Laminated rubber support reinforced by combining fine high-strength steel wire meshes and steel fibers

A technology of laminated rubber bearings and high-strength steel wires, applied to bridge parts, bridges, building components, etc., can solve the problems of plate bearings losing their function, limited shear deformation capacity, and large bearing height ratio, and achieve light weight , a wide range of applications, and the effect of ensuring traffic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

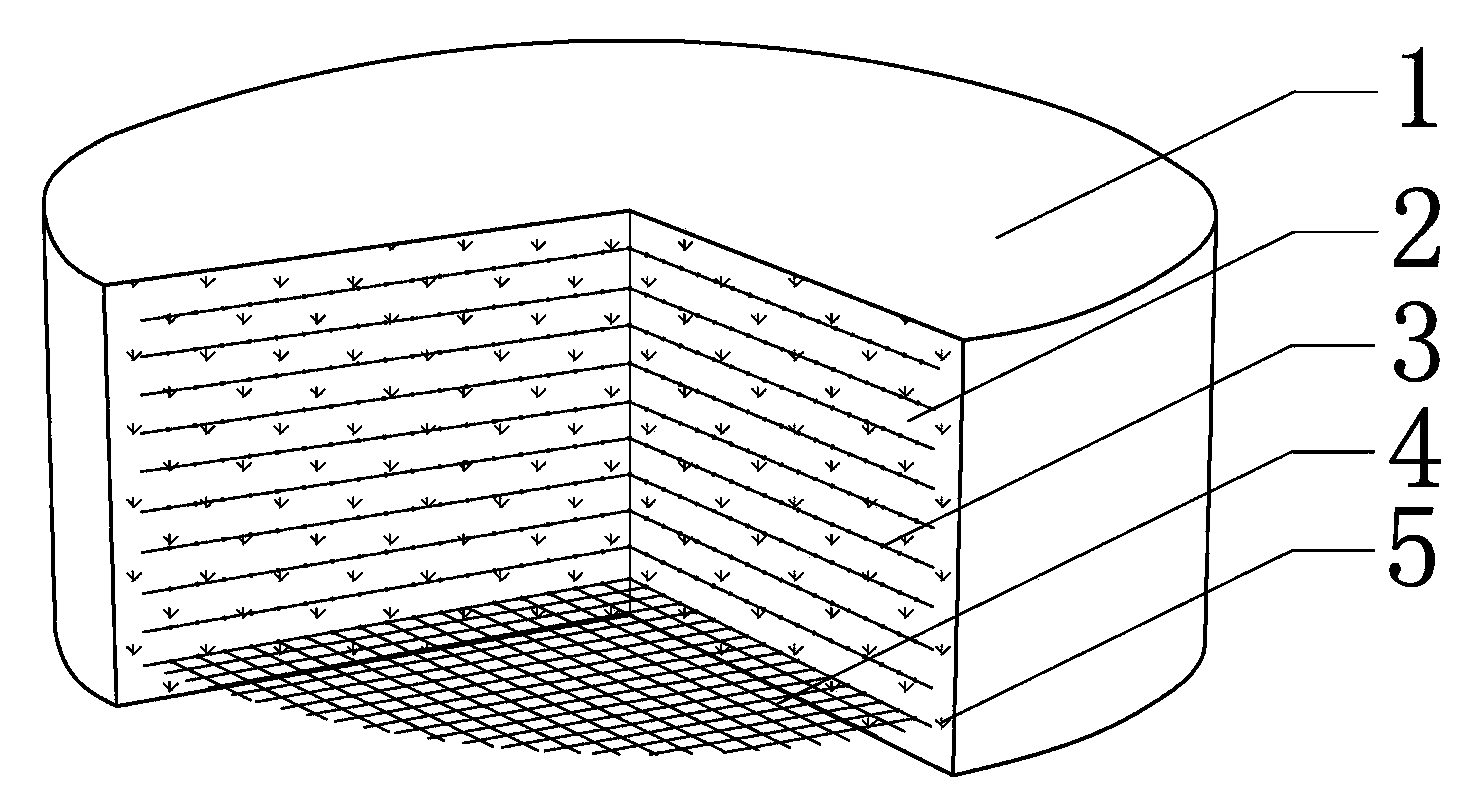

