Wig

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

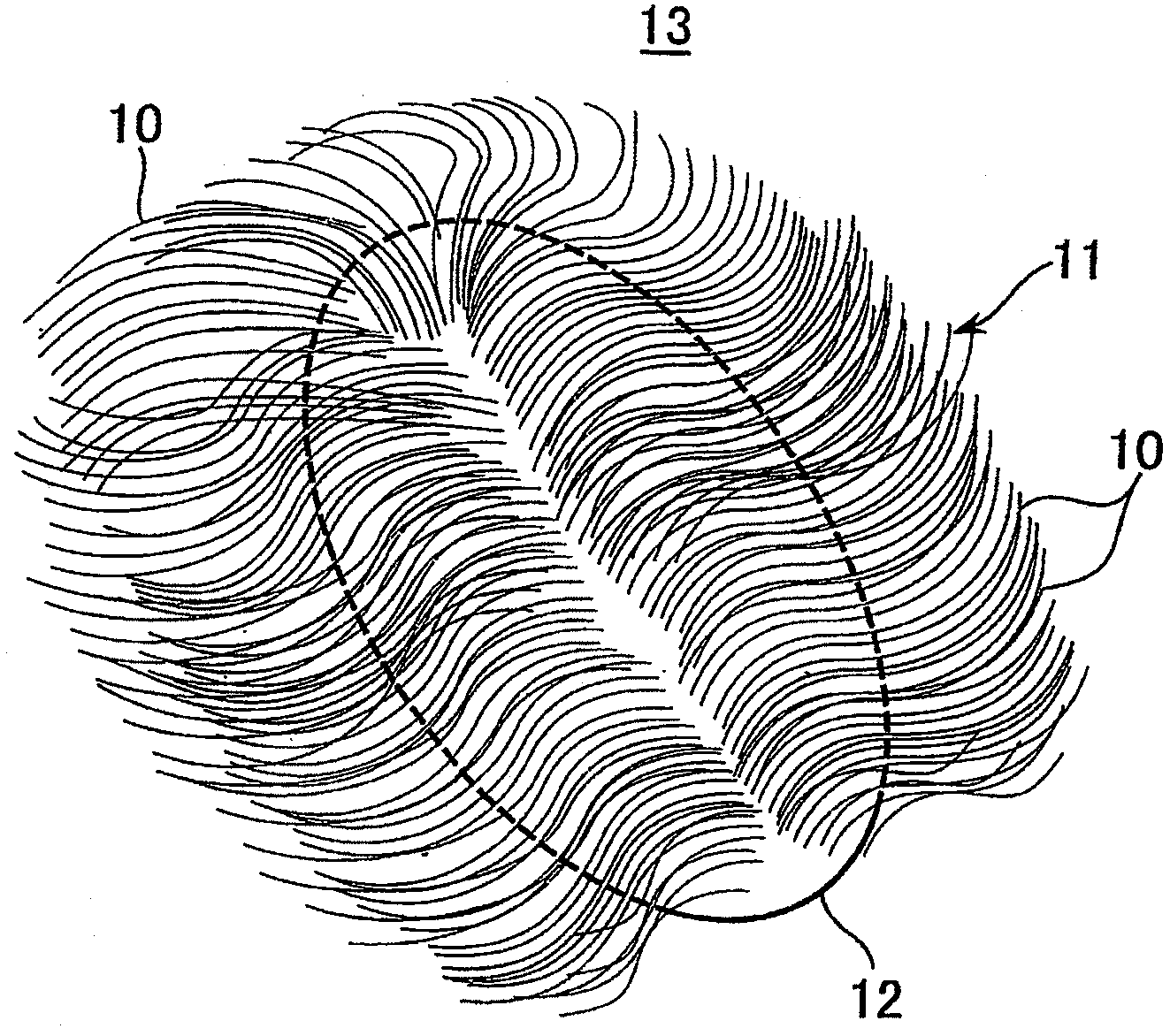

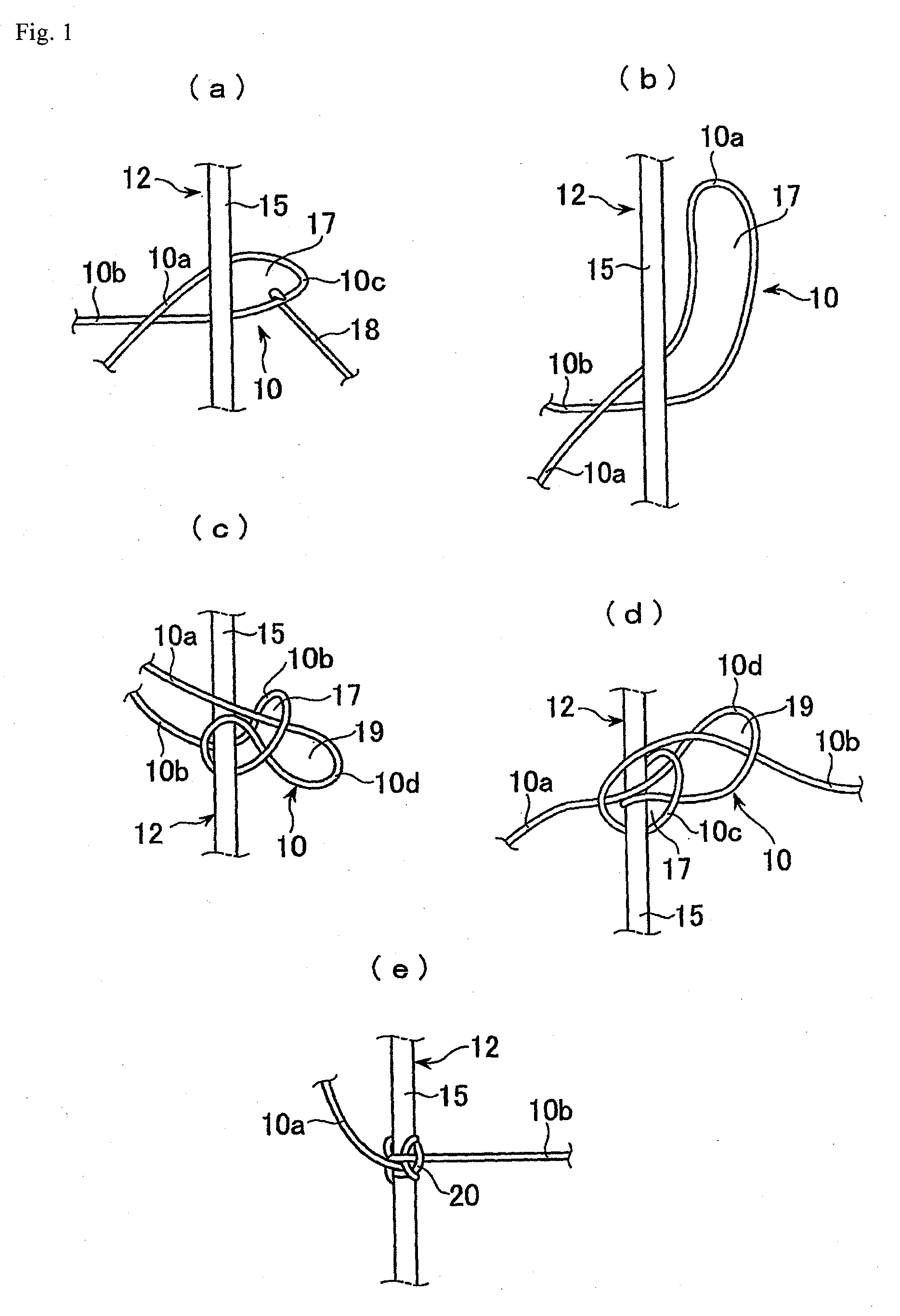

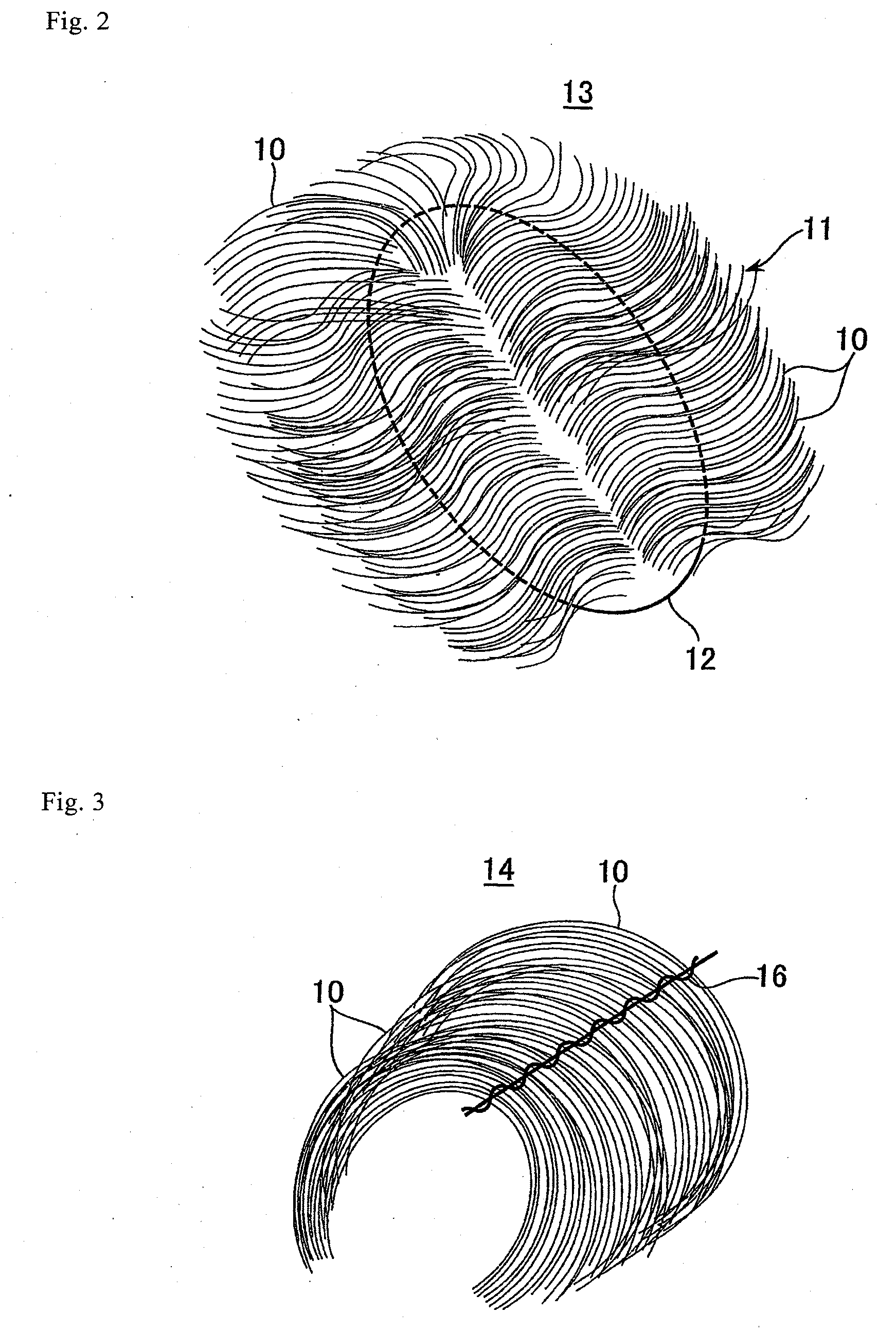

[0043]In the following, embodiments of the present invention will be described with reference to FIGS. 1 through 20. Of the drawings, FIGS. 1 through 5 show the present invention. FIGS. 1(a) through 1(e) are plan views illustrating the operation of fastening a hair material to a filament of a wig base in the form of a net, FIG. 2 is a perspective view of a wig, FIG. 3 is a perspective view of a weft, FIGS. 4(a) through 4(d) are perspective views of a single hair material, and FIG. 5 is a front view of hair materials as fastened to a filament of a wig base.

[0044]In the first embodiment of the present invention shown in FIGS. 1 through 5, a large number of hair materials 10 are fastened to a wig base 12 as hair 11 to form a wig 13 as shown in FIG. 2. As the hair materials 10, human hairs or synthetic resin hairs are used. In the state of a weft 14 prior to the fastening to the wig base 12, curl is imparted to hair pieces 10a, 10b beforehand. When large number of hair materials 10 are ...

