a hair-thumping machine

A technology of a driving mechanism and a reducer, applied in the field of hammering machines, can solve the problem of high labor cost, and achieve the effects of high degree of automation, convenient pressure adjustment and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

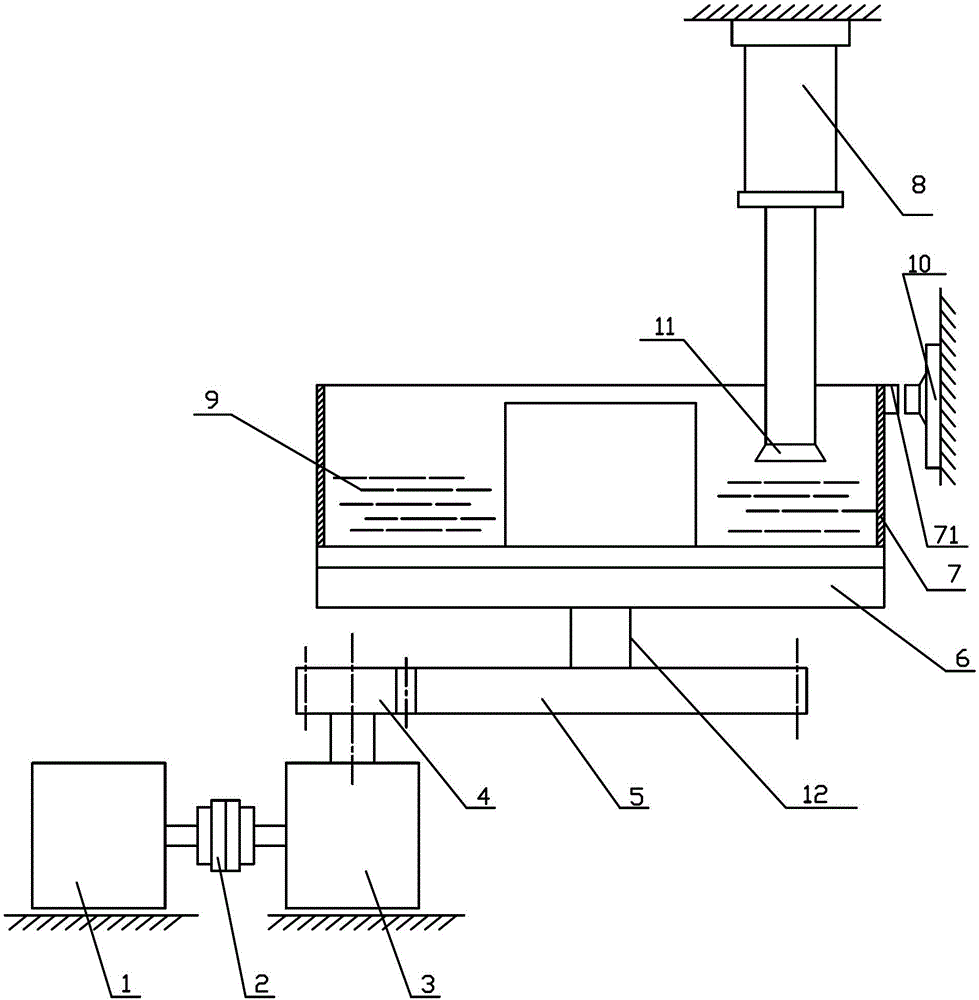

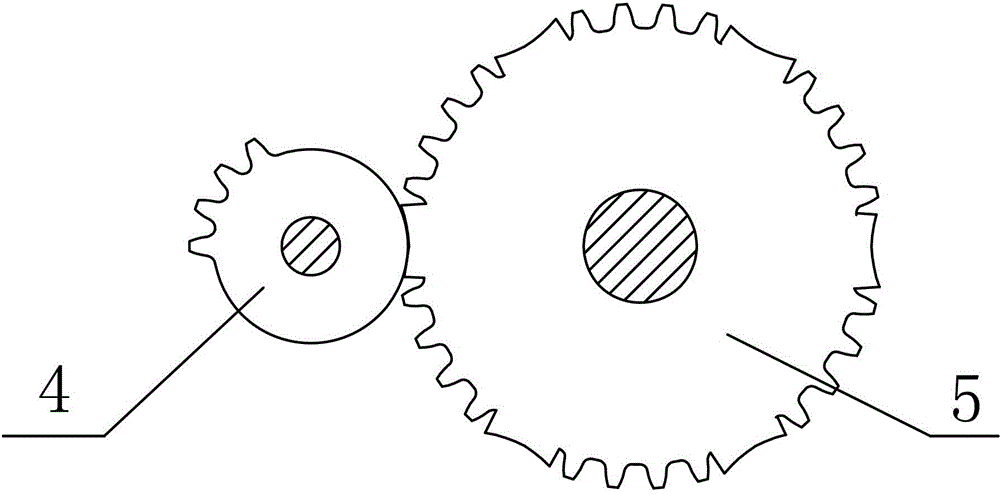

[0012] figure 1 Shown is a kind of hammering machine, including motor 1, reducer 3 and coupling 2 connected to motor 1 and reducer 3, and also includes turntable 6 and barrel 7 placed on turntable 6 and rotating with it. The output shaft of the reducer 3 is connected to the driving wheel 4, and the driving wheel 4 is meshed with the driven wheel 5, and the driving wheel 4 and the driven wheel 5 form an incomplete gear mechanism; the rotating disk 6 is disc-shaped, and the driven wheel 5 is connected with the turntable 6 through the connecting shaft 12, the axis of the connecting shaft 12 is coaxial with the rotation axis of the turntable 6; the upper part of the barrel 7 is provided with a beating device. Described beating device is made up of driving mechanism 8 and pounding 11, and the piston rod of described driving mechanism 8 links to each other with pounding 11; The distance from the axis of rotation of the turntable 6 is greater than a quarter of the radius of the turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com