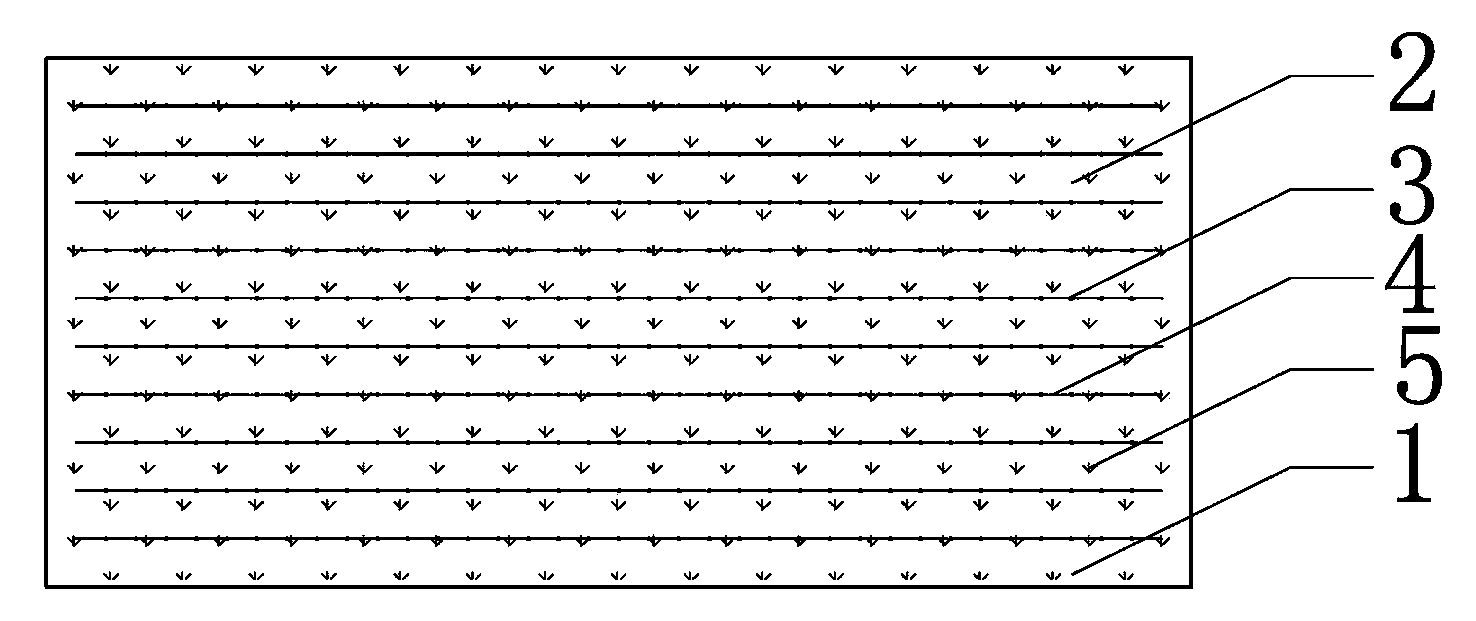

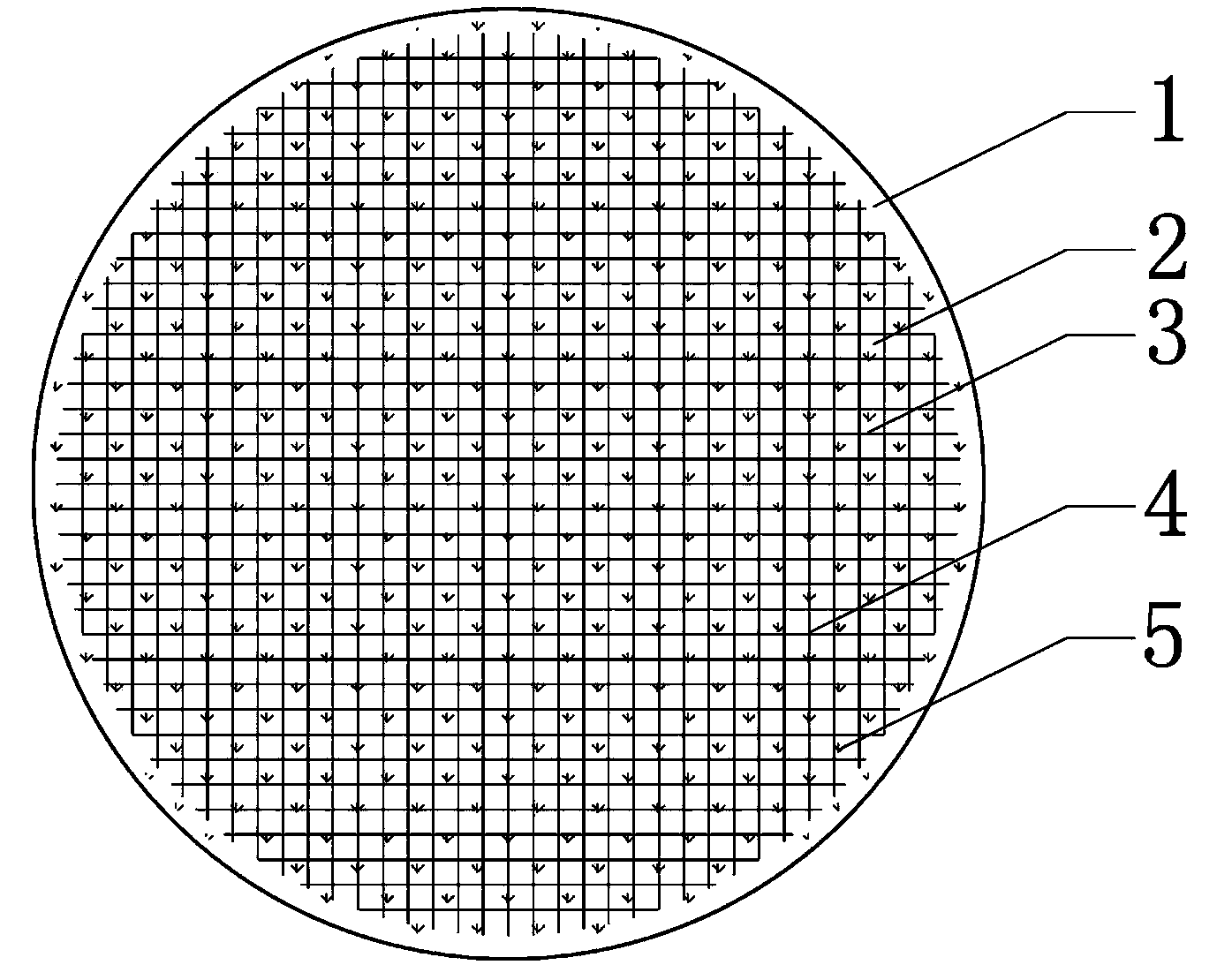

[0025] Example 1: see figure 1 , figure 2 , image 3 , The laminated reinforced rubber bearing of fine and dense high-strength steel wire mesh is composed of outer protective rubber 1 , inner rubber 2 , fine and dense high-strength steel wire mesh 4 and steel fiber 5 . The fine-density high-strength steel wire mesh 4 is made of high-strength steel wire 3, and then the rubber with steel fiber material and the multi-layer fine-density high-strength steel mesh 4 are placed in a mold, and finally vulcanized to form a whole, and the outer layer is covered with an outer layer of protective rubber 1.

[0026] When the support of the scheme bears the vertical load, the rubber expands outwards, but because the inner rubber 2 is densely covered with fine and high-strength steel wire mesh 4 and steel fibers 5, the lateral expansion of the rubber is effectively restrained, and the vertical compression decreases, thus The support of the scheme obtains the necessary vertical stiffness an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com