A processing method of fan-shaped clamping rod

A processing method and technology for clamping rods, which are applied to metal processing equipment, workpieces, manufacturing tools, etc., can solve the problems of inability to process fan-shaped clamping rods, and achieve the effects of avoiding fracturing damage, reducing costs, and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a processing method for a fan-shaped clamping rod, comprising the following steps:

[0038] (1) The cutter is installed on the milling machine, the blank is fixed on the milling machine console, and then the blank is processed into a long strip by the cutter;

[0039] (2) Fix the strip-shaped blank to fixture A1, fix fixture A1 to the milling machine console, and then perform high-speed milling on the six sides of the blank, and ensure the machining accuracy of the clamping rod through high-speed milling, and process the blank into a height of 0.6 mm, width 0.3mm.

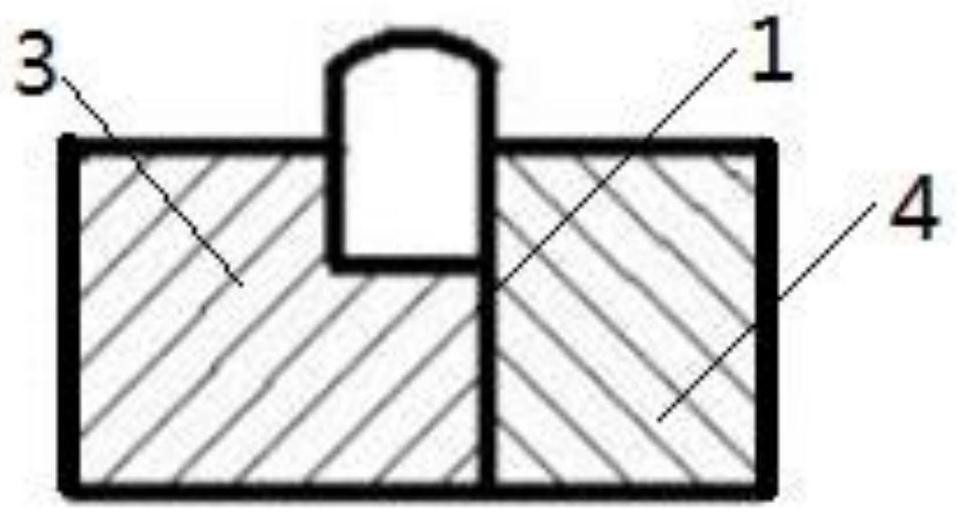

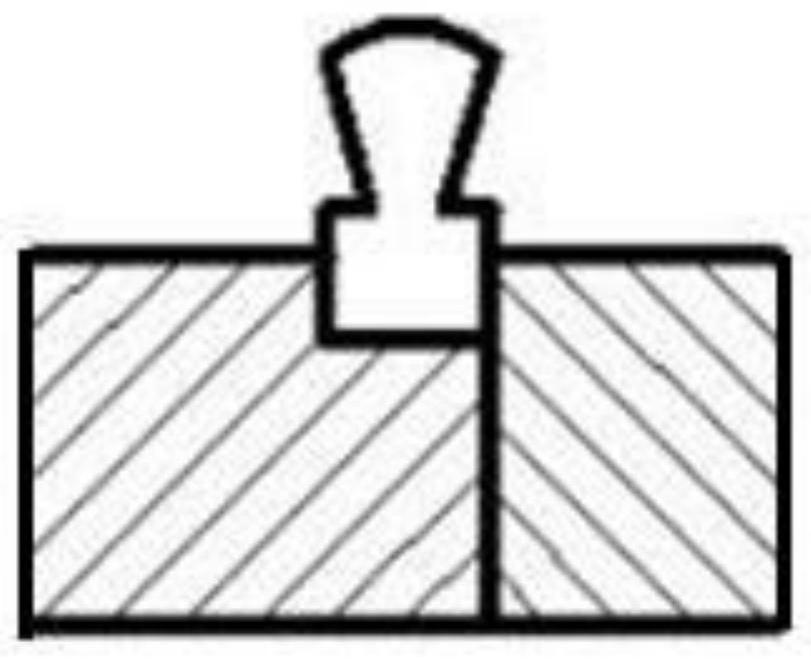

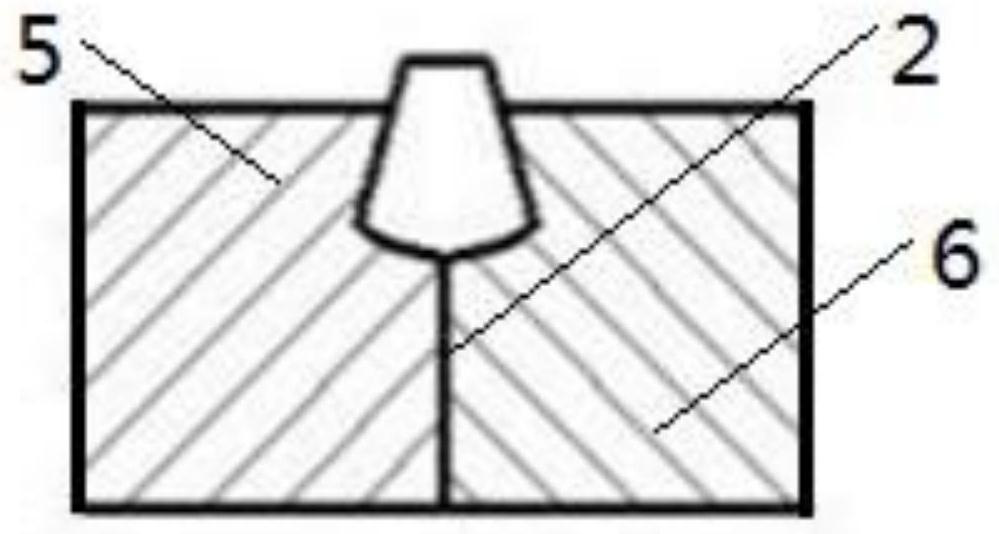

[0040] (3) The milling machine is replaced with a broaching tool. The arc of the broaching tool is consistent with the arc of the large arc surface on the fan-shaped clamping rod. Use the broaching tool to process the large circular arc surface on the fan-shaped clamping rod. The tool processing parameters are: feed speed 5m / min, feed rate 0.01mm, the processed blank is as follows ...

Embodiment 2

[0053] A method for processing a fan-shaped clamping rod, the operation steps are as described in Embodiment 1, the difference is that the length of the blank in step (1) is 190mm, the height is 1.6mm, and the width is 0.8mm.

[0054] Step (2): Processing the blank to a height of 1.3 mm and a width of 0.6 mm. The processing parameters during high-speed milling are: speed 30000r / min, feed speed 15m / min, feed rate 0.03mm.

[0055] Step (3): The processing parameters of the broaching tool are: feed speed 15 m / min, feed rate 0.03 mm.

[0056] Step (4): The processing parameters of tool A are: feed speed 15m / min, feed rate 0.03mm;

[0057] Step (5): The tool processing parameters are: rotational speed 30000r / min, feed speed 15m / min, feed rate 0.03mm. Step (6): The processing parameters of tool B are: feed speed 15 m / min, feed rate 0.03 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com