Fully automatic environment-friendly non-porous paint brush processing device

A technology without planting pores and a processing device is applied in the field of devices for processing paint brushes, which can solve the problems of low processing efficiency, high cost, and large environmental pollution of paint brushes, and achieve the effects of improving processing efficiency and firm connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

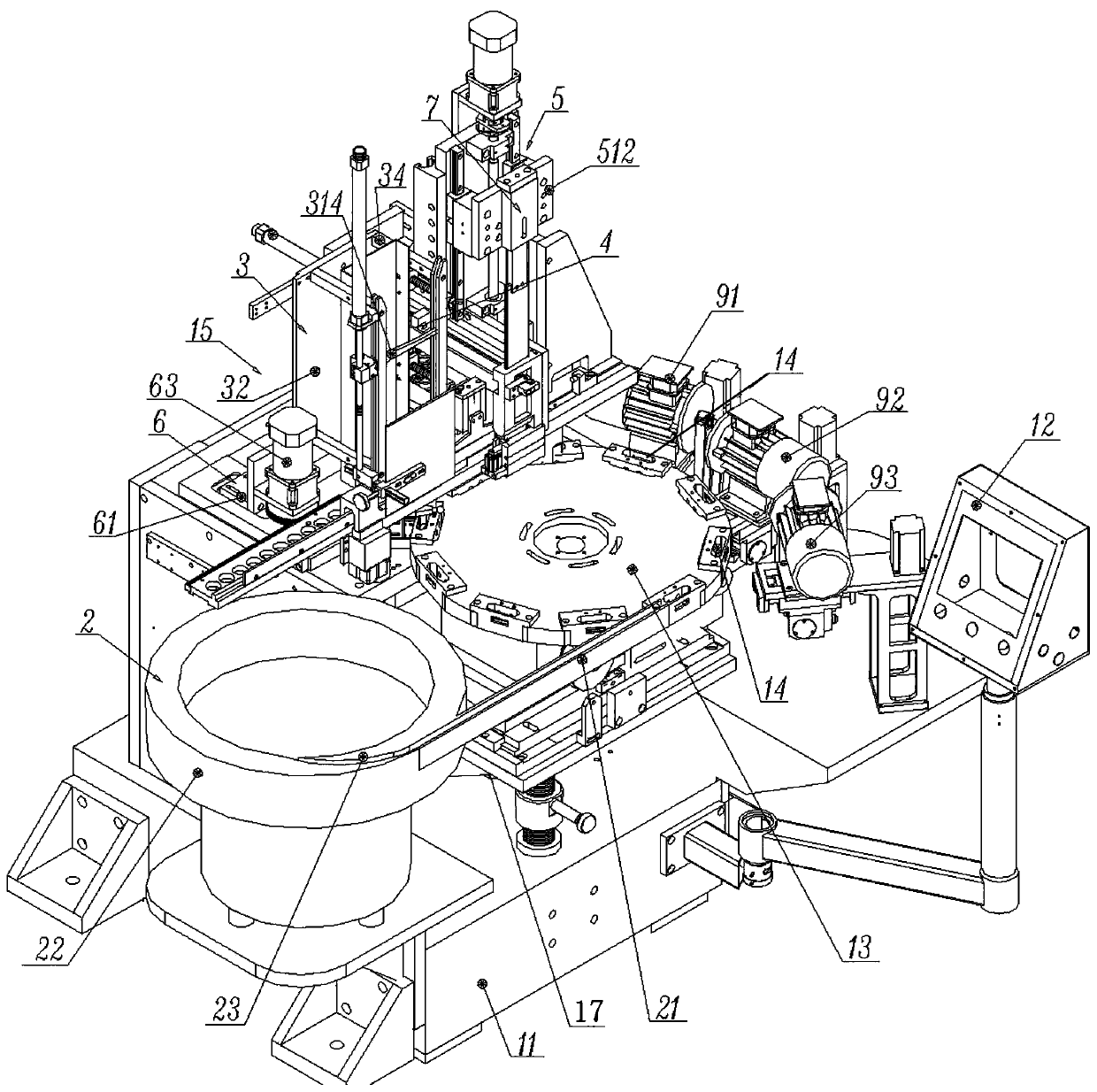

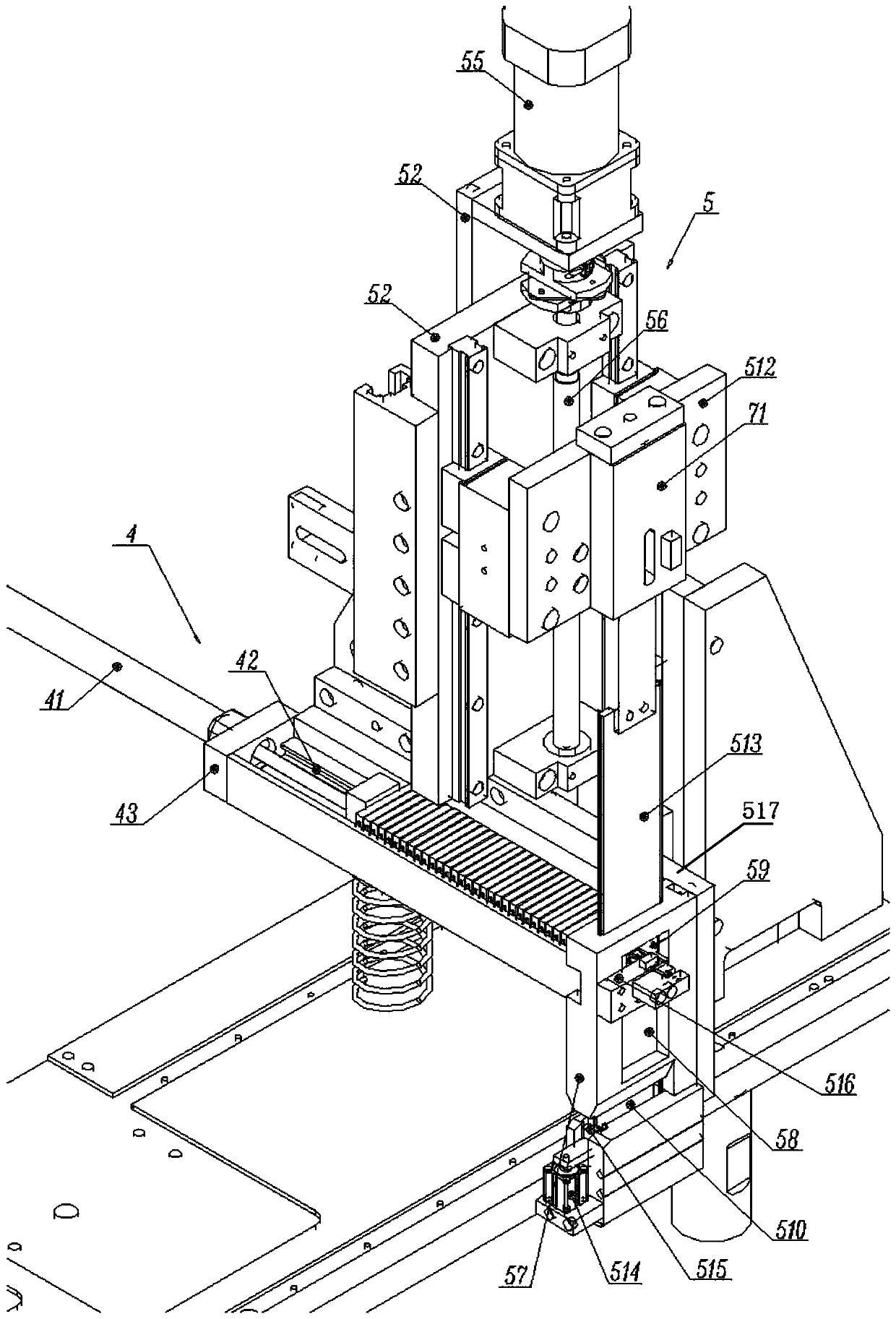

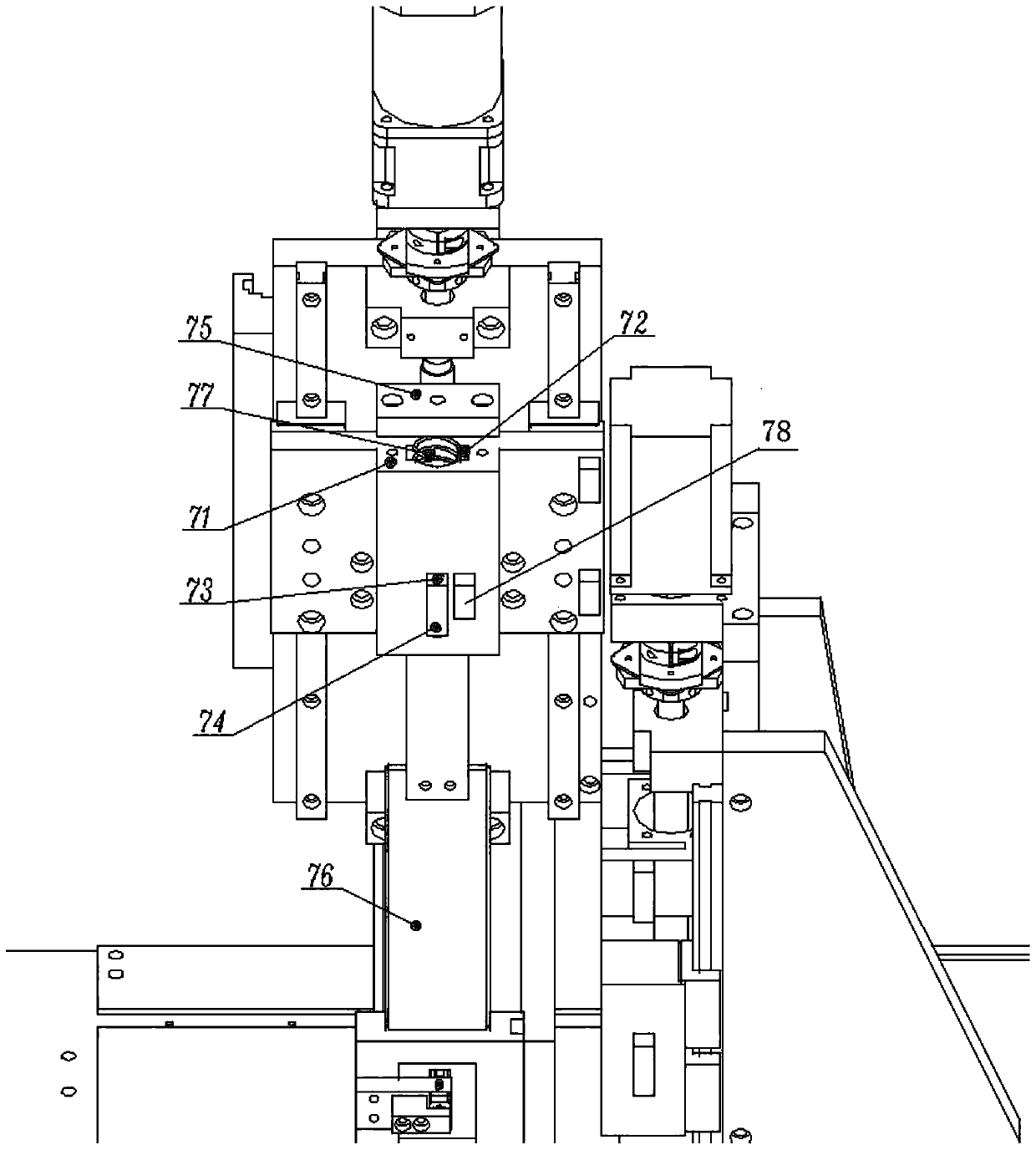

[0026] Referring to the accompanying drawings, it can be known that the fully automatic environmental protection type paint brush processing device without planting holes is characterized in that it includes a body 11, a console 12, a disc 13 provided with a plurality of brush handle placement grooves 14, and is used to place the brush handle The handle delivery mechanism 2 placed in the brush handle placement groove 14, the bristle placement mechanism 15 for placing the wool and the clamping block in the brush handle of the disc 13, the console 12, the disc 13, the handle delivery mechanism 2 and the bristle placement mechanism 15 are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com