Patents

Literature

74results about How to "Low energy input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

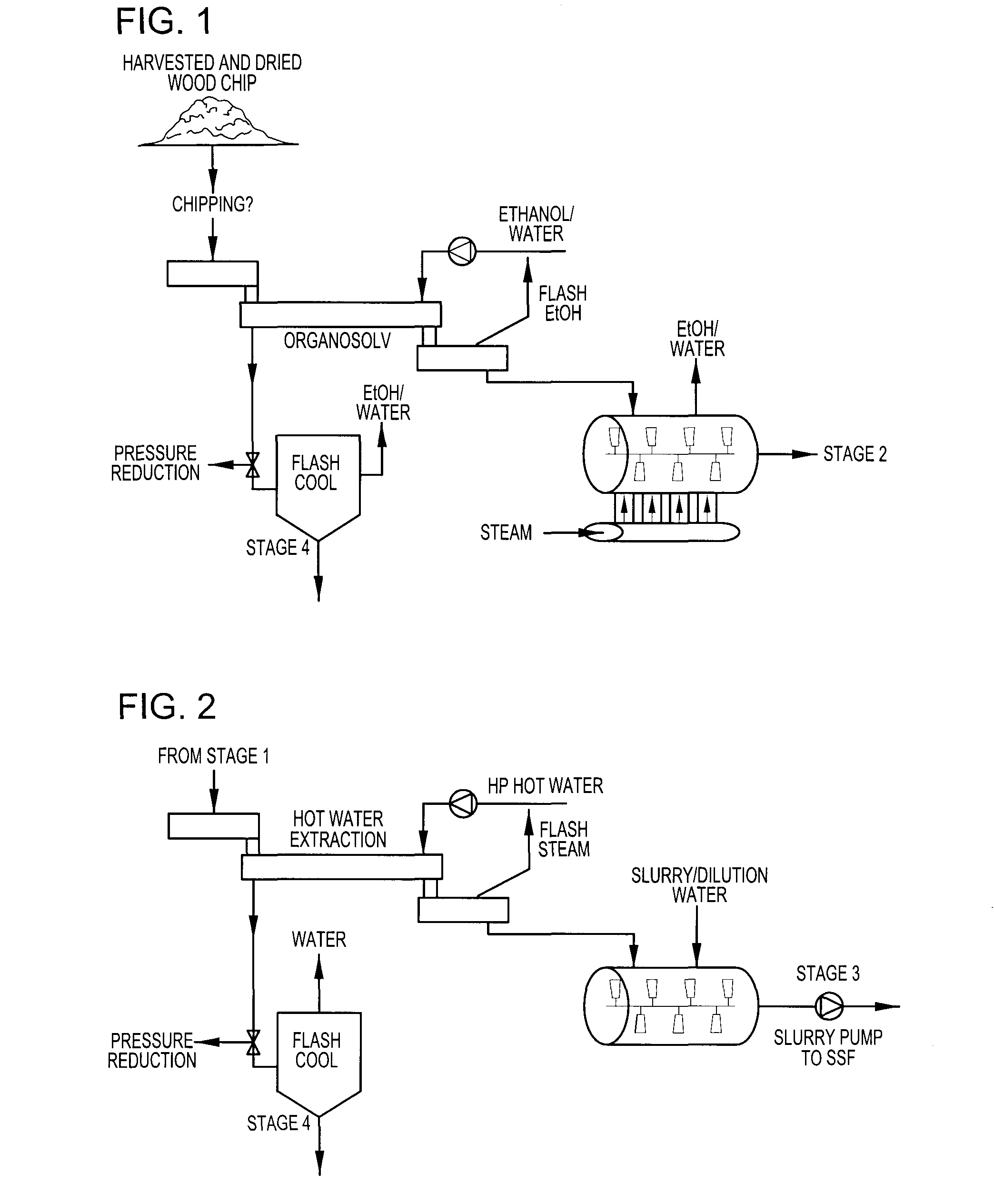

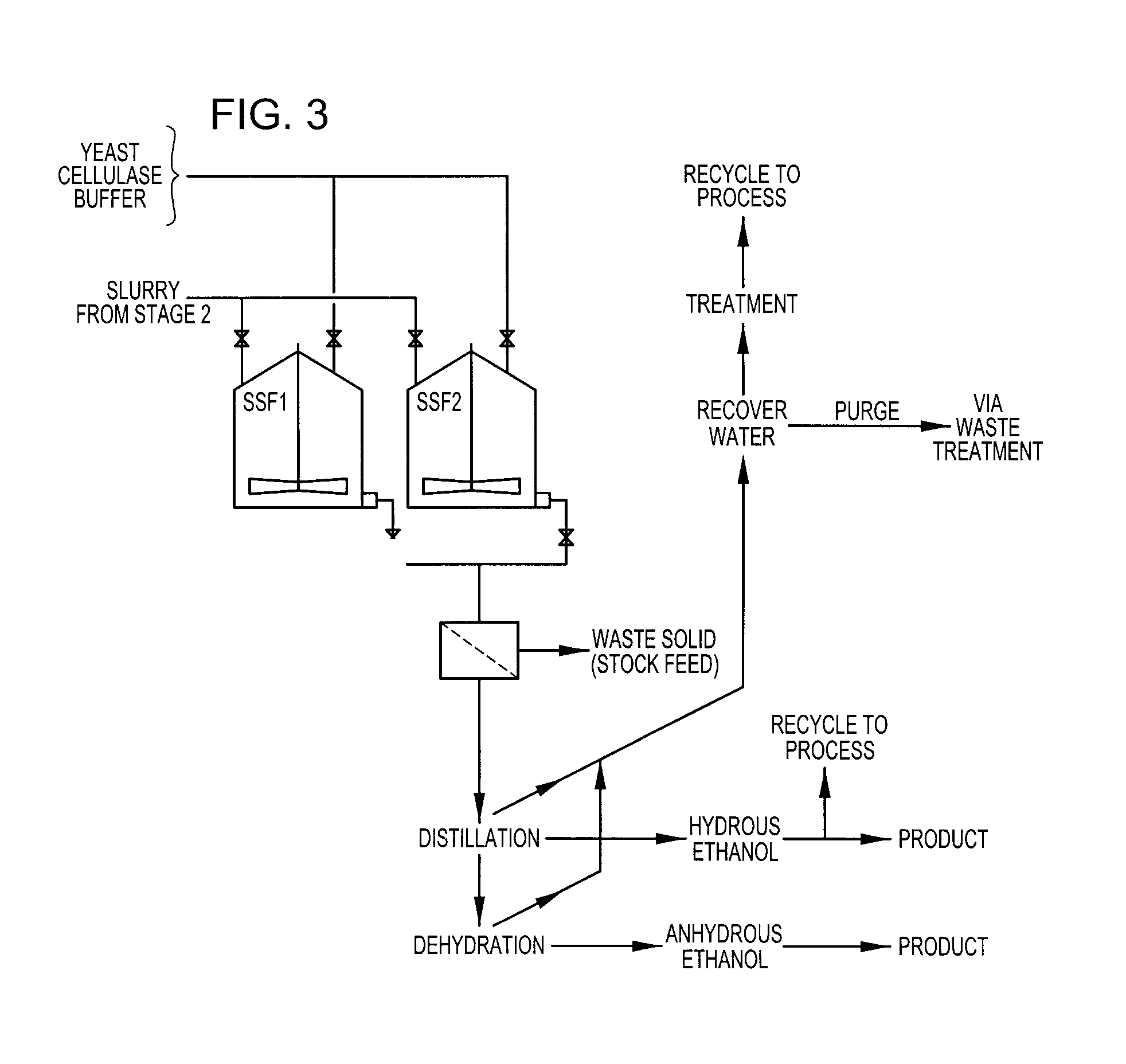

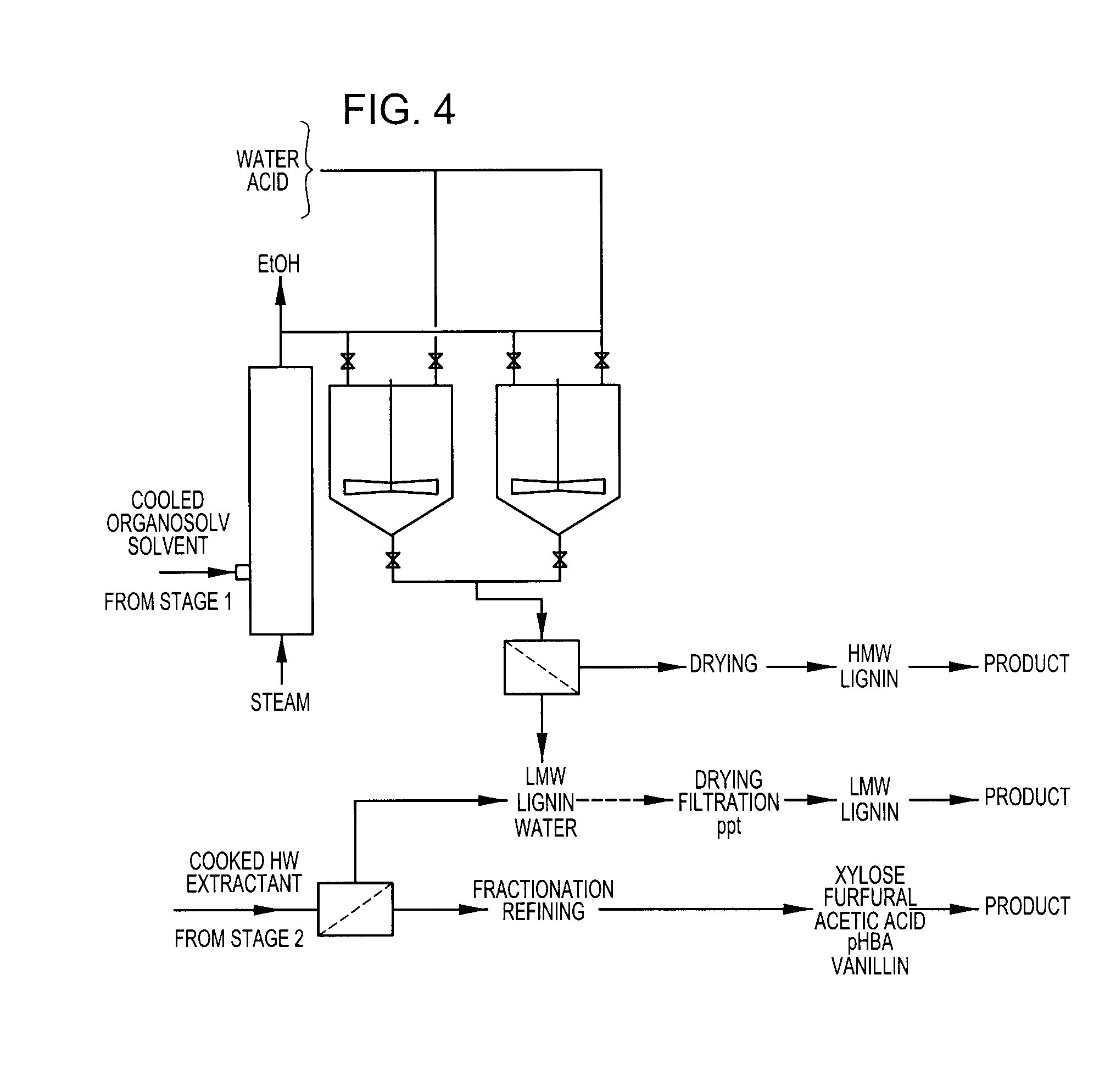

Integrated processing of plant biomass

InactiveUS7649086B2Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseWoody plant

