Round head twisted hair brush shearing and sanding integrated machine and working method and round head twisted hair brush

An all-in-one machine and brush technology, applied in the direction of brush body, brush, bristle, etc., can solve the problems of skin scratches, liquid medicine easy to enter the human body, easy to cause infection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following describes the implementation of the present invention in detail with reference to the accompanying drawings, but they do not constitute a limitation to the present invention, and are merely examples. At the same time, the advantages of the present invention are made clearer and easier to understand through the description.

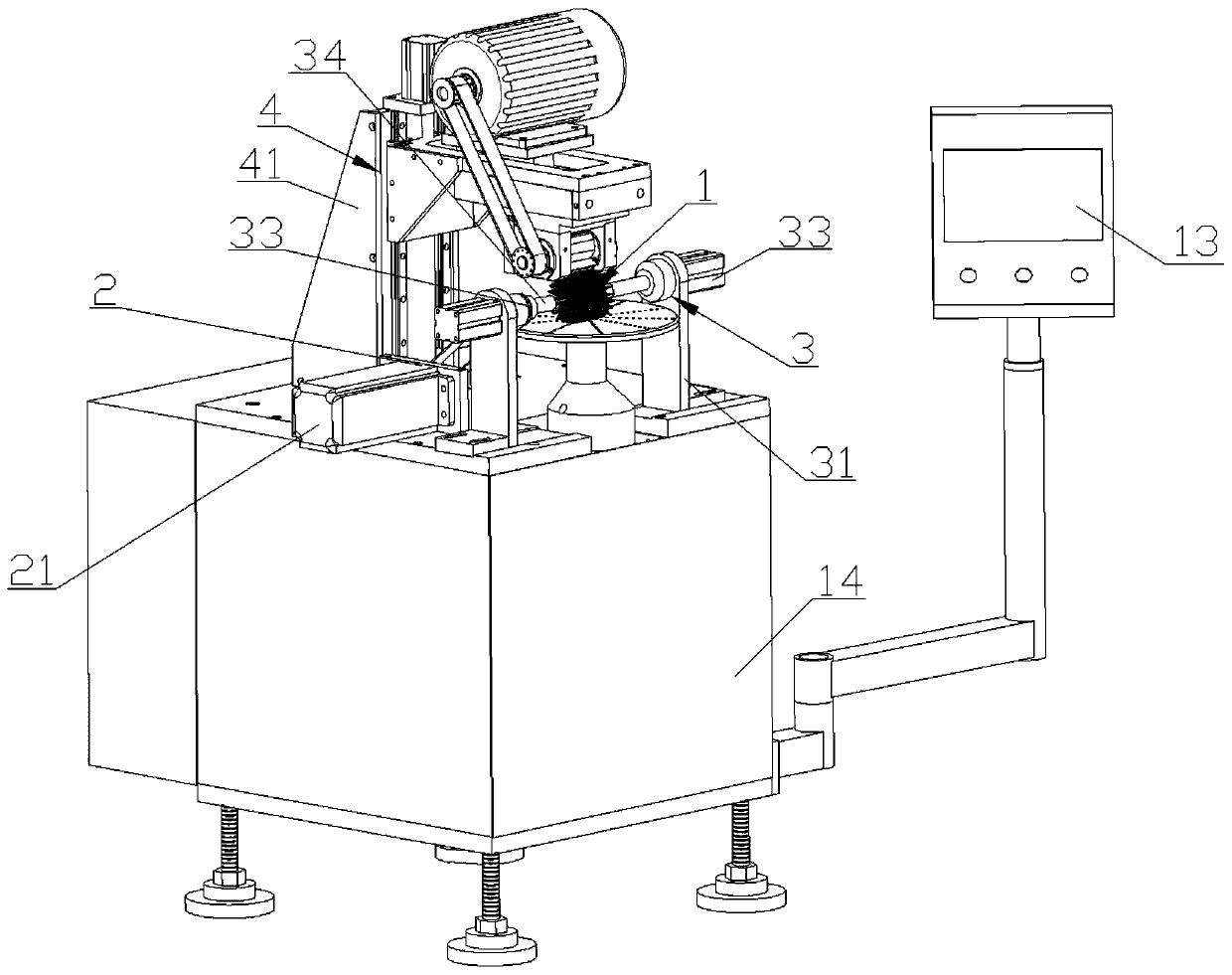

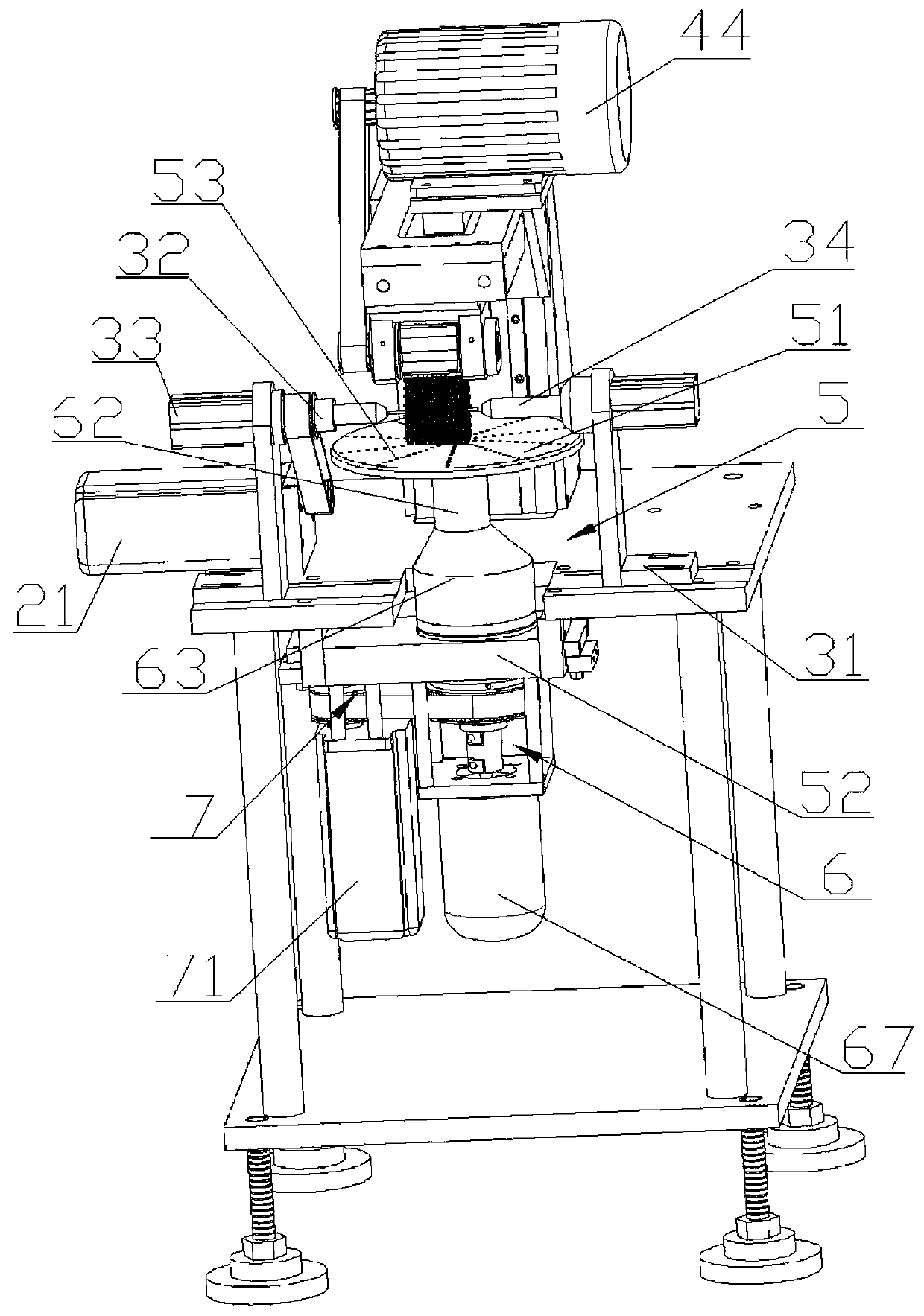

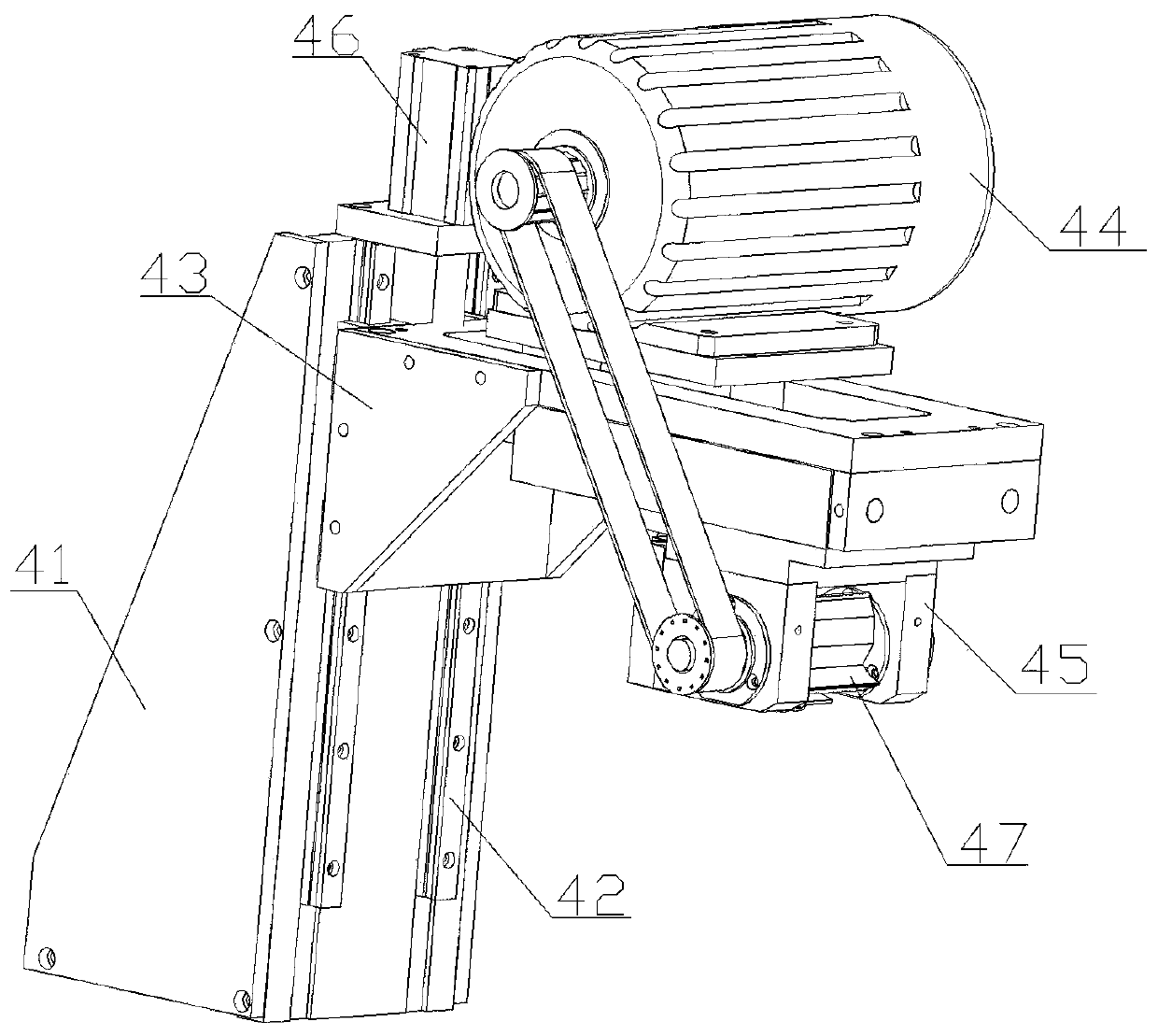

[0035] Referring to the drawings, it can be seen that the round-head twisted brush shearing and sanding integrated machine includes a brush body 1, which is composed of a wool 11 and a metal wire 12, and is characterized in that it also includes a main controller 13 (preferably PLC controller), workbench 14, wire clamping and pulling mechanism 3 for clamping the metal wire 12 and capable of pulling the metal wire 12, wire turning mechanism for rotating the metal wire 12, 2, for performing the wool 11 The shearing shearing mechanism 4, the sanding mechanism 5 for rounding the sheared wool 11, the sanding mechanism 5 includes a sanding tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com