Self-resetting piezoelectric semi-active friction damper

A friction damper, self-reset technology, applied in building components, shock-proof and other directions, can solve the problems of non-recyclable use, no reset function, no consideration, etc., to achieve the effect of simple control system, good restraint effect, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

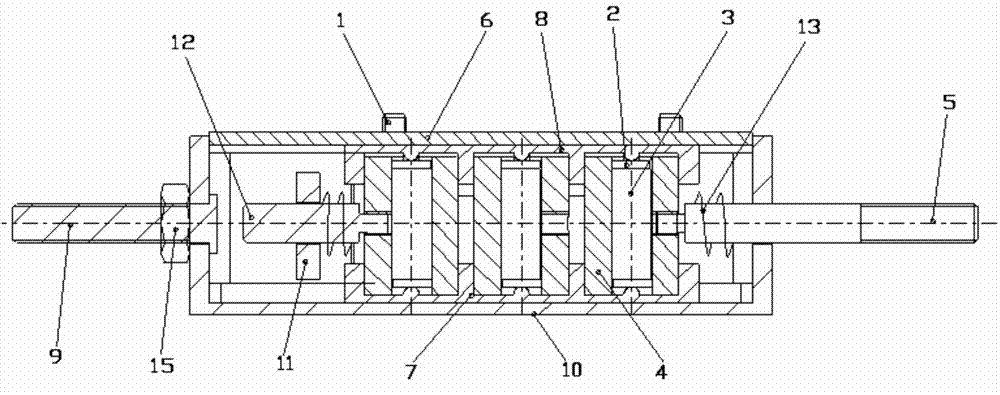

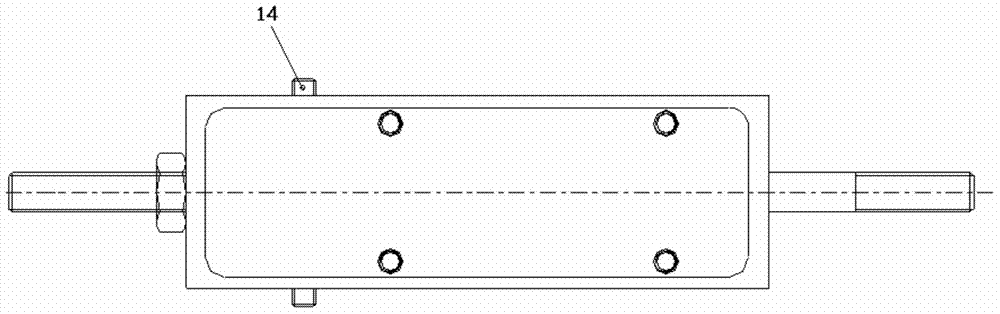

[0027] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

[0028] like figure 1 and figure 2 As shown, the present invention is a self-resetting piezoelectric semi-active friction damper, and the shell is composed of a top cover 6 and a small box 10; the inner surface of the top cover 6 and the bottom surface of the small box 10 is pasted with a wear-resistant carbon fiber friction material, The lower surface of the top cover 6 is provided with a top seat 8, and the bottom surface of the small box 10 is provided with a base 7; a plurality of parallel sleeves 4 are placed between the two groove supports; the piezoelectric ceramic driver 3 is placed in the sleeve, and the piezoelectric ceramic driver 3 There are spacers 2 at both ends, and the power cord of the piezoelectric ceramic driver 3 is led out from the small groove on the outer wall of the sleeve 4, and connected to the external powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com