Multi-component topological optimization design and processing method and system for microstructure product

A technology of topology optimization and design method, applied in the direction of geometric CAD, etc., can solve the problems of the connection part of the microstructure unit, the physical properties and manufacturing process constraints of the connection part of the component are not considered, and the calculation efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

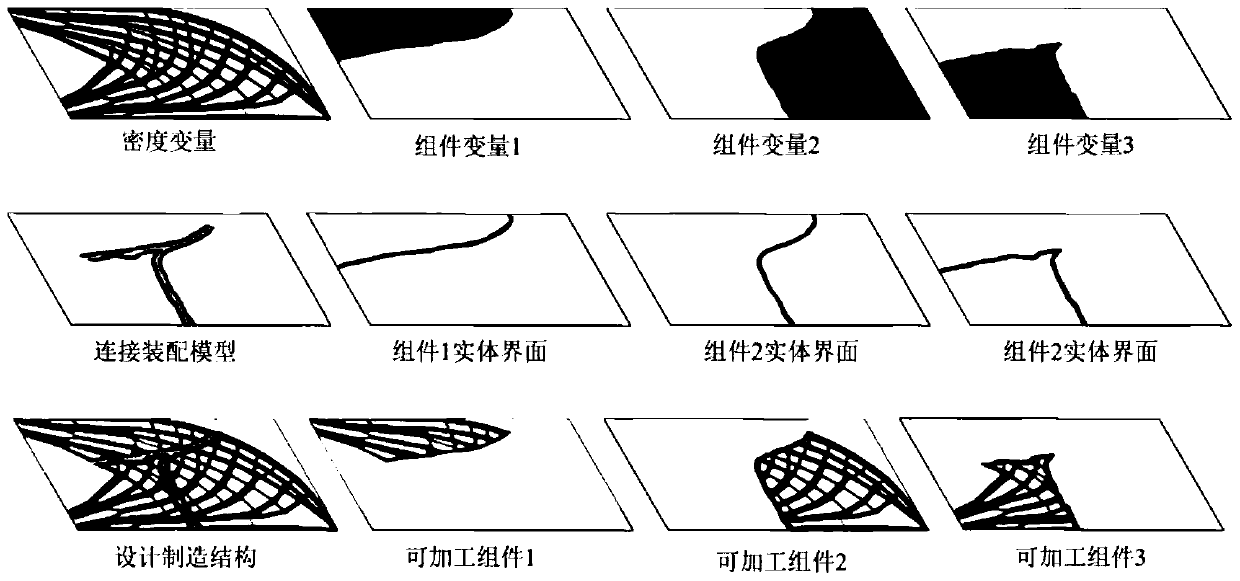

[0092] This embodiment discloses a multi-component topology optimization design method for microstructure products, including the following steps:

