A processing method for a low-rigidity polymer material sealing ring

A technology of polymer materials and processing methods, which is applied in the processing field of low-rigidity polymer material sealing rings, can solve the problems of repeated clamping times and low processing efficiency, optimize processing steps, improve processing efficiency, and avoid clamping The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with specific embodiments. The up, down, left, and right directions of the present invention are only relative to the accompanying drawings, and do not constitute any direction restriction on the present invention.

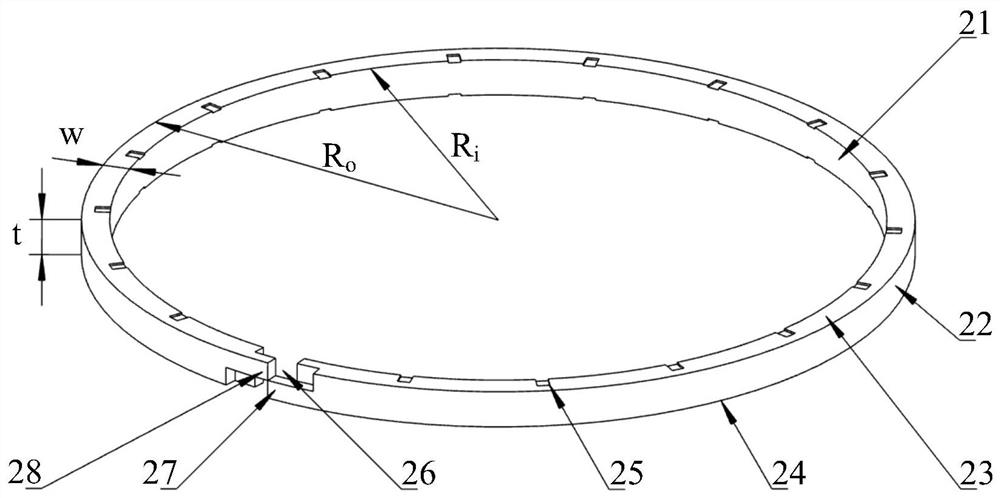

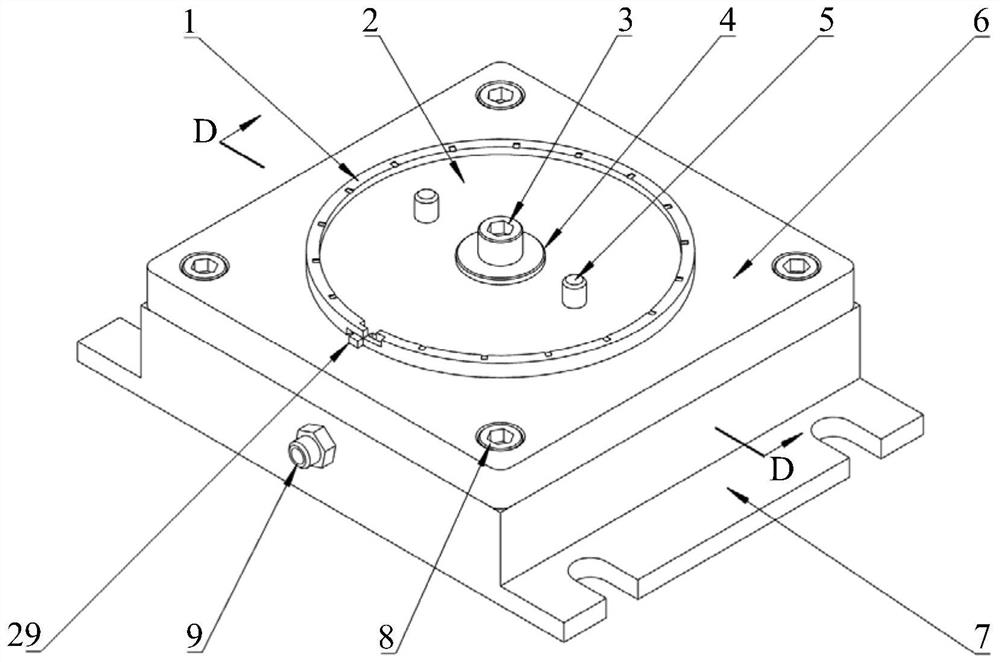

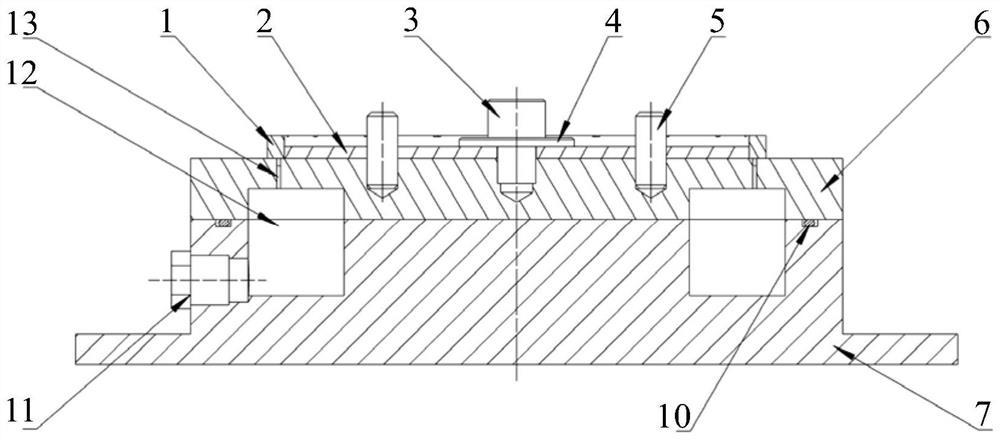

[0051] Such as Figure 1-6 Shown, a kind of processing method of low-rigidity macromolecular material sealing ring, the material of described sealing ring 1 is macromolecular material and modified material thereof; The radius R of outer circular surface 22 o is 25-125mm, the difference w between inner and outer diameters is 1-10mm, and the thickness t is 1-10mm; both end surfaces have a certain depth of friction-reducing functional structures 25; there is a cutout 26 in the circumferential direction, and the cutout 26 is multiple Sectional incision; the incision 26 is radially divided into an inner ring incision and an outer ring incision; the inner ring incision is an axial incision, tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com