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

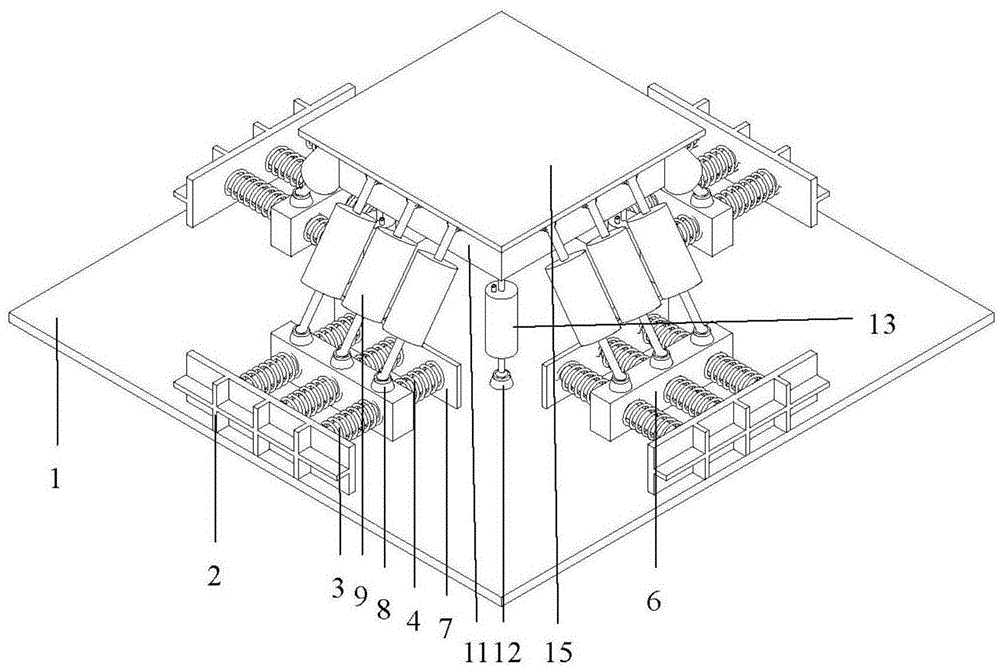

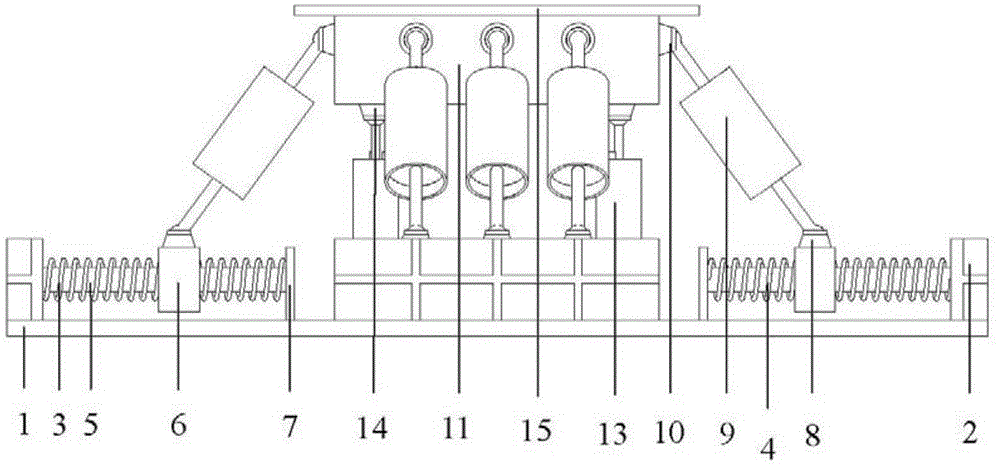

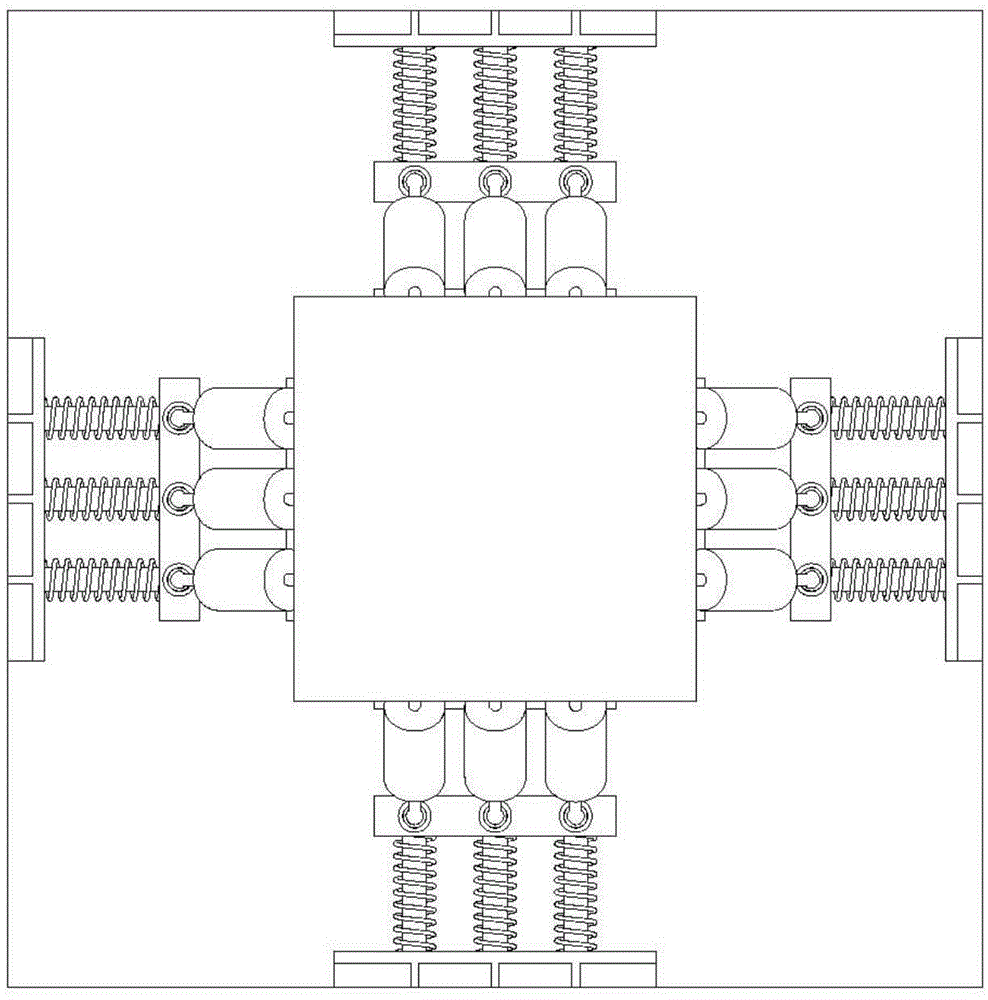

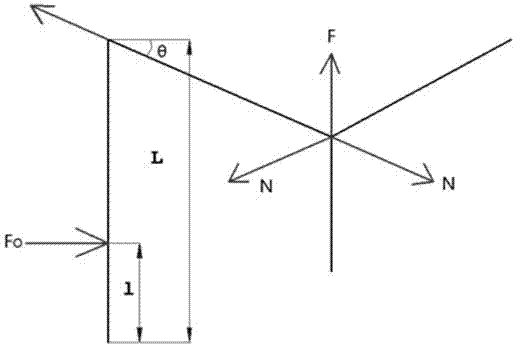

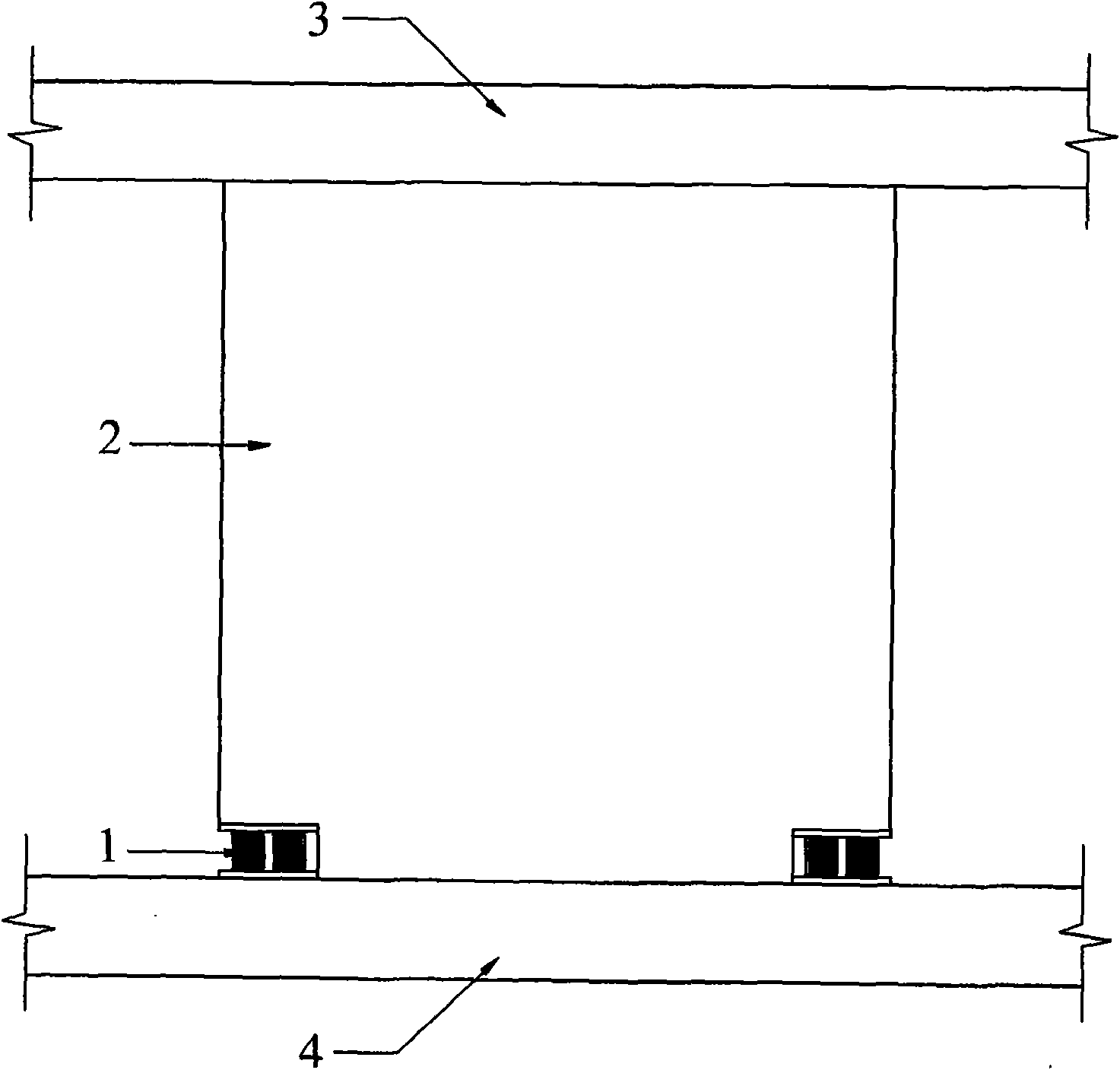

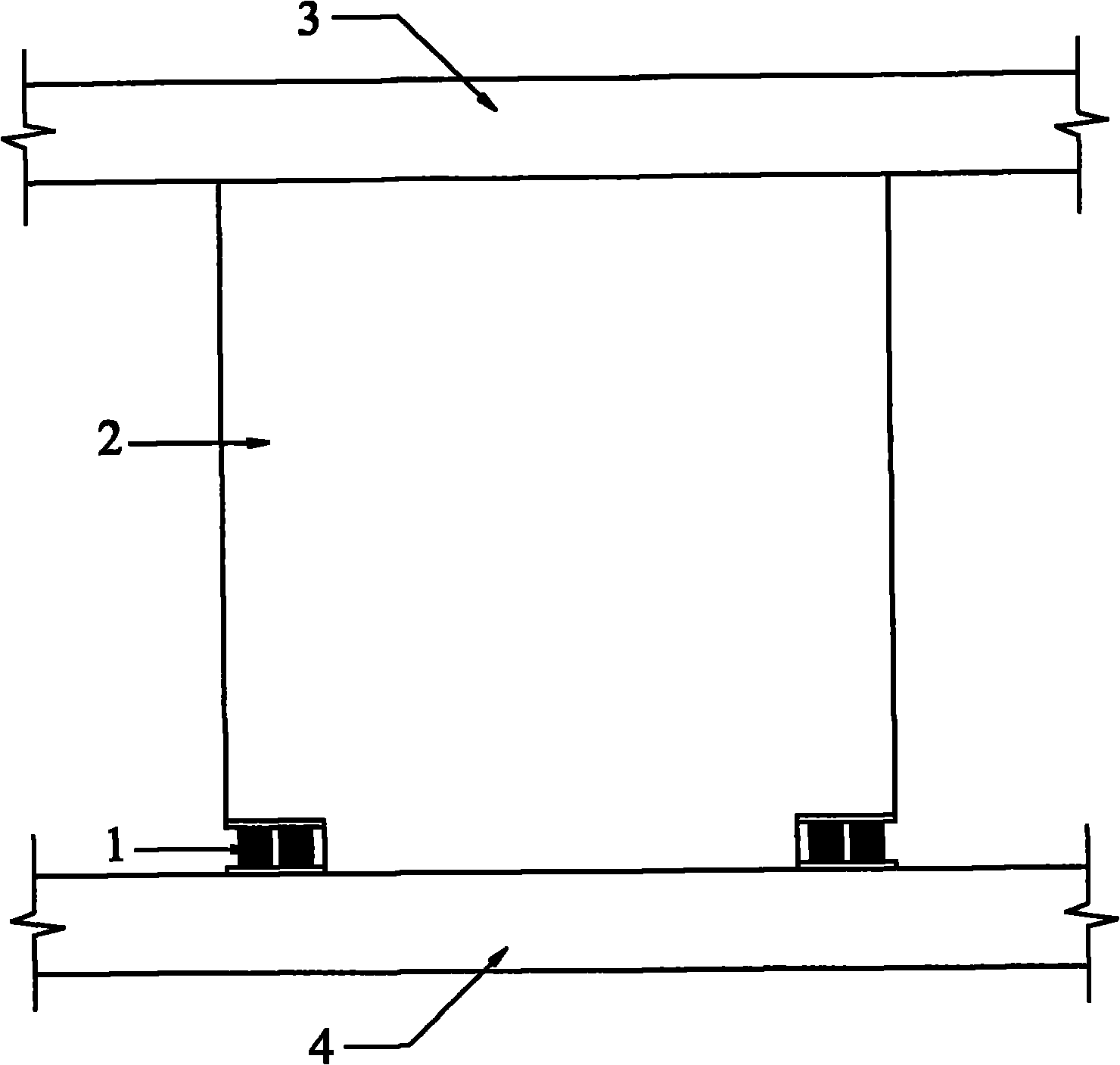

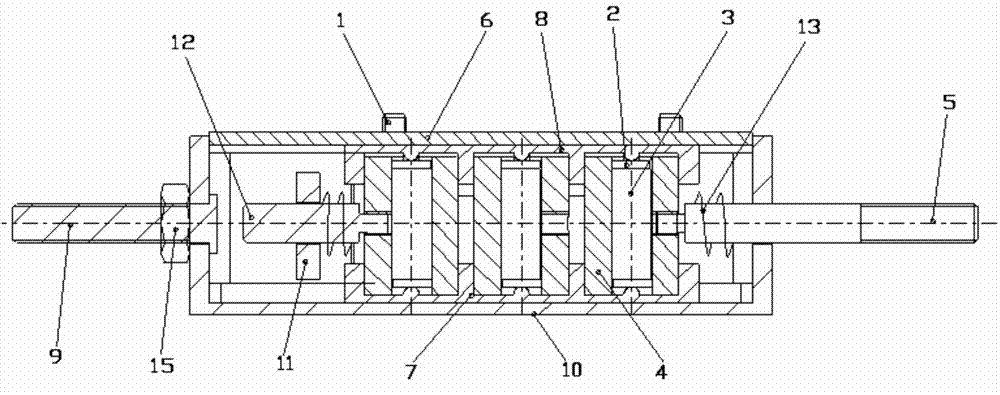

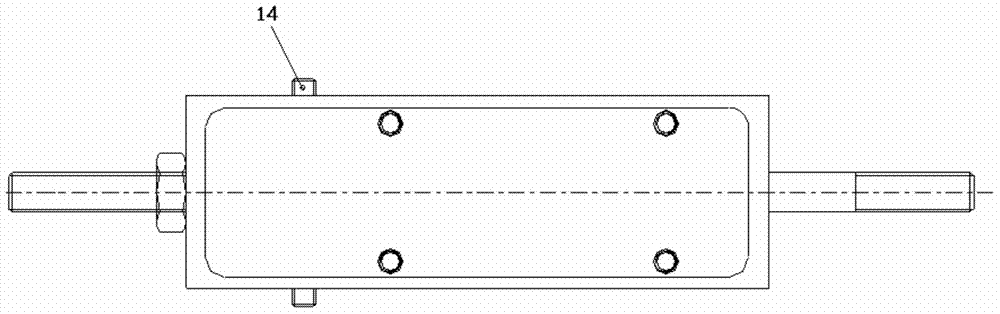

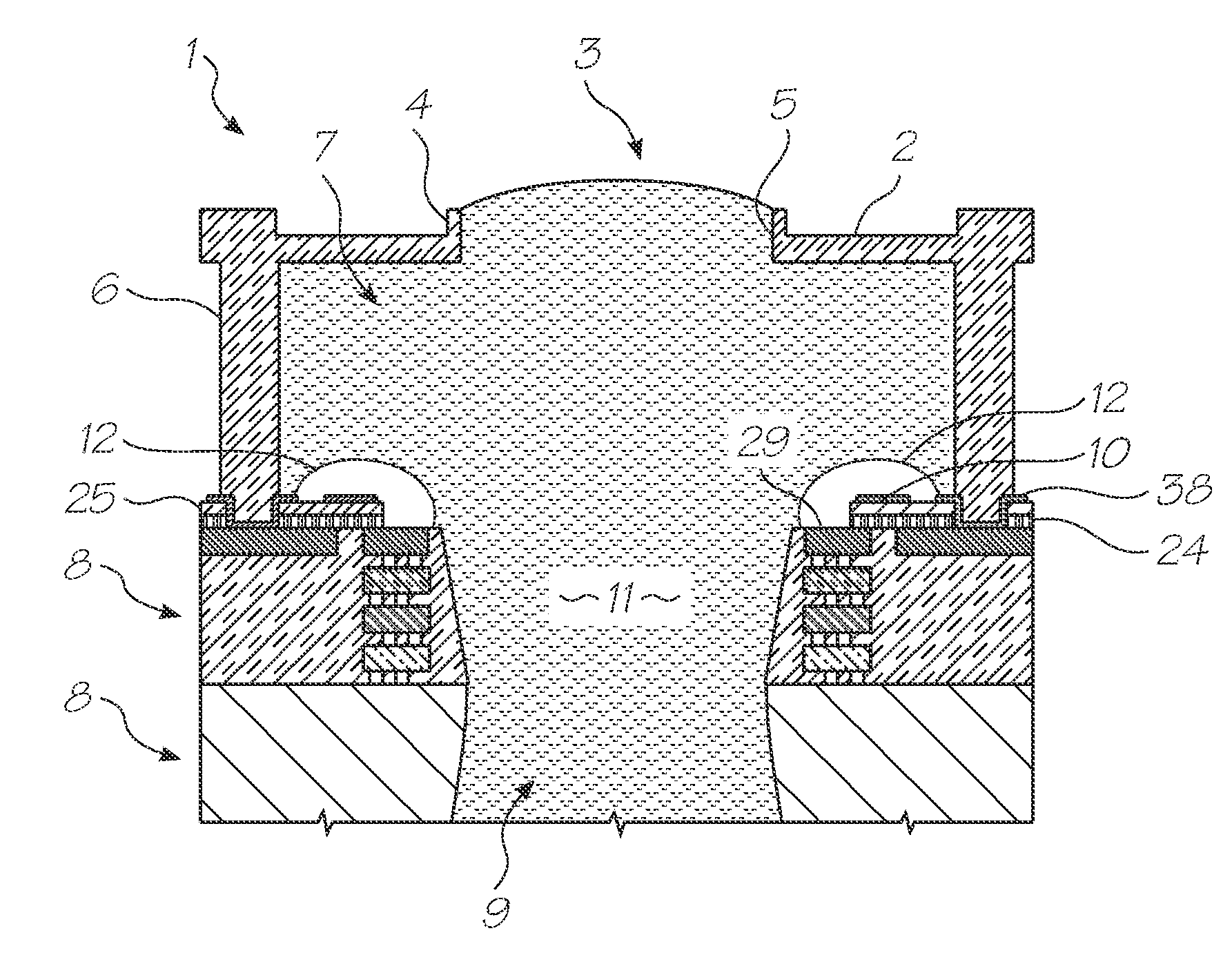

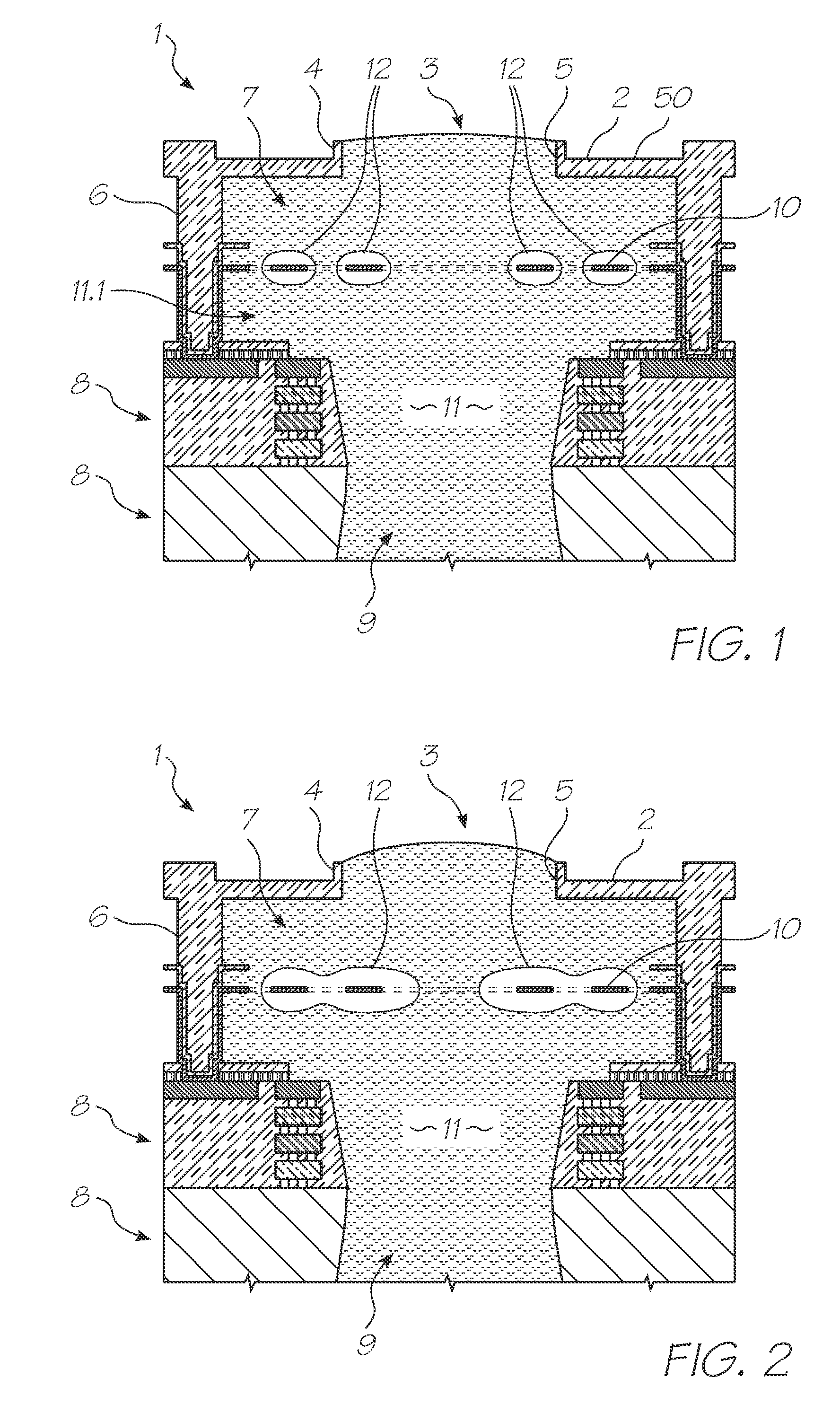

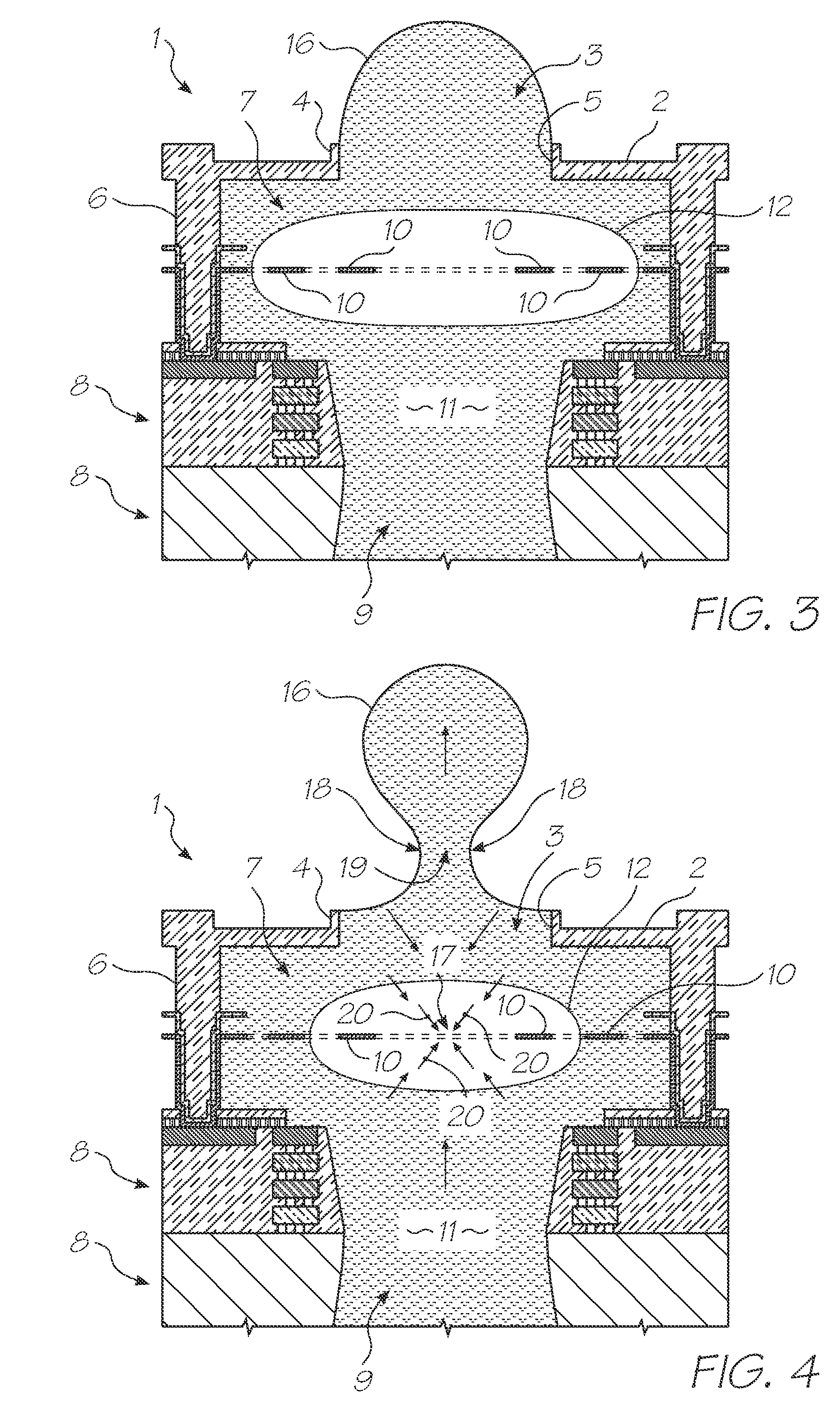

Three-way shock insulation pedestal with spring damp guide rod device

ActiveCN104315079AReduce the purpose of seismic protectionReduce the purpose of protectionNon-rotating vibration suppressionShock proofingEngineeringMechanical engineering

The invention relates to a three-way shock insulation pedestal with a spring damp guide rod device. The pedestal comprises a bottom plate, a lower disc shock insulation device, a middle disc conversion device, an upper disc shock insulation device and a top disc, wherein the lower disc shock insulation device is fixed to the bottom plate; the lower disc shock insulation device is connected with the top disc through the middle disc conversion device; the upper disc shock insulation device is connected between the bottom plate and the top disc. According to the pedestal, the purposes of horizontally insulating shock while reducing the vertical earthquake effect are achieved, the shock insulation protection is provided for a structure with vertical and horizontal shock reduction and insulation requirements, the path of transmission of the earthquake effect to protected equipment or reserved cultural relics is cut off or weakened to the maximum extent, and the earthquake input energy is reduced to protect the equipment or the reserved cultural relics.

