not affected by local stress concentration, and can be widely used in laser shocking of flat and curved workpieces, ensuring that the laser temperature peening confinement layer effectiveness and reliability. Such as figure 1 As shown, the specific steps are as follows,

[0041] A) Place the workpiece 18 coated with black paint 17 on the heating platform 20, and turn on the computer system 30 and the air pump 16 at the s...

Embodiment 2

[0058] Such as figure 1 shown.

[0059] A device for improving the confinement effect of laser high-temperature shot peening, which can be divided into several parts such as a focusing device, a confinement device, a workpiece platform, and a high-pressure pulse gas generating device. The focusing device includes a lens system 6 and a fixture 5, the lens system 6 is clamped on the fixture 5, the fixture 5 and the guide rail 4 are connected by a lead screw, the lead screw is rigidly connected to the output shaft of the stepping motor 3, and the step The feed motor 3 drives the jig 5 and the lens system 6 to move up and down through the screw and the guide rail 4 to realize focusing; the restraint device includes the top cover 7 and the nozzle 15, which are connected by bolts, and a rubber gasket 8 is installed in the middle to ensure the joint. Tightness, the top cover 7 clamps the high pressure resistant lens 9 on the rubber gasket 8; the nozzle 26 and the nozzle 15 are conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com