third embodiment

[0062]Of the drawings, FIGS. 7 through 16 show the FIG. 7 is a perspective view illustrating the operation of blending hair materials, FIG. 8 is a plan view of a sewn weft, FIG. 9 is a plan view of a weft as placed on a sheet material, FIG. 10 is a plan view of a weft placed on a sheet material as combed, FIG. 11 is a sectional view of a weft on a sheet material, FIG. 12 is a plan view illustrating how hair a tuft and a sheet material are wound around a pipe member, FIG. 13 is a sectional view showing a weft and a sheet material as wound around a pipe member, FIG. 14 is a perspective view showing, like FIG. 13, hair a tuft and a sheet material as wound around a pipe member, FIG. 15 is a front view of a hair material as fastened to a filament, and FIG. 16 is a plan view of hair materials drawn out of hair a tuft.

[0063]The third embodiment shown in FIGS. 7 through 16 is suitable for imparting curl to human hairs as the hair materials 10 (including human hairs from which the cuticles ...

fifth embodiment

[0088]In this way, in the fifth embodiment, it is possible to apply moist air and dry air continuously with ease, without using any special device, through a combination of the material and weight per unit area [metuske] of the non-woven fabric wound together with the weft 14, the aluminum pipe member 33, and the aluminum foil 37, and through adjustment of the temperature and time of the heat treatment, thereby making it possible to obtain a curl of still higher retaining property.

[0089]Next, the sixth embodiment of the present invention will be described with reference FIGS. 7 through 16 common to the third through fifth embodiments plus FIGS. 19 and 20. A detailed description of the components that are the same as those of the third through fifth embodiments will be omitted. This embodiment is suitable for an artificial hair described below. That is, an artificial hair of a core / sheath structure is preferable, with the core portion being formed of a semi-aromatic polyamide with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com