Owner:INST OF ENG MECHANICS CHINA EARTHQUAKE ADMINISTRATION

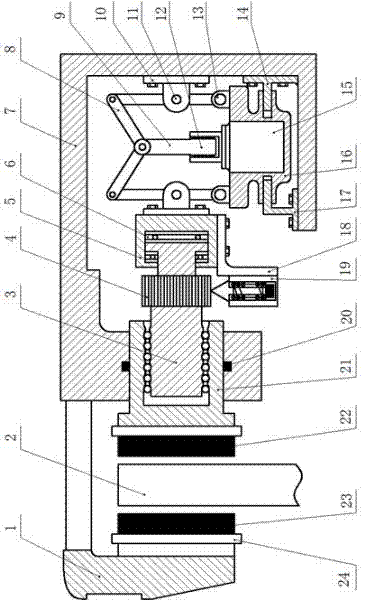

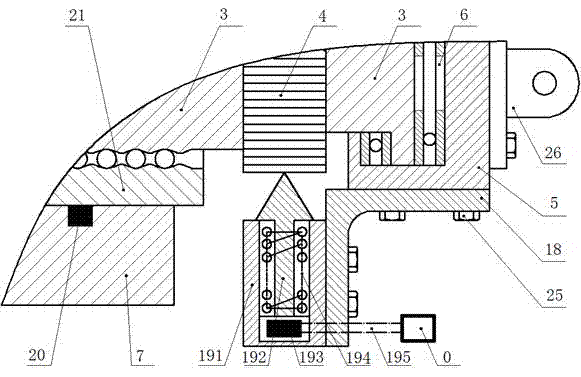

Automobile electromechanical brake

ActiveCN102518718AWith parking brakeIncrease boost effectBrake actuating mechanismsSlack adjustersEngineeringCalipers

The invention discloses an automobile electromechanical brake, which comprises a front floating caliper and a floating caliper block. The front floating caliper is connected with a front friction disc, the floating caliper block is connected with a back friction disc through a nut-piston, a brake disc is arranged between the front friction disc and the back friction disc, and the nut-piston is connected with a motor through a boosting linkage and is connected with a gap regulating mechanism. The motor pushes the back friction disc and the front friction disc to attach onto the brake disc by the boosting linkage, thereby realizing braking. The automobile electromechanical brake has a gap regulating function, and gaps among the brake disc and the friction discs can be regulated freely, so that constancy of the brake response speed of automobiles is guaranteed and braking performance is guaranteed further. The automobile electromechanical brake is fine in braking performance, simple in structure, convenient in installation, easy to maintain and low in energy consumption.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

