a pounding machine

A technology of driving mechanism and reducer, which is applied in the field of hammering machine, can solve the problems of high labor cost, achieve high degree of automation, convenient pressure adjustment, and avoid breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

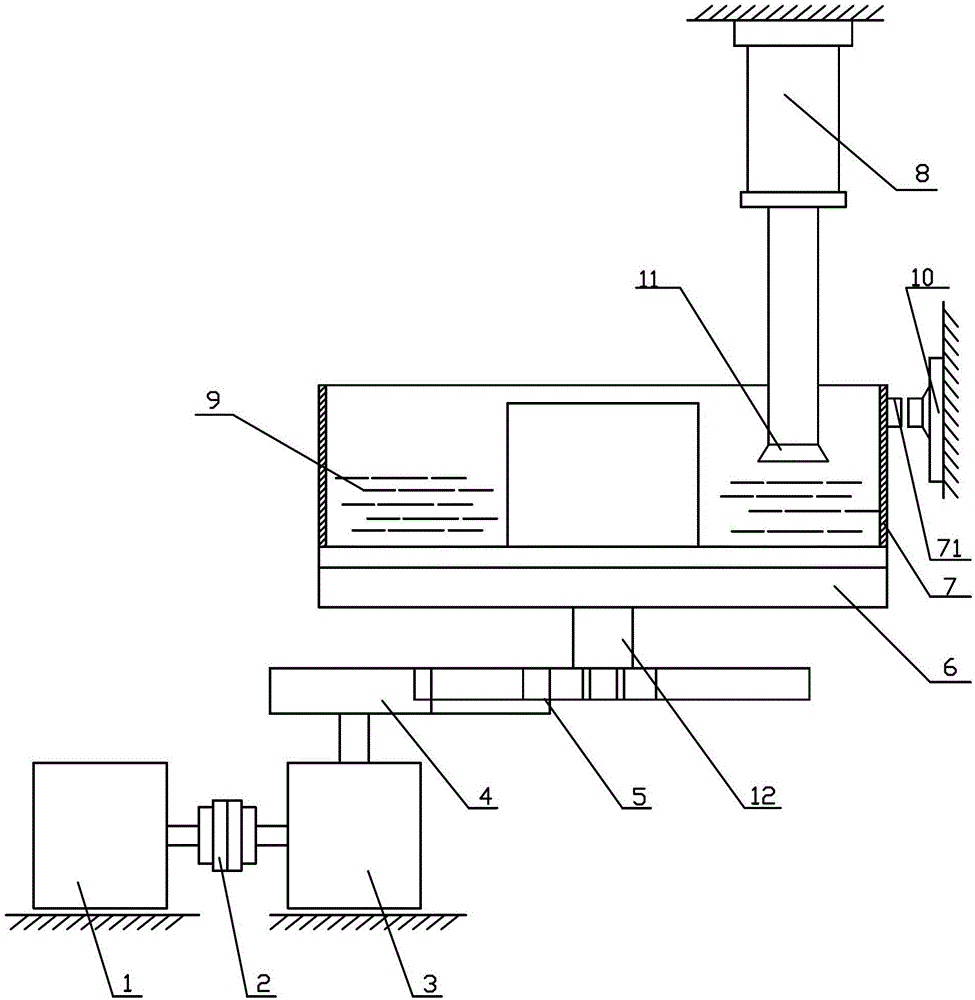

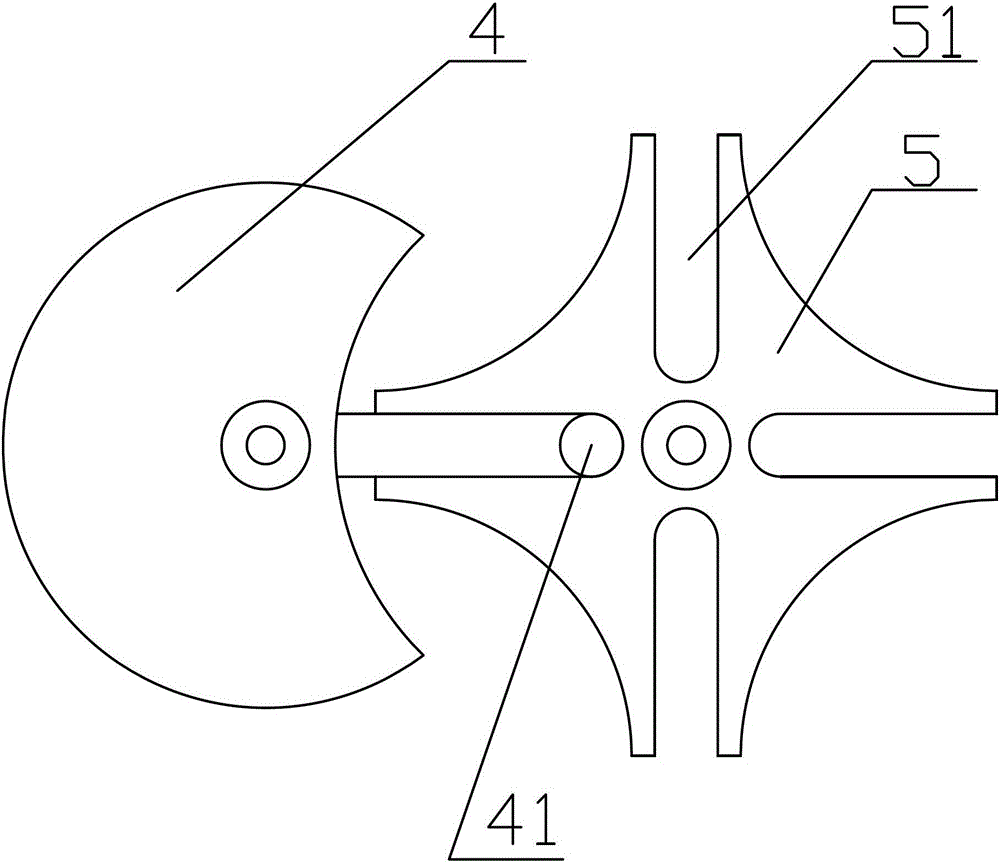

[0012] figure 1 Shown is a kind of hammering machine, including motor 1, reducer 3 and coupling 2 connected to motor 1 and reducer 3, and also includes turntable 6 and barrel 7 placed on turntable 6 and rotating with it. The output shaft of the reducer 3 is connected to the driving dial 4, and the driving dial 4 is provided with a round pin 41 that can enter or break away from the radial groove 51 on the driven sheave 5, and drives the driven sheave 5 to rotate or stop. The driving dial 4 and the driven sheave 5 constitute a sheave mechanism; the turntable 6 is disc-shaped, and the driven wheel 5 is connected to the turntable 6 through a connecting shaft 12, the axis of the connecting shaft 12 is connected to the turntable 6 The axis of rotation is coaxial; the upper part of the barrel 7 is provided with a beating device. Wherein, described beating device is made up of driving mechanism 8 and pounding hammer 11, and the piston rod of described driving mechanism 8 links to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com