Patents

Literature

44 results about "Hair - material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

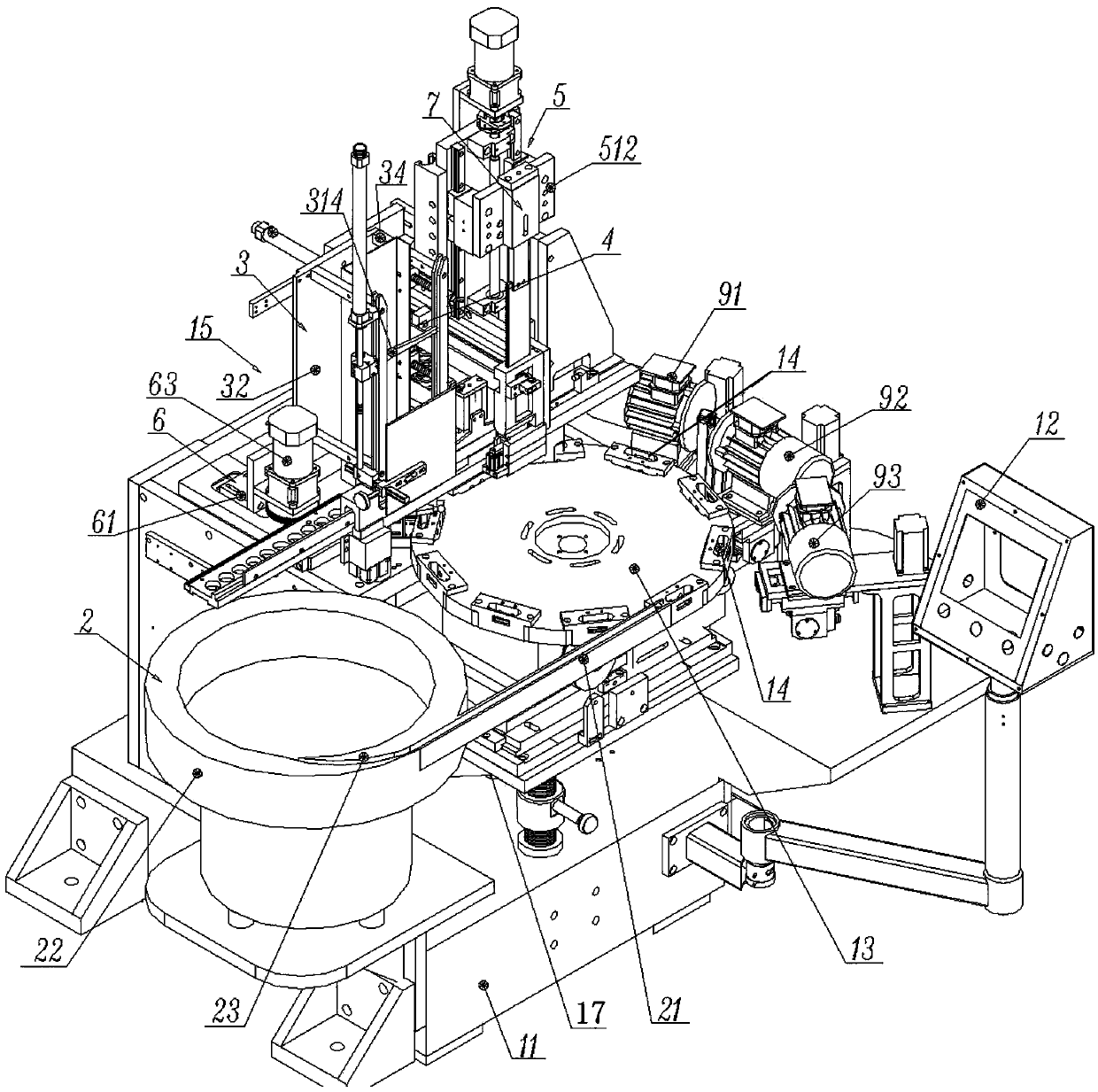

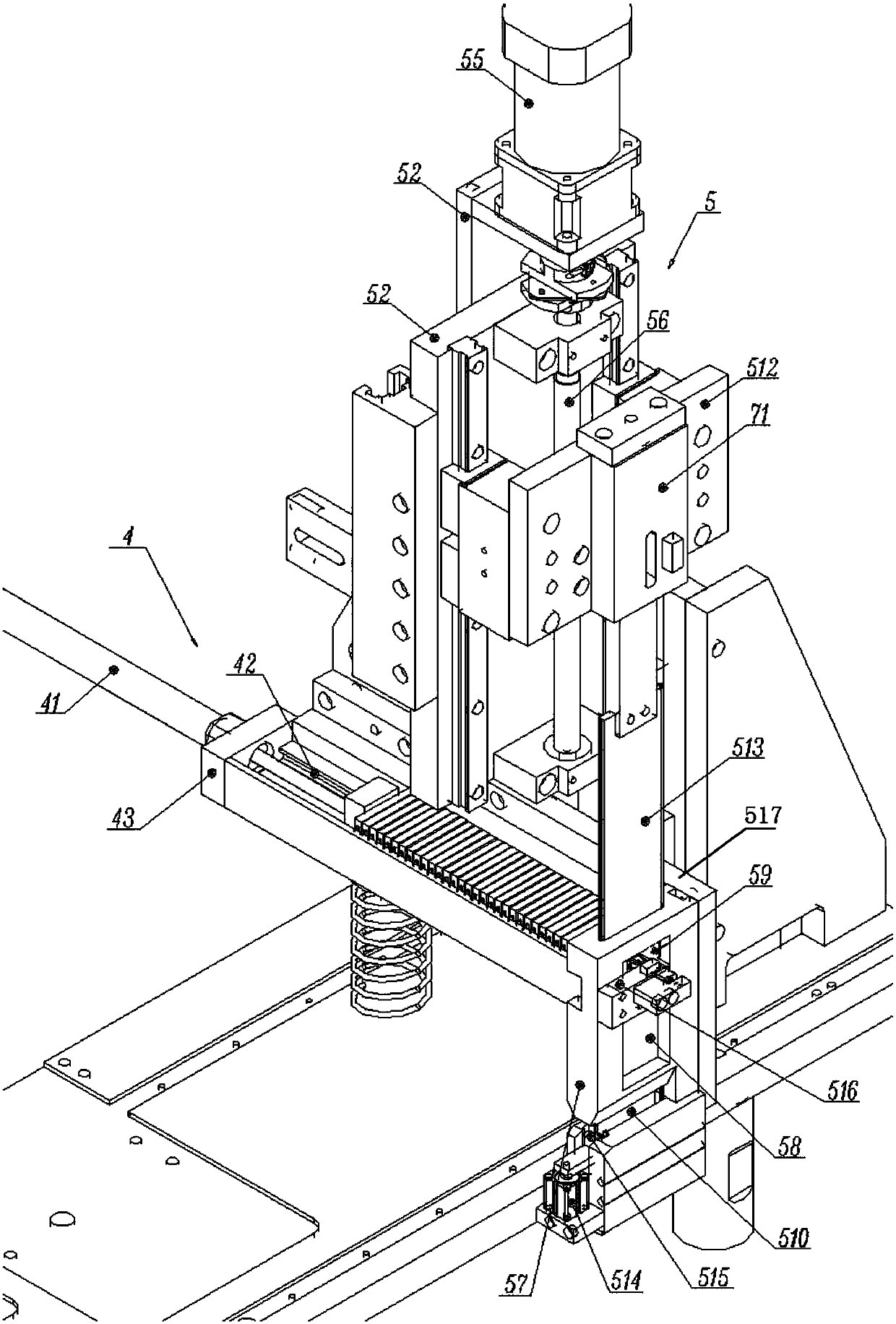

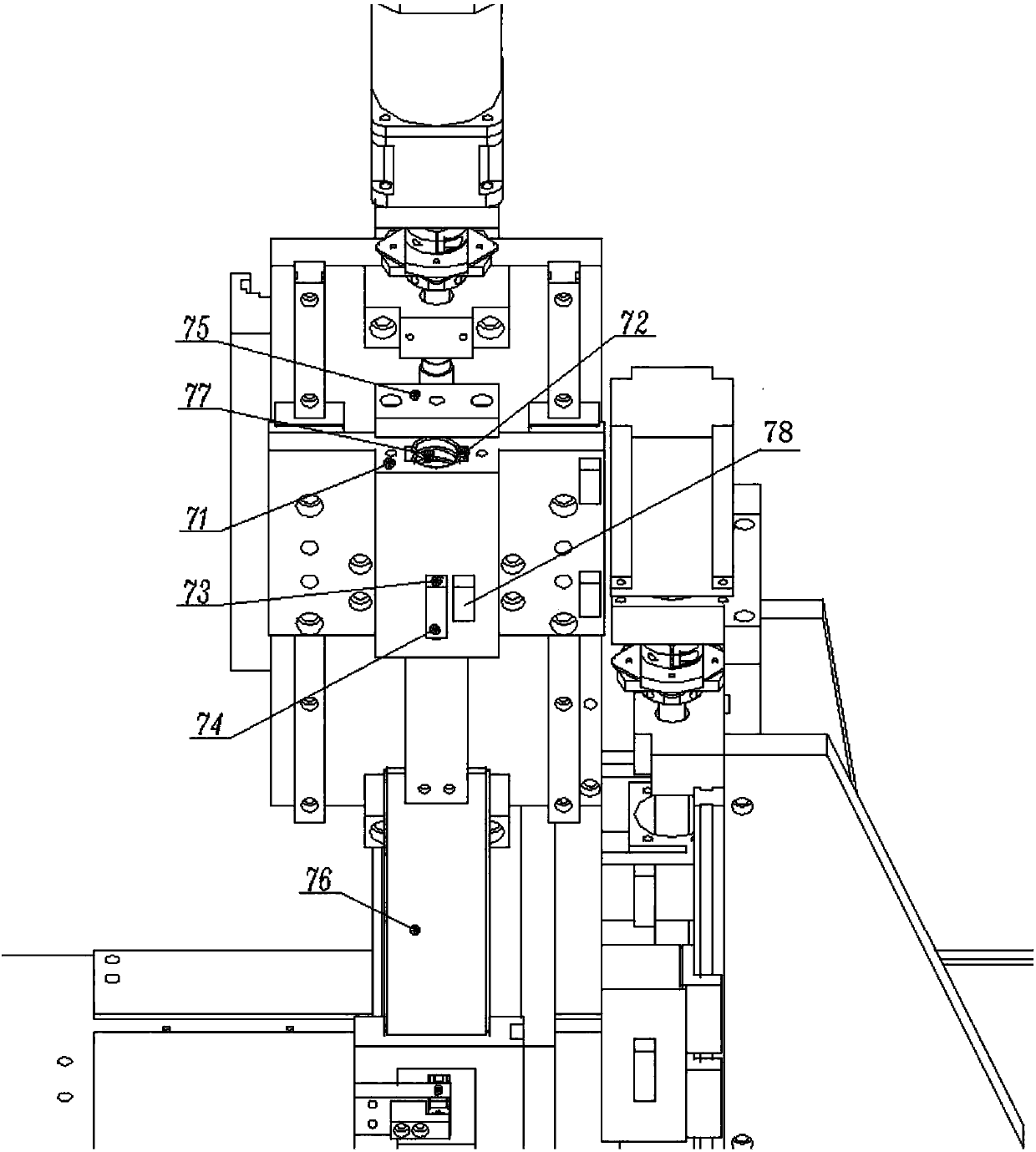

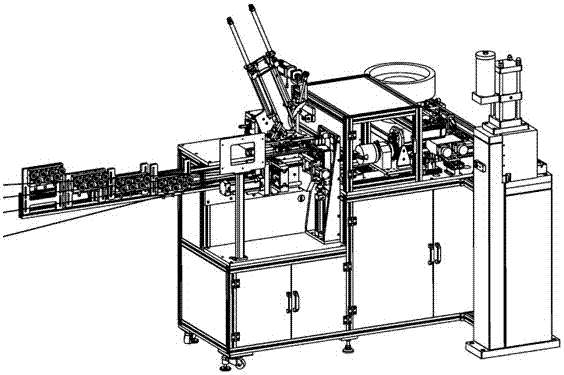

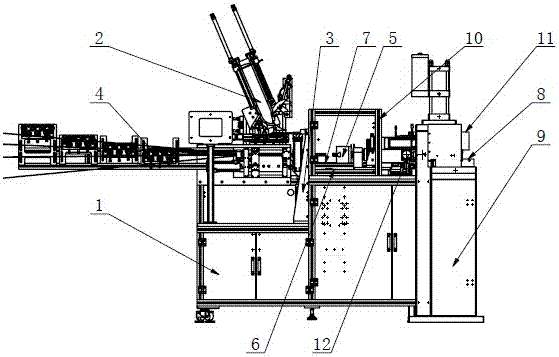

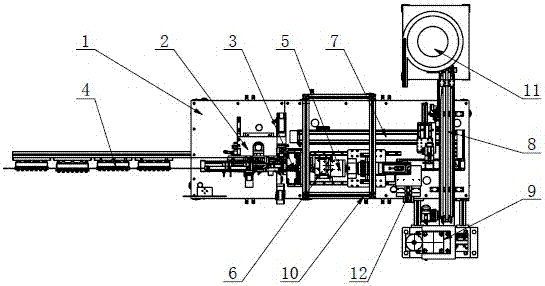

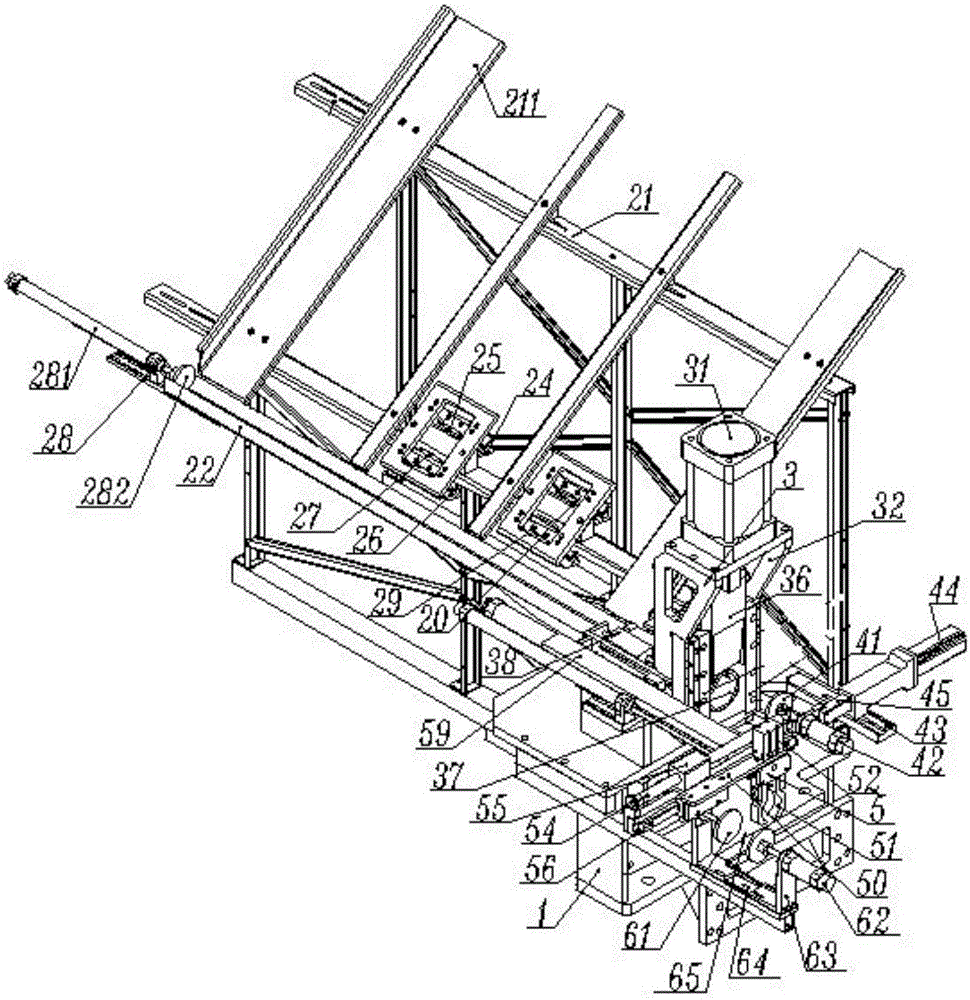

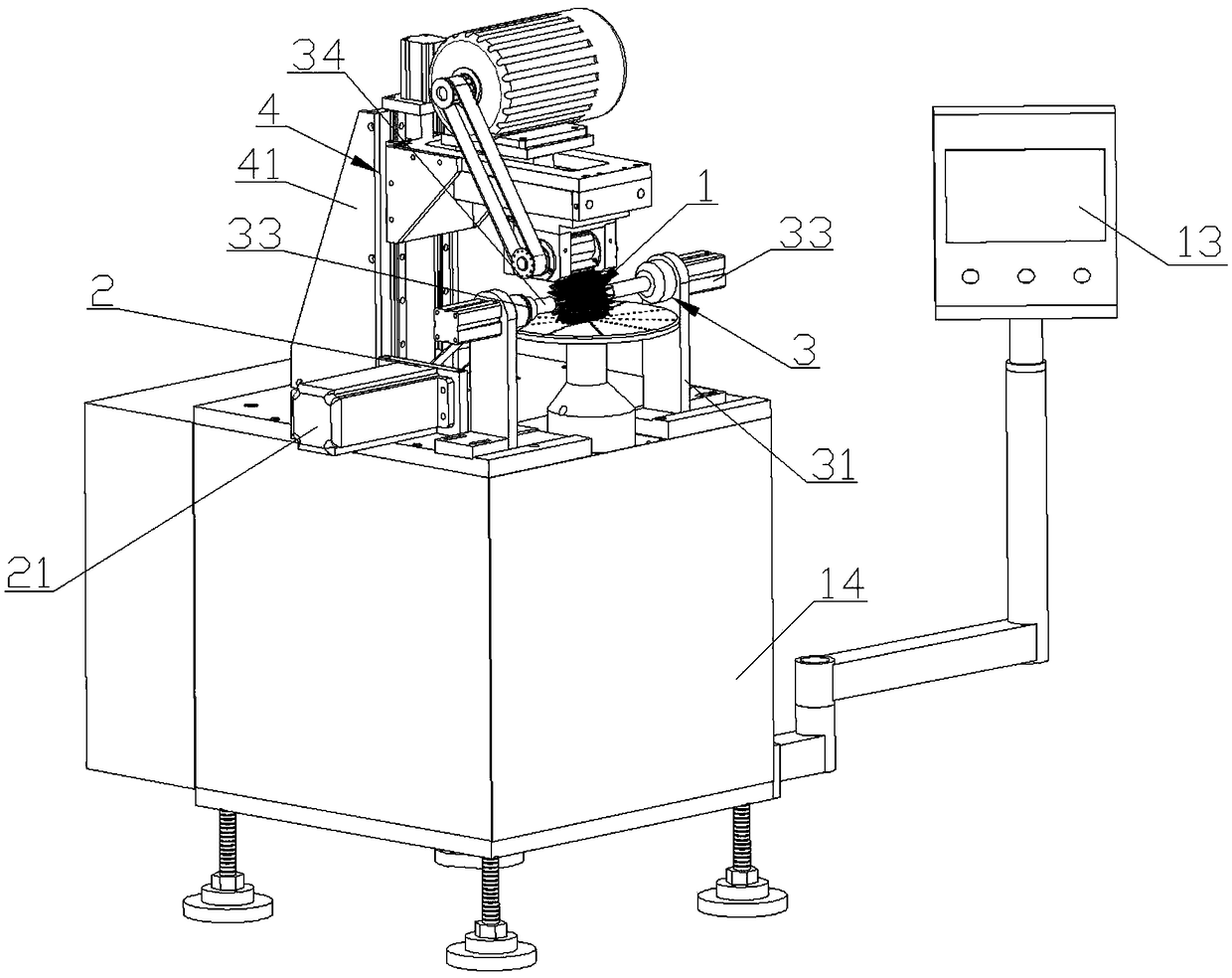

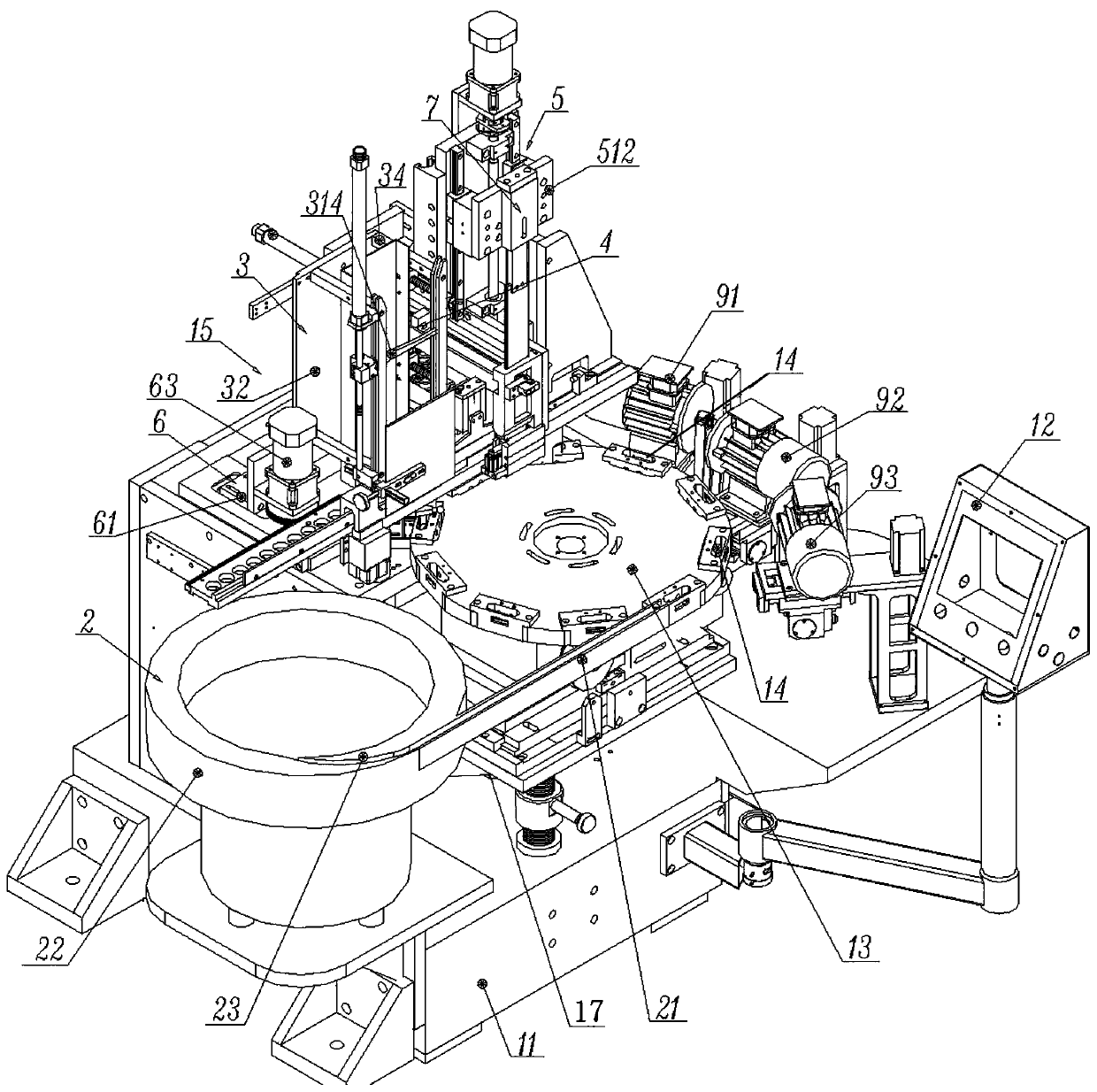

Full-automatic environment-friendly non-hair-planting porous paint brush processing device

The invention discloses a full-automatic environment-friendly non-hair-planting porous paint brush processing device, and relates to a device for processing the paint brush. The device comprises a machine body, a console, a disc on which a plurality of brush handle placing grooves are arranged, a handle feeding mechanism for placing brush handles into the brush handle placing grooves, and a bristle placing mechanism for placing hair materials and clamping blocks into the brush handles on the disc, wherein the console, the disc, the handle feeding mechanism and bristle placing mechanism are arranged on the machine body, and the console, the handle feeding mechanism and the bristle placing mechanism are distributed along a circumferential direction of the disc; the bristle placing mechanismcomprises a hair placing mechanism for placing the hair materials, a sheet feeding mechanism for feeding the clamping blocks to the upper sides of the hair materials, a pressing block mechanism for pressing the hair materials that the upper sides are pressed by the clamping blocks onto the brush handles, and a hair feeding mechanism for feeding the hair materials in the hair placing mechanism ontothe pressing block mechanism; the hair placing mechanism is arranged between the hair feeding mechanism and the pressing block mechanism; and the sheet feeding mechanism is arranged between the hairplacing mechanism and the pressing block mechanism.