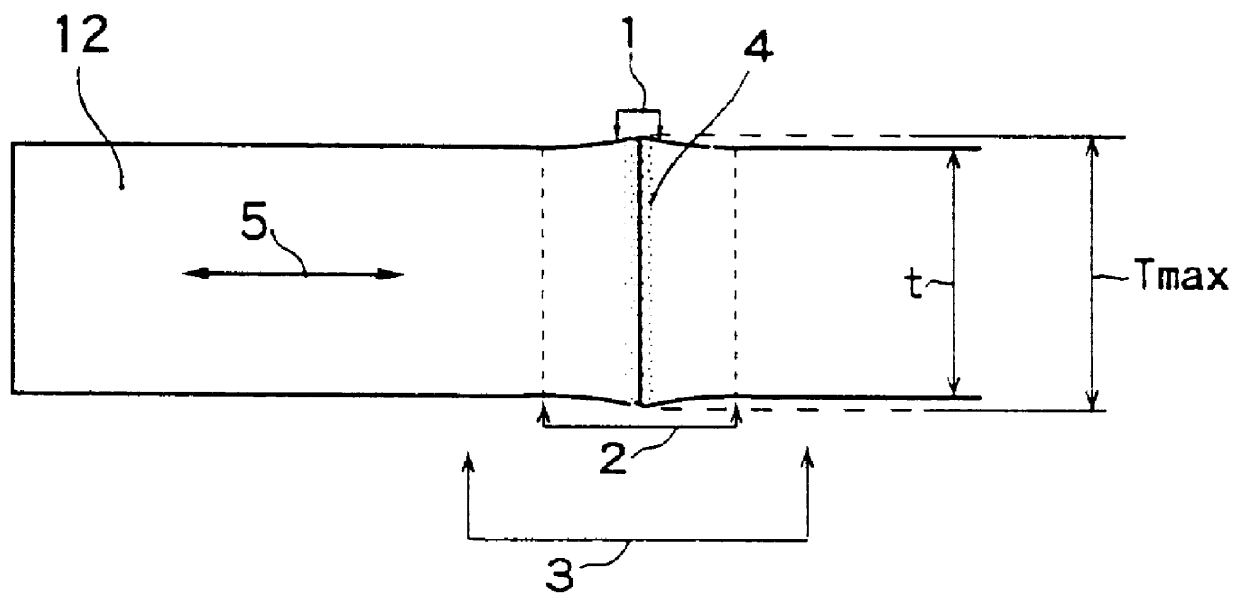

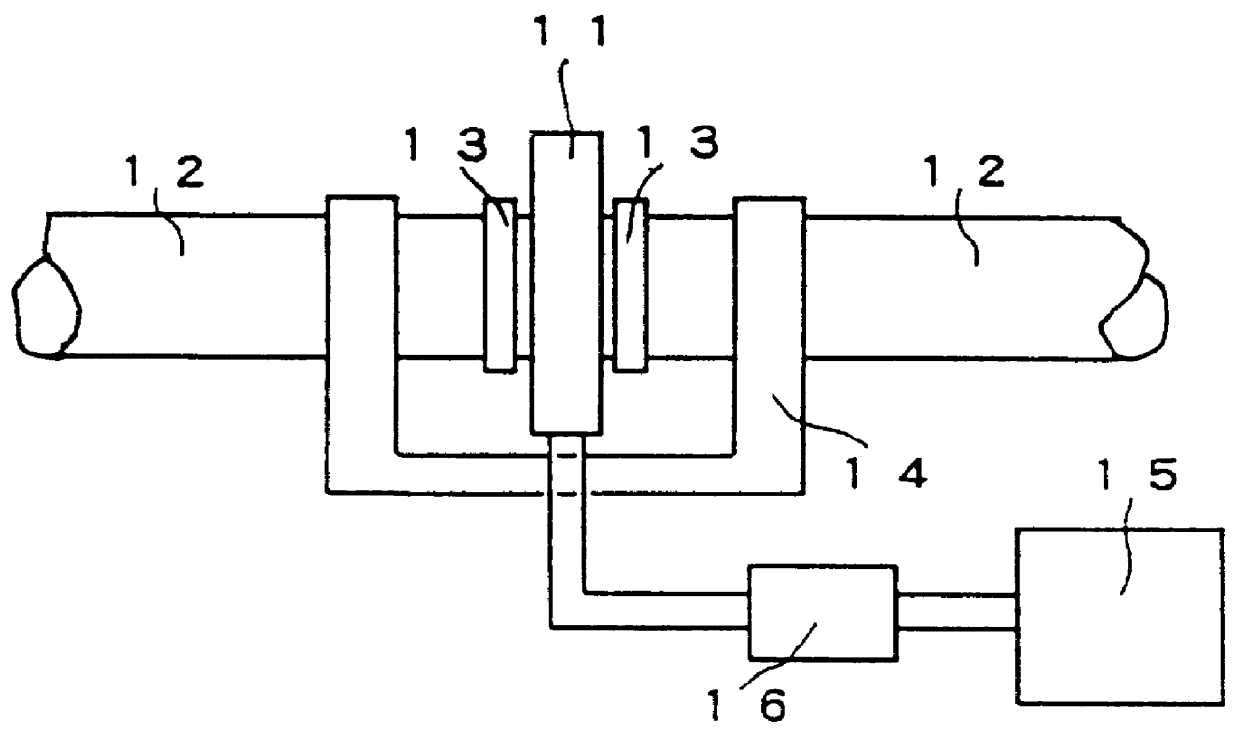

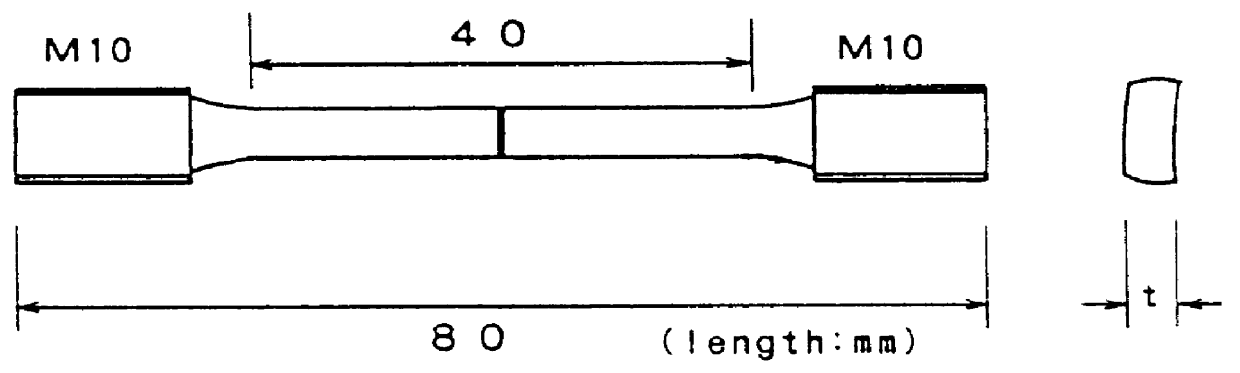

Method for joining metallic materials by diffusion bonding and joined structure thereby

InactiveUS6059175ALow density of input energyLow energy inputWelding/cutting media/materialsWelding/soldering/cutting articlesMetallic materialsAlloy

The present invention provides (1) diffusion bonding methods for joining metallic materials like carbon steels or stainless steels,interposing a bonding material, such as 10 to 80 mu m thick Ni-based alloy with the melting point of 1150 DEG C. or lower,between base materials, heating so that the length heated at 800 DEG C. or above measures from 3 to 20 mm, in case of joining stainless steels a bonded layer, further, being heated between the both melting points, and applying the compressive stress, for example 0.5 to 2 kgf / mm2, so that a lateral expansion ratio is made within 1.0 to 1.1, and (2) a joined structure having the bonded joint formed thereby.

