Writing brush head, manufacturing method and application thereof

A technology of brush tips and brushes, applied in the direction of nibs, printing, writing utensils, etc., can solve problems such as difficulty for beginners to distinguish the trajectory of brush strokes, low efficiency, monotonous and boring copying process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0138] 2. Preparation method of the nib

[0139] 2.1 Overall Technical Solution

[0140] The present invention also discloses a method for preparing the above-mentioned brush nib. The nib of the present invention can be obtained through the following technical solutions. The preparation method includes the preparation, mixing and binding process of the bristle material; it is allowed to include other steps for the purpose of optimization.

[0141] (1) Component one is selected from the group including but not limited to: degreased animal hair, degreased human hair, degreased plant fibers, chemical fibers that meet the aforementioned parameter range after hydrophilization optimization treatment, etc., or combinations thereof.

[0142] (2) The second component is selected from including but not limited to: non-defatted animal hair, non-defatted plant fiber, synthetic fiber, or animal hair, human hair, plant fiber, and chemical fiber are hydrophobized and modified to meet the afo...

Embodiment 1

[0197] In Example 1, the core does not absorb ink, and the stroke trace is displayed blank.

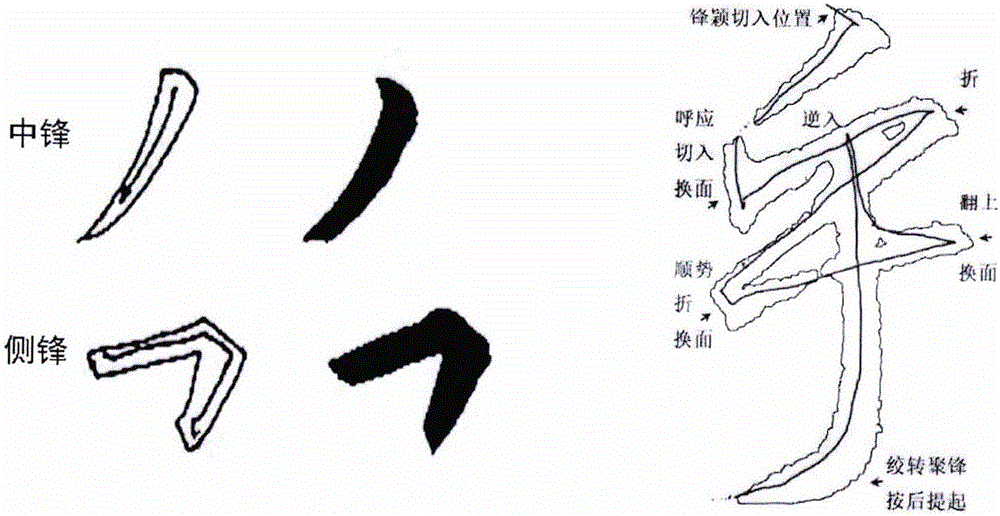

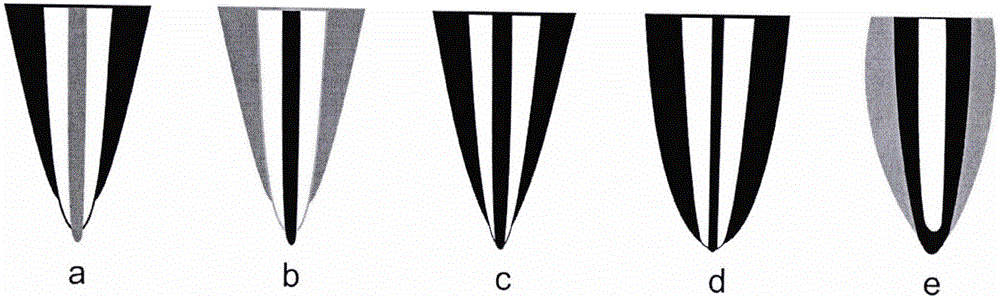

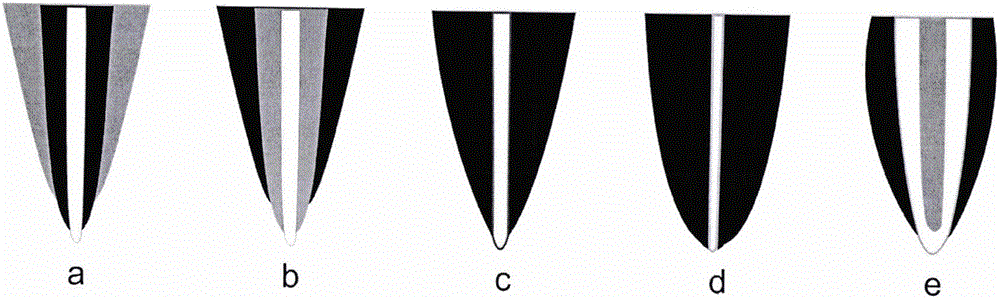

[0198] It is obtained from brush hairs and polypropylene fiber (PP fiber) purchased from the market. Use PP fiber with a length of about 3.3cm to make a fiber bundle with a diameter of about 3mm, and wrap the core with substantially equal length brush hair. After ligation, the diameter of the end of the nib is about 8.5mm, and it is bound to make a nib, which is installed on the pen holder to make a writing brush ( Figure 10). The bristles have a shell-core structure, refer to image 3 c. image 3 d. Figure 5 a(1), Figure 5 The hair distribution of a(2). Use the center stroke method to write, and the trajectory of the pen is as follows: Figure 11 shown. At this time, the hydrophobic PP fiber does not absorb ink, and the center track is displayed in a blank manner.

[0199] Using the same method, the PP fiber bundle is about 2mm higher than the brush hair, and the length o...

Embodiment 2

[0200] The island-in-the-sea distribution of embodiment 2 hydrophobic brush hairs

[0201] Take Langhao brush brush hair and polyester hair purchased from the market, the length is about 4.5cm, and the content is about 50%. The polyester hair is made into nylon fiber bundles with a diameter of about 0.5mm, which are randomly distributed among the brush hairs, and the nibs with a diameter of about 9mm and 10mm are made respectively. Refer to Figure 5 e(1). After ligation and binding, it is installed on the pen holder to make a writing brush. Use the center stroke method to write, and the trajectory of the pen is as follows: Figure 11 As shown in the figure on the right, it is almost a striped display.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com