Owner:HUBEI C P NC MACHINERY

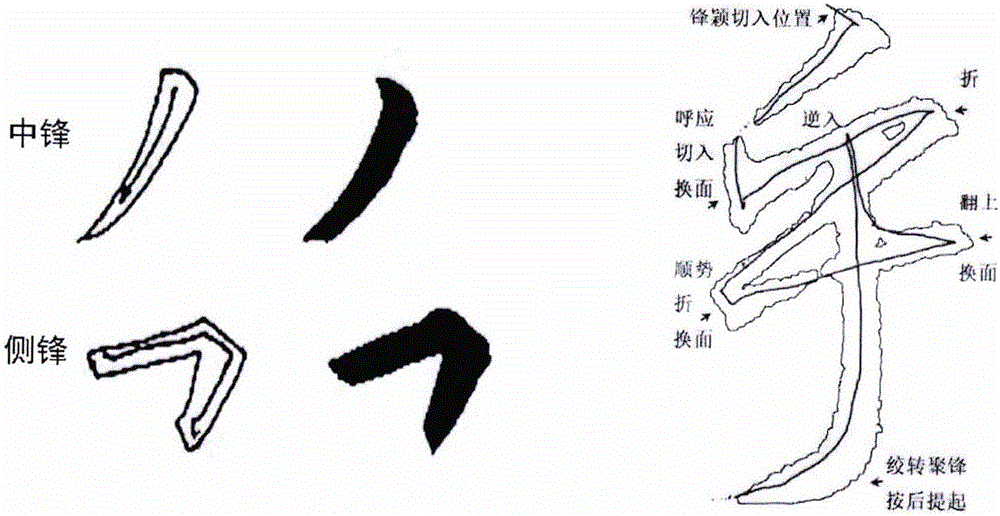

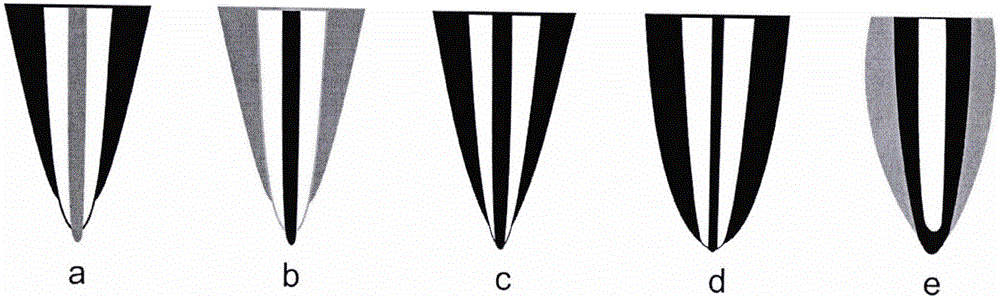

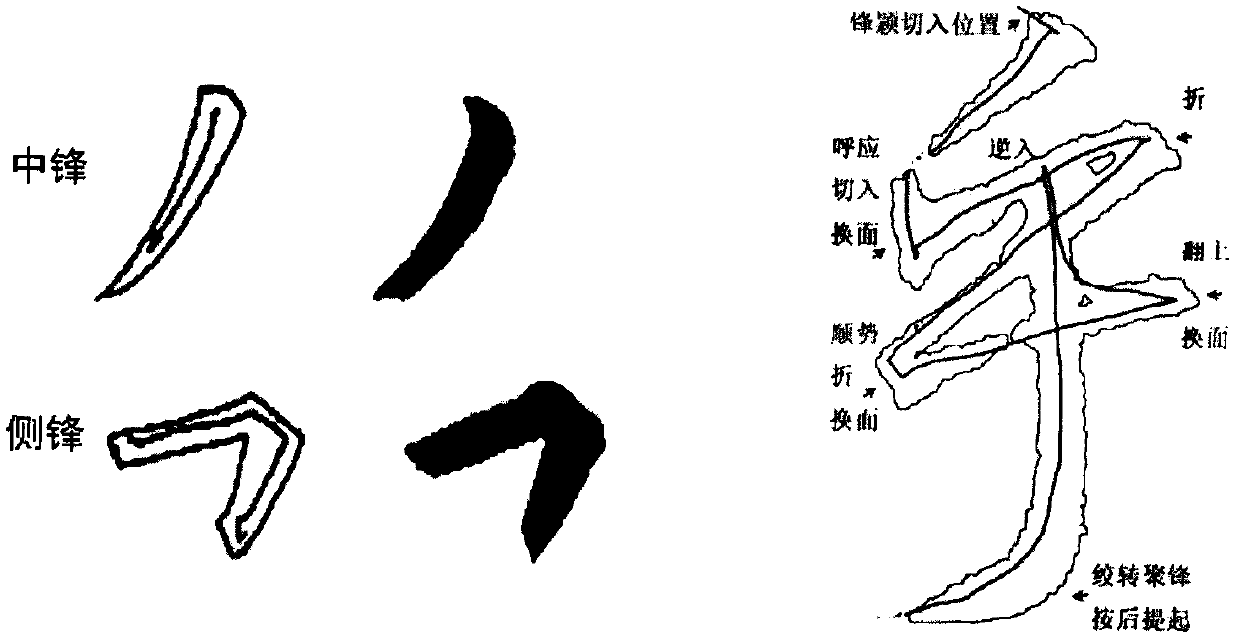

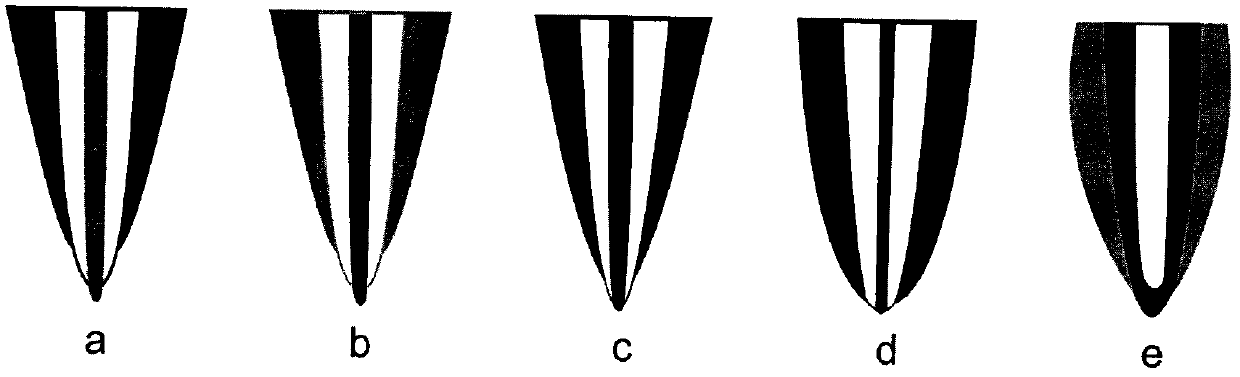

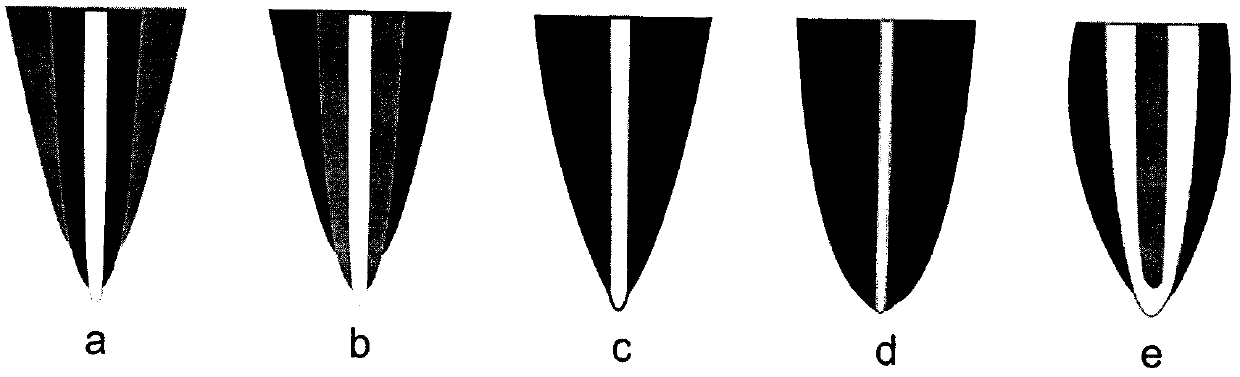

Writing brush head, manufacturing method and application thereof

ActiveCN106808837AControl ink absorption capacityConvenient teaching demonstrationNibsEngineeringHydrophilic hydrophobic

The invention discloses a writing brush head, a manufacturing method and an application thereof. The writing brush head contains at least two brush hair materials which are enough different in hydrophilic-hydrophobic property or hygroscopic property, wherein one of the two brush hair materials is better in ink resistance. The writing brush head is characterized in that in the writing process, strokes take on stroke profiles and thick-thin difference in the strokes along the brush moving track by utilizing difference of the ink absorbing amounts of different brush hair materials. The writing brush head and a writing brush disclosed by the invention have the advantages that the brush moving track in the writing or drawing process can be displayed, teaching demonstration and painting imitation training are convenient, the strokes also can show three-dimensional or richer-layered works, and the interestingness, the beauty and the appreciation are enhanced. The writing brush head can be prepared by widely adopting undegreased or incompletely-degreased animal hairs or plant fibers and the existing artificial fibers or synthetic fibers as brush hair materials, the materials are easily available, the method is simple and convenient, the process is simplified, the operation is convenient, the suitability for large-scale material supplying is achieved and the cost is low.

Owner:赫拉迪克(厦门)科技有限公司

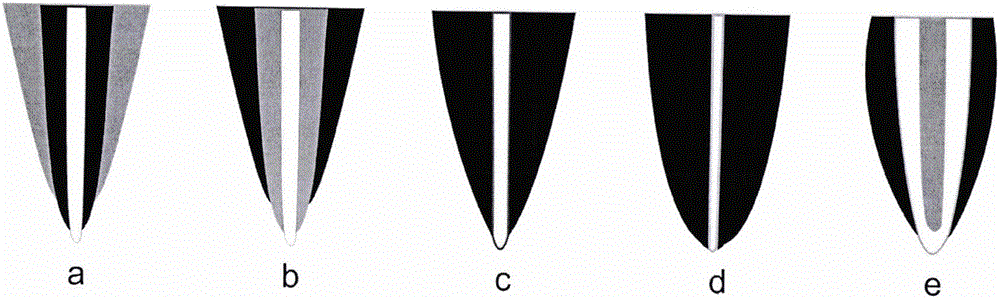

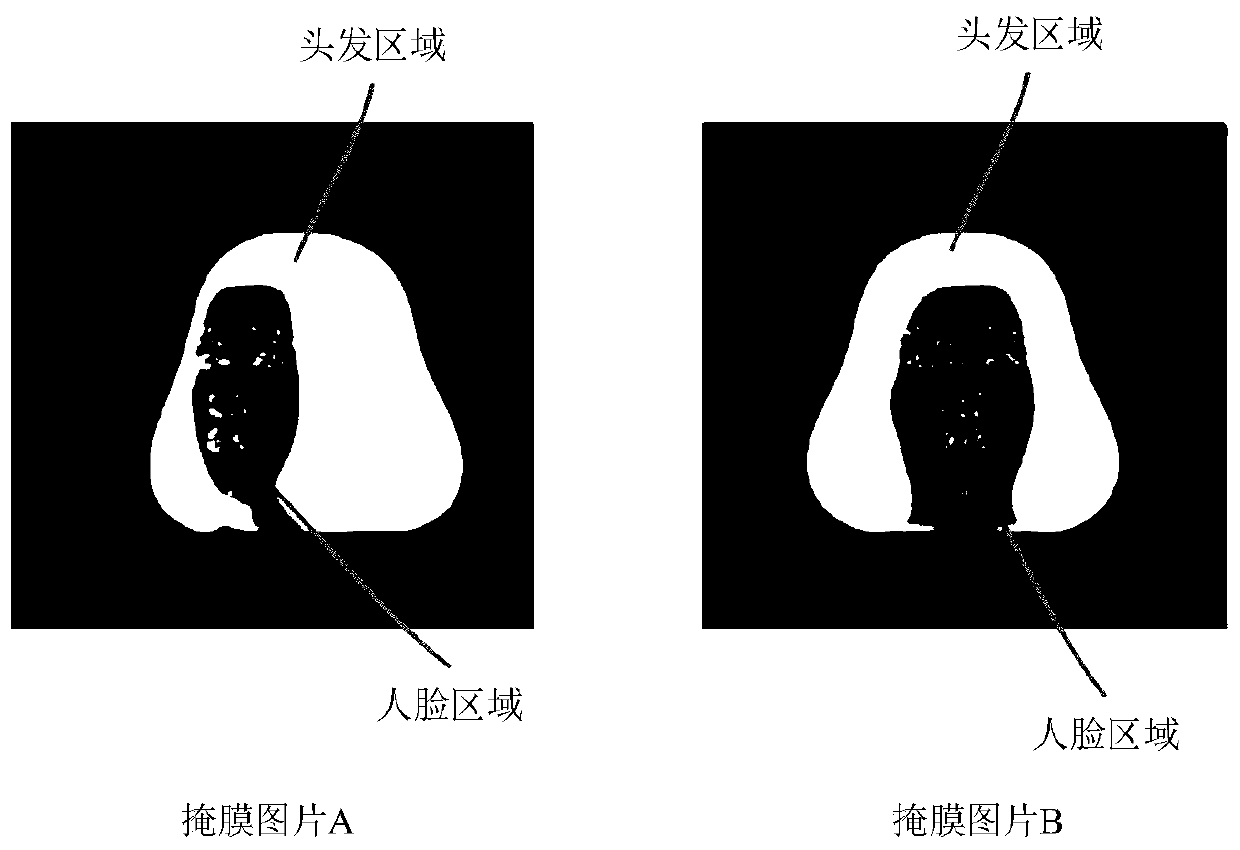

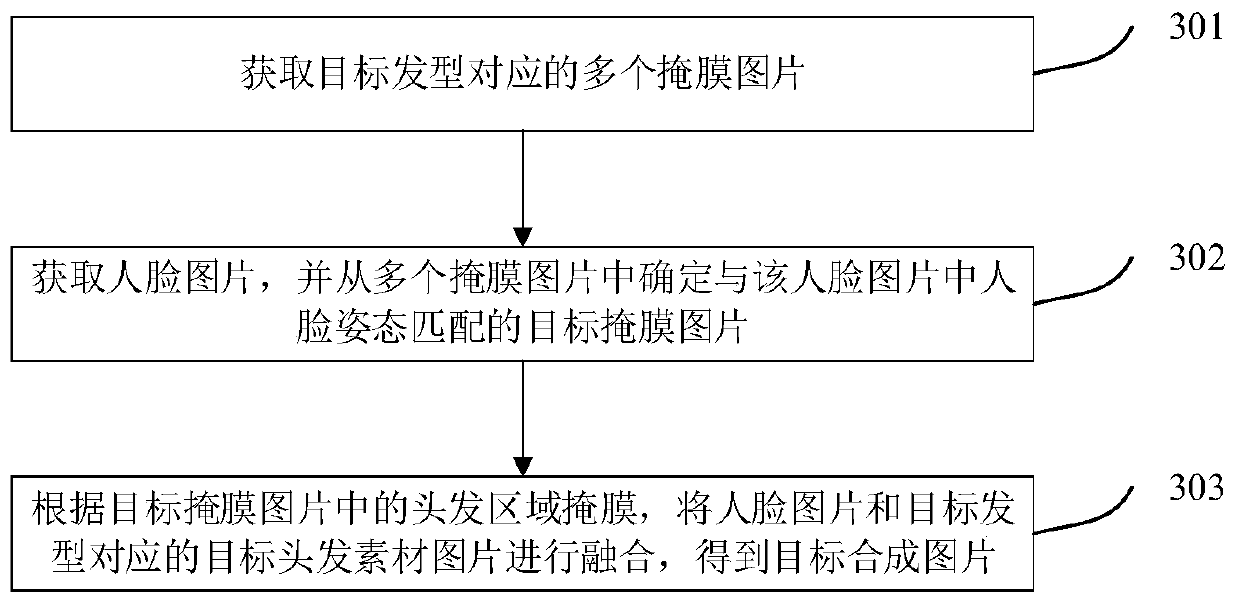

Picture processing method, device and equipment and computer storage medium

ActiveCN110738595AImprove realismImage enhancementImage analysisImaging processingComputer graphics (images)

The invention discloses a picture processing method, device and equipment and a computer storage medium, relates to the technical field of image processing, and is used for improving the integrating degree and reality sense of adding hair to a human face. The method comprises the steps of acquiring a plurality of mask pictures corresponding to a target hair style, wherein the mask pictures correspond to different postures of a human face respectively, and each mask picture comprises a hair area mask; obtaining a human face picture, and determining a target mask picture matched with the human face posture in the human face picture from the plurality of mask pictures; and according to a hair region mask in the target mask picture, fusing the face picture and a target hair material picture toobtain a target synthesized picture.