Owner:SUMITOMO METAL IND LTD

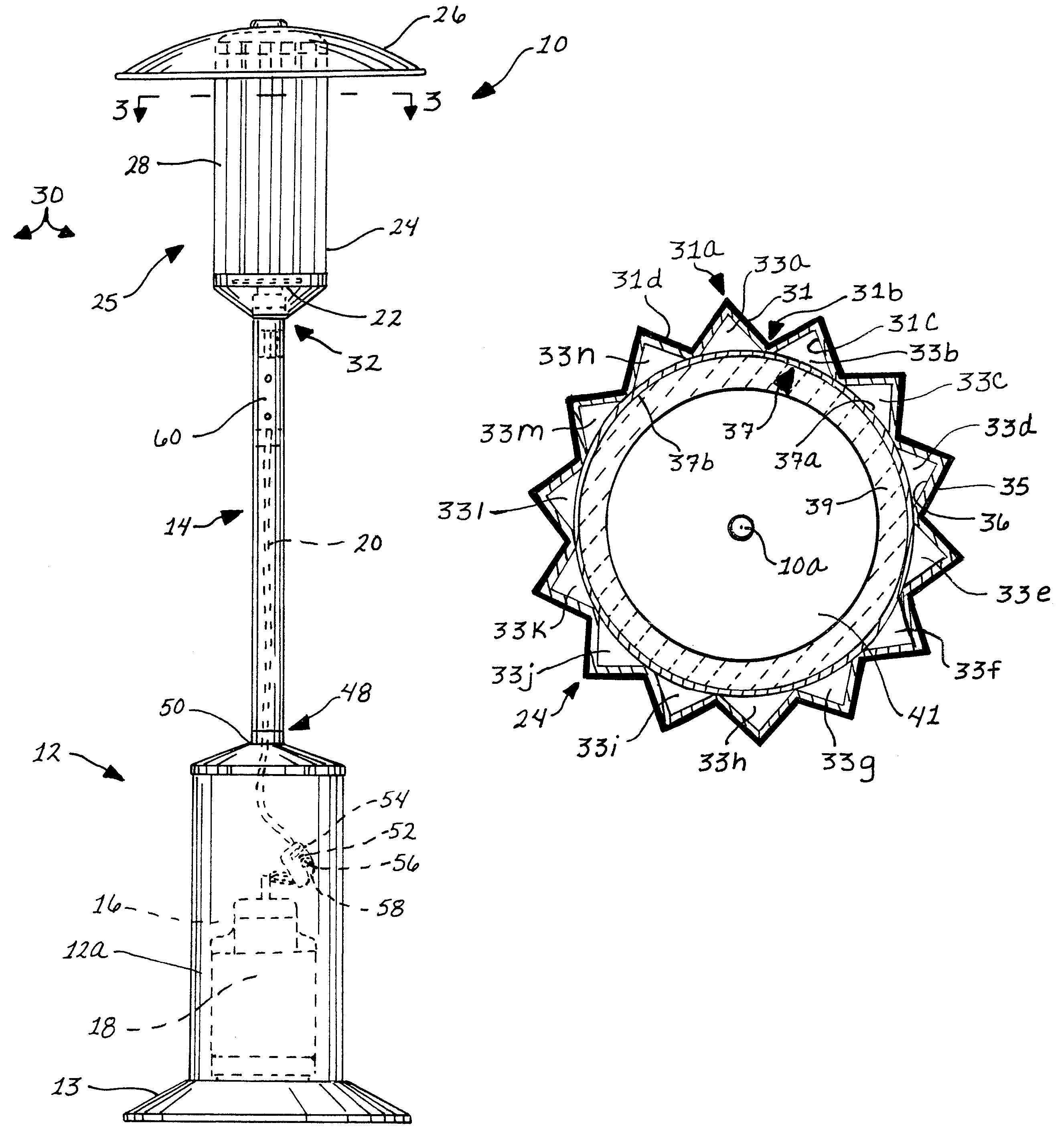

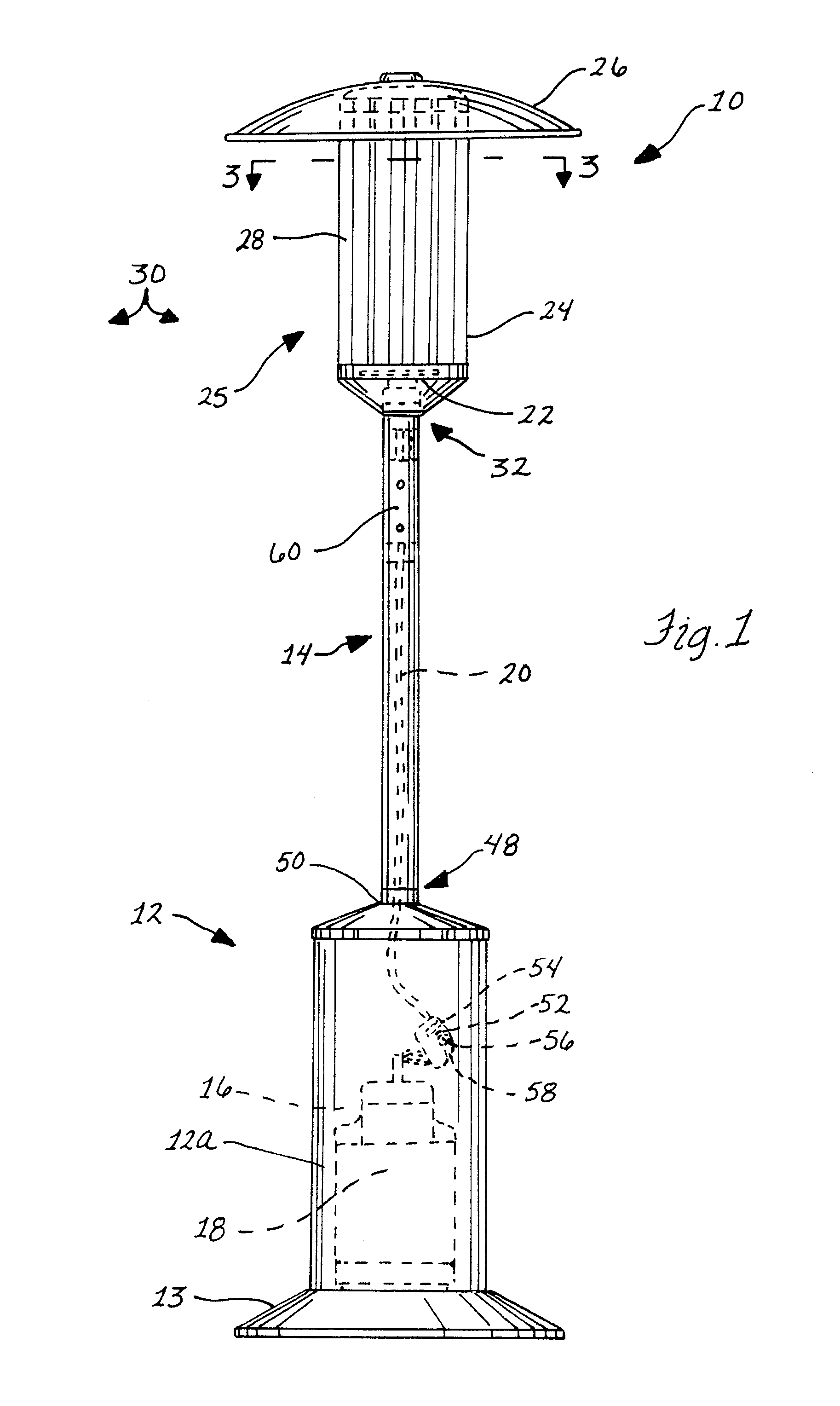

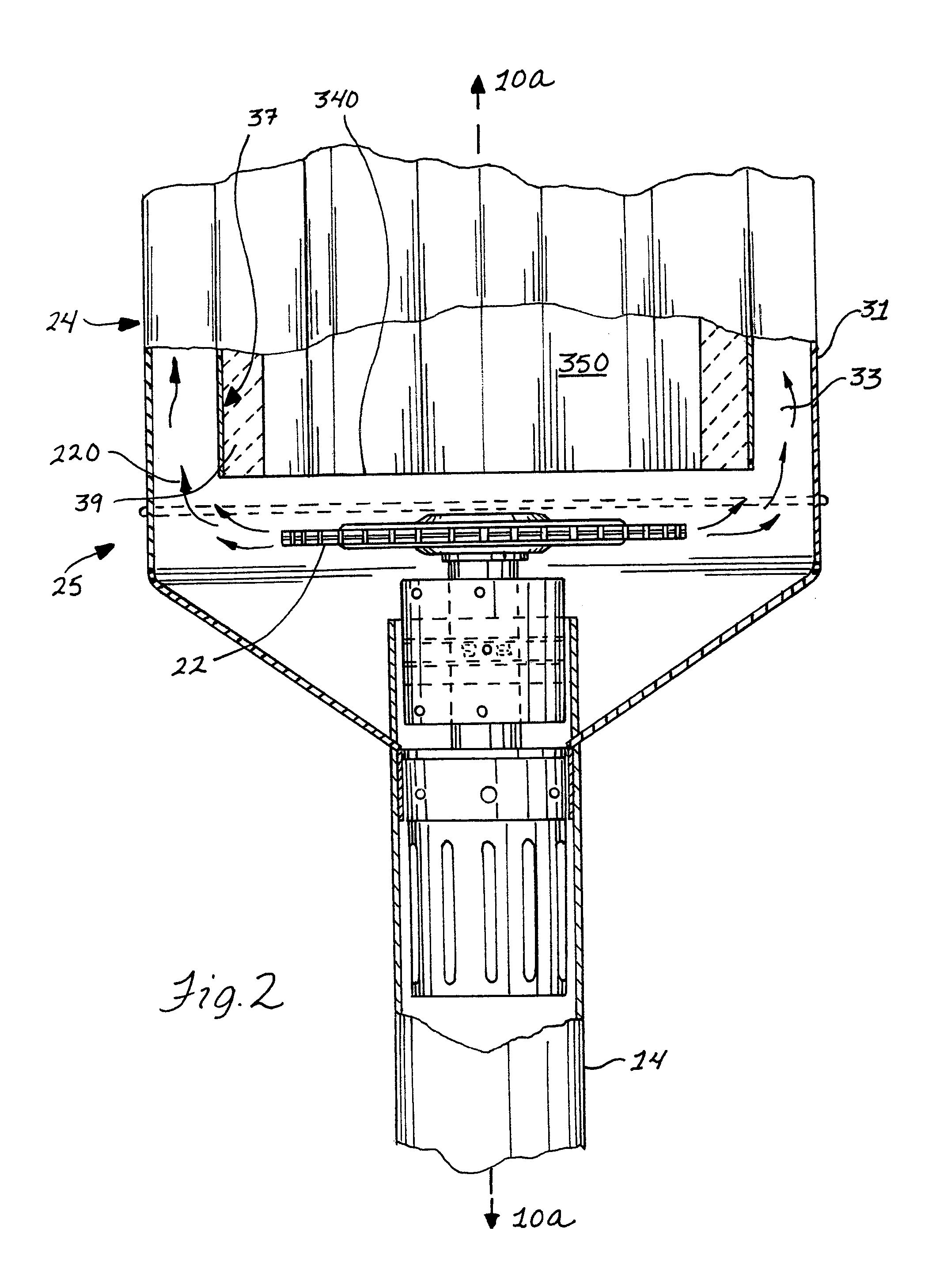

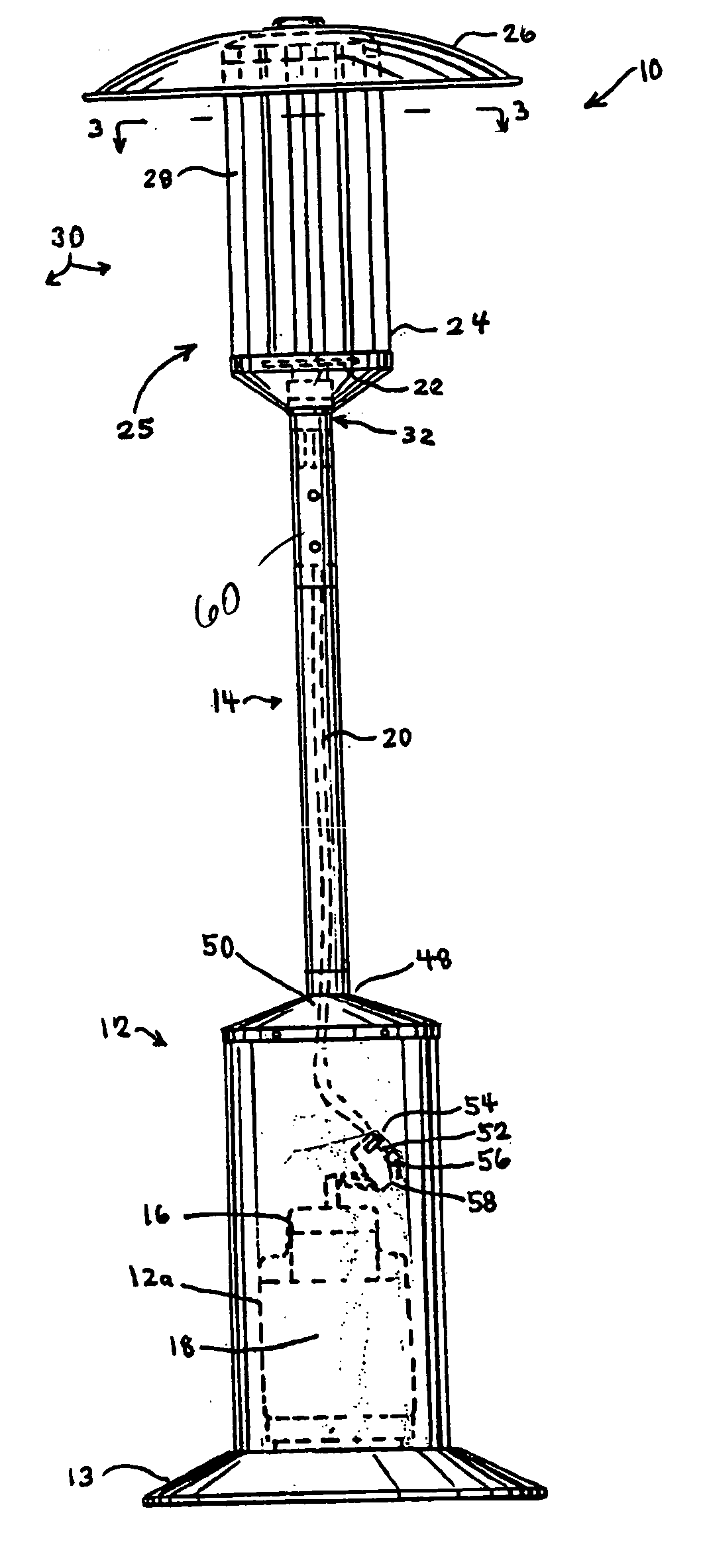

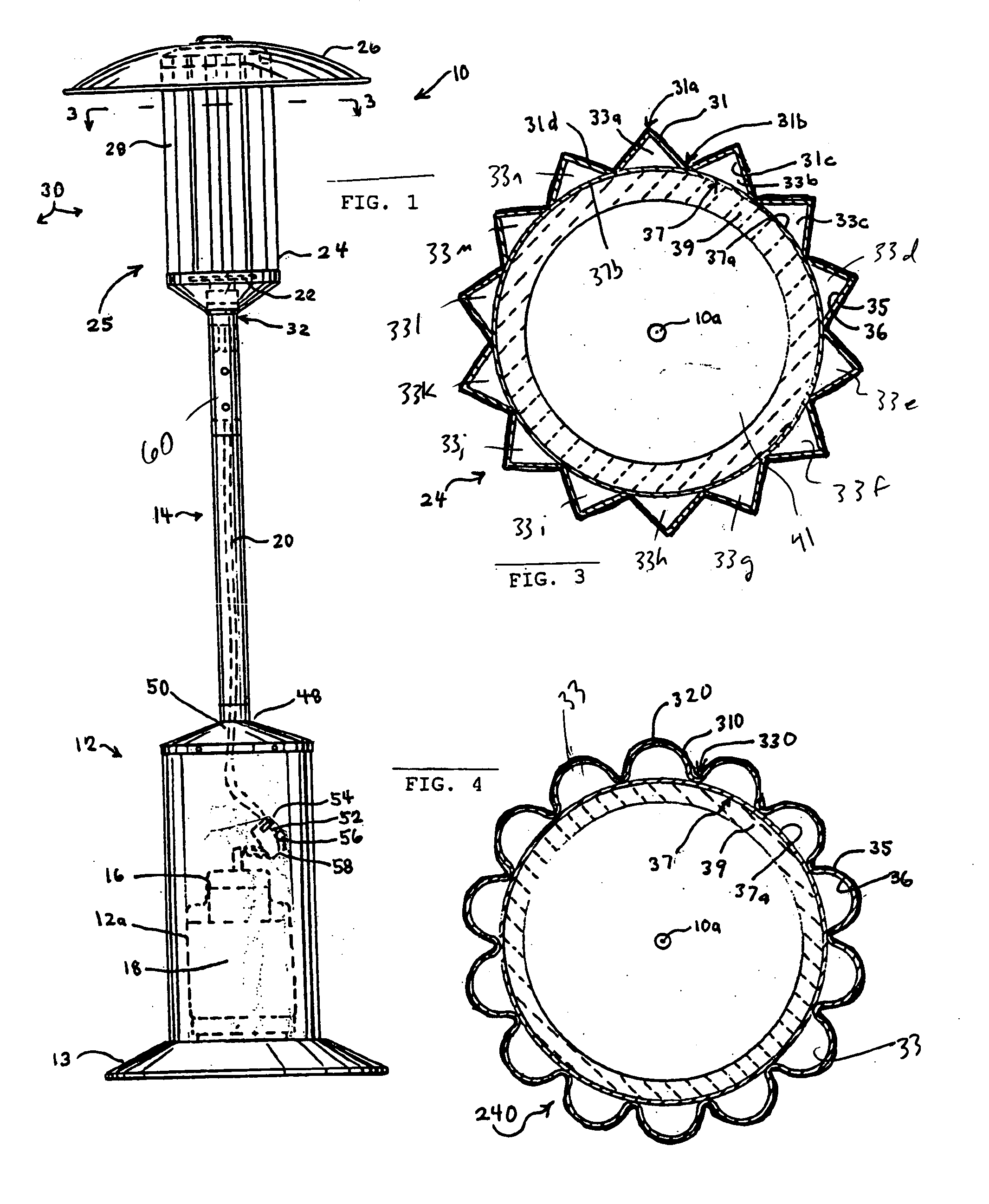

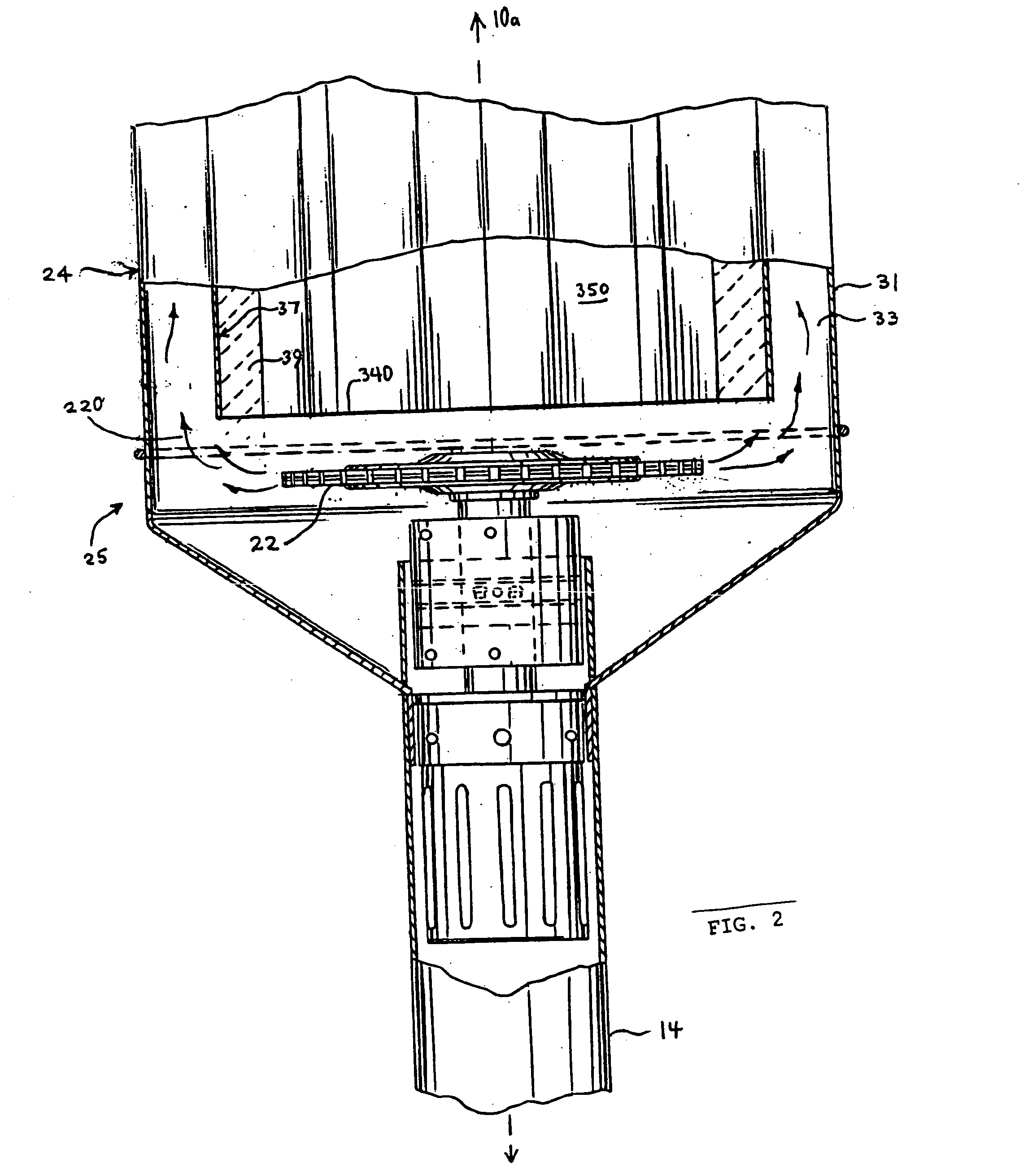

Heating apparatus

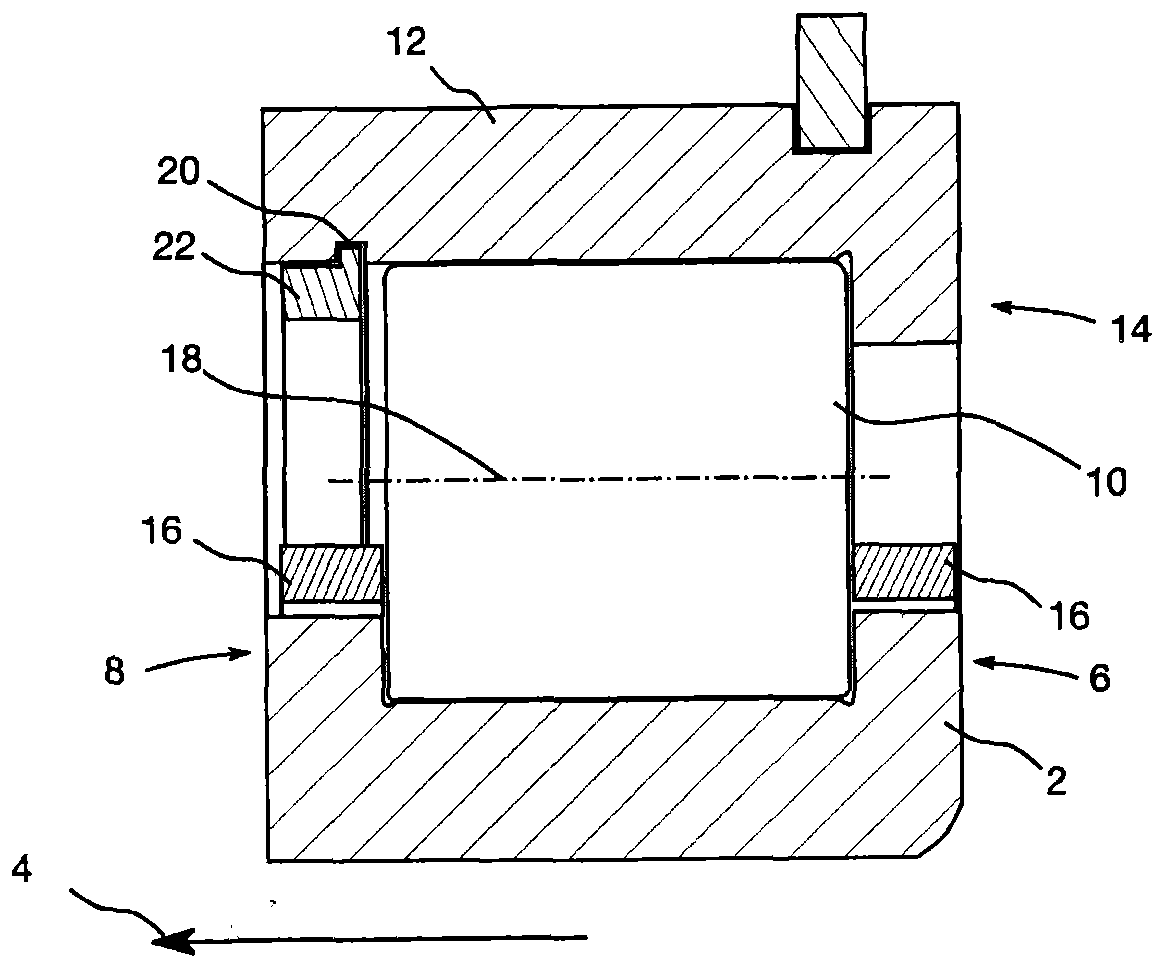

InactiveUS7086396B2Maximize heat transferMaximize sizeDomestic stoves or rangesMuffle furnacesCombustorDouble wall

A heating apparatus is provided that is optimized in terms of its heating efficiencies and wind proofing against flame out. The heating apparatus includes a heating head and a burner assembly for igniting fuel from a fuel source. The heating head has a dual-walled construction to form several flue chambers with the inner wall preferably being insulated to maximize heat transfer to the outer wall from combustion gases flowing through the flue chambers. The flue chambers can also be formed to be substantially isolated from each other and configured to generate turbulent gas flow therein for maximum heat transfer to the outer wall.