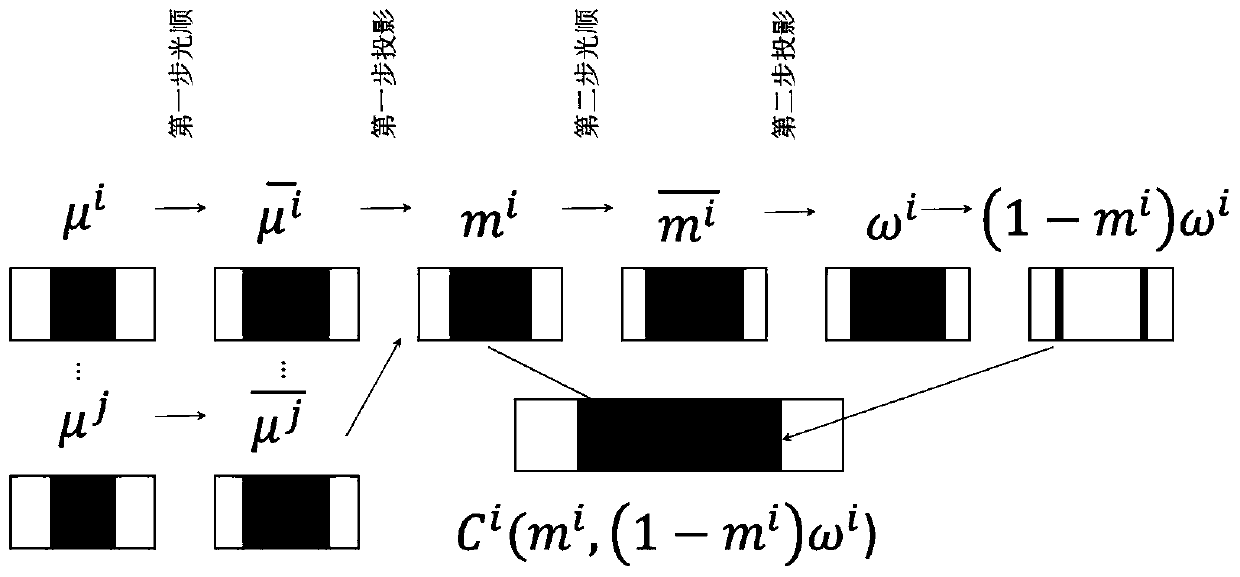

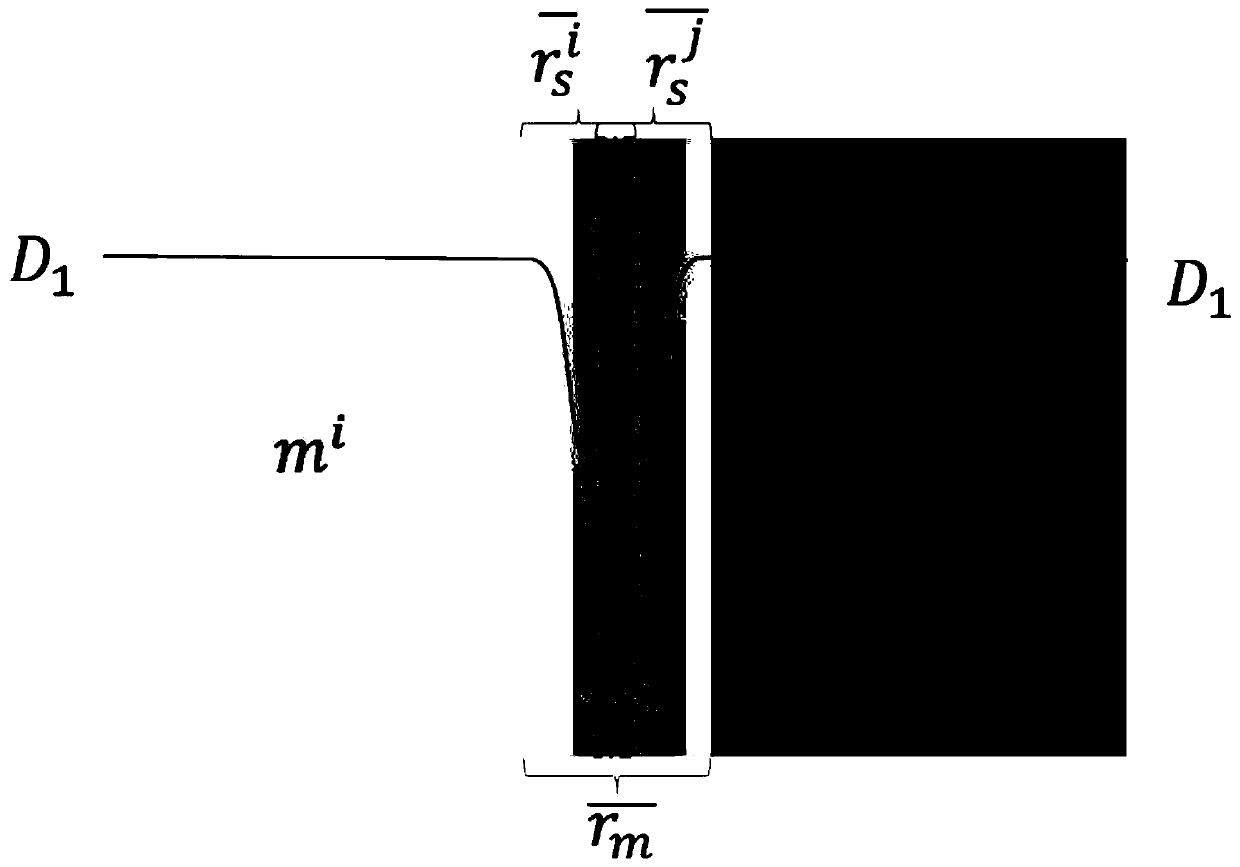

[0093] Step 1. Set the design domain of topology optimization as Ω; construct a pseudo-density design variable (topological geometric design variable) φ, φ is a continuous function in the design domain Ω, and the value of φ at each position in the design domain Ω represents the design Whether the material is arranged at the corresponding position in the domain Ω, -1≤φ≤1; construct a multi-component design vector (μ 1 , μ 2 ,..., μ k ,..., μ K ), where μ k Denotes the kth component design variable, μ k is a continuous function in the design domain Ω, μ k The value taken at each position in the design domain Ω represents the possibility that the corresponding position in the design domain Ω belongs to the kth component, 0≤μ k ≤1, k=1, 2, ..., K, K is the maximum number of components to divide the design domain into (manually s...

Embodiment 2

[0151] This embodiment discloses a multi-component processing method for a microstructure product, comprising the following steps:

[0152] Step i, using the multi-component topology optimization microstructure design method in Example 1 to solve φ, μ k The optimal value of , and its corresponding pseudo-density design variable ρ, variable m k , the average pseudo-density design variable ρ l and parameter ω k ;

[0153] Step ii, obtain the mathematical model of each component that forms this microstructure according to the following formula:

[0154] C k = ρm k +g(ρ l )(1-m k )ω k

[0155] Among them, C k Indicates the kth component that constitutes the microstructure;

[0156] Step iii, using processing equipment to process all components according to the mathematical model of each component of the microstructure;

[0157] Step iv, assembling each component to obtain a microstructure product.

Embodiment 3

[0159] This embodiment discloses a multi-component topology optimization design system for microstructure products, including a memory and a processor, and a computer program is stored in the memory, and when the computer program is executed by the processor, the processor realizes The microstructure product multi-component topology optimization design method in the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com