Owner:TENCENT TECH (SHENZHEN) CO LTD

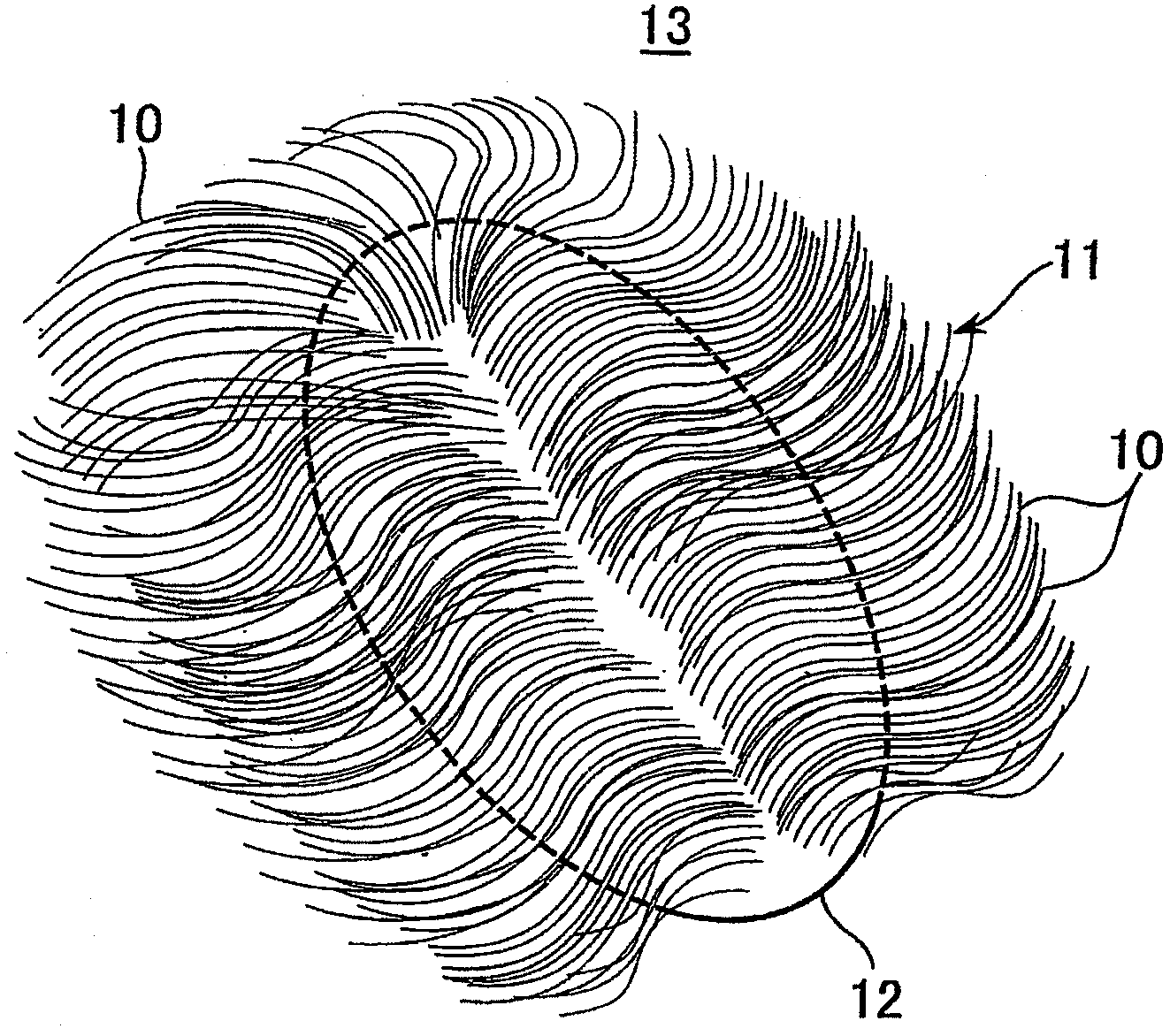

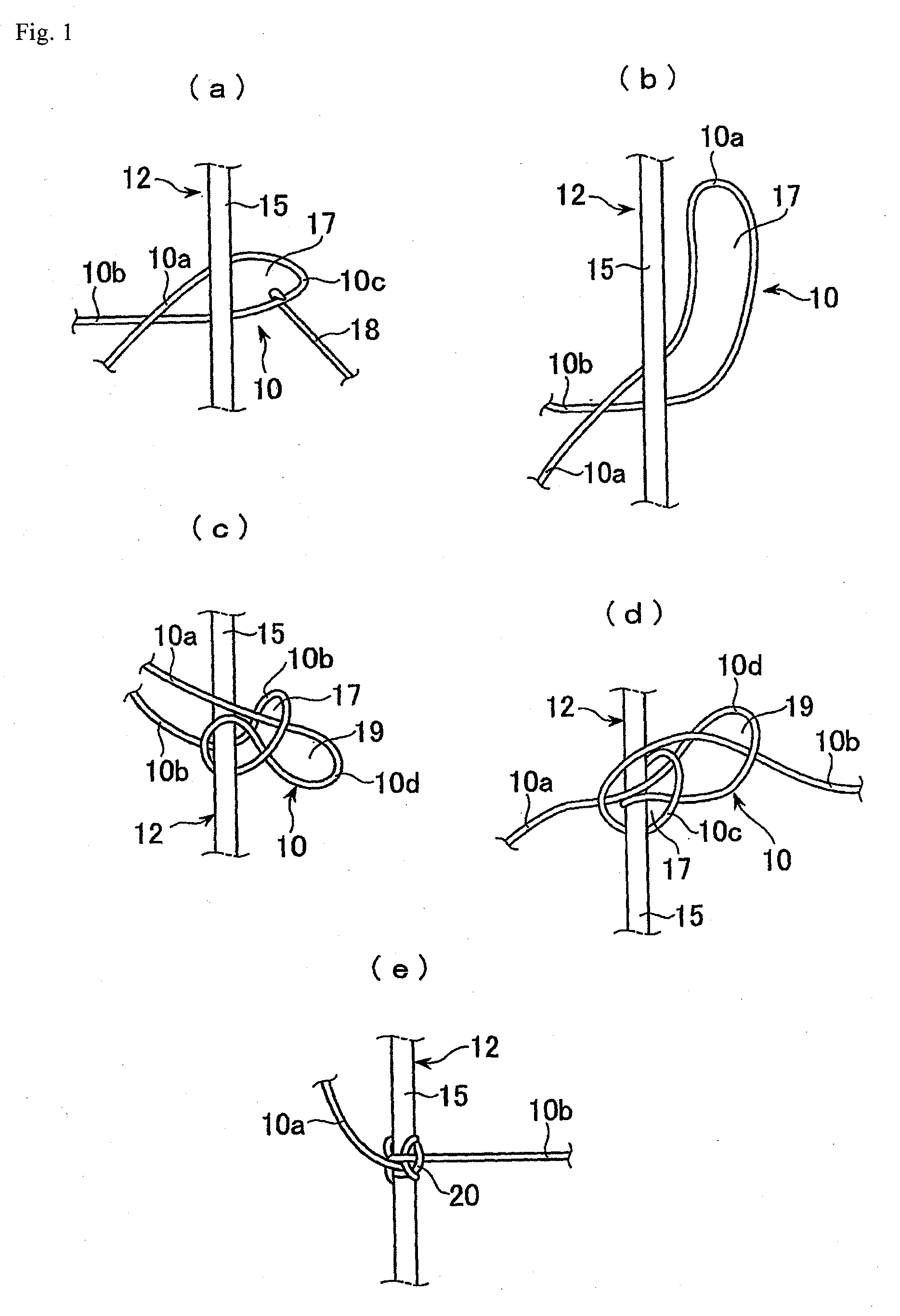

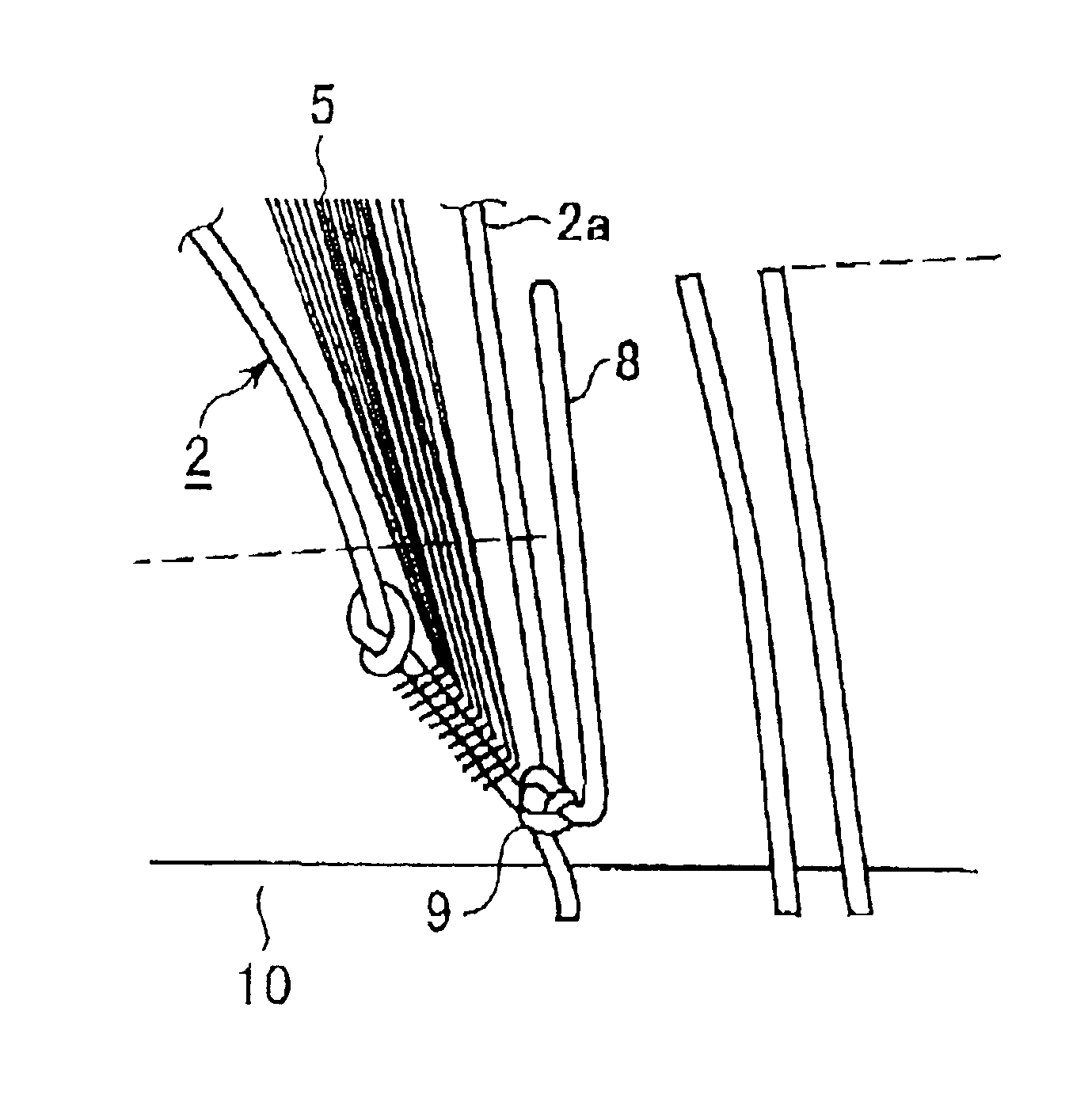

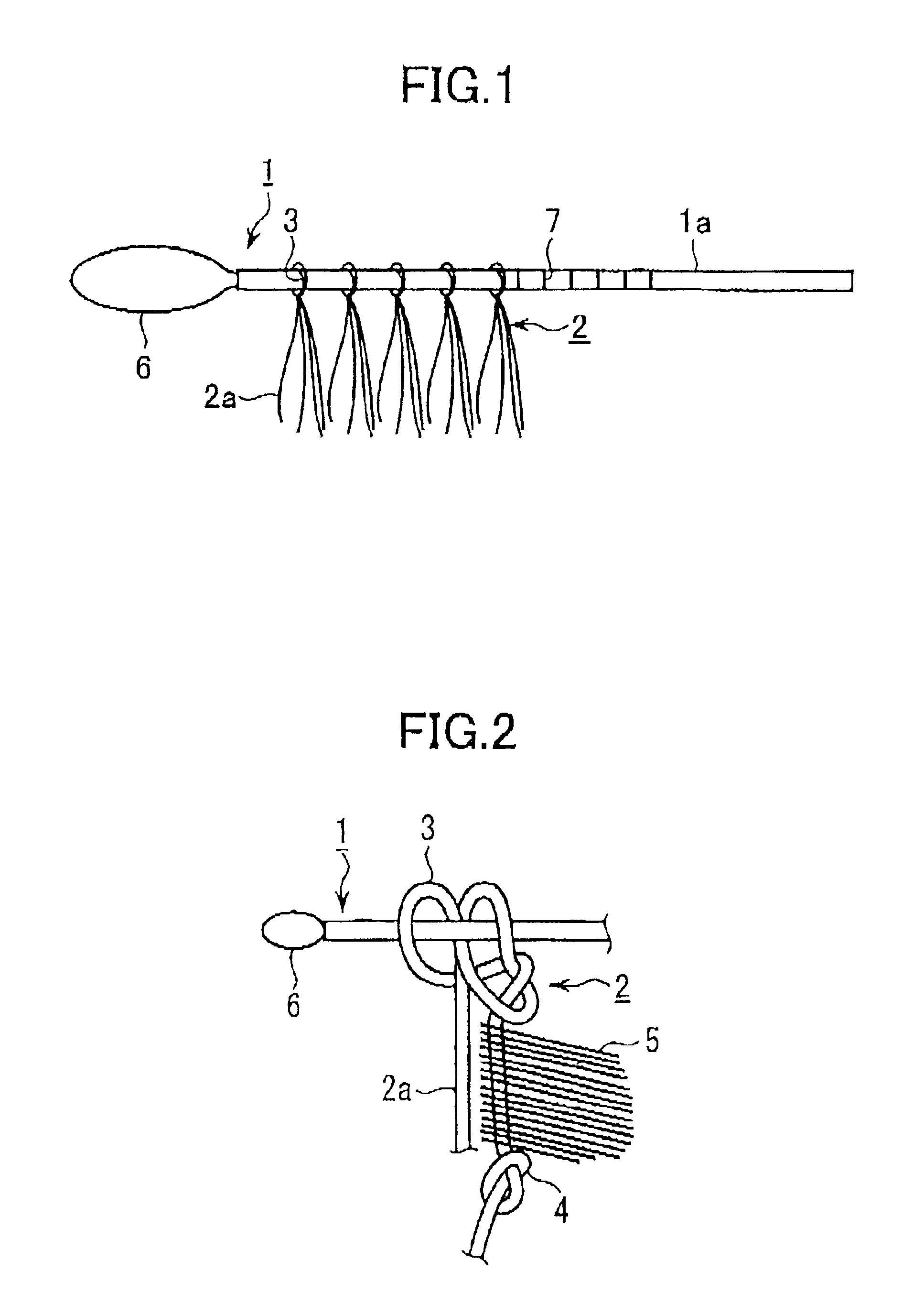

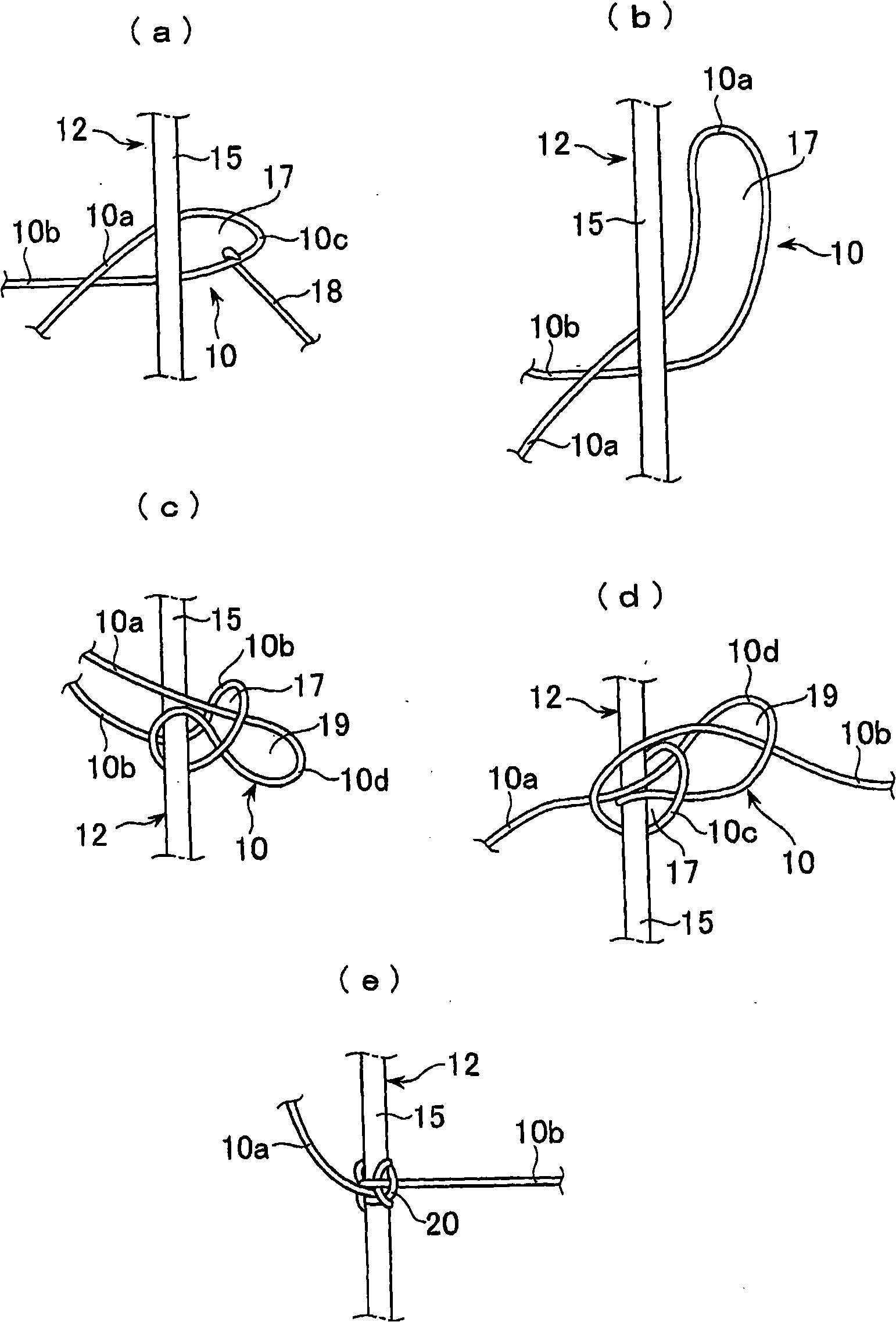

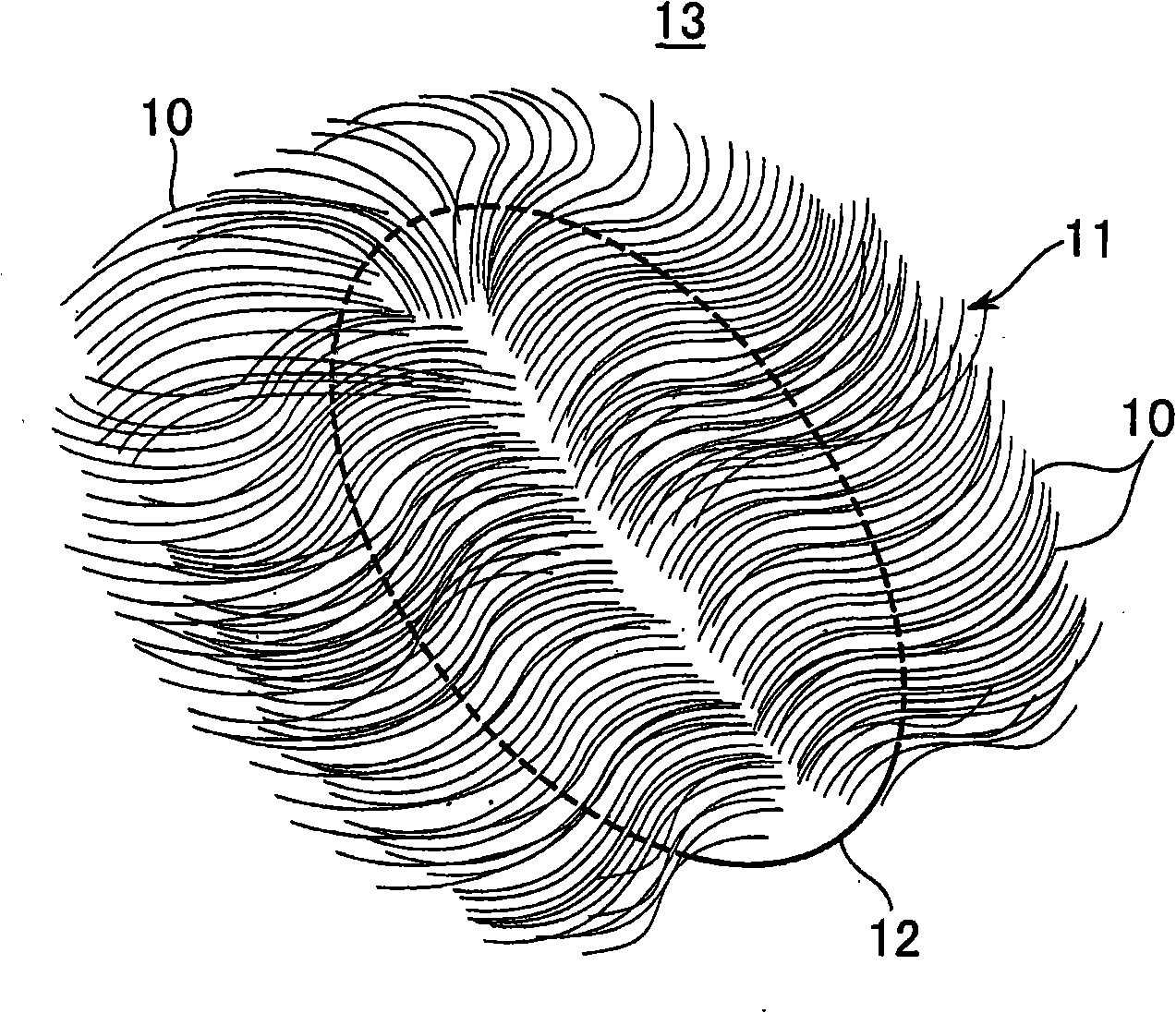

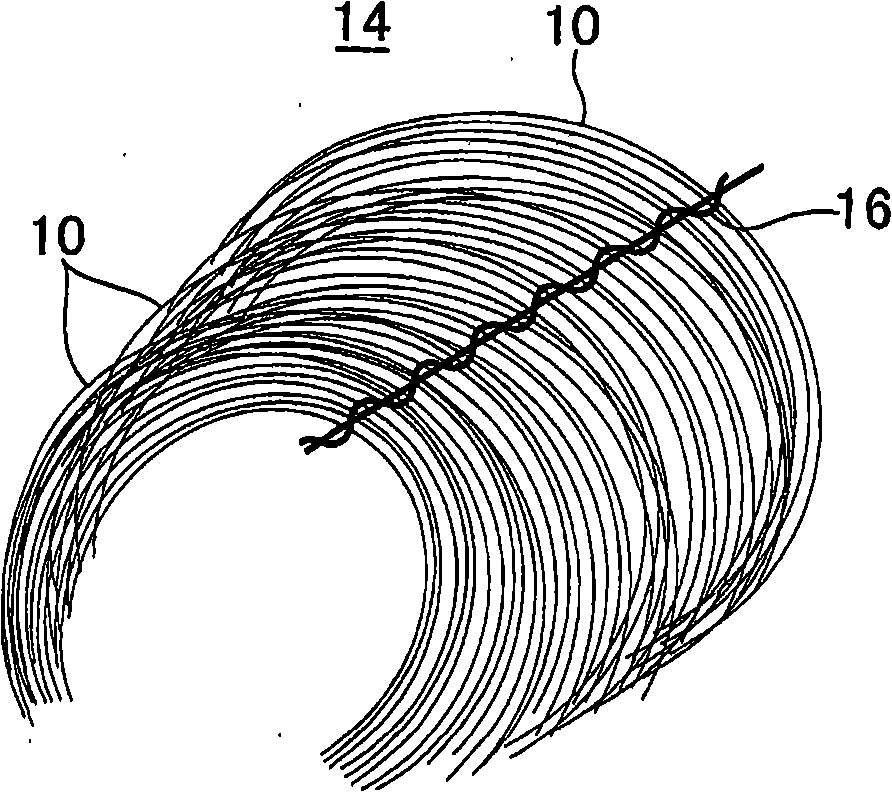

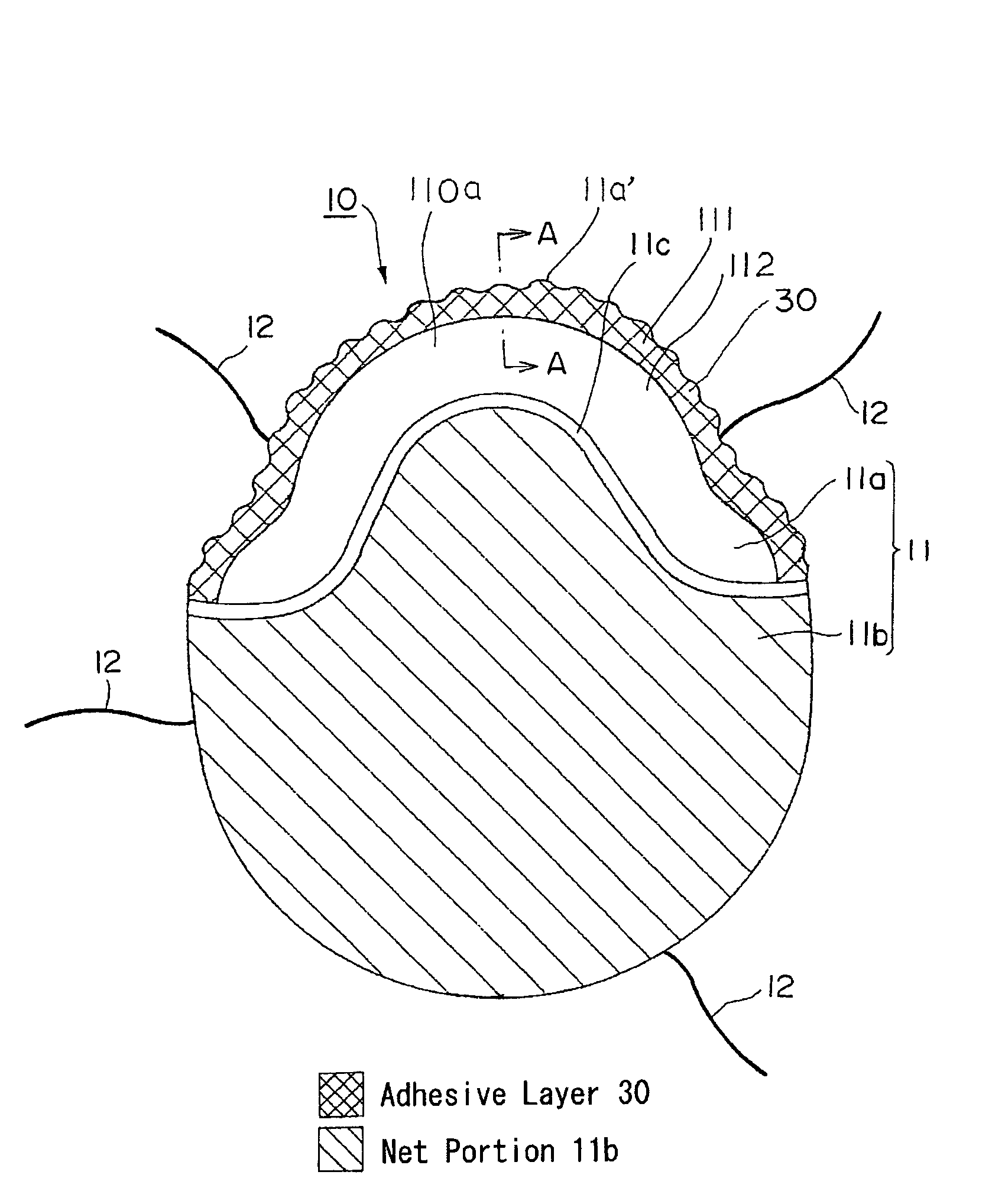

Wig

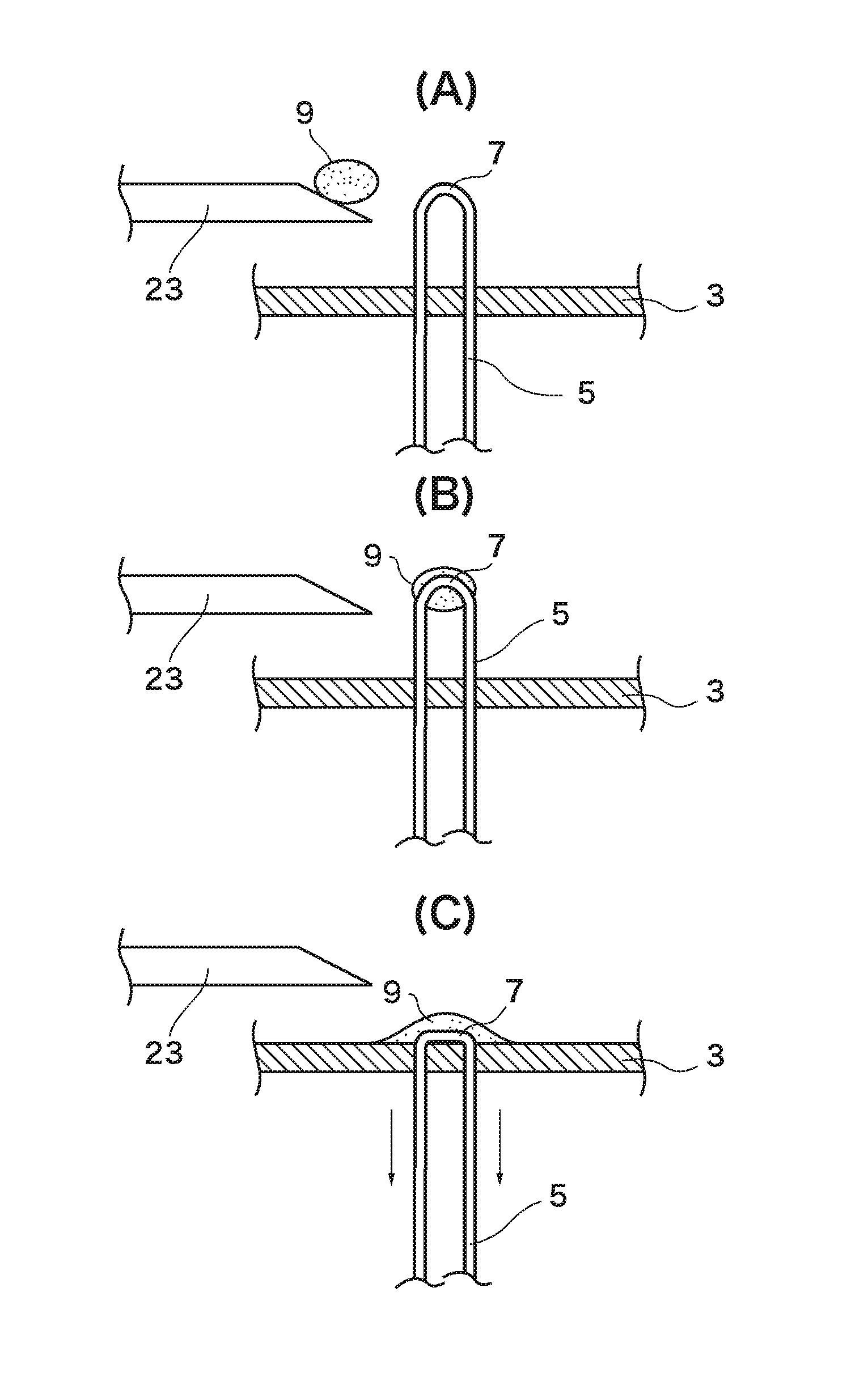

InactiveUS20090165810A1Easy to getIncrease freedomHair accessoriesToupeesMechanical engineeringHair - material

A hair material for a wig is preliminarily curled and then bound to a wig base to thereby orient the curled hair in a definite direction. A folded part (10c) of a hair material (10) is penetrated from one side of a filament (15) to the other side under a wig base (12) so that a first loop (17) is formed in the inner side of the folded part (10c). A curved part (10d) is inserted though the first loop (17) so that a second loop (19) is formed in the inner side of the curved part (10d). A part (10b) of the hair material is inserted through the second loop (19). Next, the hair material parts (10a, 10b) are pulled in directions opposite to each other and tied with the filament (15) to (20). Thus, the hair material (10) is bound to the filament (15).

Owner:ADERANS HLDG CO LTD

Iron wire automatic hair-twisting machine

The invention provides an iron wire automatic twisting machine. The machine comprises a machine frame, a hair distribution mechanism, a hair combination mechanism, an alignment mechanism, a hair-twisting mechanism, a hair-flying mechanism, a carrying mechanism, a rear section moving load, a punching mechanism, a middle-section outer cover, a squeeze mechanism and a scissor mechanism. The hair distribution mechanism distributes hair materials; the alignment mechanism sends iron wires and the iron wires are combined on the hair combination mechanism, and twisted by the twisting mechanism, and superfluous hair materials are flied off by the hair-flying mechanism; the squeeze mechanism sends handle samples to the rear section moving load; the carrying mechanism sends the semi-finished products to the rear section moving load for butt-joint; the semi-finished products are conveyed to the scissor mechanism by the rear section moving load and the superfluous iron wires are cut; finally, the semi-finished products are sent to the punching mechanism for molding to obtain finished products. The iron wire automatic twisting machine can be applied to the production process of multiple material assemblies; bulk materials are taken in the fixed position and twisted with the iron wires to achieve non-stop feeding, and the efficiency is many times than that of manual labor; the production workshop can be optimized. The iron wire automatic twisting machine can be applied to the specialized production of hair brushes made by four iron wires clipping with three layers of hairs.

Owner:HUNAN TENYUM INTELLIGENT EQUIP +1

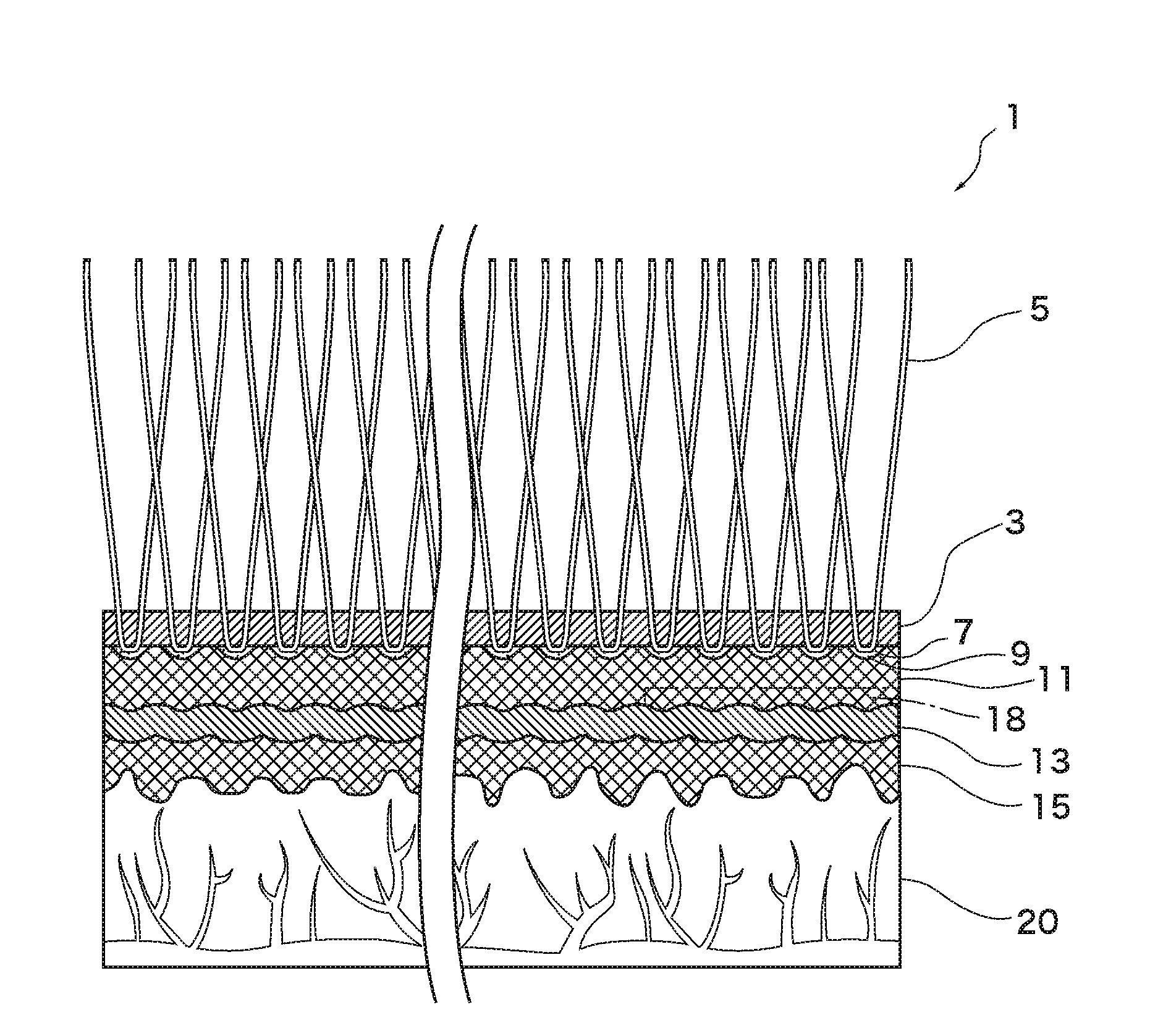

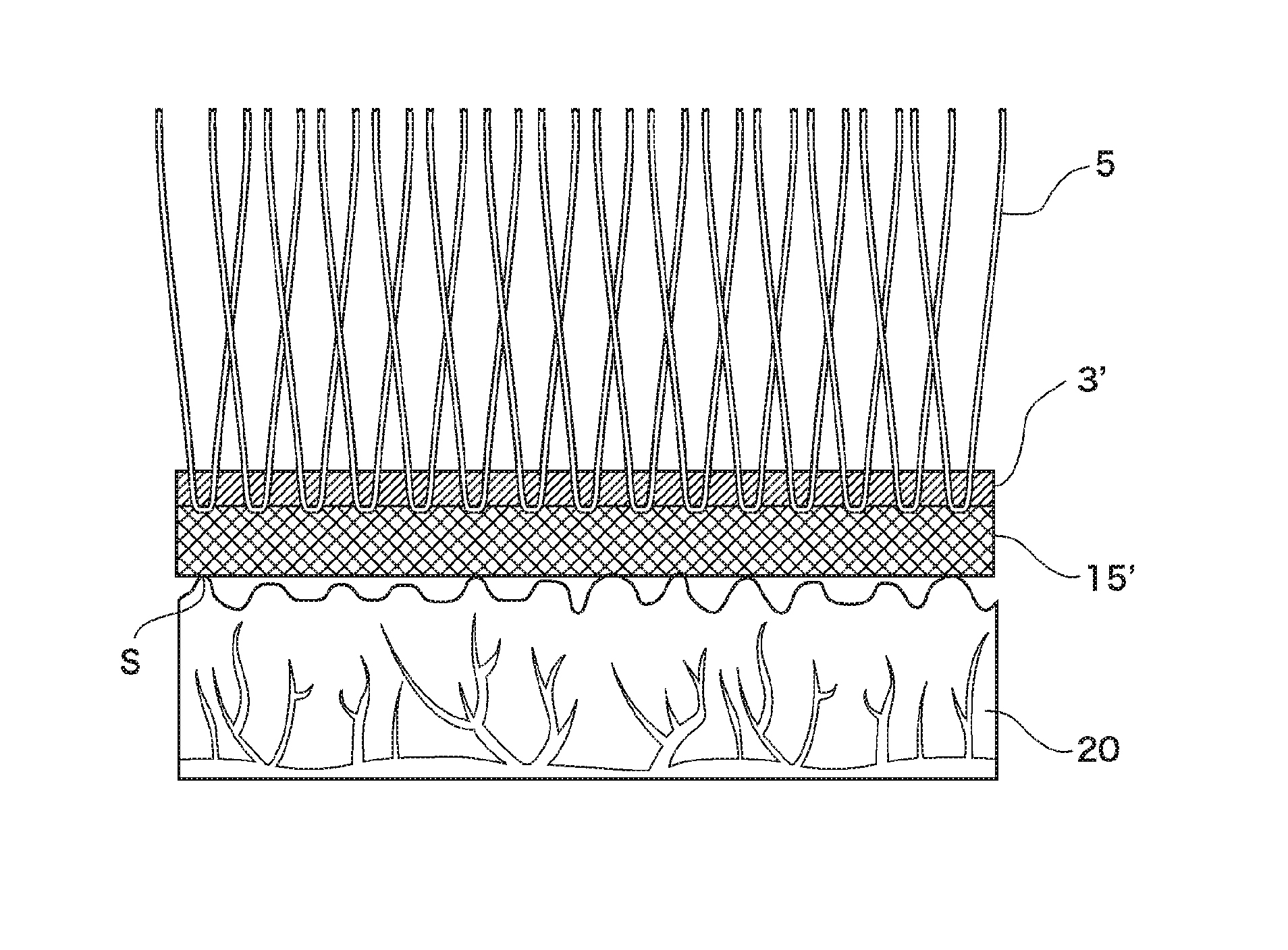

All-purpose wig, method for fitting wig, and customized wig

In order for reliable fitting by means of enabling a planar bond to the skin regardless of if a weak bonding agent is used, a base (3) comprises an ultrathin and moisture permeable film-shaped material. The base sections (7) that form the implanting base ends of hair materials (5) are provided adhered to one surface of the base. A first adhesion layer (11) comprises an adhesion agent having the properties of comparatively strong adhesion and a comparatively large degree of gelling. A second adhesion layer (15) comprises an adhesion agent having the properties of comparatively weak adhesion and a comparatively small degree of gelling. A tank layer (13) comprises the same film-shaped material as the base. The first adhesion layer and the second adhesion layer are provided adjacent to each other with the tank layer therebetween. A first release layer (17) is attached peelably to the whole surface of the second adhesion layer on the side that is fit to the skin, and a second release layer (18) is applied peelably to the first adhesion layer and is layered on a portion of the surface between the abovementioned first adhesion layer and the abovementioned tank layer. The aforementioned layers are layered in order, forming a flat surface.