Owner:WATERS

Heating apparatus

InactiveUS20050175950A1Maximize heat transferMaximize sizeDomestic stoves or rangesMuffle furnacesCombustorEngineering

A heating apparatus is provided that is optimized in terms of its heating efficiencies and wind proofing against flame out. The heating apparatus includes a heating head and a burner assembly for igniting fuel from a fuel source. The heating head has a dual-walled construction to form several flue chambers with the inner wall preferably being insulated to maximize heat transfer to the outer wall from combustion gases flowing through the flue chambers. The flue chambers can also be formed to be substantially isolated from each other and configured to generate turbulent gas flow therein for maximum heat transfer to the outer wall.

Owner:WATERS

Novel shear wall capable of replacing foot part component

InactiveCN101775854AReduce engineering volume and difficultyReduce the input energy of earthquake vibrationWallsShock proofingEngineeringShear wall

The invention relates to a novel shear wall capable of replacing a foot part component, which belongs to the field of constructional engineering. The novel shear wall comprises a shear wall and a shock absorption and shock insulation component, wherein a space is reserved in the foot part of the shear wall, the shock absorption and shock insulation component is arranged in the reserved space, the upper end of the shock absorption and shock insulation component is fixedly connected with the shear wall, the lower end of the shock absorption and shock insulation component is fixedly connected with a building surface component, and the shock absorption and shock insulation component can be symmetrically arranged on the foot part of the shear wall. The invention has the advantages of simple structure and convenient construction, in addition, the foot part can be conveniently replaced after the foot part of the shear wall is damaged, and the structural function of the shear wall can be fast recovered. Compared with the traditional shear wall, the invention greatly reduces the engineering quantity and the difficulty of the reinforcement after the shock.

Owner:TONGJI UNIV

Garlic oil nanometer-scale microemulsion liquid and preparation method thereof

InactiveCN104921005AUniform particle size distributionThe system is clear and transparentCosmetic preparationsToilet preparationsVegetable oilRoom temperature

The present invention relates to a garlic oil nanometer-scale microemulsion liquid and a preparation method thereof. The garlic oil nanometer-scale microemulsion liquid comprises the following components (in mass percentage): surfactant 6%-65%, auxiliary surfactant 2%-30%, garlic oil 2%-13%, vegetable oil 0%-80%, and water 0-85%. Furthermore, the present invention also relates to a garlic oil nanometer-scale microemulsion liquid preparation method which includes the following steps: at room temperature, the garlic oil and the vegetable oil are mixed into mixture oil phase, and then the surfactant and auxiliary surfactant are added and mixed, and mixed in a swirl manner by slowly stirring, water is added into the system under the slowing stirring condition until the mutation of viscosity, and thus the clear and transparent garlic oil nanometer-scale microemulsion liquid is obtained. The garlic oil nanometer-scale microemulsion liquid can be used in the fields of food, health-care food, medicines and cosmetic, and the application scope of the fat-soluble garlic oil is extended.

