A Clockwork Production System

A production system and clockwork technology, applied in wigs, clothing, applications, etc., can solve problems such as inability to realize automation, and achieve the effect of large number of stands, easy management, and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

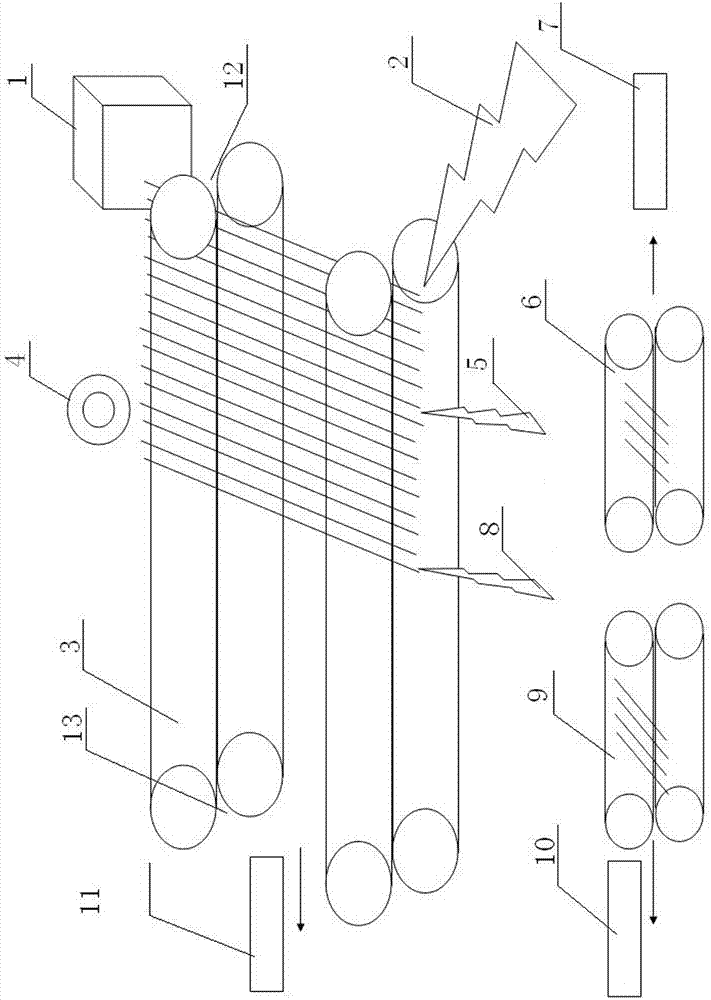

[0014] like figure 1 As shown, the production system of the spring in this embodiment includes a hair product raw material pretreatment system and a spring preparation system; the hair product raw material pretreatment system includes a placer 1 for holding the hair product raw material, in the One side of the placer is provided with a hair-taking manipulator 2, and the hair-getting manipulator takes out 5 hairs of 8 inches in length from the placer successively, and places them on the hair raw material straightening placer 3, and the hair is placed in parallel and is held. The raw material straightening and placing device includes two sets of conveyor belts arranged in parallel, and each set of conveyor belts includes two conveyor belts distributed up and down, and the upper conveyor belt and the lower conveyor belt in each set of conveyor belts are vertically misaligned, and each set of conveyor belts is provided with hair at the longitudinal misalignment. Entrance 12 and ha...

Embodiment 2

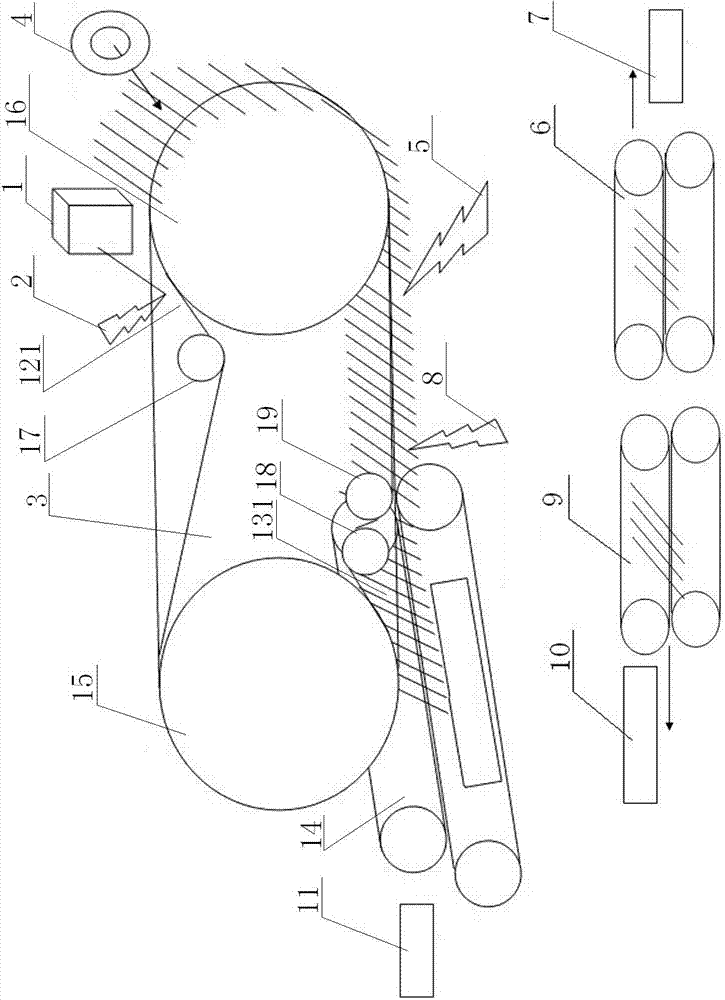

[0020] like figure 2 As shown, the production system of the spring in this embodiment includes a hair product raw material pretreatment system and a spring preparation system; the hair product raw material pretreatment system includes a placer 1 for holding the hair product raw material, in the One side of the placer is provided with a hair-taking manipulator 2, and the hair-getting manipulator takes out 10 hairs of 5 inches in length from the placer successively, and places them on the hair raw material straightening placer 3, and the hair is placed in parallel and is held. The raw material straightening and placing device includes a wheel and two conveyor belts overlapped on the same wheel. The wheel includes a wheel I15 and a wheel II16; a guide wheel I17 is provided between the conveyor belts at the wheel II, and the guide wheel A hair inlet 121 is formed between the wheel I and the conveyor belt above, and a guide wheel II18 is provided between the conveyor belts at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com