Owner:PROPIA CO LTD

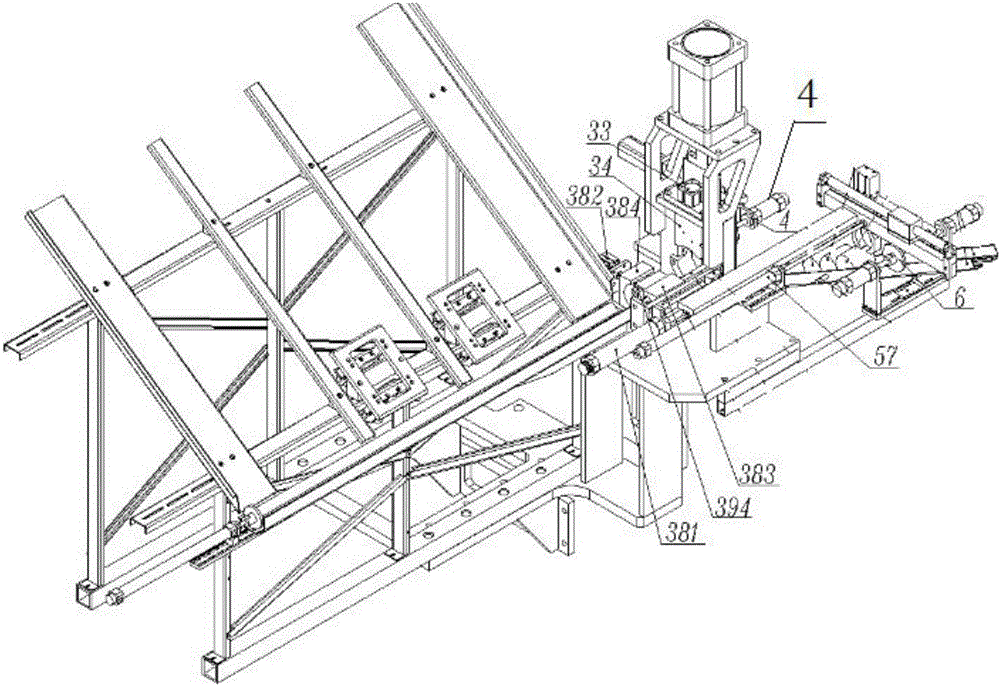

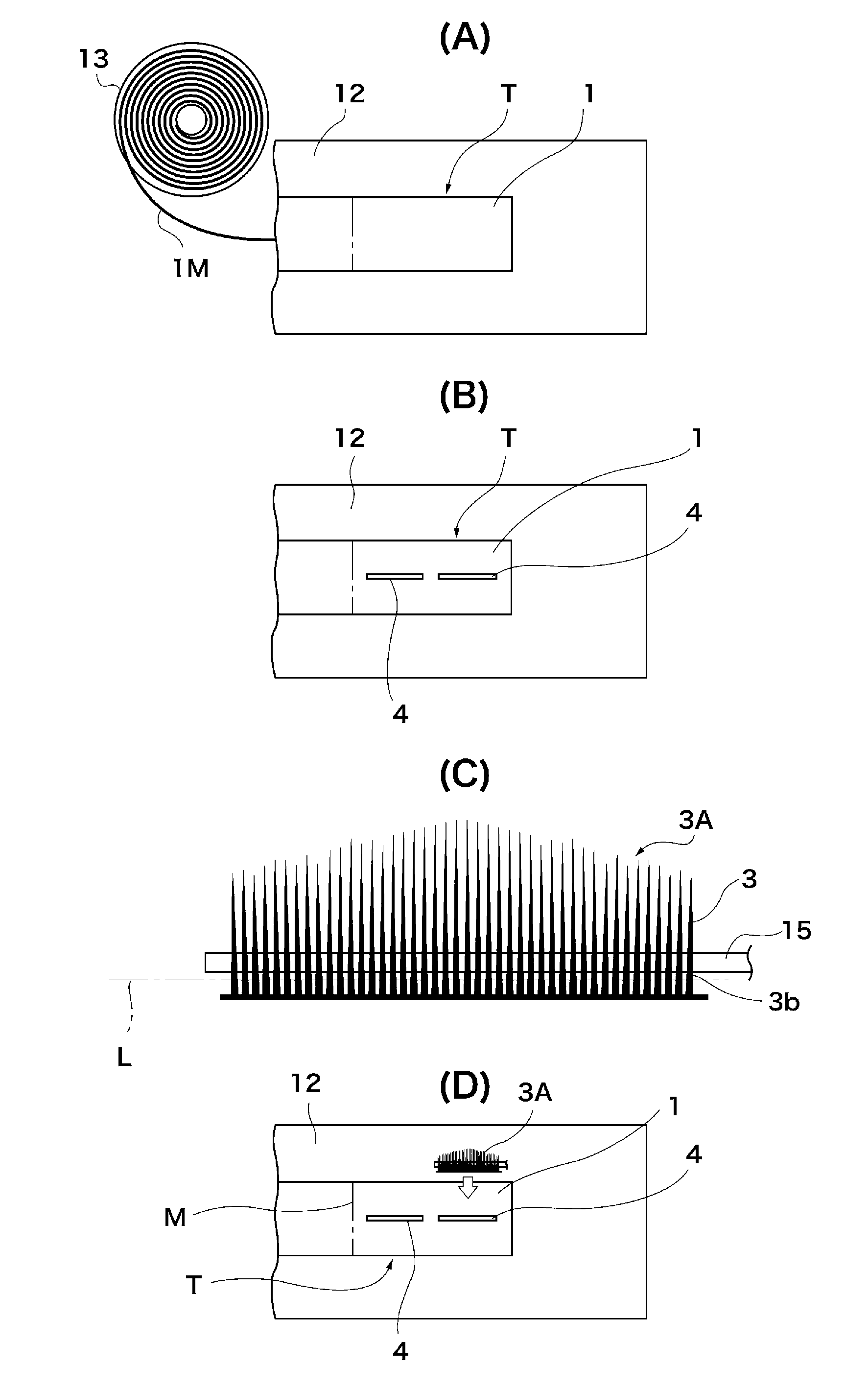

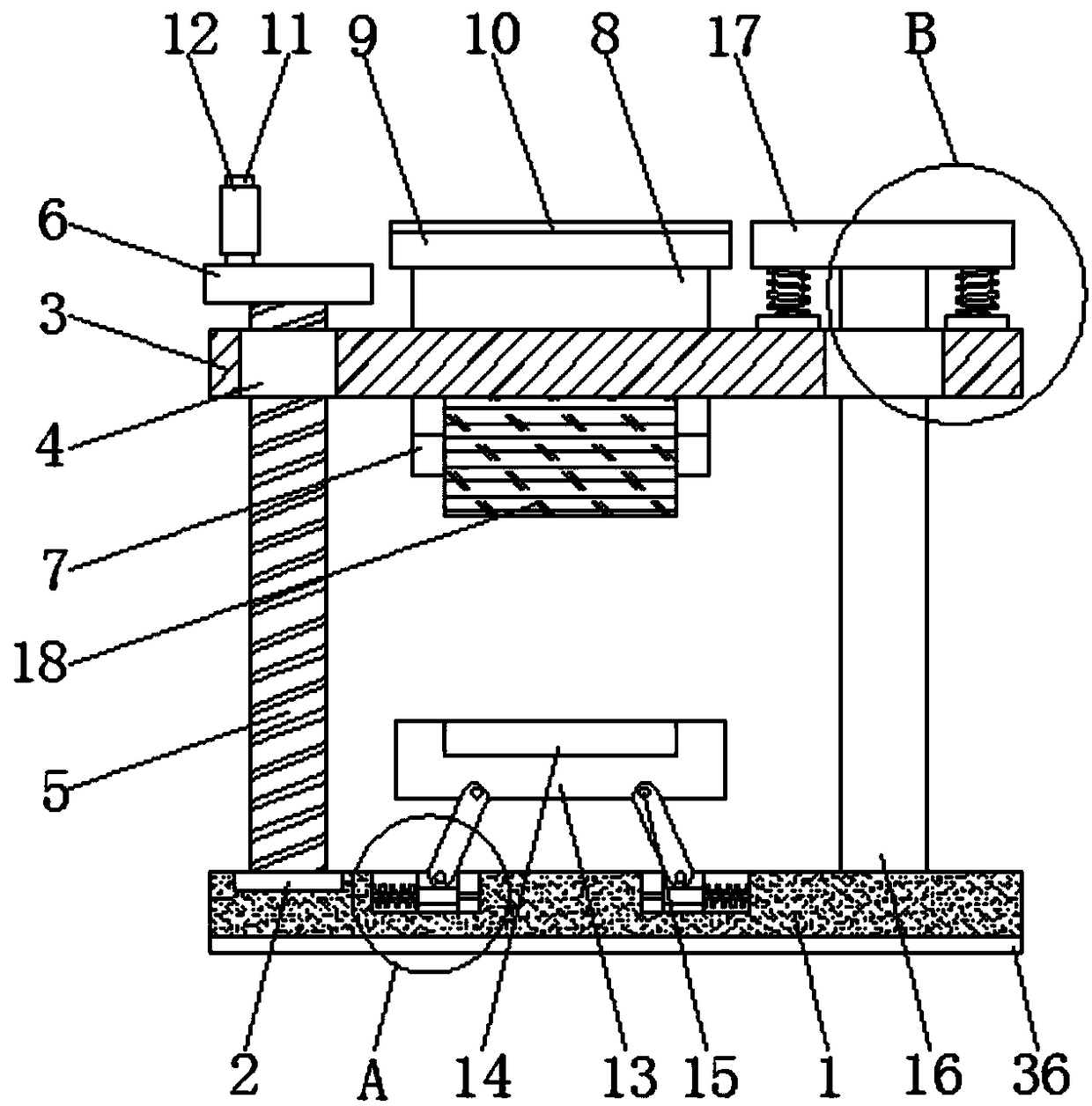

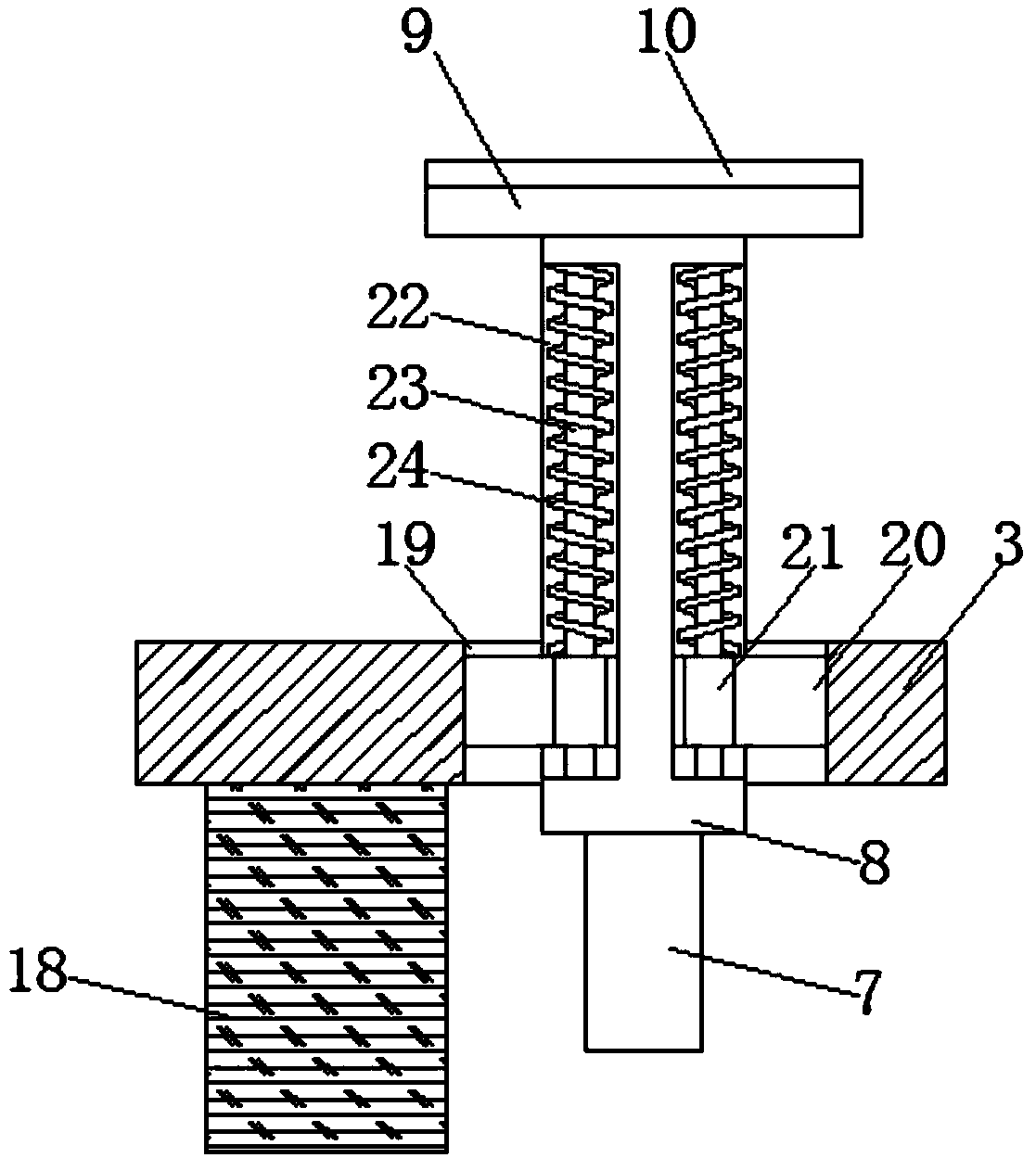

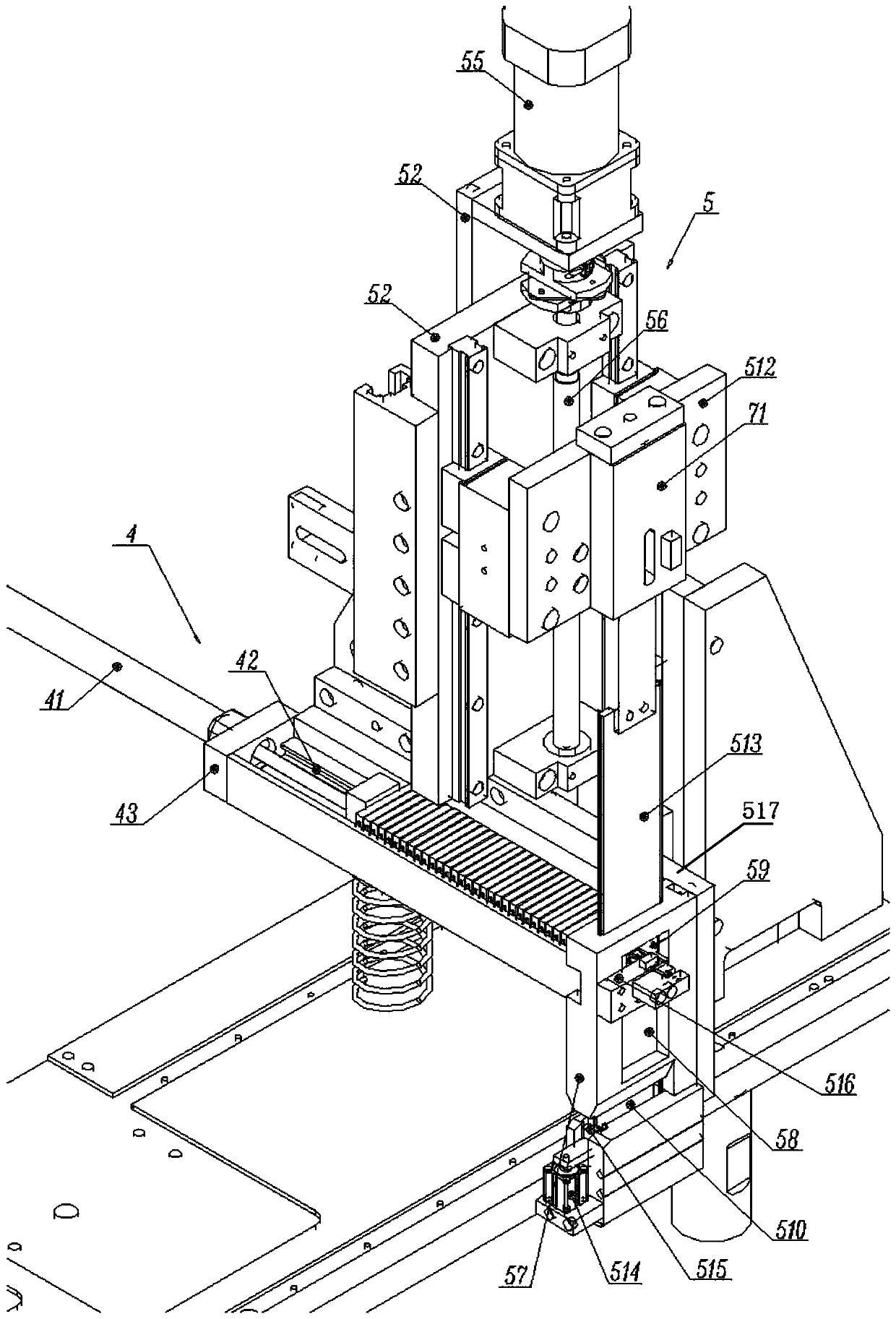

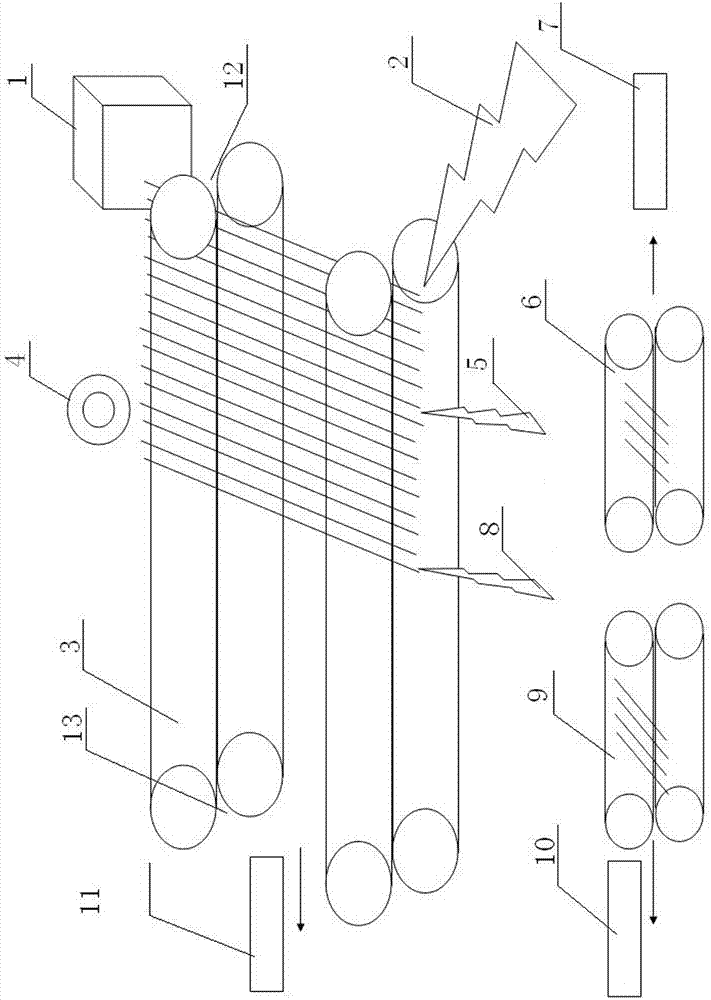

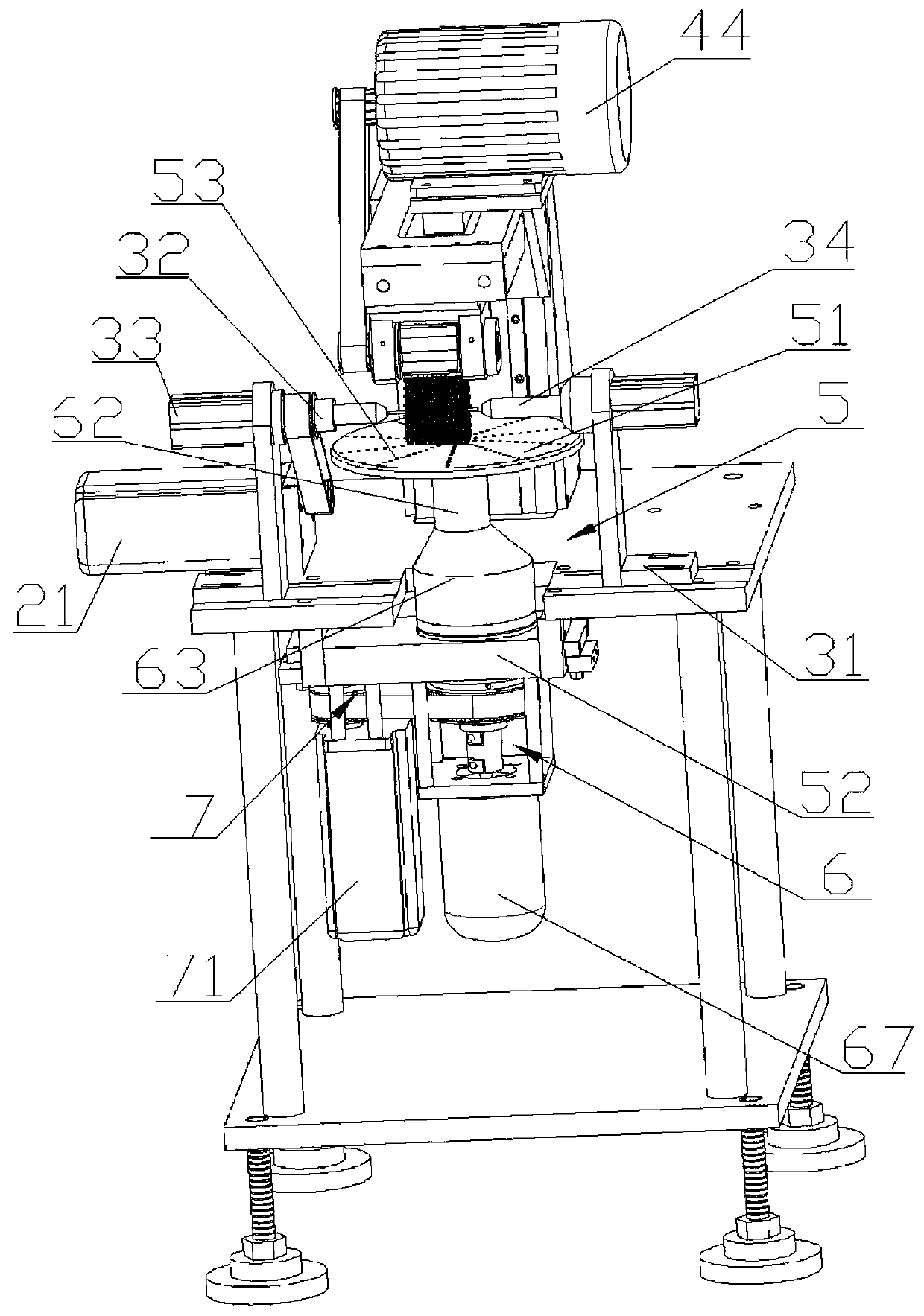

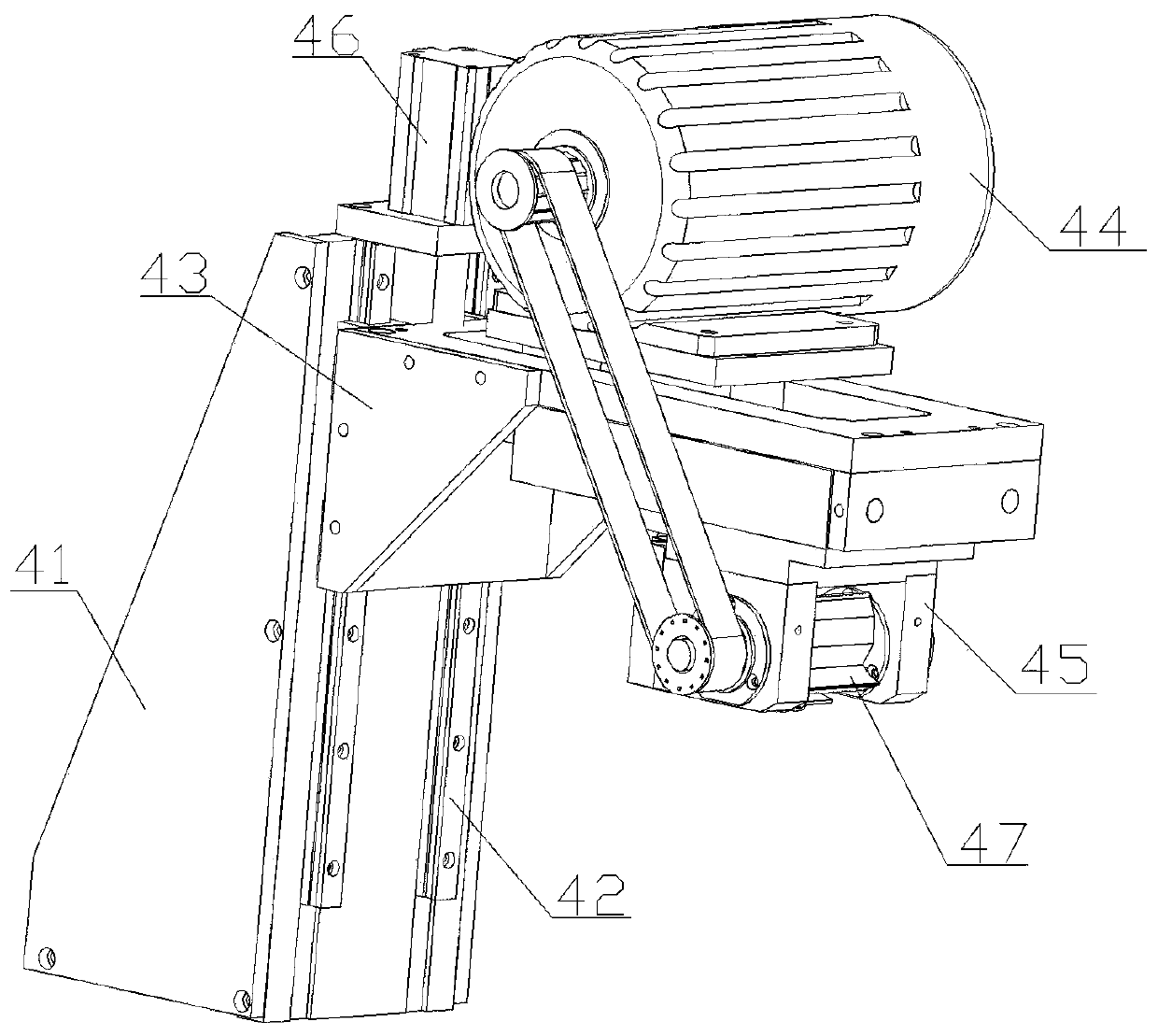

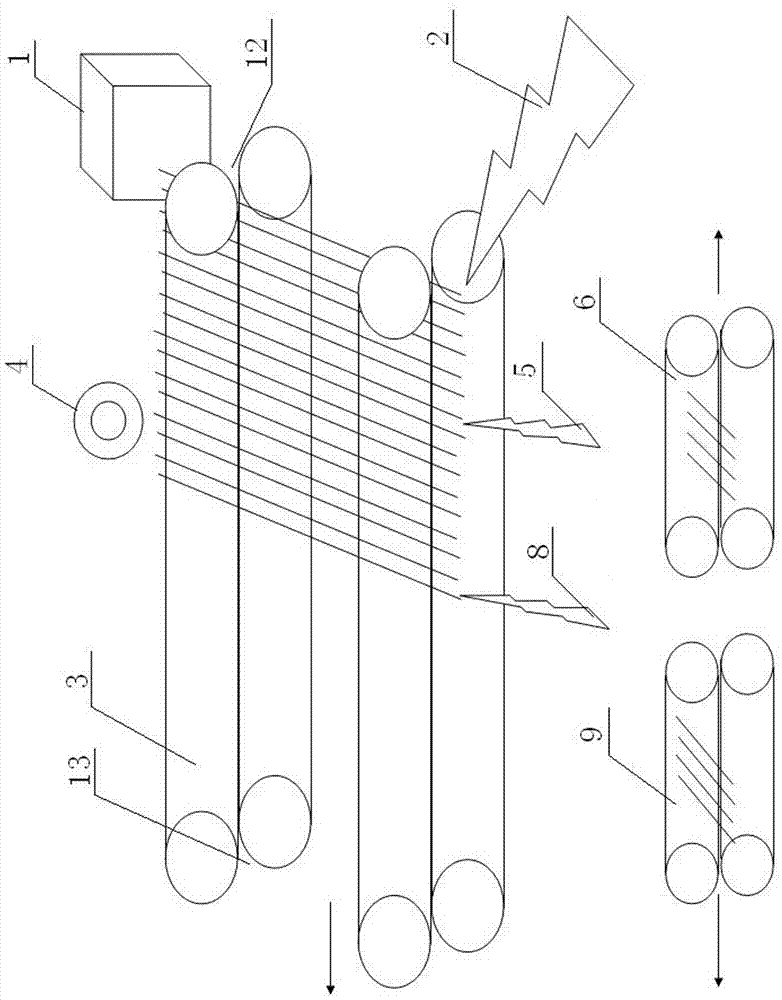

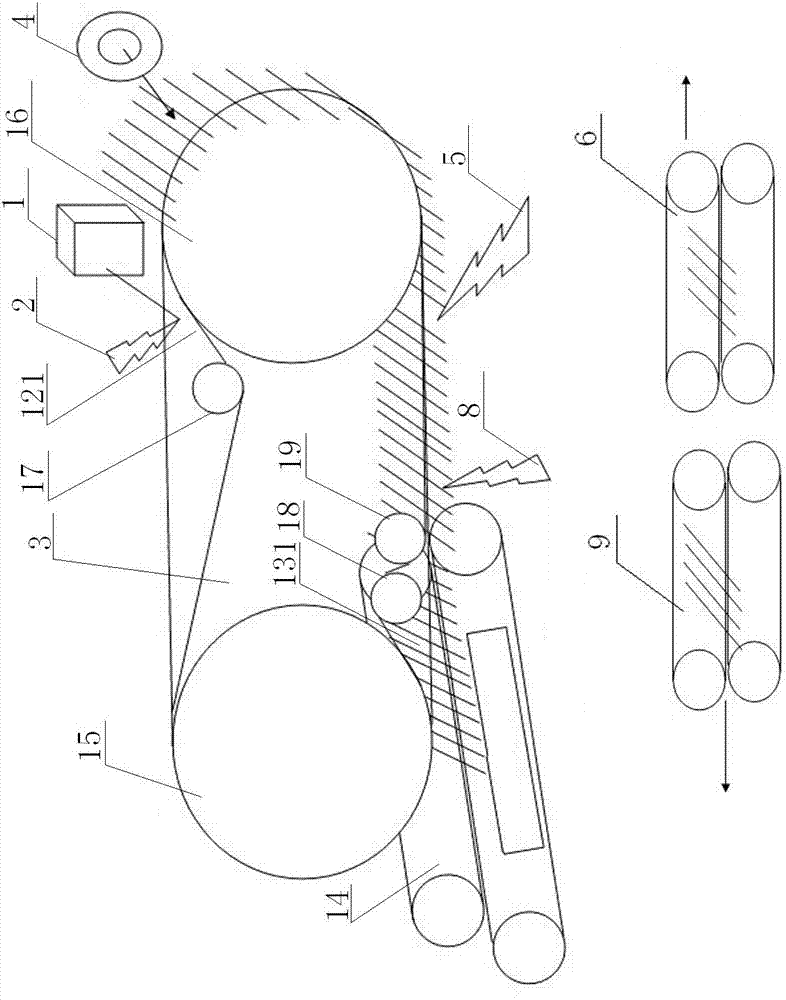

Full-automatic photo-electro-mechanical integrated numerical control hairbrush hair cutting method and hair cutting device

ActiveCN105919278AReduce defective rateReduce scrap rateBrush bodiesBristleNumerical controlEngineering

The invention discloses a full-automatic photo-electro-mechanical integrated numerical control hairbrush hair cutting method, and relates to a method for cutting hair of an hairbrush. The method comprises the following steps: stopping an hair material on an hair material rack, and sequentially loosening the hair material by virtue of a hair separating mechanism and a hair releasing mechanism, so that the hair material slips into a hair material groove; pushing the top end of the hair material to a hair cutting movable knife edge by virtue of a hair pushing mechanism, and cutting off the top end of the hair material by virtue of a hair cutting movable knife; and moving a hair baffle plate to the front side of the hair cutting movable knife edge, pushing the hair material by virtue of the hair pushing mechanism so that the hair material continuously moves towards a hair