Owner:江苏黎明食品集团有限公司 +1

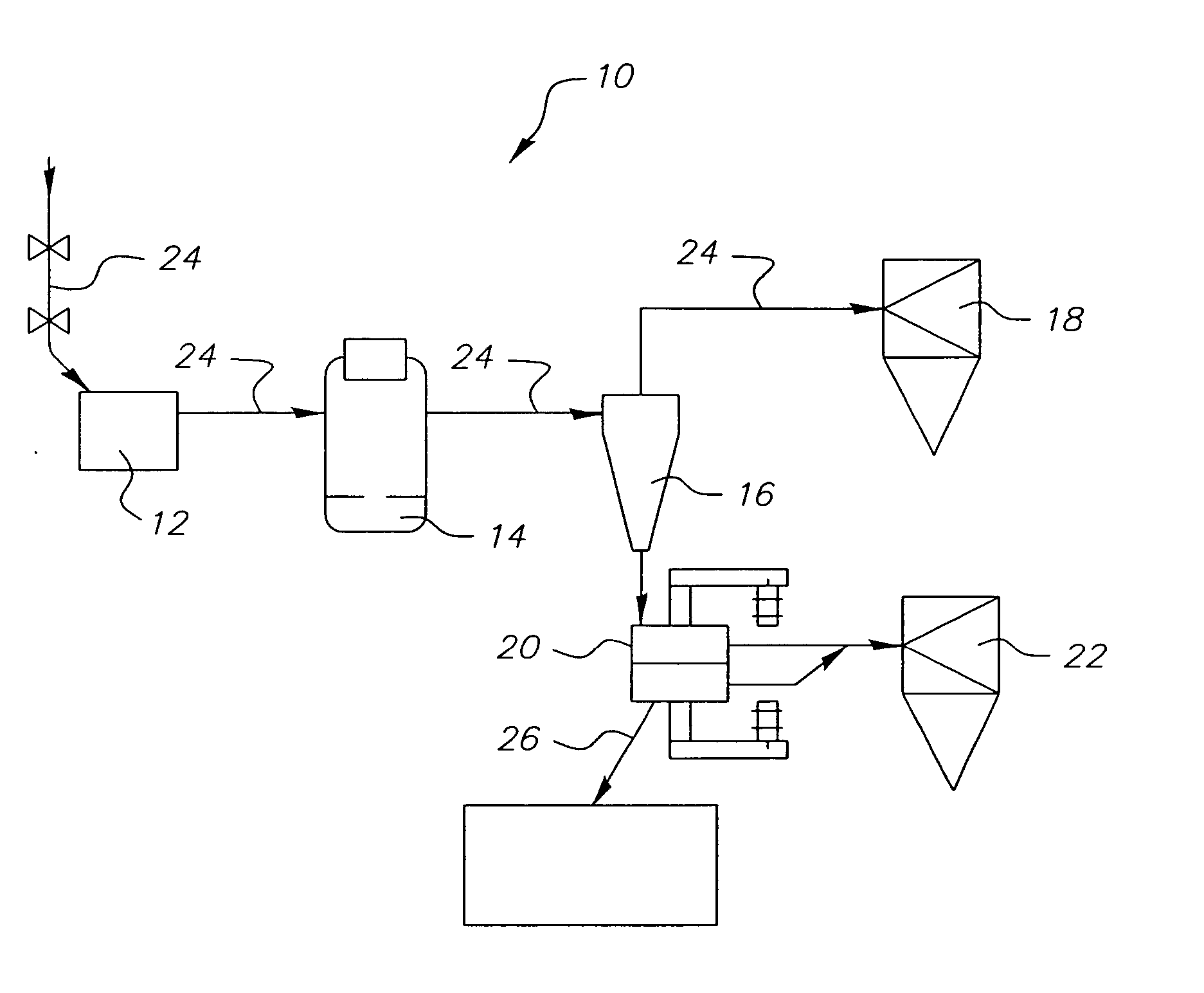

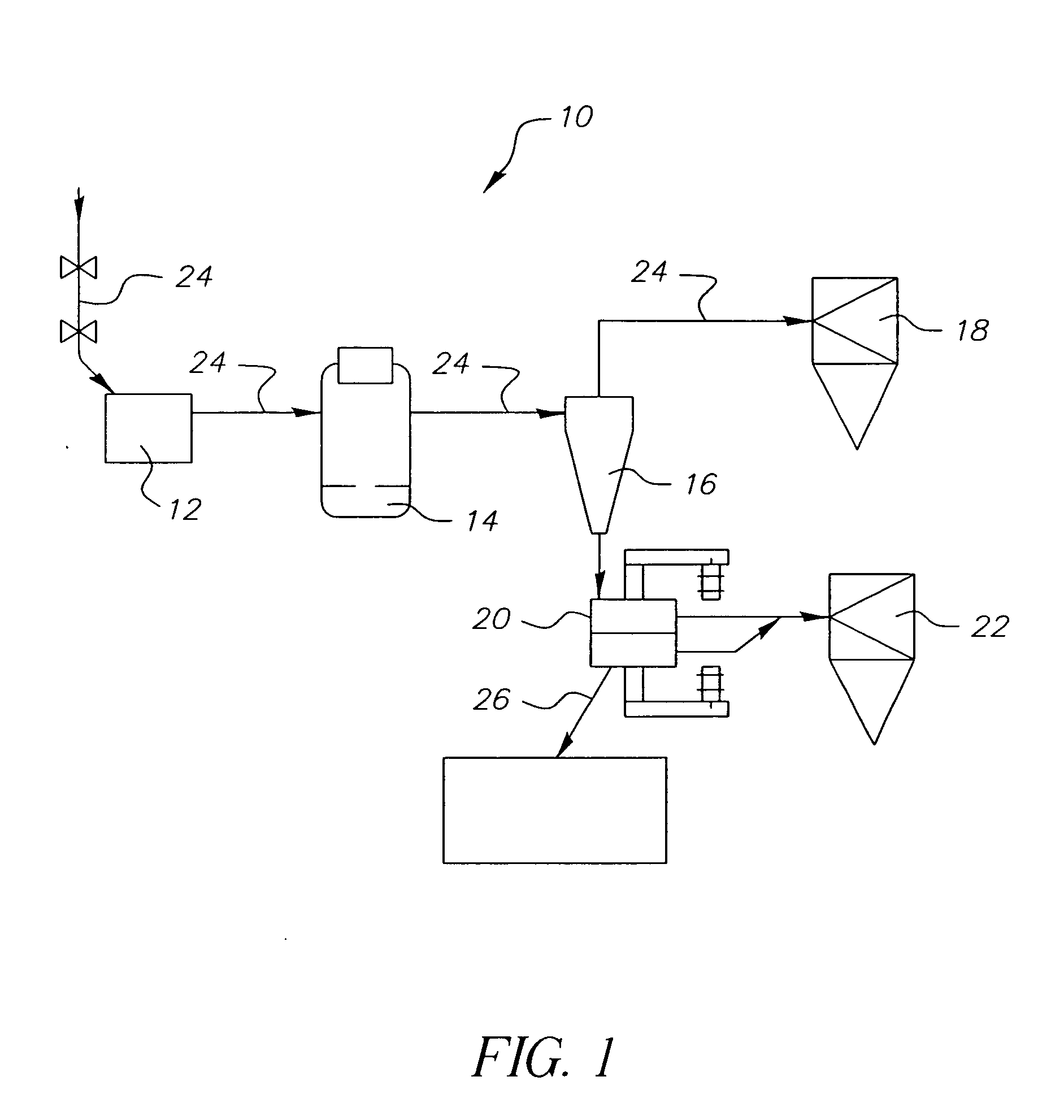

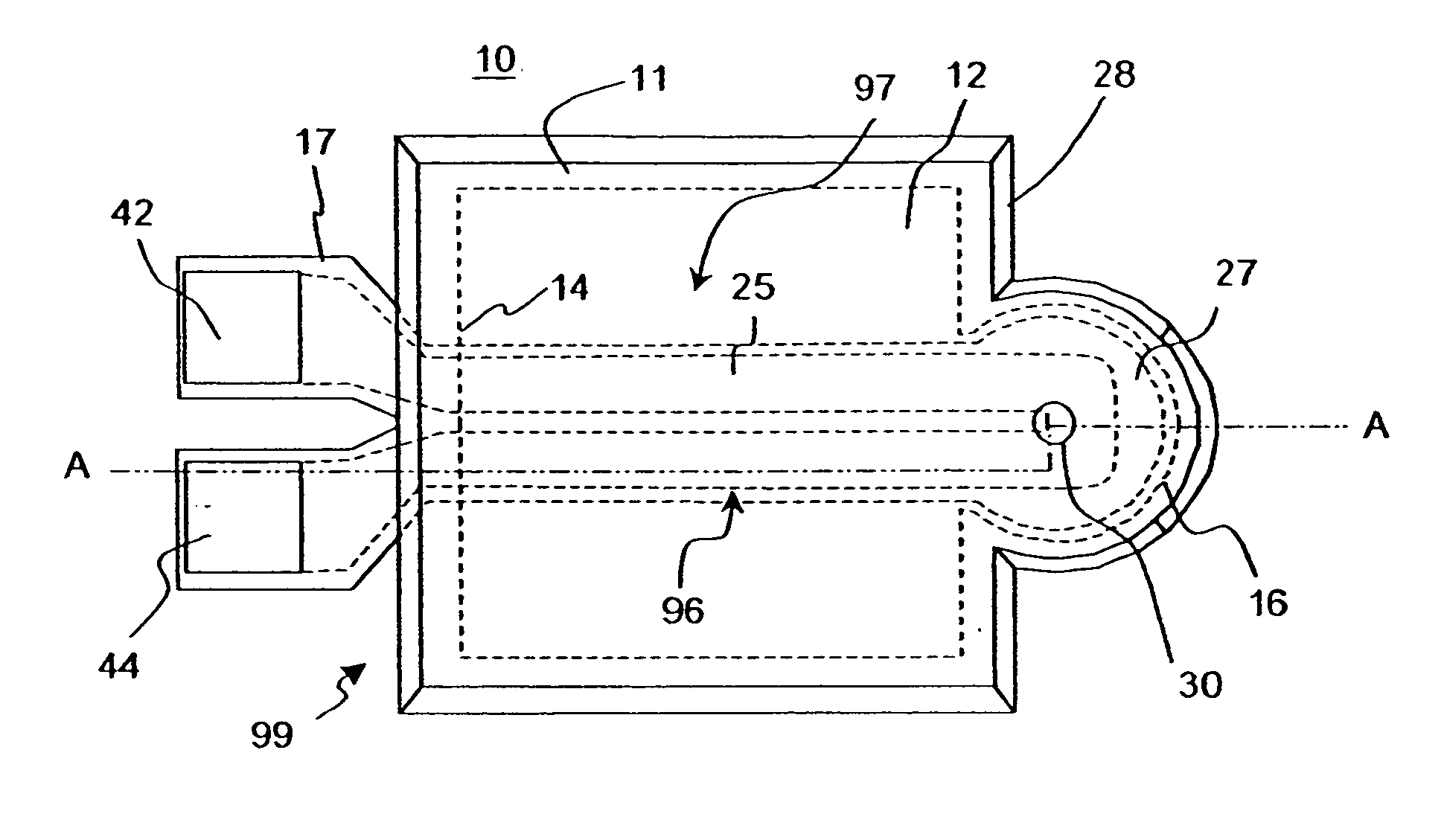

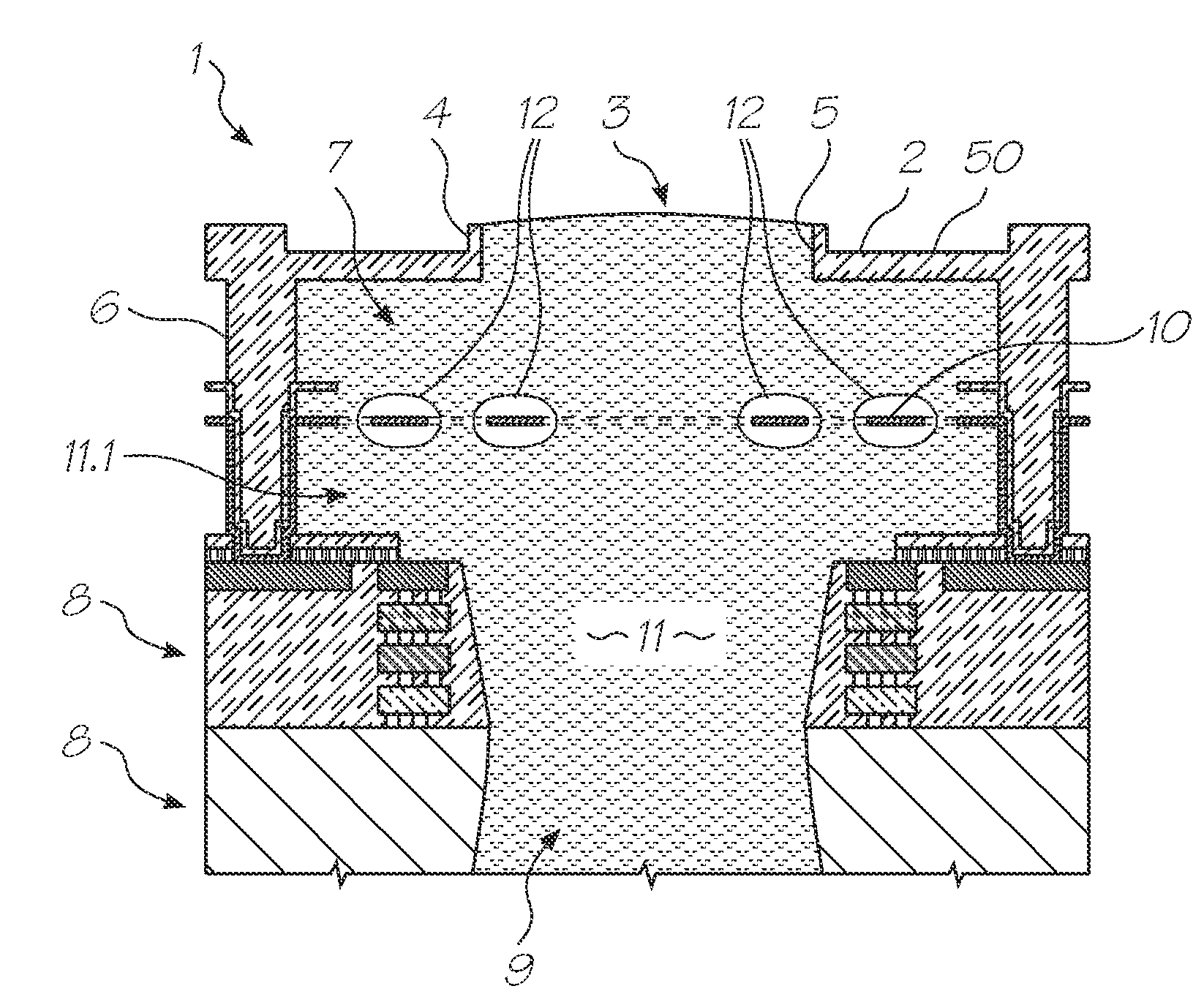

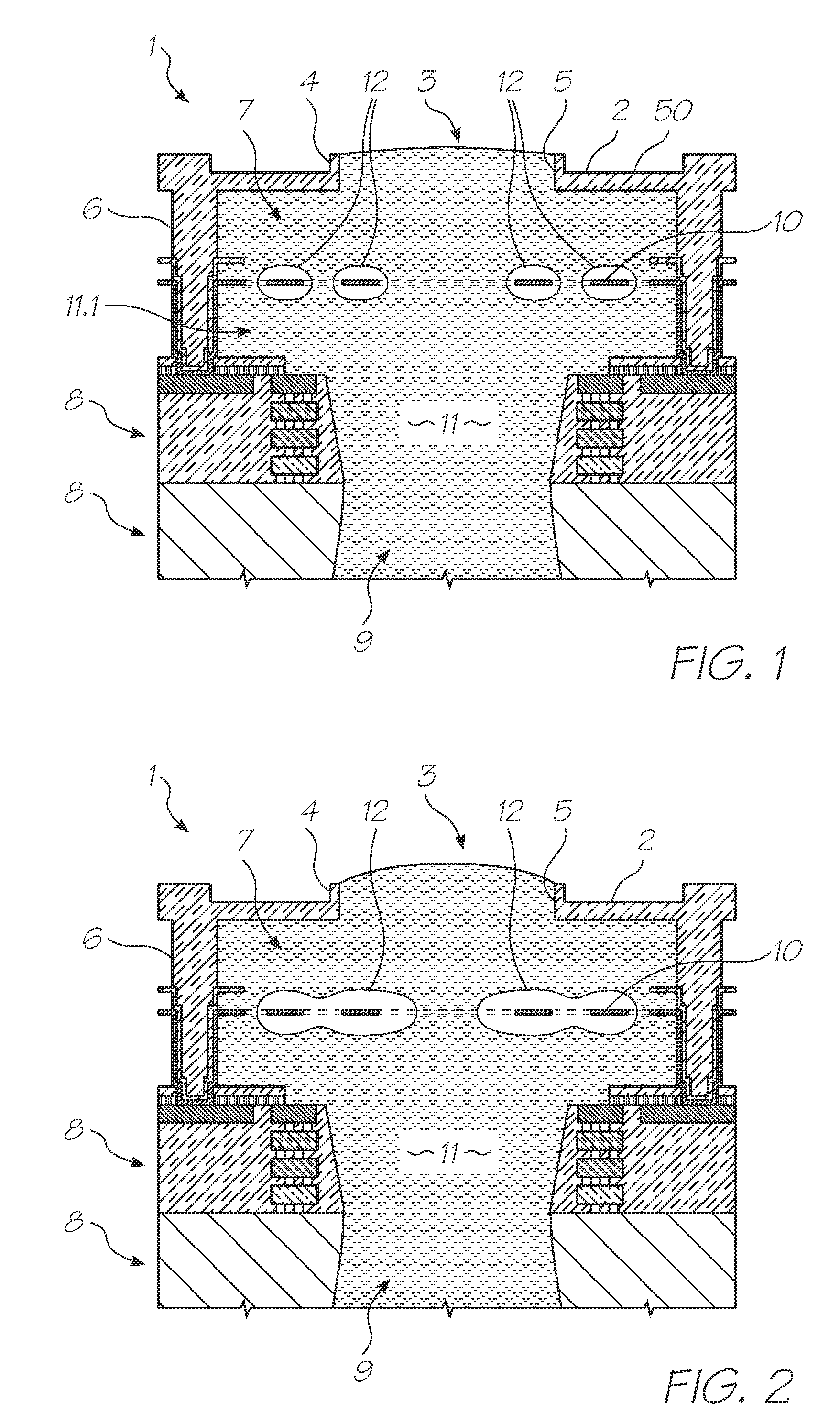

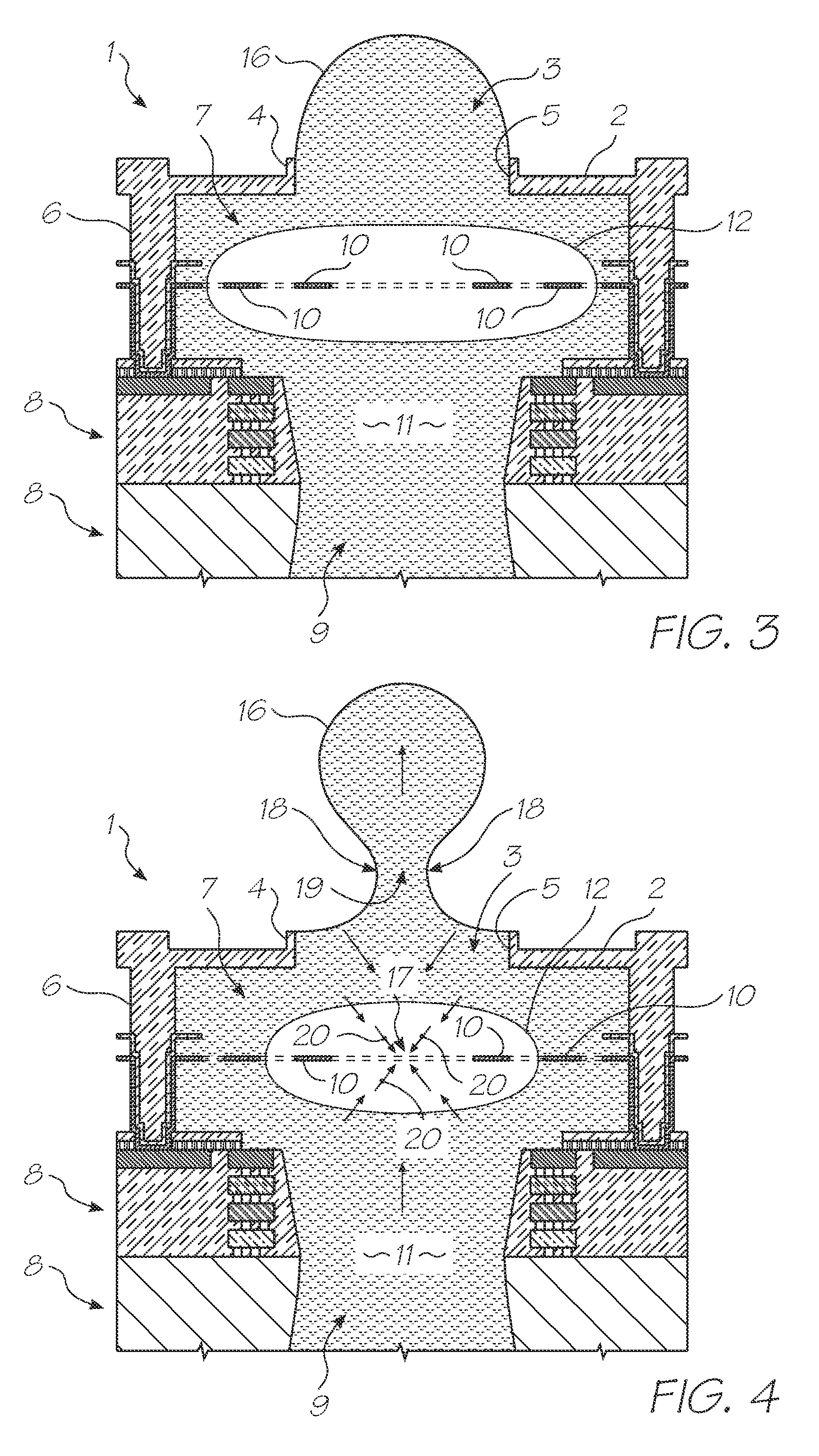

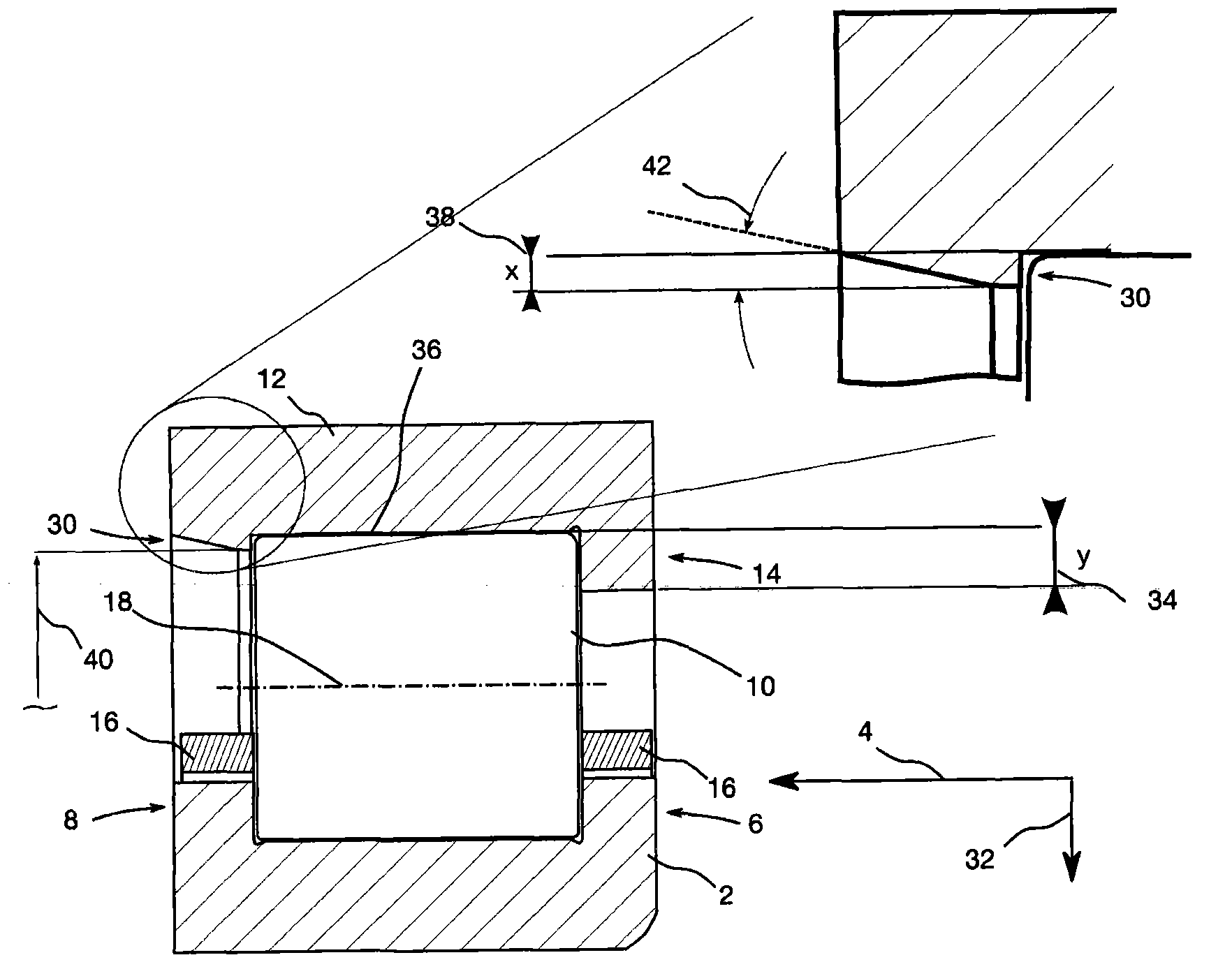

Method and apparatus for energy efficient particle-size reduction of particulate material

InactiveUS20050145729A1Reduce input energySmall particle sizeGrain treatmentsParticulate materialMaterials science

An apparatus (10, 100) for reducing the particle size of a bulk particulate or powder material includes one or more first particle-size reducing stages (12, 120) and a final particle-size reducing stage (14, 140). The first particle-size reducing stage (12, 120) receives the bulk material and reduces the particle size thereof to an intermediate particle size. The final particle-size reducing stage (14, 140) receives the bulk material having the intermediate particle size and further reduces the particle size thereof from the intermediate particle size to a desired particle size.

