A microstructure product multi-component topology optimization design, processing method and system

A technology of topology optimization and design method, applied in the direction of geometric CAD, etc., can solve problems such as low calculation efficiency, existence of connection parts of microstructure units, failure to consider physical properties of connection parts of components and constraints of manufacturing process, etc., to achieve low manpower and material resources consumption, The effect of meeting the size constraints of equipment and meeting the requirements of high-precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

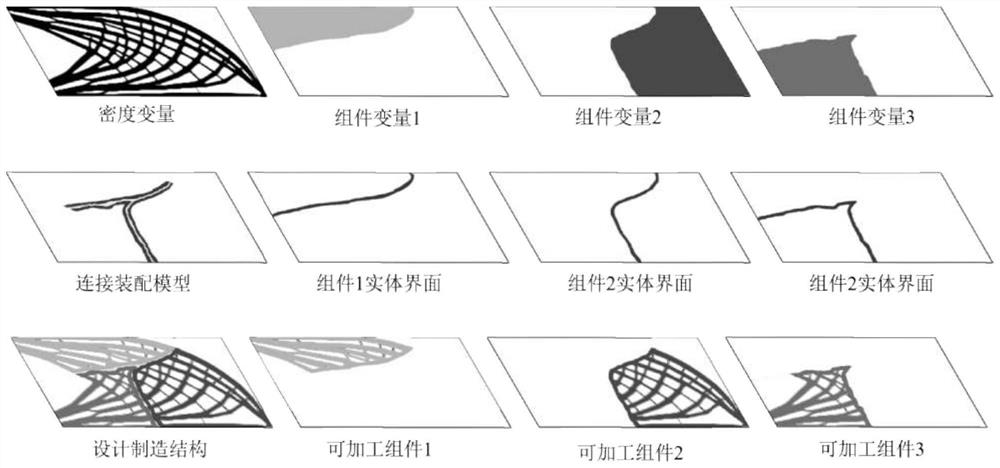

[0092] The present embodiment discloses a multi-component product microstructure topology optimization method, comprising the steps of:

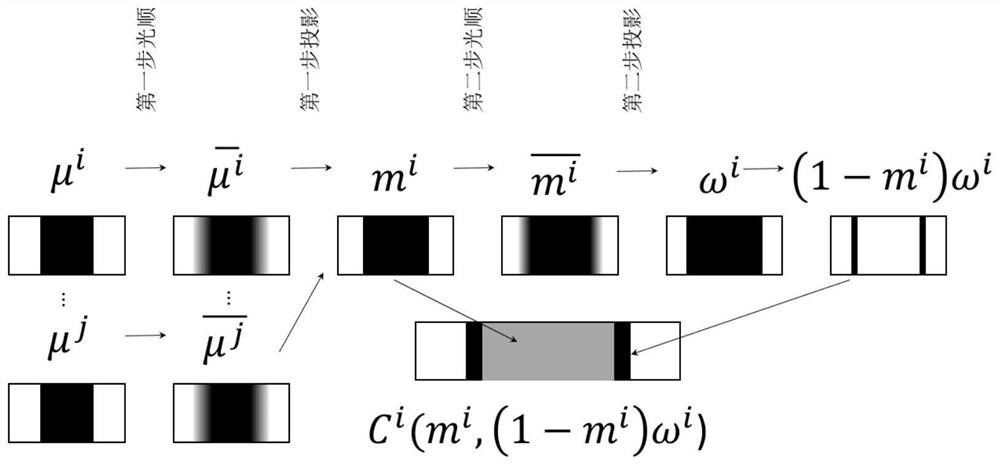

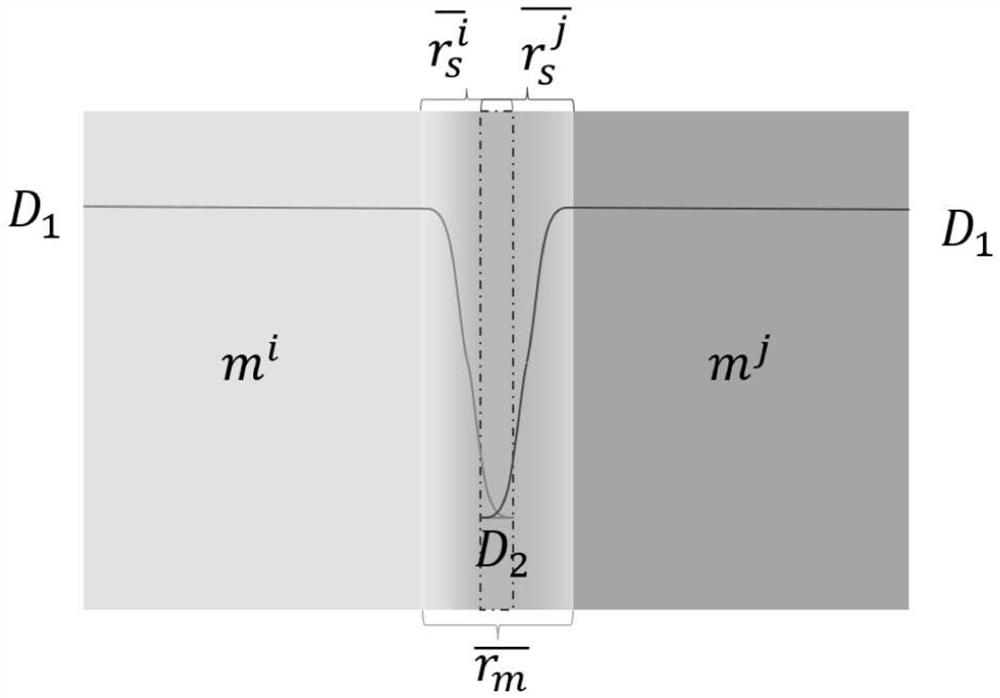

[0093] A step, provided topology optimization design domain [Omega]; constructing a pseudo-density design variable (geometric topology design variables) φ, φ is a continuous function of the design domain [Omega], [Phi] value at each position in the design of the design domain [Omega], respectively at respective positions within the domain Ω material whether arranged, -1≤φ≤1; multi-component design vector construct ([mu] 1 Μ 2 , ...., μ k , ...., μ K ), Where μ k Indicates the design variable of the king of the king, μ k Continuous function in design domain Ω, μ k Values at each location in the design area Ω respectively indicate the possibility of the corresponding position within the design domain Ω, 0 ≤ μ k ≤1, k = 1,2, ...., K, K is the design domain is divided into the maximum number of (artificial setting) component; final optimized desig...

Embodiment 2

[0151] The present embodiment discloses a multi-component product microstructure processing method, comprising the steps of:

[0152] Step i, using micro-architectural design method of multi-component Topology Optimization in Example 1, the solved φ, μ k The optimal value, and its corresponding dummy density design variable ρ, variable M k , Average dummy density design variable ρ l Parameter Ω k ;

[0153] Step ii, the mathematical model of each component constituting the microstructure is obtained according to the following formula:

[0154] C k = ΡM k + g (ρ l (1-m k ) Ω k

[0155] Where C k Represents the kth component constituting the microstructure;

[0156] Step iii, all components are processed in accordance with the mathematical model of each component of the microstructure;

[0157] Step IV, assemble each component to obtain a microstructured product.

Embodiment 3

[0159] The present embodiment discloses a multi-component product microstructure topology optimization design system including a memory and a processor, the memory stores a computer program, the computer program when executed by the processor, cause the processor to implement in the above-described Example 1 multi-component product microstructure topology optimization method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com