cutting mechanism until the hair material gets into contact with the hair baffle plate, moving hair clamping jaws to be above the hair material so as to clamp the hair material, cutting the hair material by virtue of the hair cutting movable knife once again, leading the first section of the hair material into a hair beating groove by virtue of a hair clamping mechanism, and beating two ends of the first section of the hair materials by virtue of a hair beating plate until two ends are regular. The invention also relates to a hair cutting device which is capable of achieving the full-automatic photo-electro-mechanical integrated numerical control hairbrush hair cutting method.

Owner:HUBEI C P NC MACHINERY

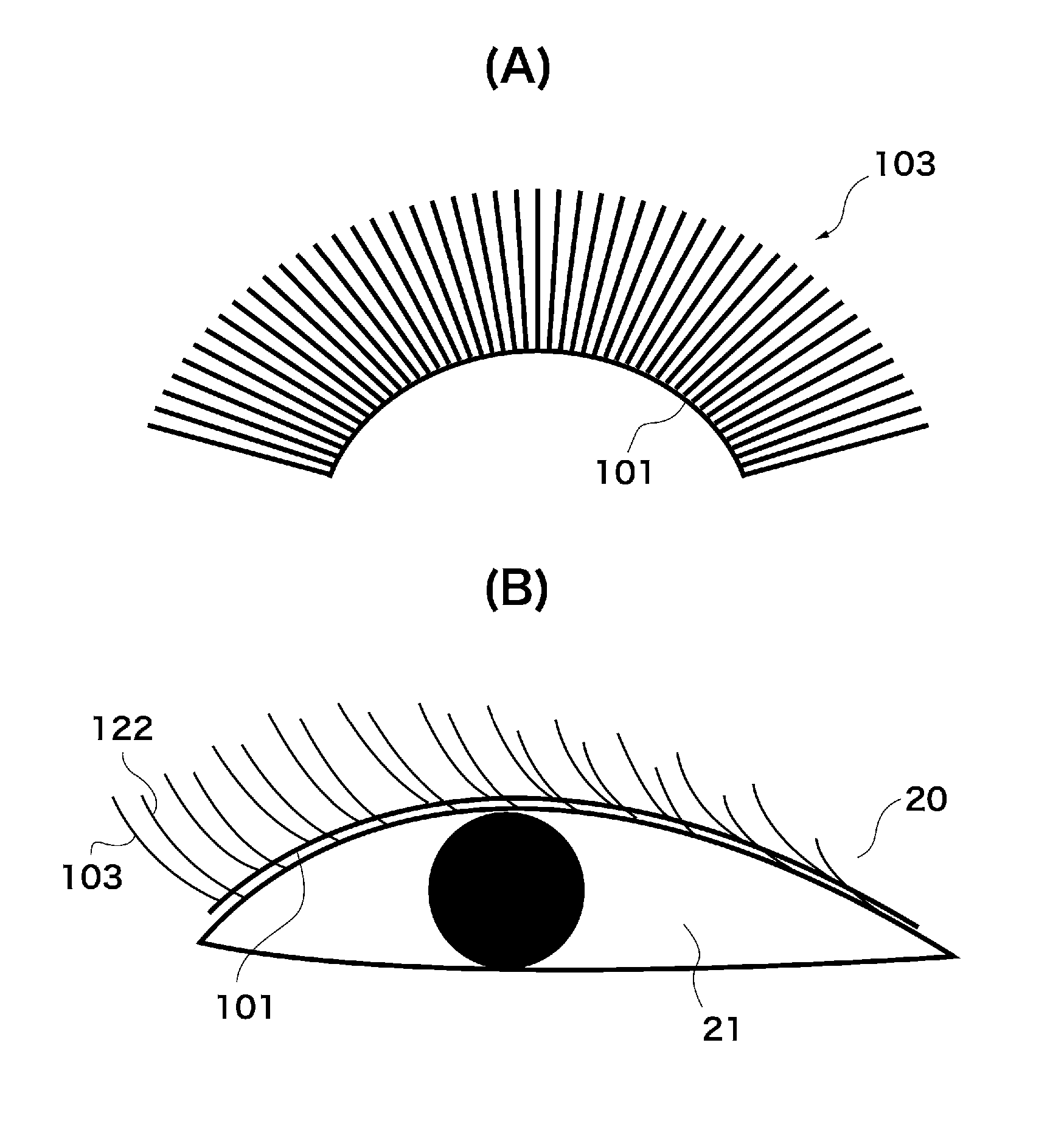

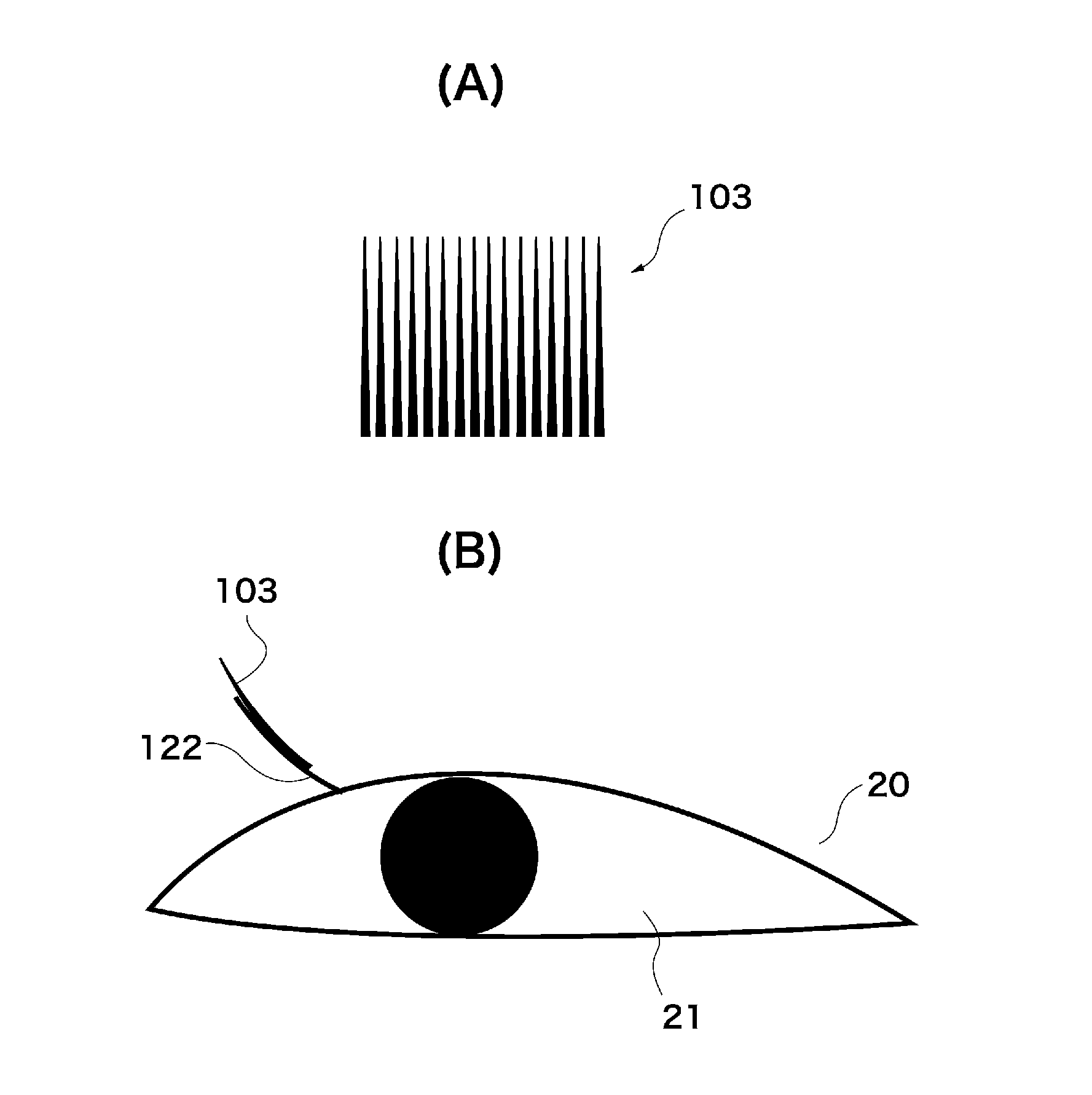

False eyelashes

Owner:PROPIA CO LTD

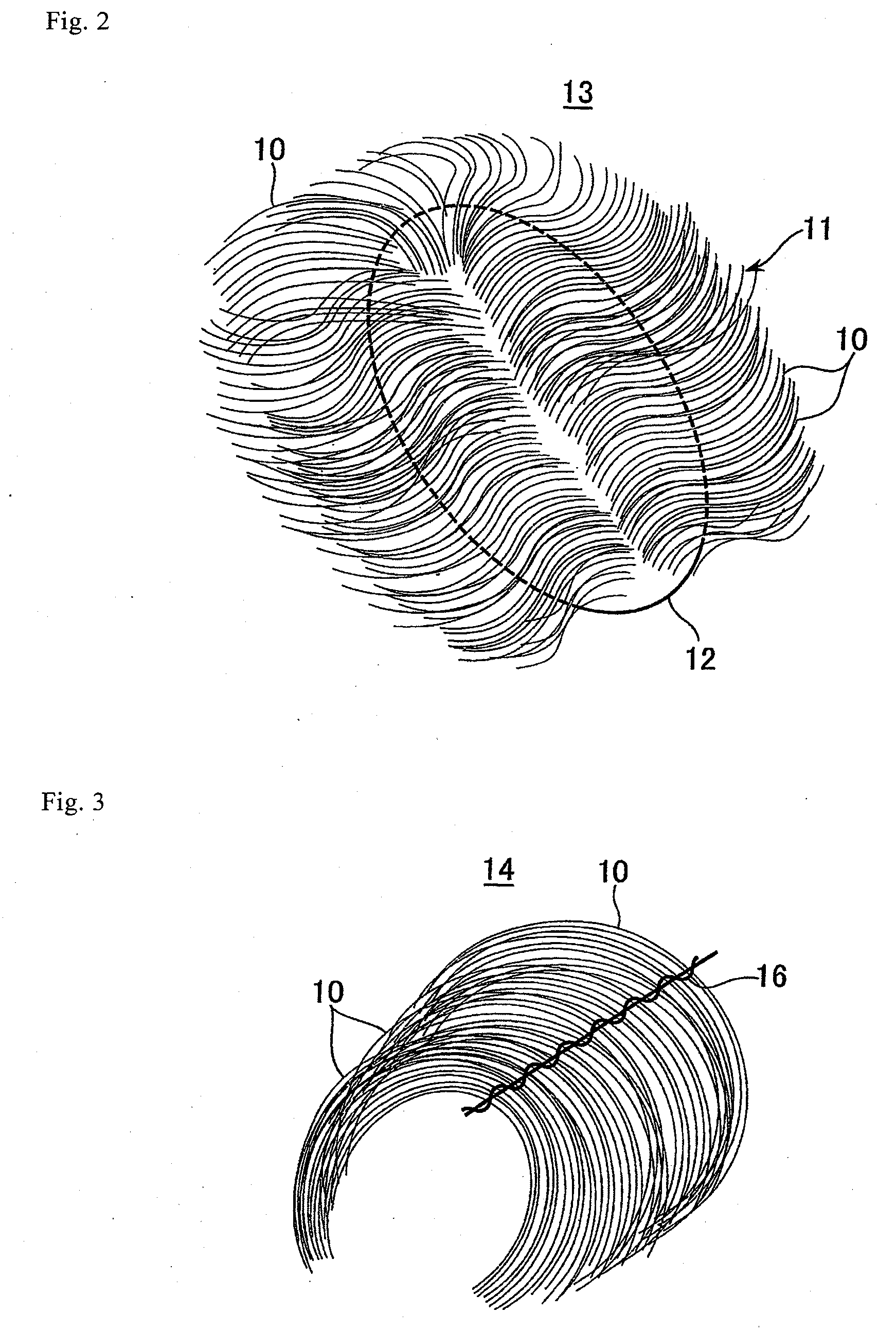

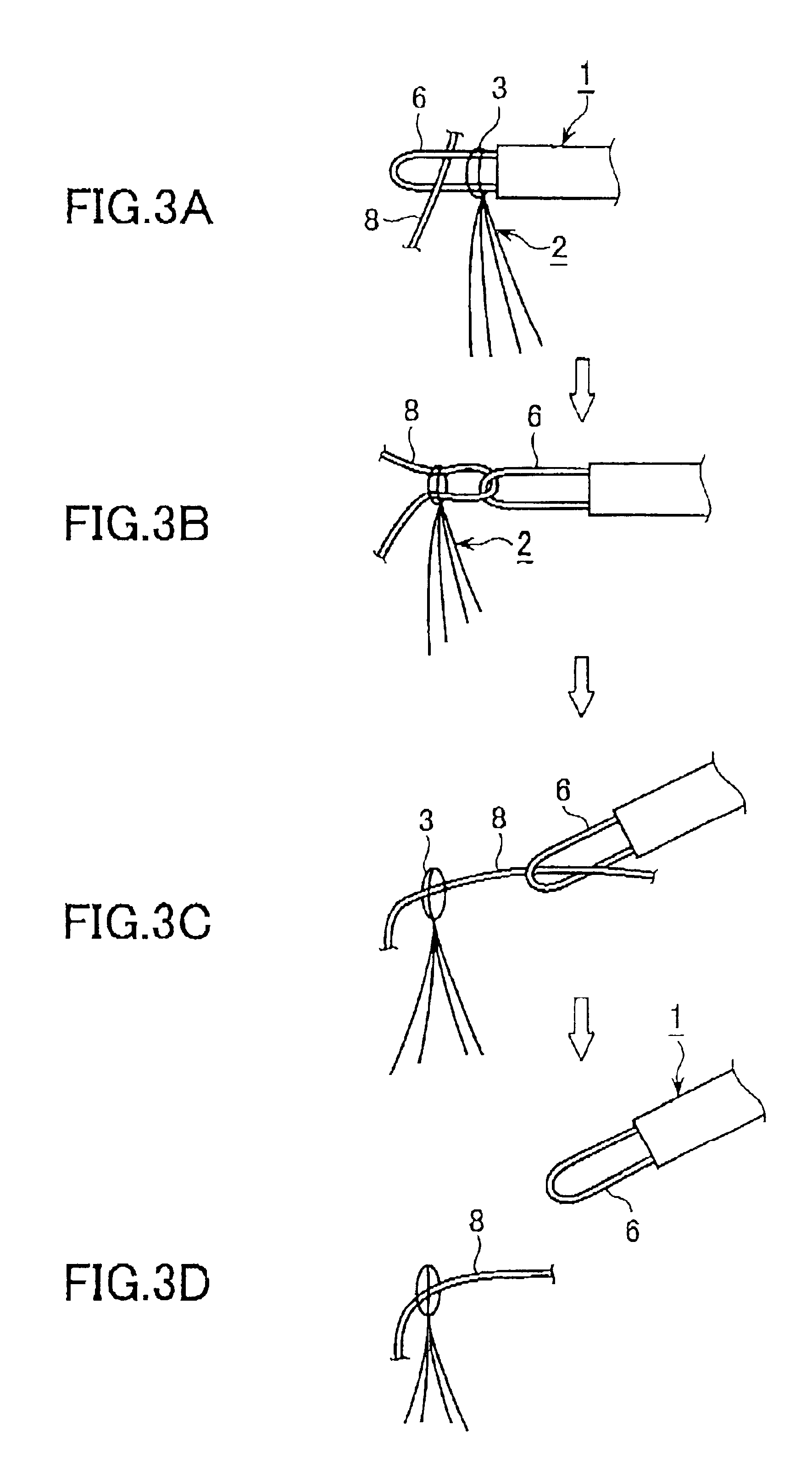

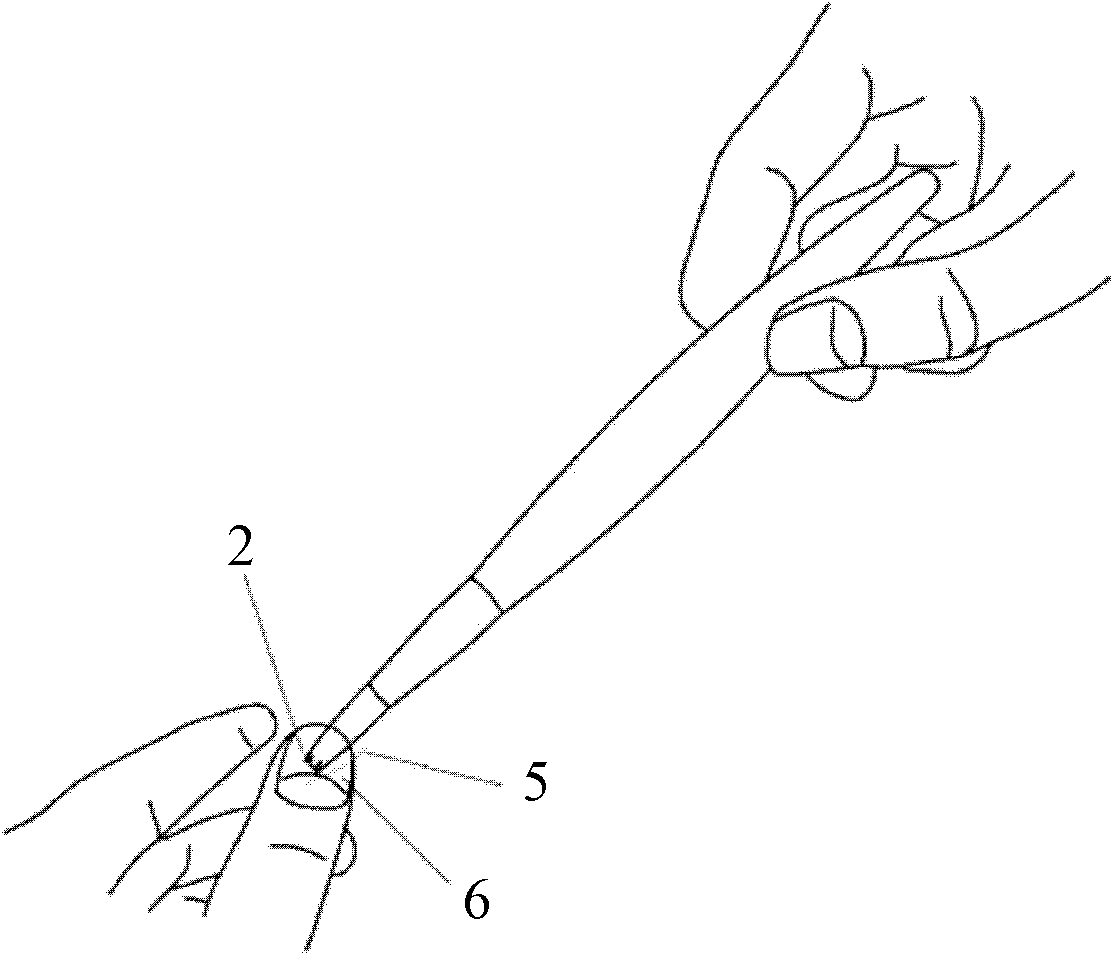

Artificial hair material, hair restoring apparatus, and hair restoring method

An artificial hair restorer has a trunk hair with plural restoring hairs fixed to certain points of the trunk hair. A loop formed by folding one or two trunk hair(s) in two, and the original hair(s) passes(pass) through the loop. A knot is provided close to the tying end of the restoring hairs but opposite to the loop. A hair restoring method comprises inserting one or more original hair(s) into the loop of the trunk hair, and then fixing the trunk hair to a point in the vicinity of the original hair root.

