Multi-procedure wolf hair softening treatment process

A softening treatment, multi-process technology, applied in the direction of fiber treatment, improved hand-feeling fibers, textiles and papermaking, etc., can solve problems such as large damage, excessive softness, reduced wear resistance, etc., to achieve sharp and neat nibs and good usability. , The effect of softening and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

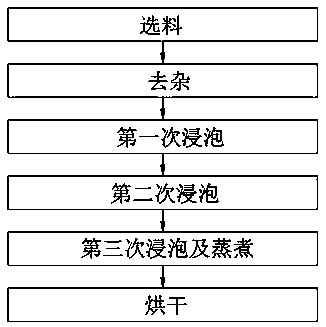

[0024] Example 1: Please refer to figure 1 , The present invention provides a multi-step wolf mill softening treatment process, including the following steps:

[0025] 1) Material selection: take a certain amount of high-quality raw materials;

[0026] 2) Removal of impurities: the raw materials taken from Langhao are sparsely beaten to remove impurities;

[0027] 3) The first soak: use 50% Ca(OH) 2 The mixture with water is added with an auxiliary softener of 1-5% by weight of the raw material of Langhao, and the raw material of Langhao is soaked for the first time after impurities are removed;

[0028] 4) The second soak: use 30% Ca(OH) 2 The mixture with water is added with an auxiliary softener of 1-5% by weight of the raw material of Langhao to soak the raw material of Langhao for the second time;

[0029] 5) The third soaking and cooking: use 10% Ca(OH) 2 The mixture with water is used to soak the raw materials of Langhao after the second soaking for the third time, and put them ...

Embodiment 2

[0040] Example 2: Please refer to figure 1 , The present invention provides a multi-step wolf mill softening treatment process, including the following steps:

[0041] 1) Material selection: take a certain amount of high-quality raw materials;

[0042] 2) Removal of impurities: the raw materials taken from Langhao are sparsely beaten to remove impurities;

[0043] 3) The first immersion: use 50% Ca(OH) 2 The mixture with water is added with an auxiliary softener of 1-5% by weight of the raw material of Langhao, and the raw material of Langhao is soaked for the first time after impurities are removed;

[0044] 4) The second soak: use 30% Ca(OH) 2 The mixed liquid with water is added with an auxiliary softener of 1-5% by weight of the raw material of Langhao, and the raw material of Langhao is soaked for the second time;

[0045] 5) The third soaking and cooking: use 10% Ca(OH) 2 The mixture with water is used to soak the raw materials of Langhao after the second soaking for the third ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com