Owner:ADERANS HLDG CO LTD

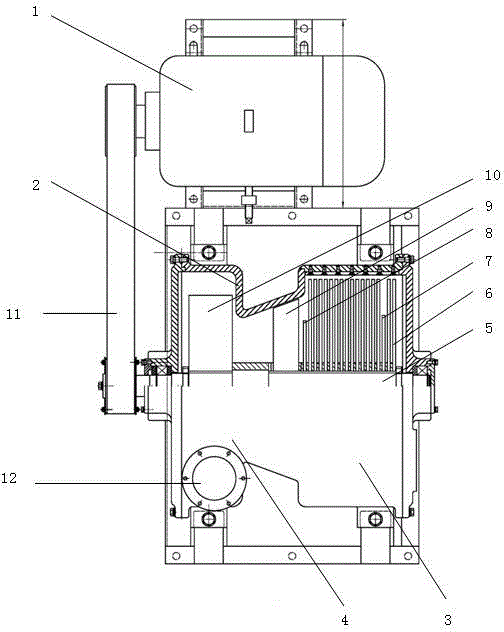

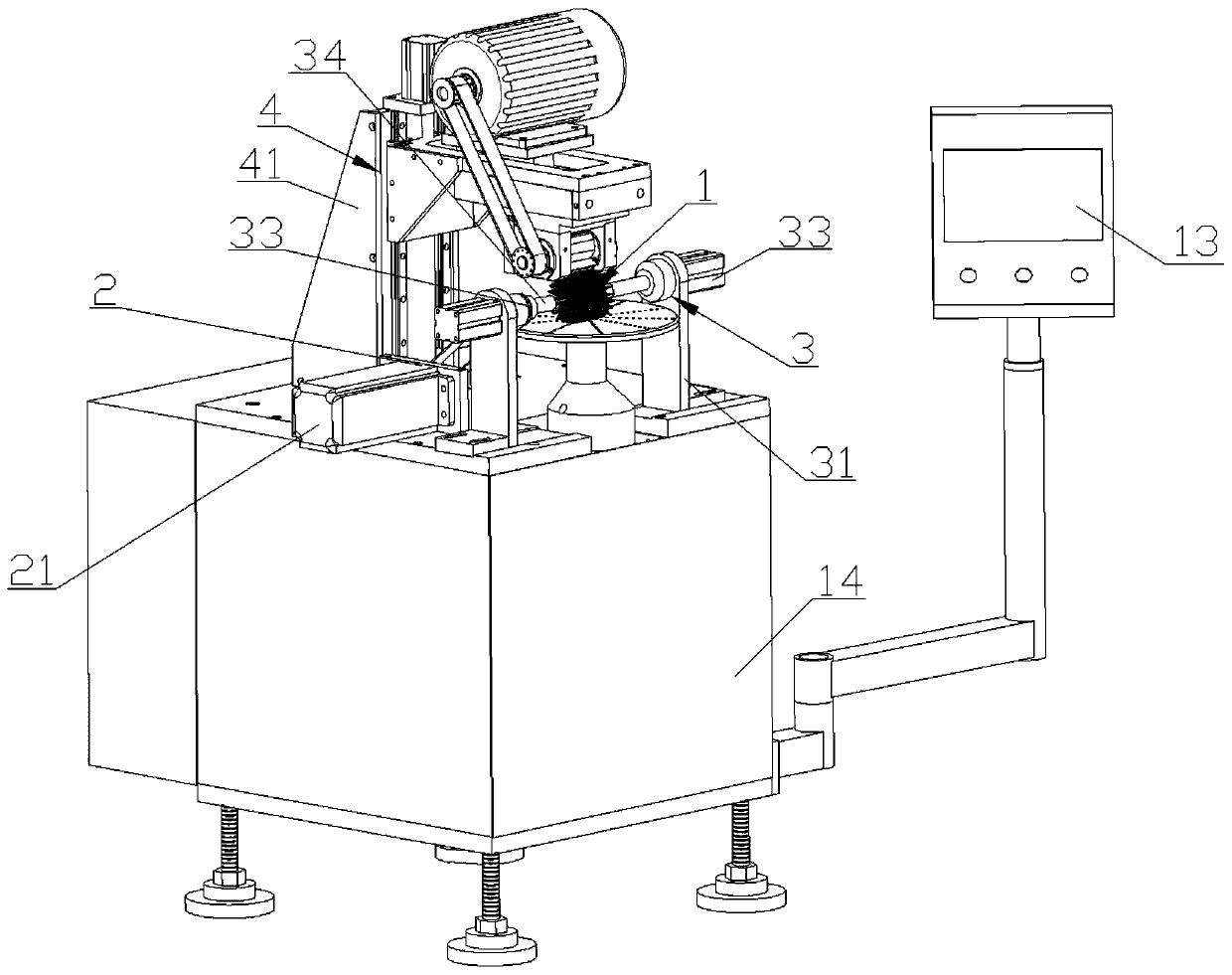

Hair grinding machine

The invention provides a hair grinding machine, which integrates loosening, grinding and grading of the hair materials and can grind the hairs such as wools into nano-level powders by one time in a high-efficiency and continuous manner. The technical scheme of the hair grinding machine is as follows: the hair grinding machine comprises a driving motor, a fixed base and a machine body, wherein the machine body is internally provided with a grinding cavity and is also provided with a grading cavity; the grinding cavity is internally provided with a grinding device; the grinding device comprises knocking blades, a poking blade, an air uniformizing blade and a scraper component which are connected on a transmission shaft; one end of the side surface of the grinding cavity is provided with a feeding port; one end of a discharging port is connected with the grading cavity; and the grinding device is fixed on the transmission shaft in the grinding cavity. The hair grinding machine provided by the invention has the advantages that grading blades are adopted for grading the materials, and another grading machine does not need to be arranged, so that the working efficiency is improved; and a deeply-cold air source is adopted as a cold source, and the cold air directly enters from the lower side of the cavity of the grinding machine, so that the materials boil up and down in the grinding cavity, and multi-time and effective shearing is formed for the materials.

Owner:河南鼎大生物科技有限公司

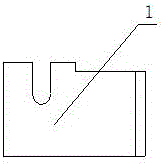

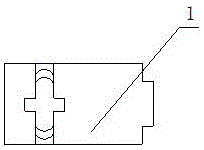

One-hole double-color toothbrush hair planting machine

ActiveCN105852400AChange structureChange positional relationshipBrush bodiesEngineeringHair - material

The invention relates to a hair planting machine, in particular to a one-hole double-color toothbrush hair planting machine, and aims at providing a one-hole double-color toothbrush hair planting machine which can plant a hair material with a first color in the middle of a hair planting hole and wrap a hair material with a second color at the periphery of the hair material with the first color. A hair bucket comprises a hair flatting bucket element, a hair bucket element with a guide hair mouth and a connecting element, the hair flatting bucket element and the hair bucked element with the guide hair mouth are fixed to the same end face of the connecting element, the hair flatting bucket element is located on the hair bucket element with the guide hair mouth, the center line of a hair planting hole of the hair flatting bucket element coincides with that of a hair planting hole of the hair bucket element, the hair planting hole of the hair bucket element is larger than that of the hair flatting bucket element, a guide channel for feeding hair is formed between the hair flatting bucket element and the hair bucket element and stops at the upper end opening of the hair planting hole of the hair bucket element with the guide hair mouth, and the two sides of the hair bucket are each provided with a hair feeding mechanism and the like. The one-hole double-color toothbrush hair planting machine has the advantages of being reasonable in design, convenient to use and the like.

Owner:TONGXIANG XINGSHENG BRUSH MACHINERY

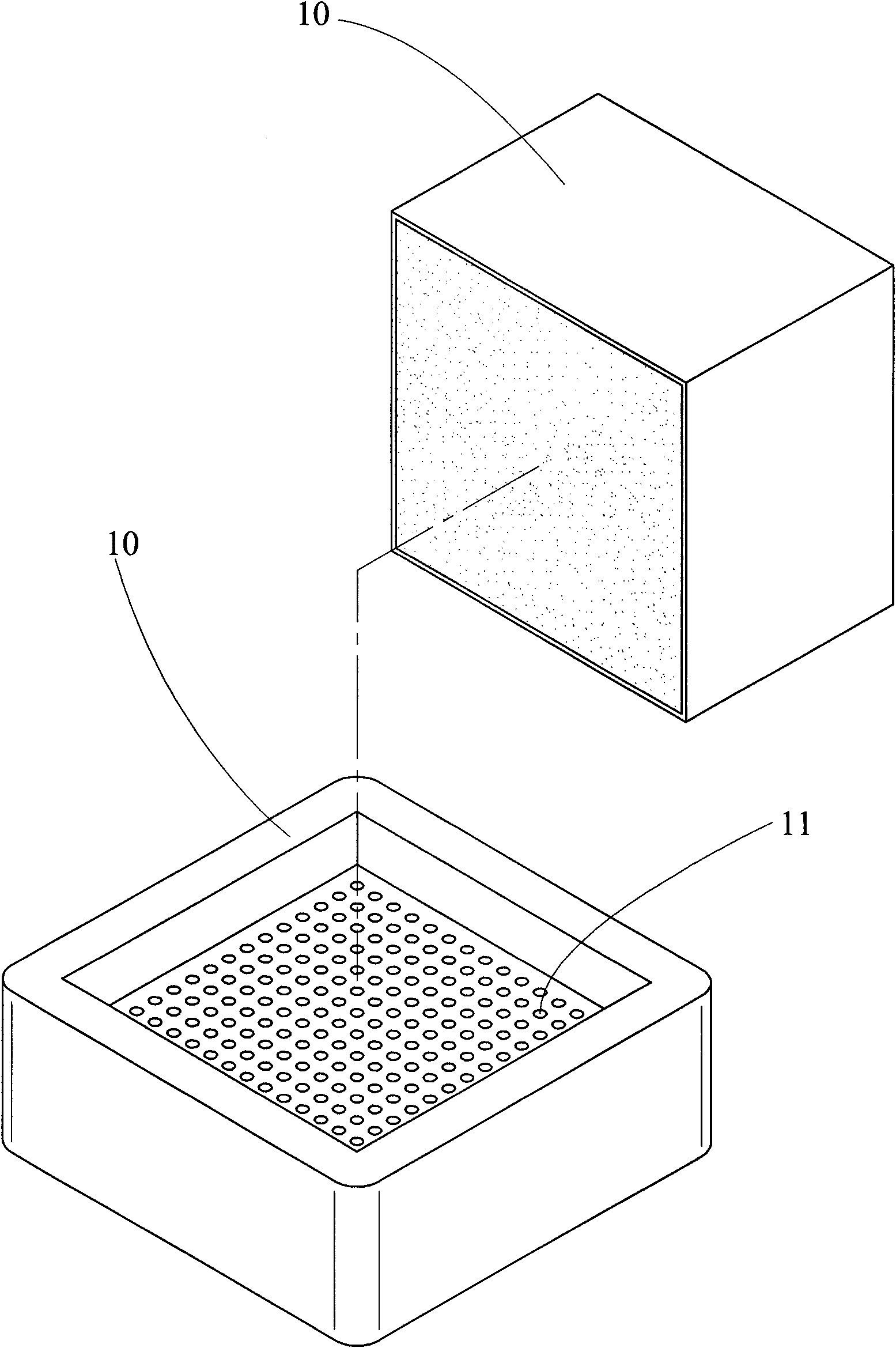

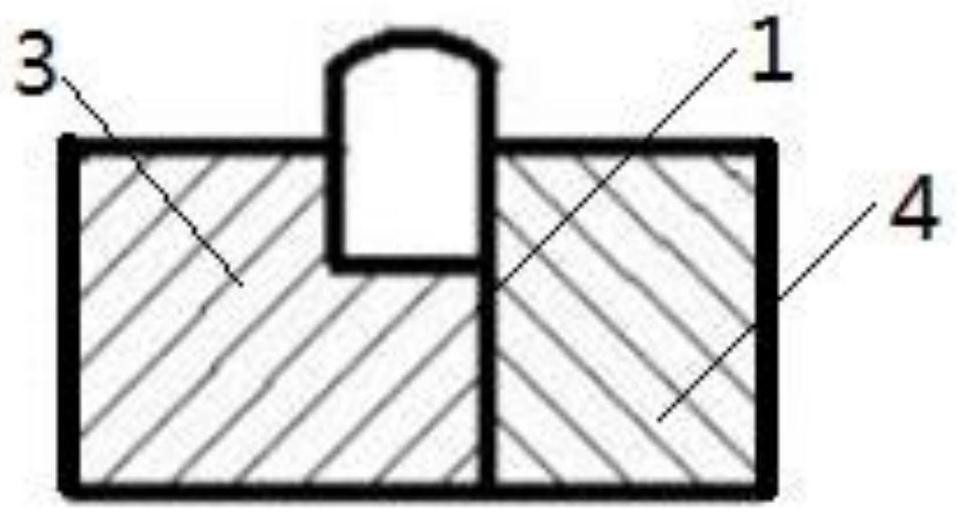

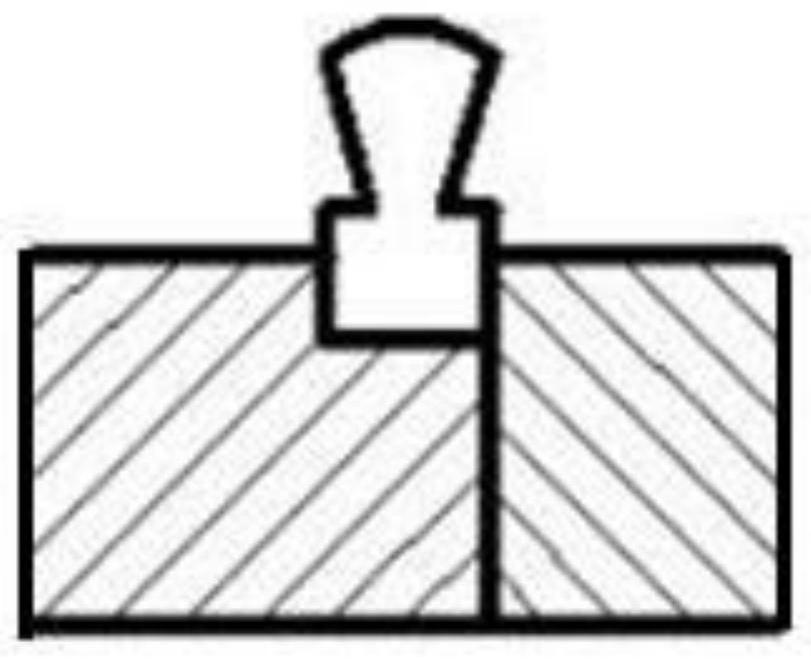

Manufacturing method of hair brush

ActiveCN102309134ASimplify the manufacturing processReduce production man-hoursBristleEnvironmental resistanceWork in process

The invention relates to a manufacturing method of a hair brush, comprising the following sequential steps of: putting hair materials into a jig; b, vibrating the hair materials into a hole with predefined specification; c, using a hair clamping tool to clamp off redundant hair materials; d, putting in a machine, and cutting off redundant parts through a heating plate; e, putting on a freezing plate for cooling; f, taking out a semifinished product for dipping a setting agent, and putting into a setting template; g, putting into a steam box for steaming for a preset time; h, putting into a drying box for drying for a preset time; and I, taking out a finished product. Therefore, the manufacturing process of the hair brush is effectively simplified, the manufacturing time is saved, the quality is improved, the energy is saved and multiple effects such as environmental protection and the like are achieved.

Owner:ZHUHAI DING RONG PLASTIC PROD CO LTD

Wig

InactiveCN101404904AIncrease freedomImprove completion rateWigsMonocomponent polyamides artificial filamentEngineeringArtificial hair wig

A hair material for a wig is preliminarily curled and then bound to a wig base to thereby orient the curled hair in a definite direction. A folded part (10c) of a hair material (10) is penetrated from one side of a filament (15) to the other side under a wig base (12) so that a first loop (17) is formed in the inner side of the folded part (10c). A curved part (10d) is inserted through the first loop (17) so that a second loop (19) is formed in the inner side of the curved part (10d). A part (10b) of the hair material is inserted through the second loop (19). Next, the hair material parts (10a, 10b) are pulled in directions opposite to each other and tied with the filament (15) at (20). Thus, the hair material (10) is bound to the filament (15).

Owner:ADERANS CO LTD

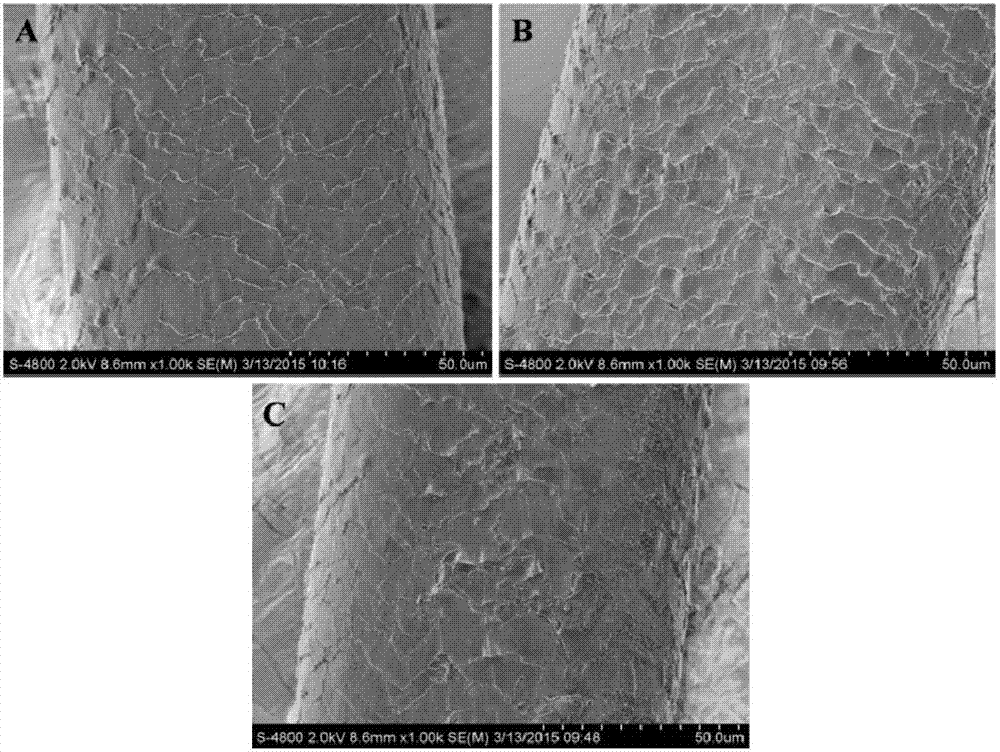

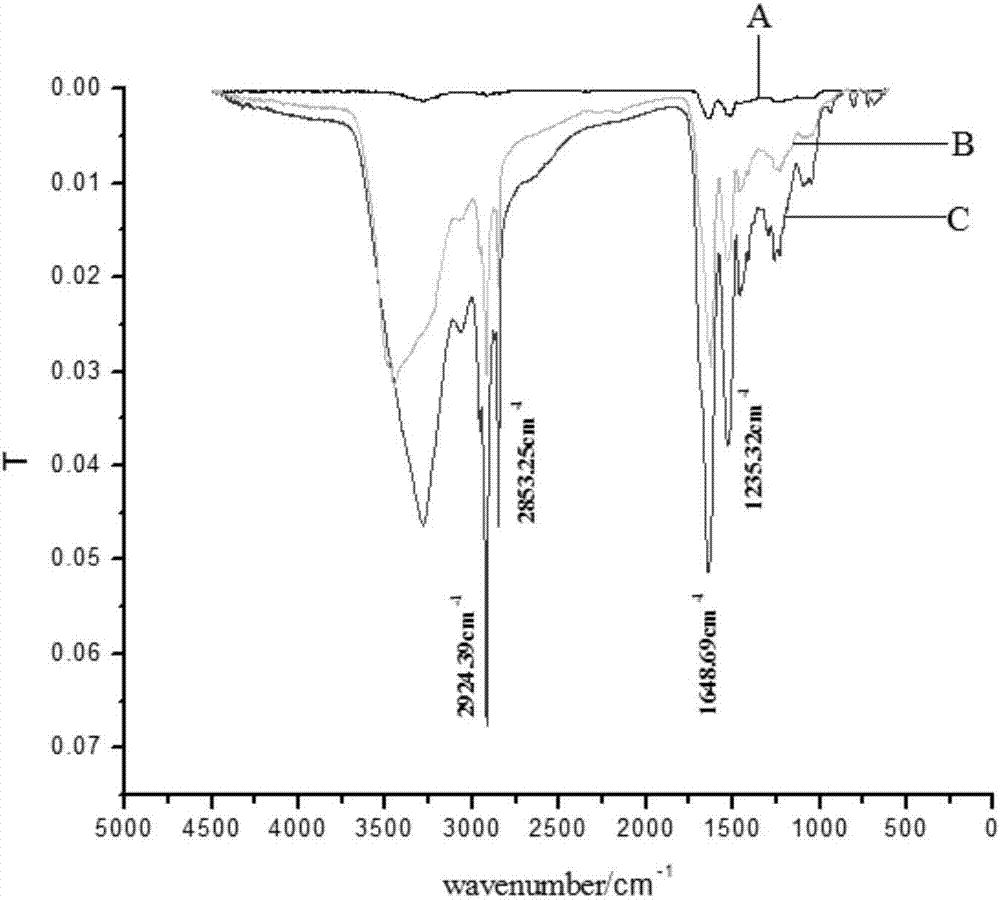

Preparation method of polypeptide growth factor modified hair-based material

ActiveCN107343967AComplete structureFacilitate cross-linking reactionProsthesisAlcoholAqueous solution

The invention discloses a preparation method of a polypeptide growth factor modified hair-based material. The method comprises the following steps of (1), placing hair into an aqueous solution of ethyl alcohol, soaking, taking out the hair, and carrying out washing and drying; placing the dried hair in an aqueous solution of an acid, soaking, taking out the hair, and carrying out the washing and the drying, so as to obtain a hair-based material; (2), under the action of an initiator, enabling the hair-based material obtained in the step (1) and a polypeptide nerve growth factor to react in water, so as to obtain the polypeptide growth factor modified hair-based material. According to the method provided by the invention, surface treatment is carried out on the surface of the hair by utilizing the mild corrosive action of a dilute acid; a carboxyl group is exposed to the surface of the hair; multiple polypeptide factors are grafted conveniently. A hair material, serving as an autologous appendant organ, is conveniently taken. The hair-based material is used for providing supporting action for the polypeptide growth factor; the polypeptide growth factor is released; the polypeptide growth factor needed in an overall regeneration process is provided for defective tissue.

Owner:北京智枢生物科技有限公司

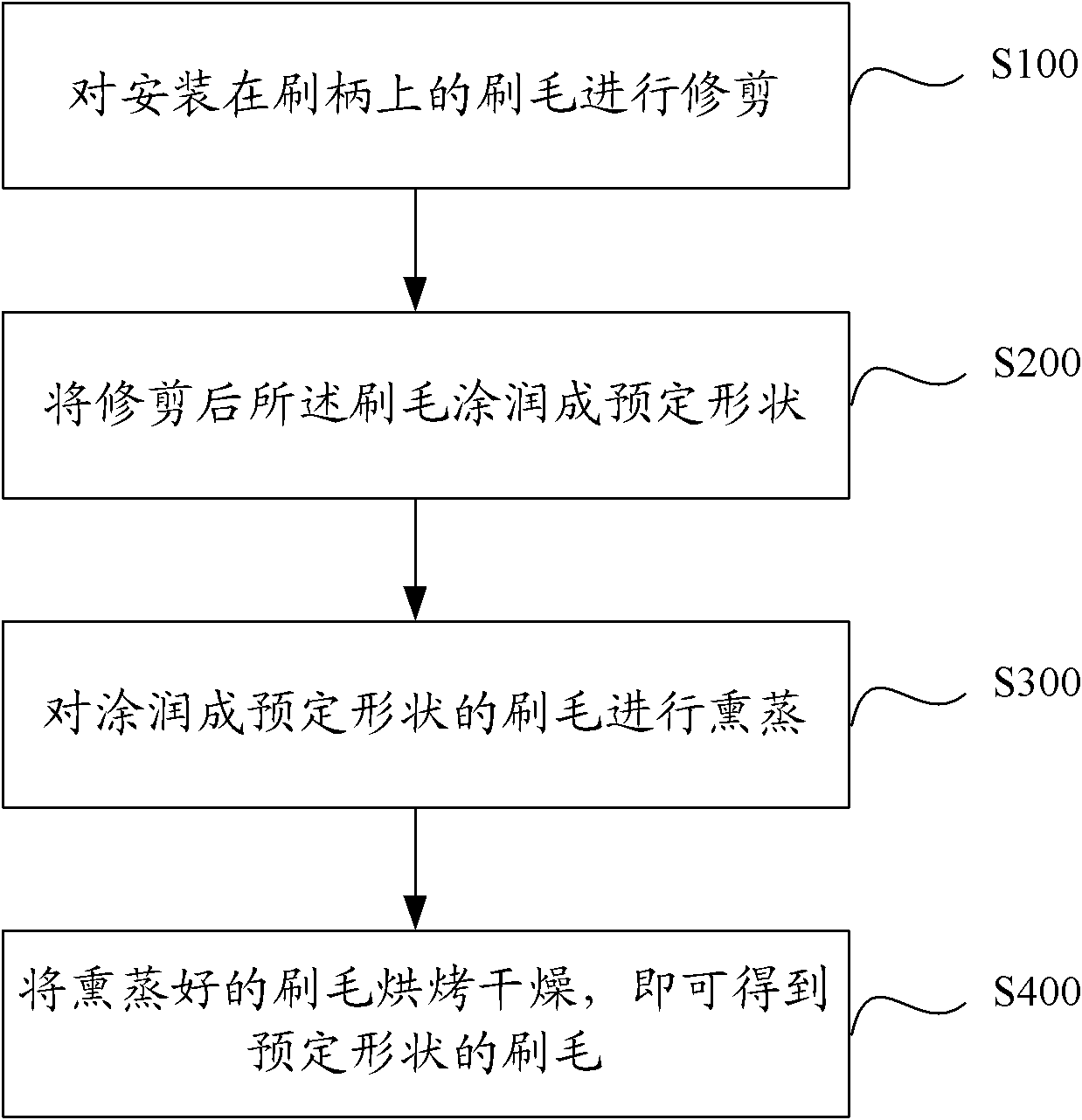

Brush hair shaping method

The invention discloses a brush hair shaping method, which comprises the following steps of: trimming brush hair mounted on a brush handle; coating and wetting the trimmed brush hair into a preset shape; fumigating the brush hair; and roasting and drying the fumigated brush hair to obtain the brush hair with the preset shape. Compared with the prior art, the shaping of the invention can be performed without using glue or by using the glue of low-concentration non-chemical raw materials; the hair quality of the brush hair is not damaged during fumigation, roasting and shaping of the brush hair; and the brush hair is not withered, forked or easily broken and can become softer, more elastic and more glossy. In addition, during fumigation, roasting and shaping of the brush hair, the hair material of the brush hair does not have specific requirement, and animal hair, artificial hair and mixed hair of the animal hair and the artificial hair are available, so that the production difficulty coefficient of the hair material is reduced, the production of a brush is facilitated, and the shaped brush has a good brush hair tipping and shaping effects and the brush hair is difficult to scatter.

Owner:雅香丽化妆用品(深圳)有限公司

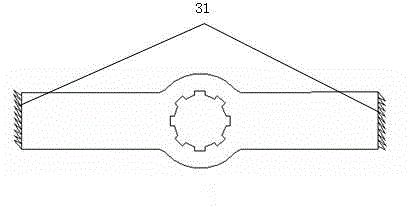

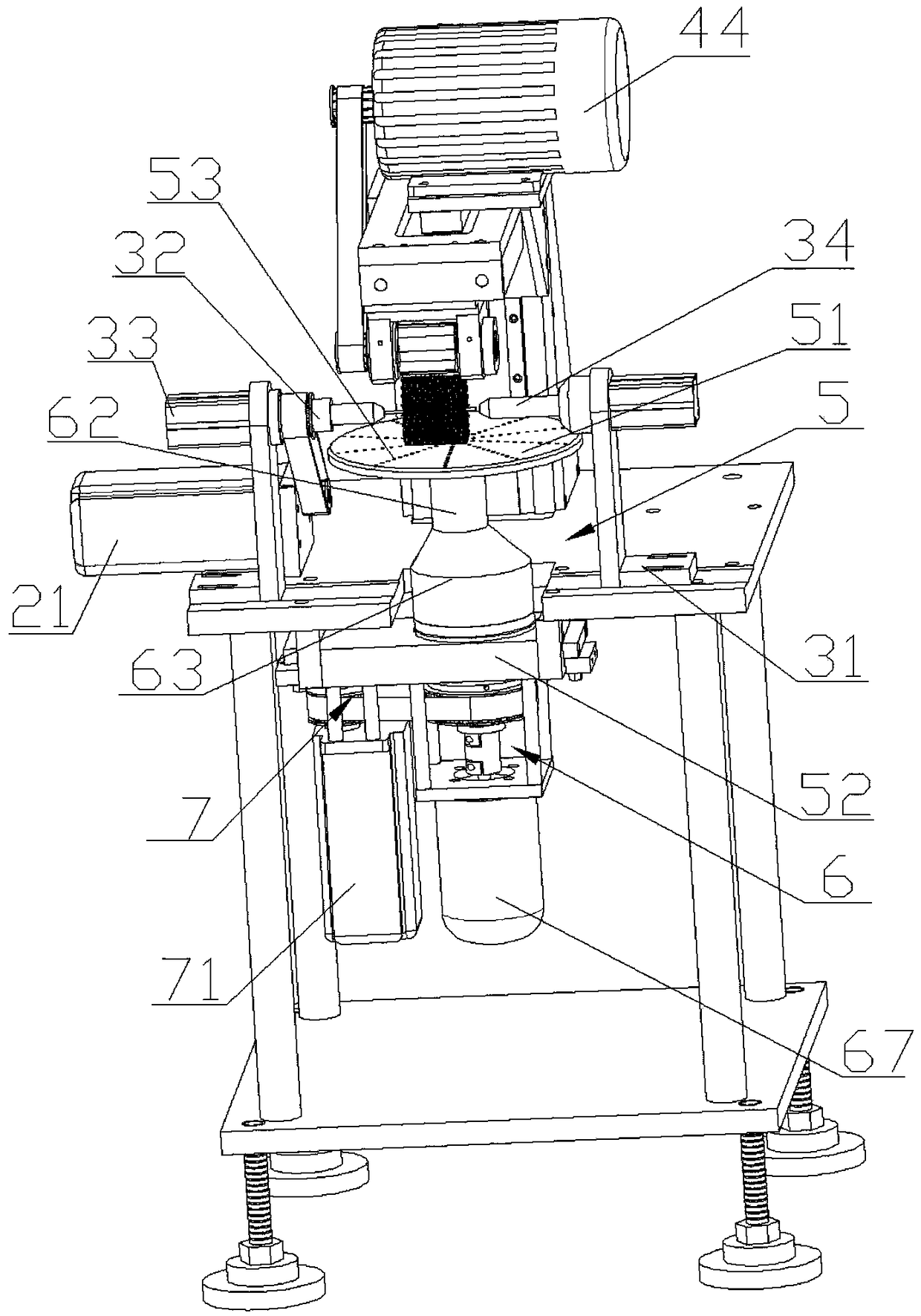

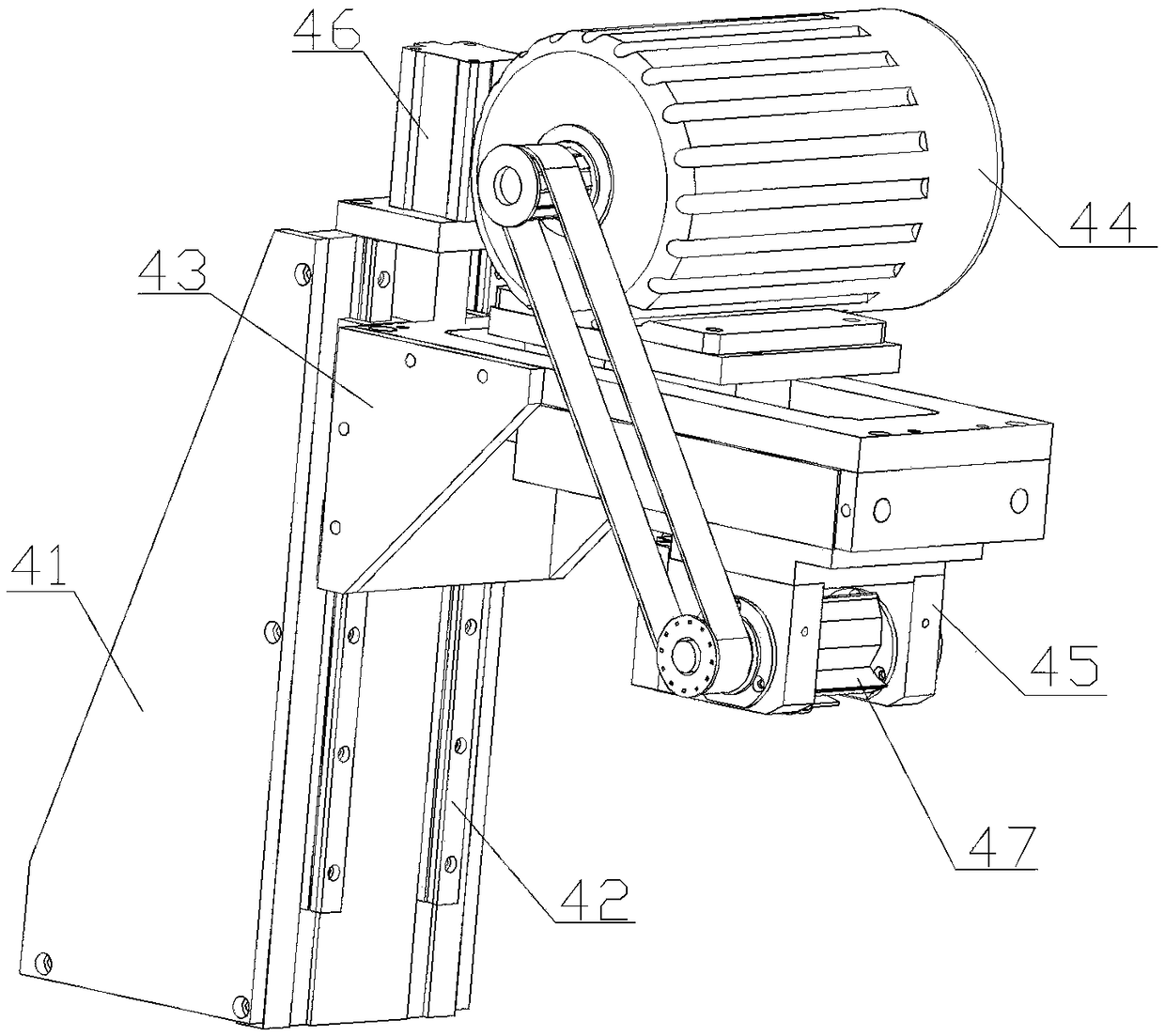

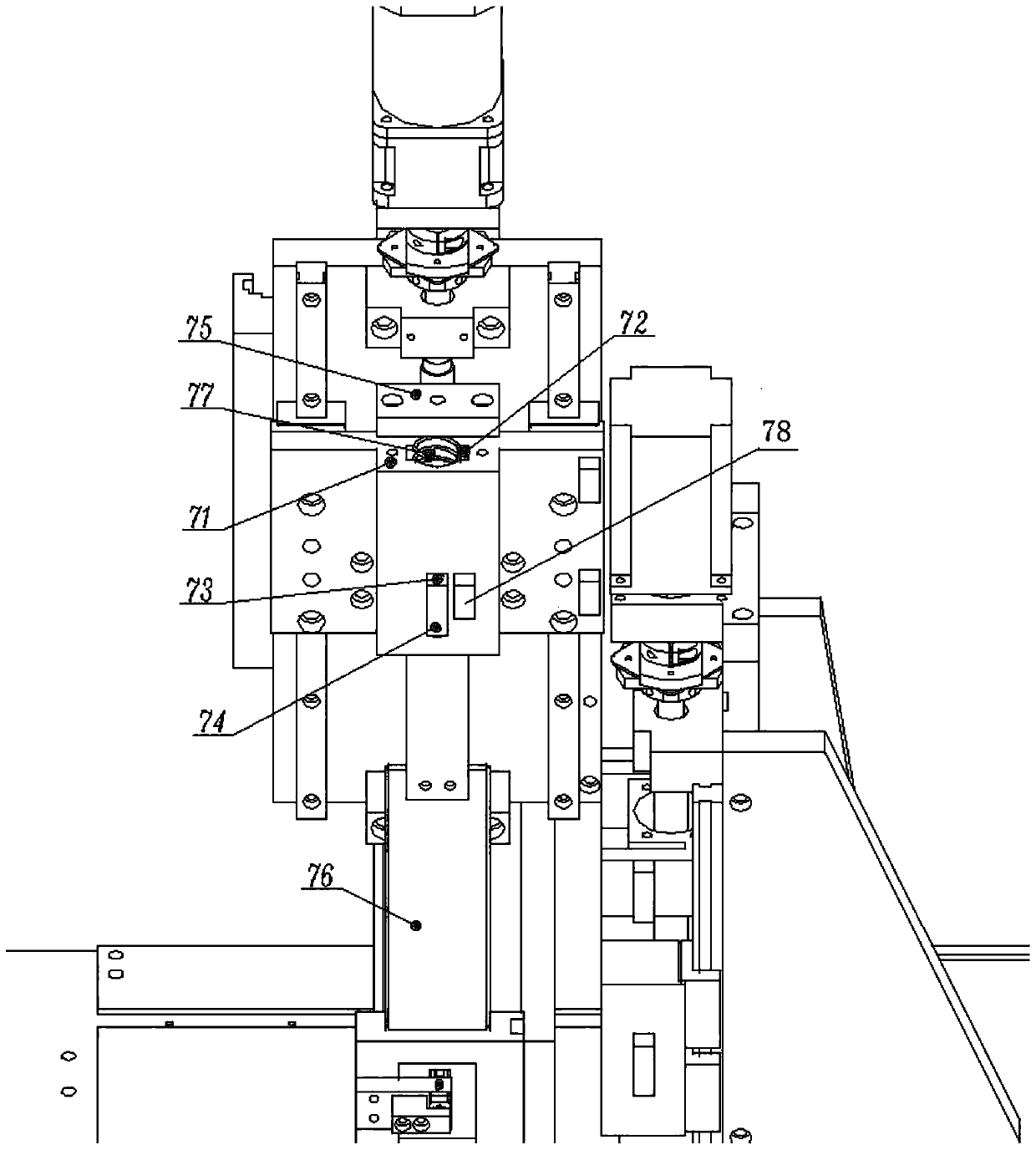

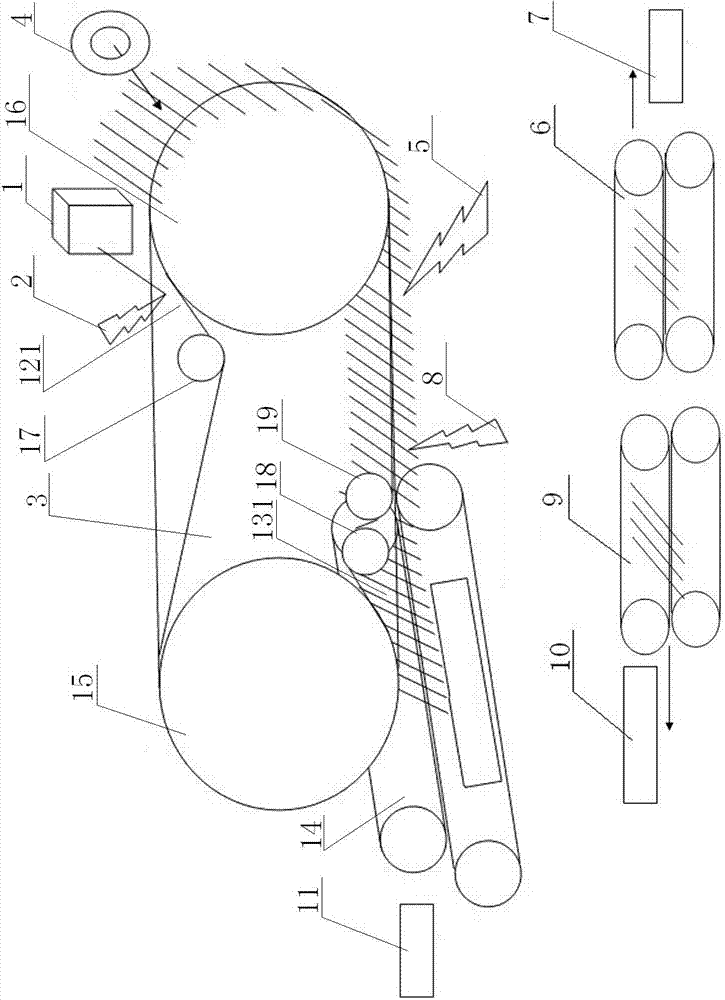

Hair-shearing-and-hair-rounding integrated machine for circular-head twisted hair brush, working method thereof and circular-head twisted hair brush

The invention discloses a hair-shearing-and-hair-rounding integrated machine for a circular-head twisted hair brush, and relates to a device for processing the twisted hair brush. The hair-shearing-and-hair-rounding integrated machine comprises a hair brush body, a master controller, a working table, a wire clamping-pulling mechanism, a wire rotating mechanism, a hair shearing mechanism, a hair rounding mechanism, a hair rounding tray and a tray support. The tray support is installed on the working table, a tray autorotation mechanism and a tray deflecting mechanism are installed on the tray support, a hair shearing support is installed on the working table, the hair shearing mechanism is slidingly installed on the hair shearing support, the hair brush body is located between the hair shearing mechanism and the hair rounding tray, and hair materials are in pressed connection on the hair rounding tray; the wire clamping-pulling mechanism, the wire rotating mechanism, the hair shearing mechanism, the tray autorotation mechanism and the tray deflecting mechanism are electrically connected with the master controller. The invention further provides a working method of the hair-shearing-and-hair-rounding integrated machine for the circular-head twisted hair brush. Meanwhile, the invention provides the circular-head twisted hair brush manufactured with the hair-shearing-and-hair-rounding integrated machine for the circular-head twisted hair brush.

Owner:HUBEI C P NC MACHINERY

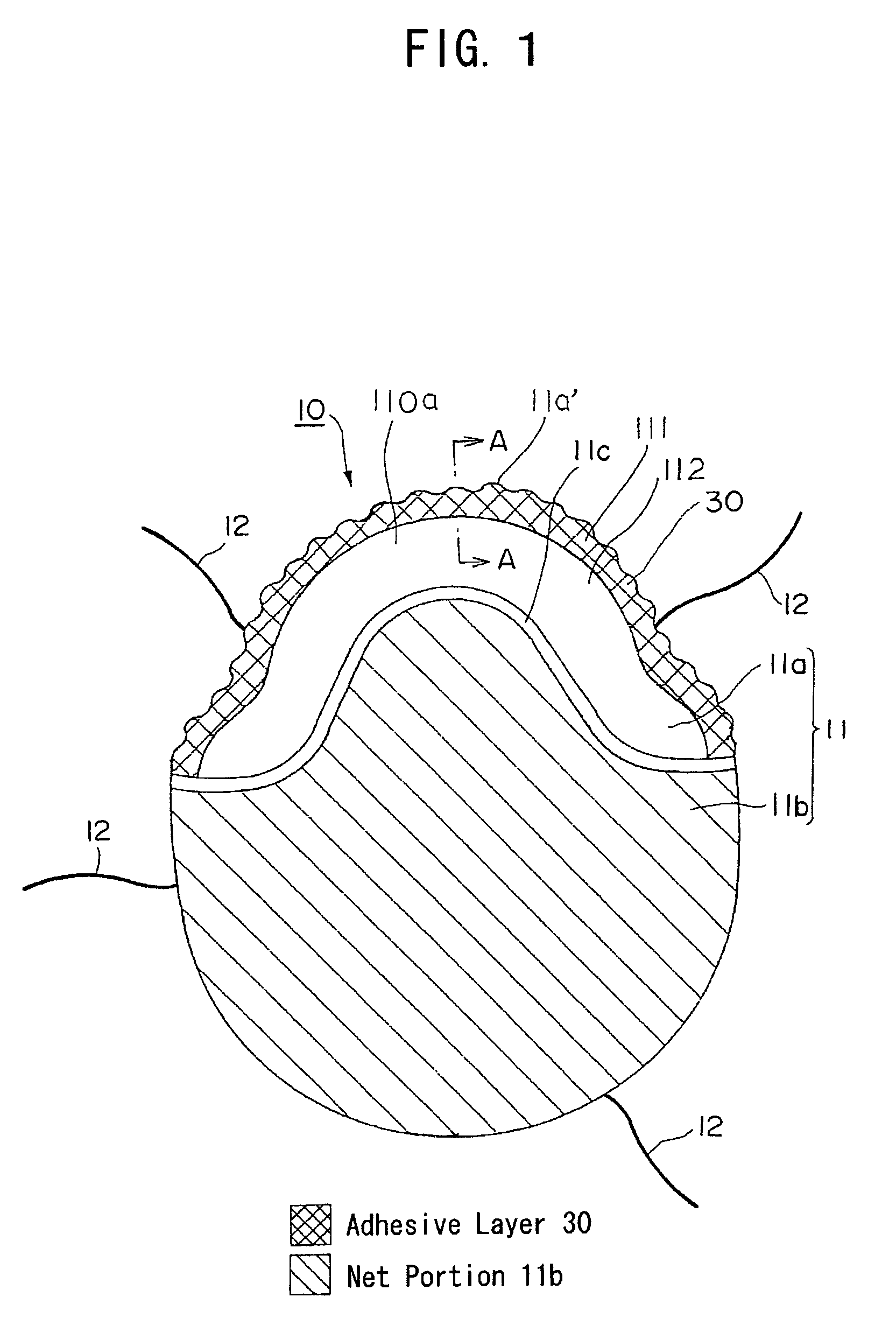

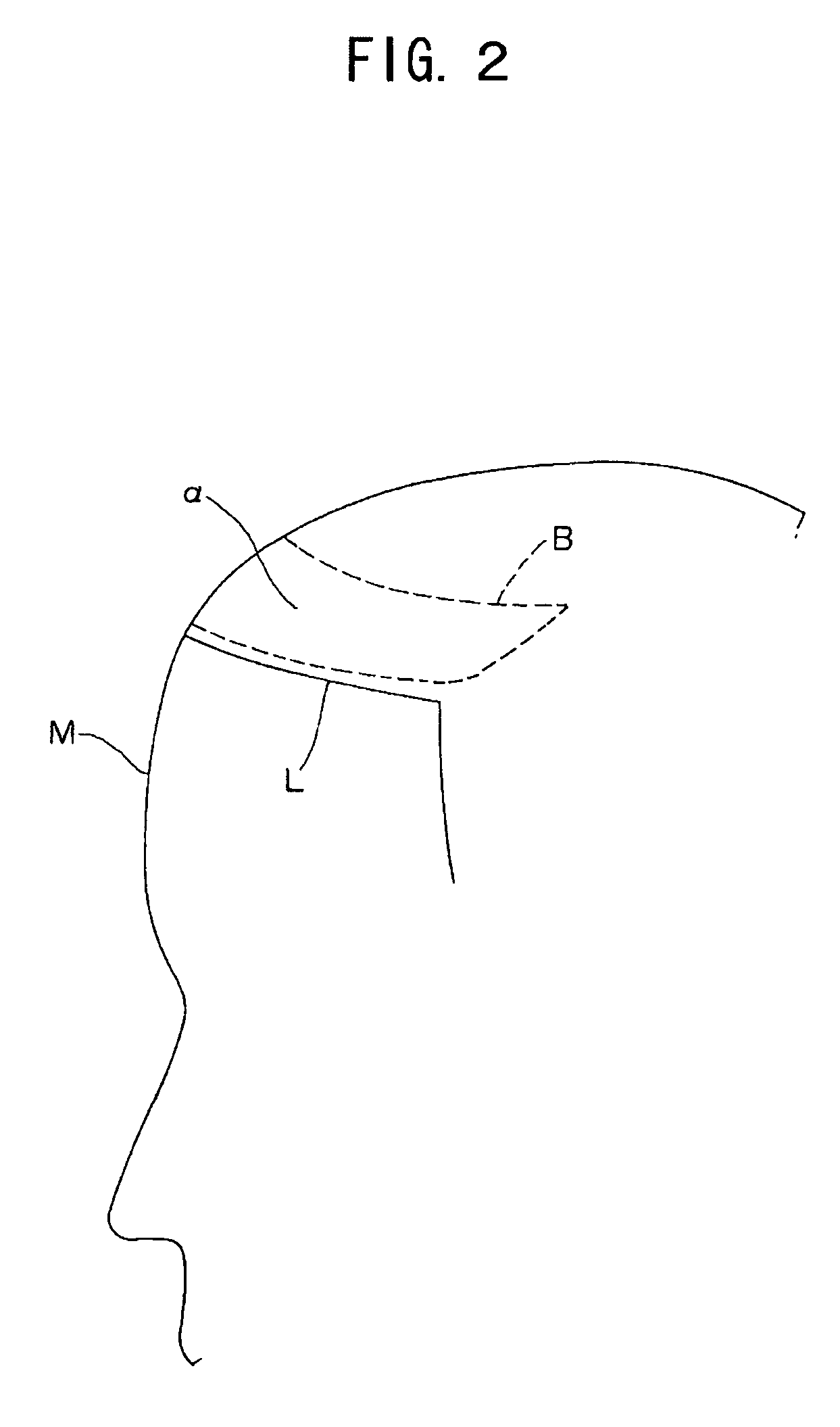

Wig and method of making the same

In the wig 10 provided with a wig base 11 and hair materials 12 attached to the wig base, the wig base 11 is zoned in its front portion 11a to an artificial skin portion 110a from a virtual hairline of the wearer's forehead portion toward a top portion and to a net pattern 11b connected thereto, the artificial skin portion is made of a synthetic resin film integrated with a shape retention net, provided with a front edge region 111 of the pre-determined width from a front edge 11a′ positioned on the wearer's virtual hairline toward inside and with a rear region 112 connected to the front edge region, and the front edge region 111 is bent to a sharper inclination than the wearer's corresponding head outline, giving a curved ridge line, resulting in an arc-shaped warp up prevention structure.

Owner:UNIHAIR COMPANY LIMITED

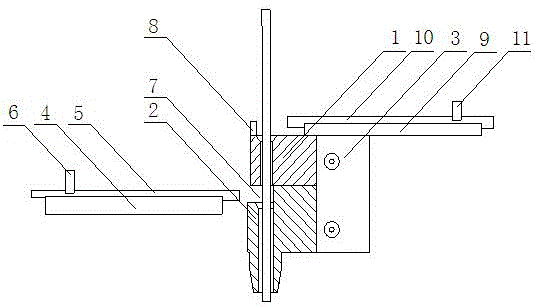

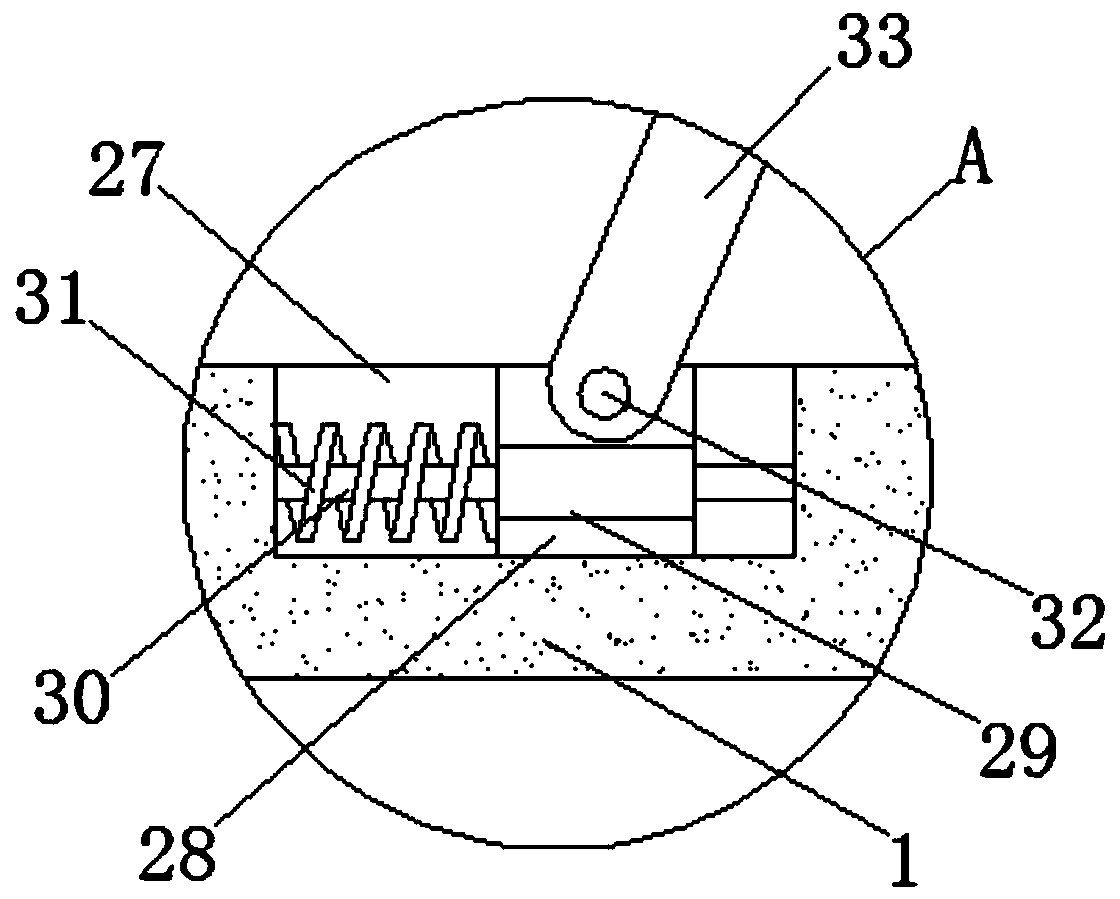

Cutting device of ink brush hair material

InactiveCN109015796AImprove protectionImplementation constraintsMetal working apparatusThreaded pipeEngineering

The invention discloses a cutting device of an ink brush hair material. The cutting device of the ink brush hair material comprises a base. A bearing is fixedly embedded into the base. A moving plateis arranged above the base. A threaded pipe is fixedly embedded into the moving plate. The inner wall of the threaded pipe is connected with a threaded rod in a threaded manner. The bottom of the threaded rod is fixedly connected with the inner ring of the bearing. The top of the threaded rod is fixedly connected with a partition plate. A group of first sliding grooves are formed in the upper surface of the base. Sliding blocks are connected into the first sliding grooves in a clamped manner. First through pipes are fixedly embedded into the sliding blocks. First sliding rods are arranged in the first through pipes in a sleeved manner. The two ends of each first sliding rod are fixedly connected with the inner side wall of the corresponding first sliding groove. First flexible springs twine around the outer surfaces of the first sliding rods. The sliding blocks are fixedly hinged to moving rods through first pin shafts. The moving rods are fixedly hinged to a supporting plate through second pin shafts. The cutting device of the ink brush hair material avoids that the hair material slides during cutting and guarantees that hair material cutting succeeds.

Owner:湖州张师傅胎毛文化有限公司

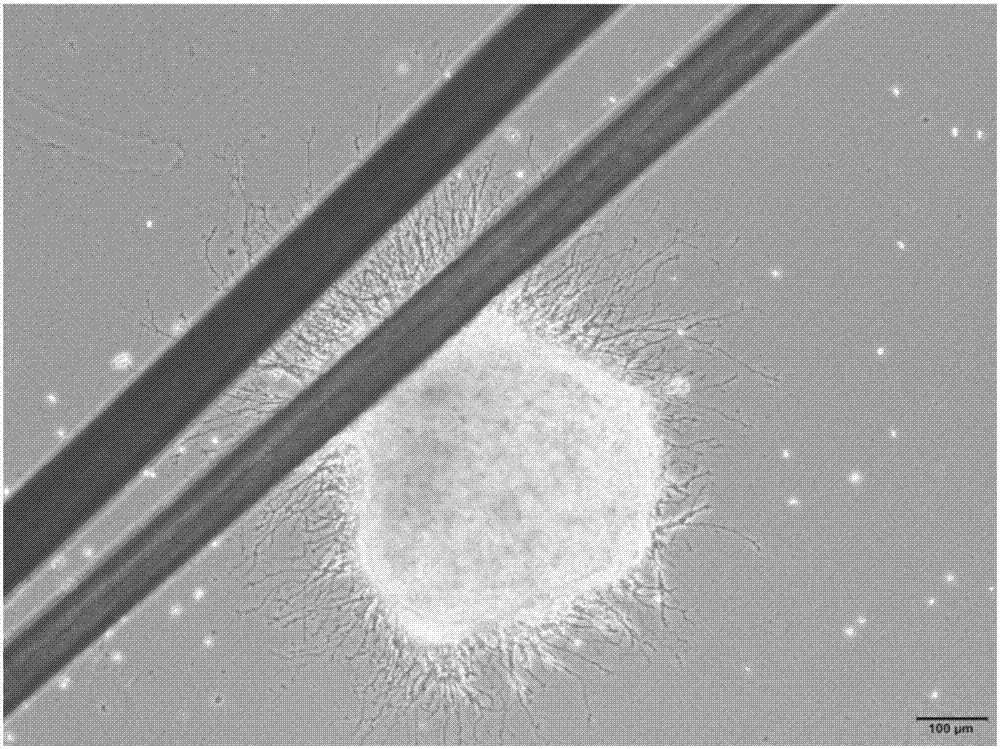

Brush nib, preparation method and application thereof

ActiveCN106808837BControl ink absorption capacityConvenient teaching demonstrationNibsPolymer sciencePlant fibre

The invention discloses a writing brush head, a manufacturing method and an application thereof. The writing brush head contains at least two brush hair materials which are enough different in hydrophilic-hydrophobic property or hygroscopic property, wherein one of the two brush hair materials is better in ink resistance. The writing brush head is characterized in that in the writing process, strokes take on stroke profiles and thick-thin difference in the strokes along the brush moving track by utilizing difference of the ink absorbing amounts of different brush hair materials. The writing brush head and a writing brush disclosed by the invention have the advantages that the brush moving track in the writing or drawing process can be displayed, teaching demonstration and painting imitation training are convenient, the strokes also can show three-dimensional or richer-layered works, and the interestingness, the beauty and the appreciation are enhanced. The writing brush head can be prepared by widely adopting undegreased or incompletely-degreased animal hairs or plant fibers and the existing artificial fibers or synthetic fibers as brush hair materials, the materials are easily available, the method is simple and convenient, the process is simplified, the operation is convenient, the suitability for large-scale material supplying is achieved and the cost is low.

Owner:赫拉迪克(厦门)科技有限公司

Processing technology of goat hair for braiding carpet

InactiveCN103122575AIncreased anti-cis friction coefficient differenceTake advantage ofAnimal fibresEngineeringHardness

The invention provides a processing technology of goat hair for braiding a carpet. The processing technology is characterized by comprising the following steps of: selecting a goat hair material, processing the goat hair by conditioning fluid; soaking the goat hair by the conditioning fluid; and dewatering, cleaning and baking, wherein the conditioning fluid contains a sodium pyrosulfite, sodium hydrosulfite and a wetting agent. Chaff scale of the goat hair processed by the processing technology expands; the original smooth surface becomes coarse; the softness is increased; and the goat hair generates certain degree of curl; and the hardness and the crimpness achieve the requirement of braiding the carpet. Therefore, the goat hair is fully utilized; and waste is avoided.

Owner:天津立秋工艺品有限公司

Fully automatic environment-friendly non-porous paint brush processing device

ActiveCN107898129BImprove processing efficiencyNot easy to fall offBrush bodiesBristleFully automatic

The invention discloses a full-automatic environment-friendly non-hair-planting porous paint brush processing device, and relates to a device for processing the paint brush. The device comprises a machine body, a console, a disc on which a plurality of brush handle placing grooves are arranged, a handle feeding mechanism for placing brush handles into the brush handle placing grooves, and a bristle placing mechanism for placing hair materials and clamping blocks into the brush handles on the disc, wherein the console, the disc, the handle feeding mechanism and bristle placing mechanism are arranged on the machine body, and the console, the handle feeding mechanism and the bristle placing mechanism are distributed along a circumferential direction of the disc; the bristle placing mechanismcomprises a hair placing mechanism for placing the hair materials, a sheet feeding mechanism for feeding the clamping blocks to the upper sides of the hair materials, a pressing block mechanism for pressing the hair materials that the upper sides are pressed by the clamping blocks onto the brush handles, and a hair feeding mechanism for feeding the hair materials in the hair placing mechanism ontothe pressing block mechanism; the hair placing mechanism is arranged between the hair feeding mechanism and the pressing block mechanism; and the sheet feeding mechanism is arranged between the hairplacing mechanism and the pressing block mechanism.

Owner:HUBEI C P NC MACHINERY

Molybdenum selenide composite carbonized sonchus oleraceus corolla hair used as electrode material of sodium ion battery

ActiveCN113036102AInhibition of volume expansionOvercoming easy reunionCell electrodesSecondary cellsSodium-ion batteryDimethylformamide

The invention provides a molybdenum selenide composite carbonized sonchus oleraceus corolla hair used as an electrode material of a sodium ion battery, which comprises the steps of putting sonchus oleraceus corolla hair powder into a porcelain boat, heating to the temperature of 500 DEG C under the protection of argon, and continuously carbonizing the sonchus oleraceus corolla hair powder for two hours to obtain a carbonized sonchus oleraceus corolla hair material; dissolving Na2MoO4 in deionized water, adding selenium powder, and dissolving with N2H2.H2O; slowly adding dimethylformamide to obtain a black solution, transferring the black solution into a polytetrafluoroethylene reaction kettle, sealing the reaction kettle, and heating at temperature of 200 DEG C for 12 hours; and after the reaction kettle is naturally cooled, taking out the solution, diluting the solution with deionized water until the pH value is neutral, carrying out suction filtration to obtain powder, and drying the powder in a drying oven at the temperature of 60 DEG C for 12 hours to obtain the molybdenum selenide composite carbonized sonchus oleraceus corolla hair electrode material. The defects that a sodium ion battery material is low in rate capability, easy to agglomerate, poor in electron and ion conductivity and the like are overcome, and the problems that a sodium ion battery is short in cycle life, low in energy density and the like are solved.

Owner:黑龙江诺康石墨新材料科技有限公司

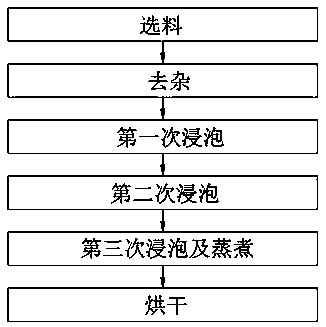

Multi-procedure wolf hair softening treatment process

InactiveCN108360249ALow wear resistanceSharp and neat tipGrip property fibresAnimal fibresHardnessWear resistance

The invention discloses a multi-procedure wolf hair softening treatment process. The process comprises steps as follows: material selection: a certain quantity of high-quality wolf hair materials aretaken; impurity removal: the taken wolf hair materials are scattered and beaten to remove impurities; first soaking: an auxiliary softening agent with the weight accounting for 1%-5% of that of the wolf hair materials is added to a mixed solution of Ca(OH)2 with the concentration of 50% and water, and the wolf hair materials without the impurities are soaked for the first time; second soaking: anauxiliary softening agent with the weight accounting for 1%-5% of that of the wolf hair materials is added to a mixed solution of Ca(OH)2 with the concentration of 30% and water, and the wolf hair materials soaked for the first time are soaked for the second time; third soaking and steaming: the wolf hair materials soaked for the second time are soaked in a mixed solution of Ca(OH)2 with the concentration of 10% and water for the third time; drying. Softened wolf hair for production of an ink brush can have alternate hardness and softness while the wear resistance of the wolf hair is not reduced.

Owner:ZAOZHUANG SHUYUAN PEN

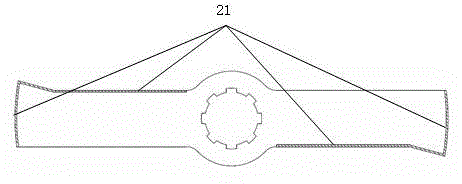

A processing method of fan-shaped clamping rod

ActiveCN112264649BMeet high precision processing requirementsImprove processing efficiencyWorkpiecesMilling equipment detailsEngineeringSpiral line

The invention relates to a processing method for a fan-shaped clamping rod, which belongs to the technical field of helical traveling wave tubes. The operation steps are as follows: (1) use a tool to process the blank into a long strip; (2) perform high-speed milling on the six sides of the blank; (3) use a broaching tool to process the large arc surface on the fan-shaped clamping rod; (4) Processing and forming the two slopes of the fan-shaped clamping rod; (5) Milling off the part of the blank exceeding the height of the fan-shaped clamping rod by a cutter; (6) Machining and forming the small arc surface of the fan-shaped clamping rod. The invention processes the fan-shaped clamping rods through the cooperation of the milling machine with the fixture and the cutting tool, so as to meet the high-precision processing requirements of the fan-shaped clamping rods, improve the processing efficiency and reduce the cost.

Owner:山东国晶新材料有限公司

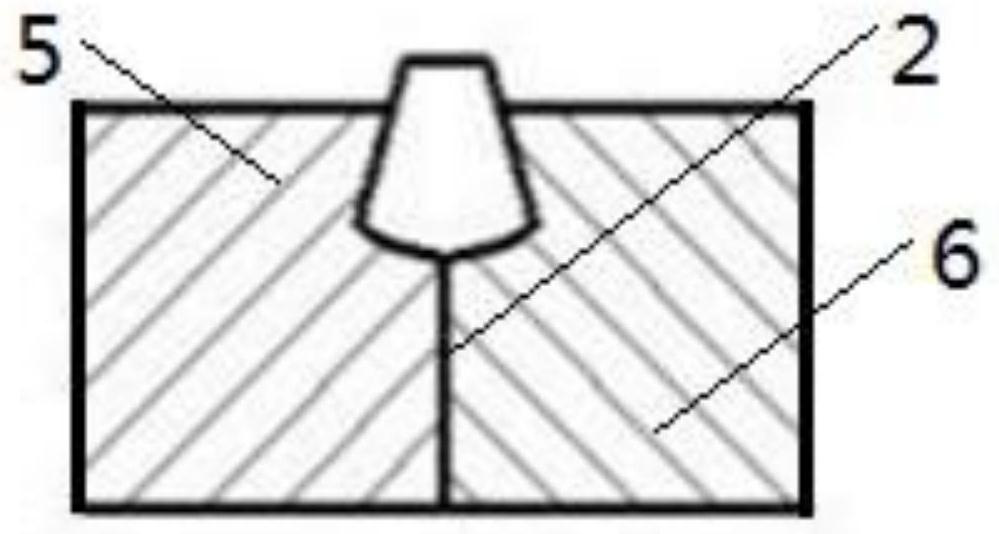

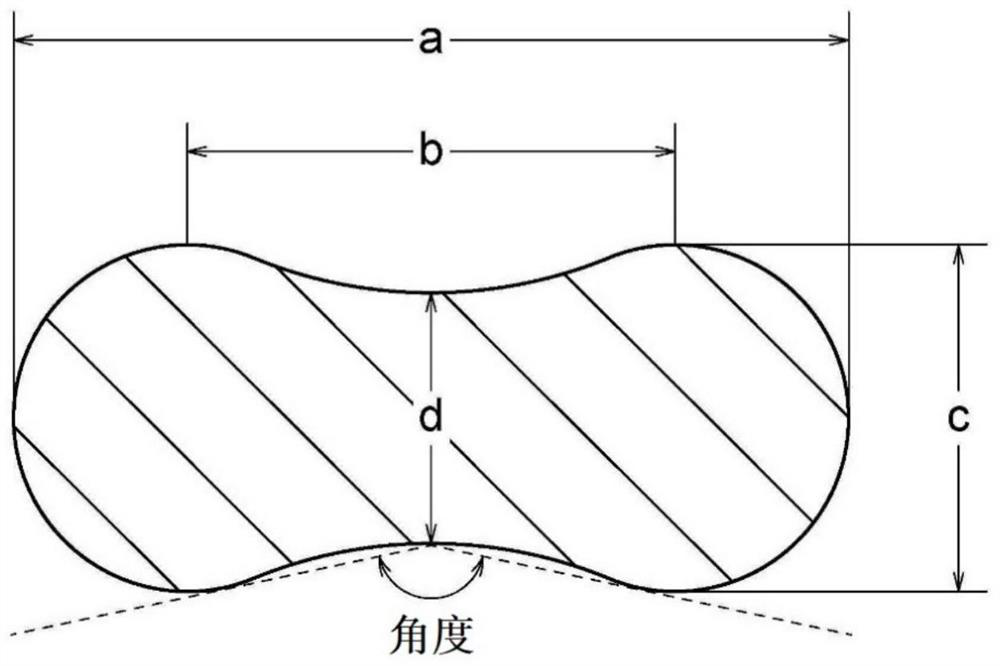

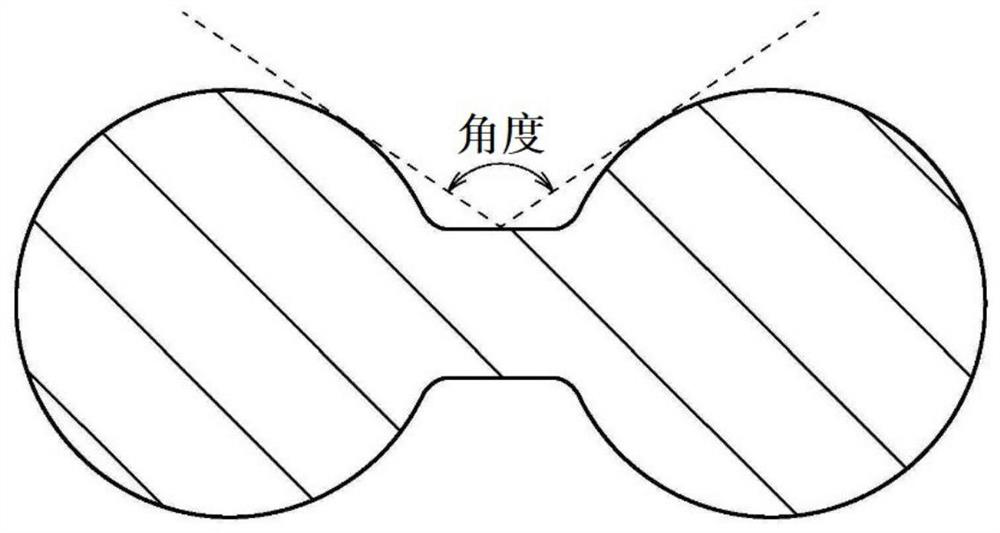

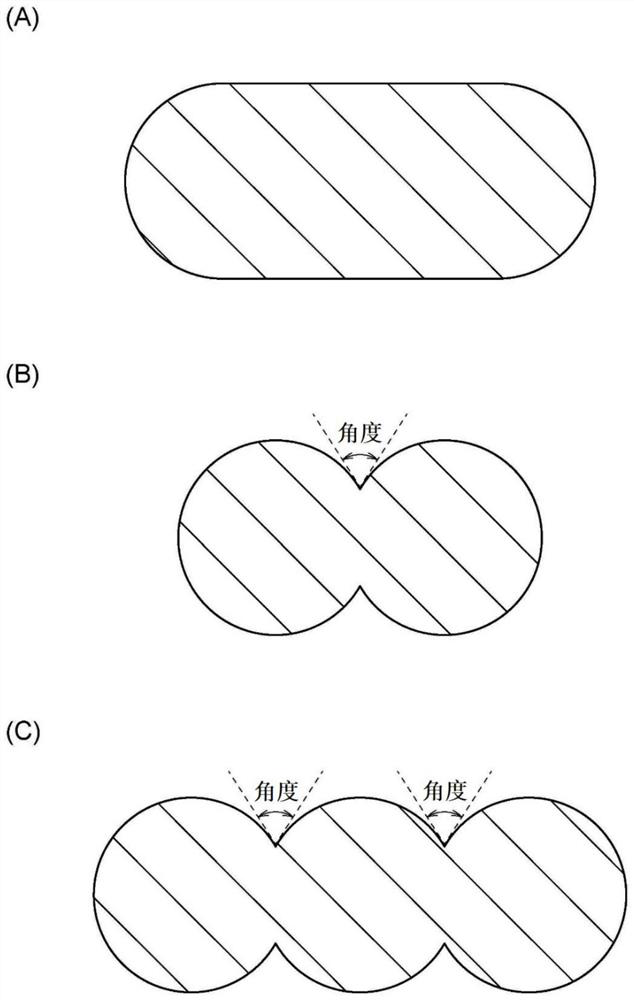

Hair material for cosmetic brush and cosmetic brush using the hair material

An object of the present invention is to provide a bristle material for a cosmetic brush, an assembly of bristle materials for a cosmetic brush, and a cosmetic brush using the assembly composed of a synthetic resin, which has good adhesion and release properties to powdery or liquid cosmetic materials. . As a solution to the problem, the present invention provides a hair material for a cosmetic brush, characterized in that it is composed of an S-twisted or Z-twisted synthetic resin monofilament, and the cross section of the monofilament in a direction perpendicular to the fiber axis is Cocoon shape.

Owner:KK TAIKI

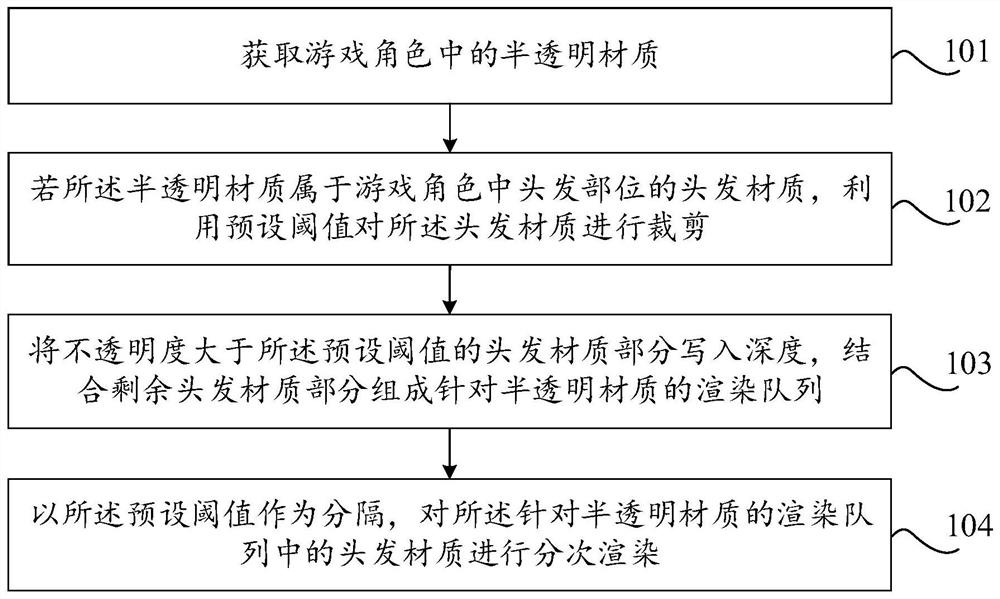

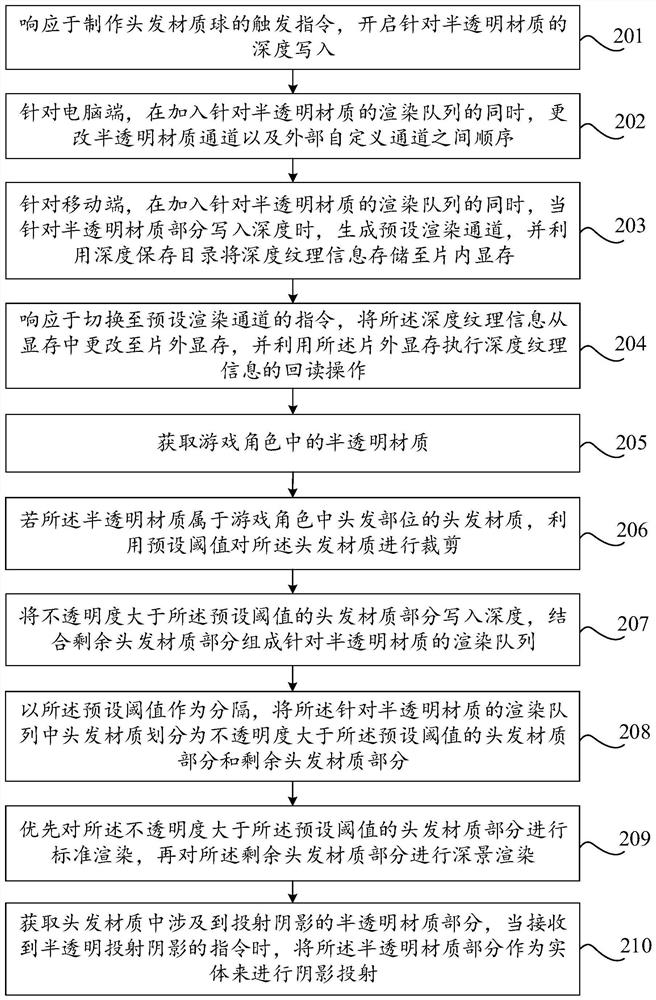

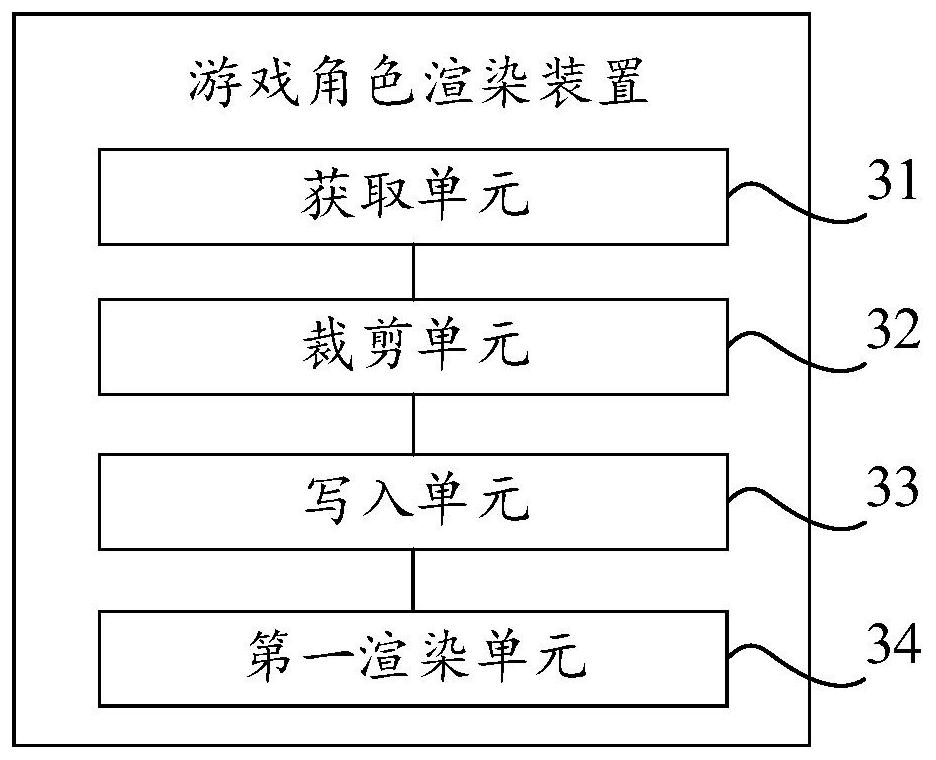

Game role rendering method, device and equipment

PendingCN113694510AThere will be no rendering faultsEasy to make artVideo gamesSimulationMechanical engineering

The invention discloses a game role rendering method, device and equipment, and relates to the technical field of 3D rendering, in the whole rendering process, two parts of a uniform material are divided into two rendering commands to be executed according to a preset threshold value, so that a rendering fault problem does not exist in a non-transparent rendering queue and a semitransparent rendering queue during hair rendering, and art manufacturing and parameter adjusting operation are facilitated. The method comprises the following steps: acquiring semitransparent materials in a game role, wherein the semitransparent materials belong to materials of different parts in the game role; if the semitransparent material belongs to the hair material of the hair part in the game role, cutting the hair material by using a preset threshold value; writing the depth for the hair material part of which the opaqueness is greater than the preset threshold value, and forming a rendering queue for the semitransparent material in combination with the remaining hair material part; and rendering the hair material in the rendering queue aiming at the semitransparent material for several times by taking the preset threshold as a partition.

Owner:BEIJING PERFECT WORLD SOFTWARE TECH DEV CO LTD

A Clockwork Production System

The invention discloses a hair spring production system, which comprises a hair product raw material pretreatment system and a spring spring preparation system; the hair product raw material pretreatment system includes a placer for holding hair product raw materials, and a hair manipulator takes the hair from the placer Take out 1‑10 hairs in turn, place them on the hair material straightening placer, the camera will send the information of white hair, reversed hair and smooth hair to the computer image processing system, after processing, the white hair, reversed hair and smooth hair Carry out positioning, and distribute the positioning information of the white hair and the reverse hair to the white hair manipulator and the reverse hair manipulator respectively; the extracted ones are folded and prepared into clockwork output. The invention can save processes such as picking up hair by hand, smoothing hair, arranging hair, sending hair, and filing hair, and can realize multi-process integrated production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Round head twisted hair brush shearing and sanding integrated machine and working method and round head twisted hair brush

The invention discloses a hair-shearing-and-hair-rounding integrated machine for a circular-head twisted hair brush, and relates to a device for processing the twisted hair brush. The hair-shearing-and-hair-rounding integrated machine comprises a hair brush body, a master controller, a working table, a wire clamping-pulling mechanism, a wire rotating mechanism, a hair shearing mechanism, a hair rounding mechanism, a hair rounding tray and a tray support. The tray support is installed on the working table, a tray autorotation mechanism and a tray deflecting mechanism are installed on the tray support, a hair shearing support is installed on the working table, the hair shearing mechanism is slidingly installed on the hair shearing support, the hair brush body is located between the hair shearing mechanism and the hair rounding tray, and hair materials are in pressed connection on the hair rounding tray; the wire clamping-pulling mechanism, the wire rotating mechanism, the hair shearing mechanism, the tray autorotation mechanism and the tray deflecting mechanism are electrically connected with the master controller. The invention further provides a working method of the hair-shearing-and-hair-rounding integrated machine for the circular-head twisted hair brush. Meanwhile, the invention provides the circular-head twisted hair brush manufactured with the hair-shearing-and-hair-rounding integrated machine for the circular-head twisted hair brush.

Owner:HUBEI C P NC MACHINERY

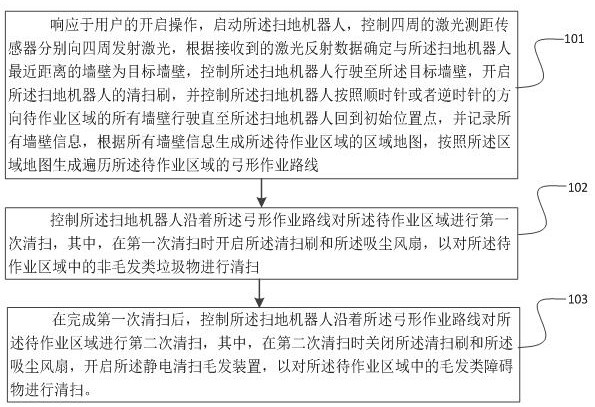

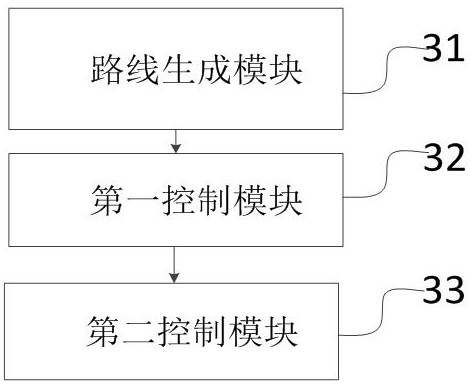

Control method, device and chip for sweeping robot to clean hair

ActiveCN111374598BImprove real-time performanceImprove work efficiencyAutomatic obstacle detectionTravelling automatic controlProcess engineeringMechanical engineering

The invention relates to a control method, device and chip for cleaning hair of a ground robot, belonging to the field of intelligent robots. The sweeping robot first generates an area map of the area to be operated based on all the wall information, and generates an arc-shaped operation route traversing the area to be operated according to the area map; then controls the sweeping robot to clean the area to be operated for the first time along the arc-shaped operation route. Turn on the cleaning brush and dust suction fan during the first cleaning to clean the non-hair substances in the area to be operated; after the first cleaning is completed, control the sweeping robot to clean the area to be operated for the second time along the bow-shaped operation route , wherein, during the second cleaning, the cleaning brush and the dust suction fan are turned off, and the electrostatic cleaning hair device is turned on to clean the hair-like substances in the area to be operated. Through the above-mentioned technical solution, the light hair and hair on the ground can be cleaned. Hair-like substances to ensure the working effect.

Owner:AMICRO SEMICON CORP

A method for picking white hair and smoothing hair with raw materials for hair products

The invention discloses a method for picking white hair and straightening hair as a raw material for hair products, which comprises the following steps: the first step, taking out hair: taking out the hair from the hair pile by a hair picking manipulator and placing it on a hair material straightening placer The second step, picking white hair: the camera takes pictures of the hair taken out in the step one, and then sends the information of the white hair obtained to the computer image processing system, after processing, the white hair is positioned, and the white hair is The positioning information of the white hair is assigned to the white hair manipulator; the third step is to pick the reverse hair: the camera takes pictures of the hair on the hair material straightening placer, and then sends the obtained reverse hair and smooth hair information to the computer image processing system, after processing Finally, locate the reversed and forwarded, and distribute the reversed positioning information to the reversed manipulator. Compared with the prior art, the present invention can save manual processes such as picking up hair, smoothing hair, arranging hair, sending hair, and filing hair, and can realize multi-process integrated production.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com