Owner:EASTMAN KODAK CO

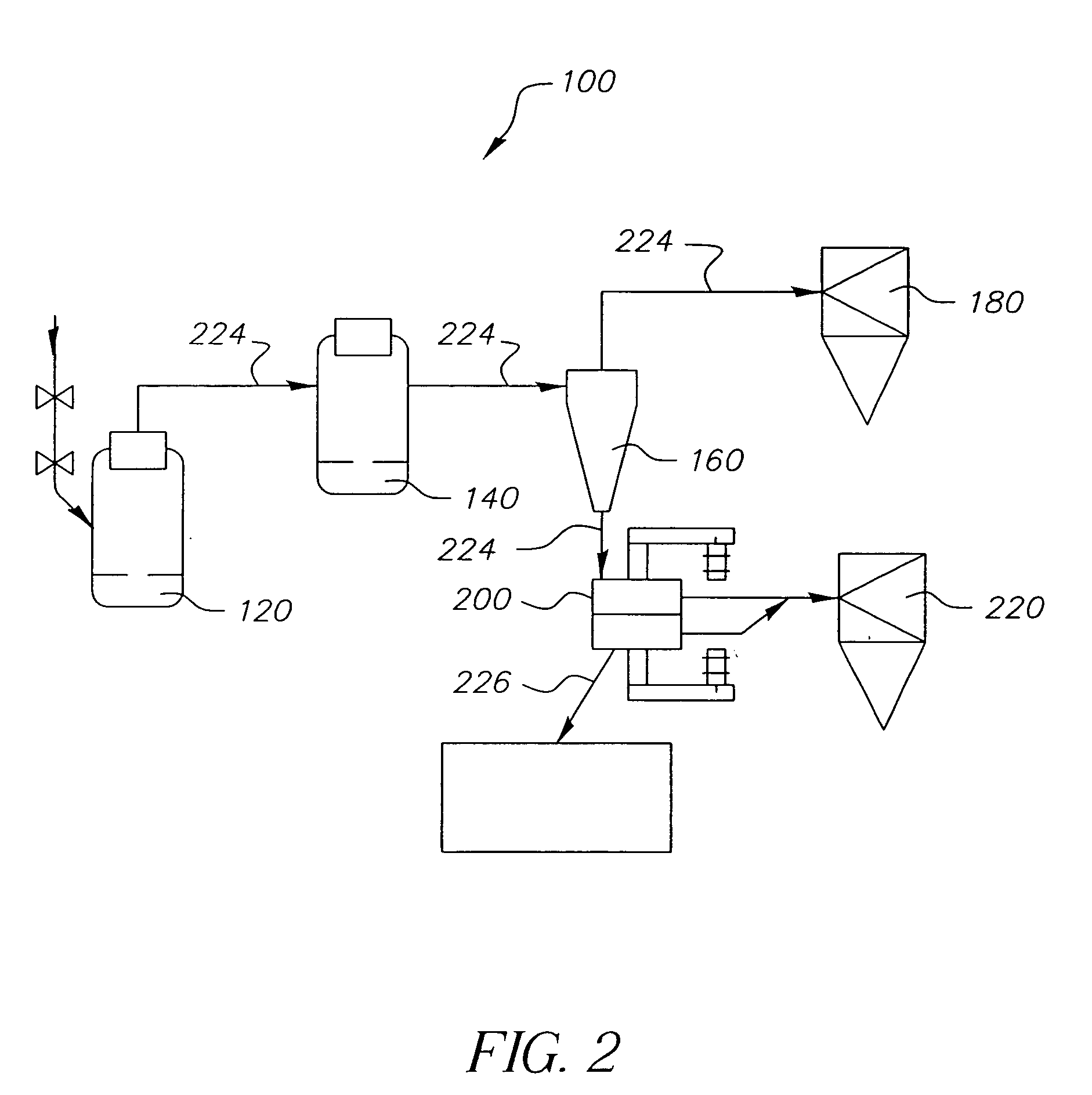

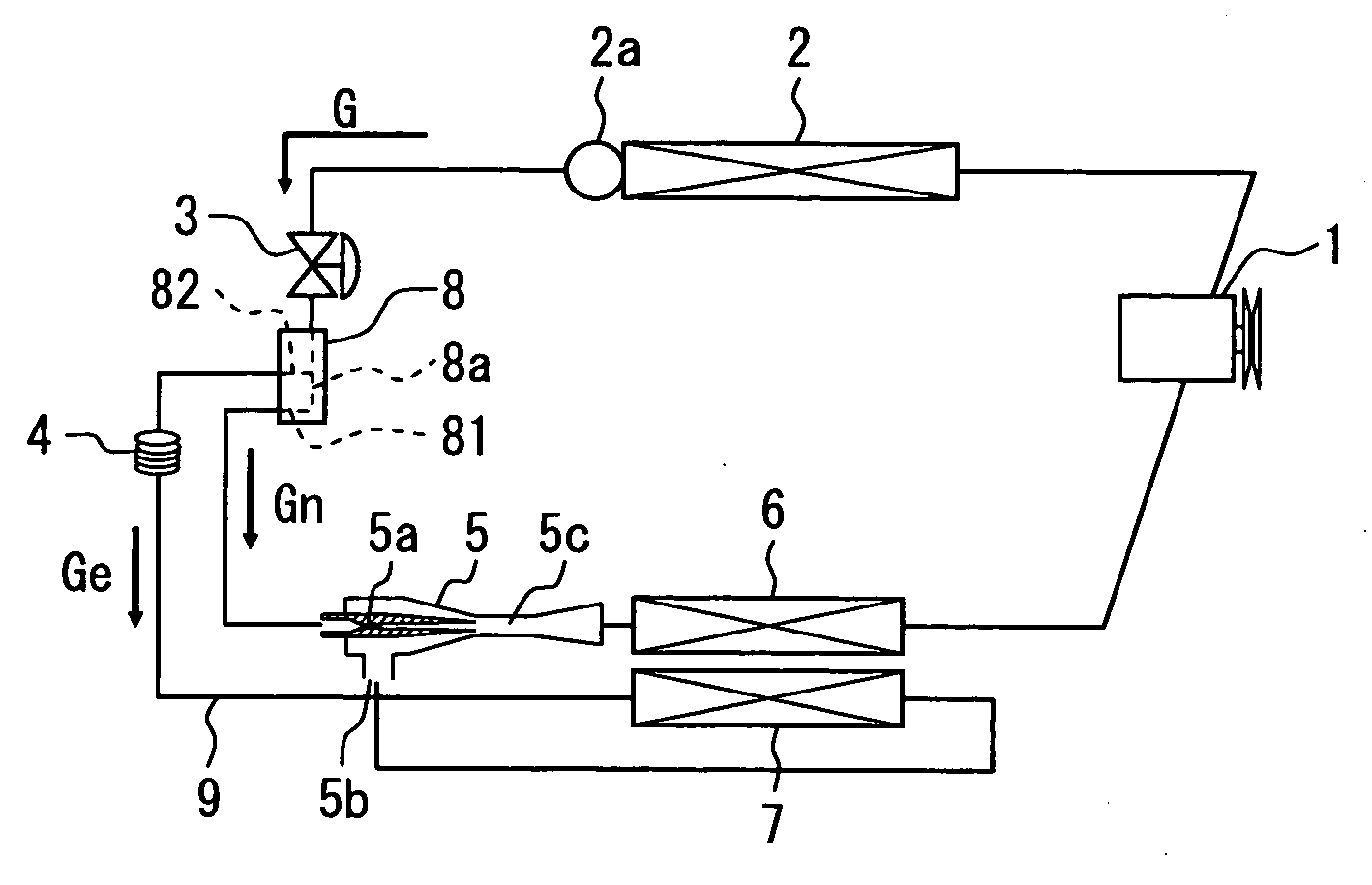

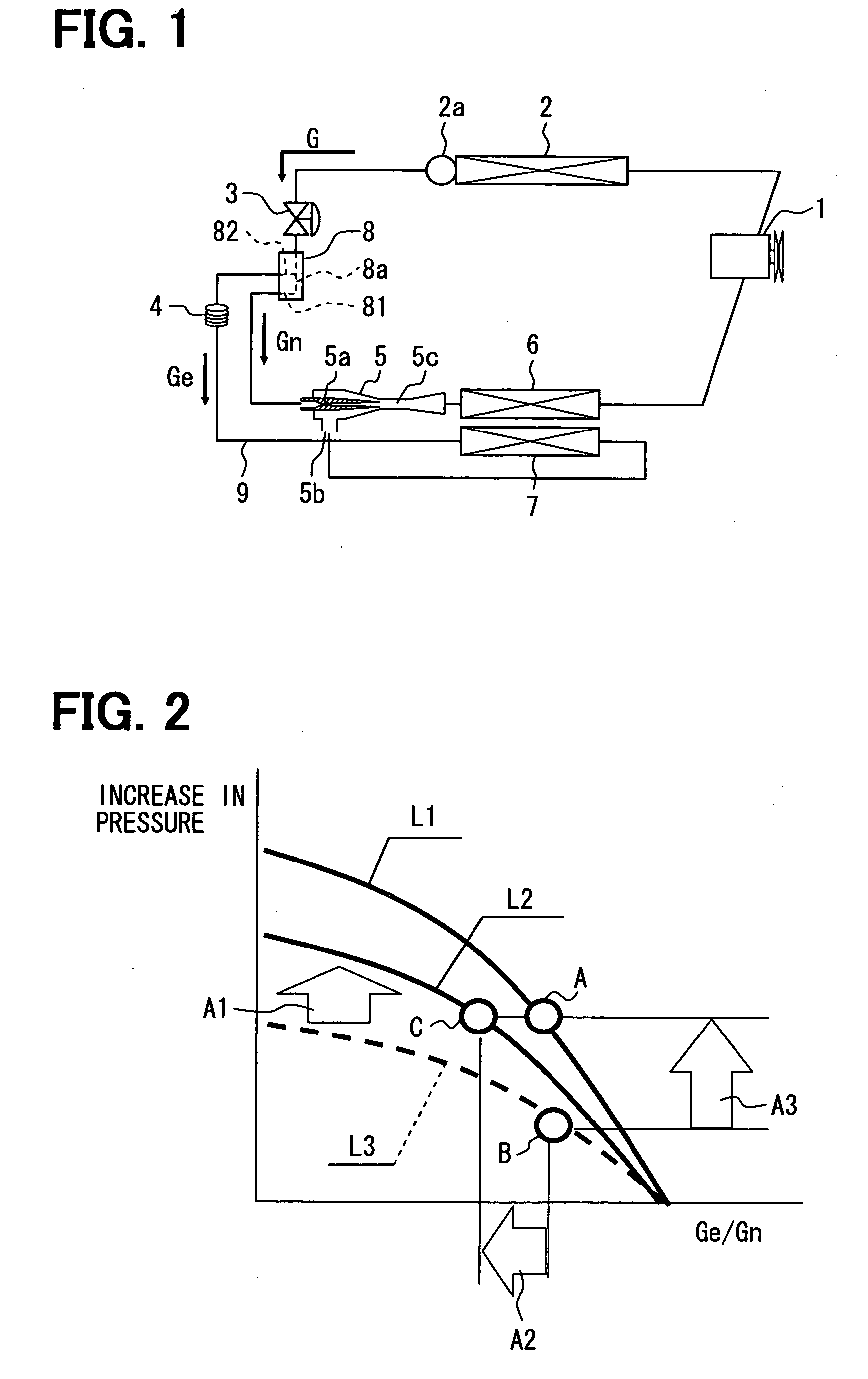

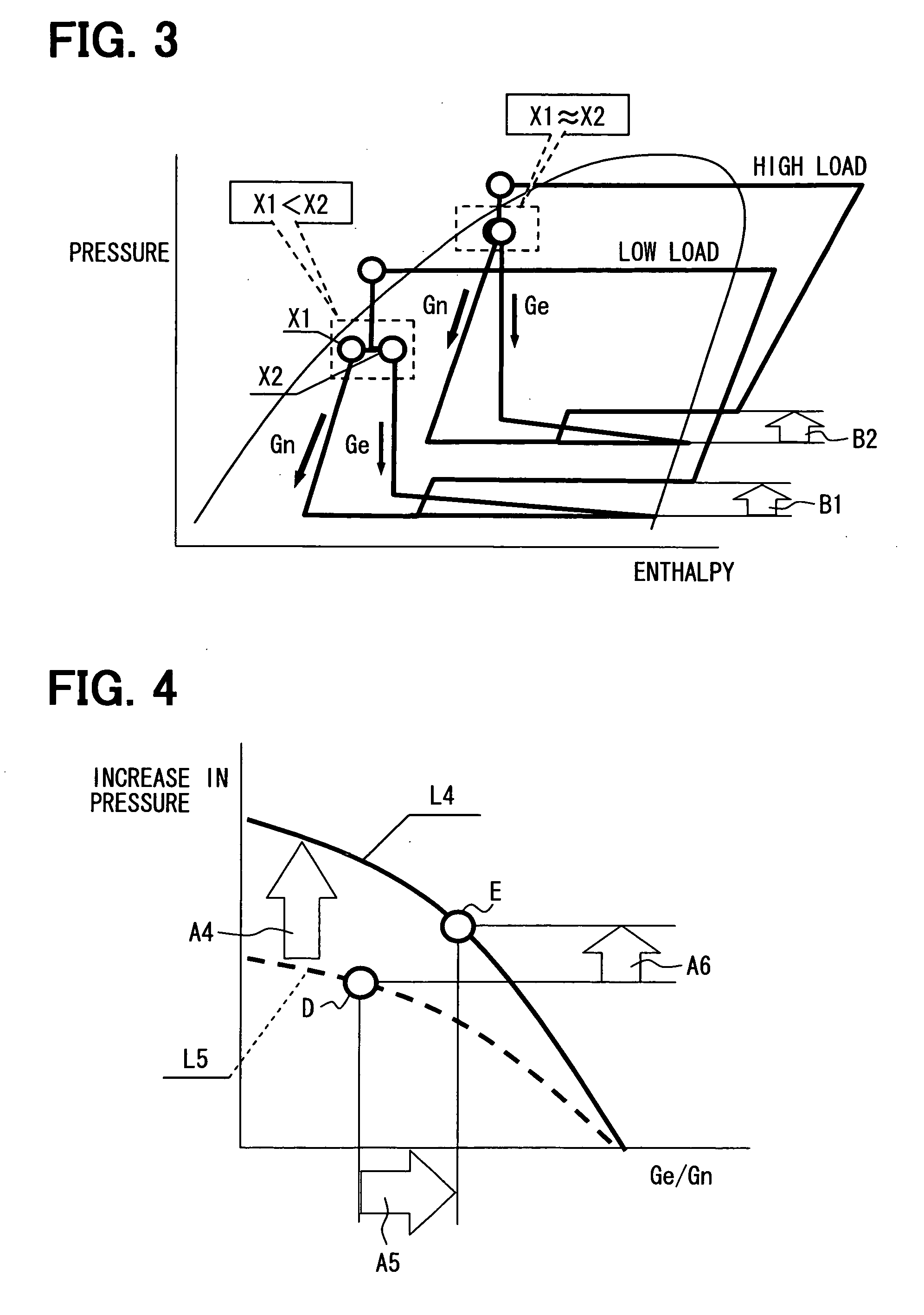

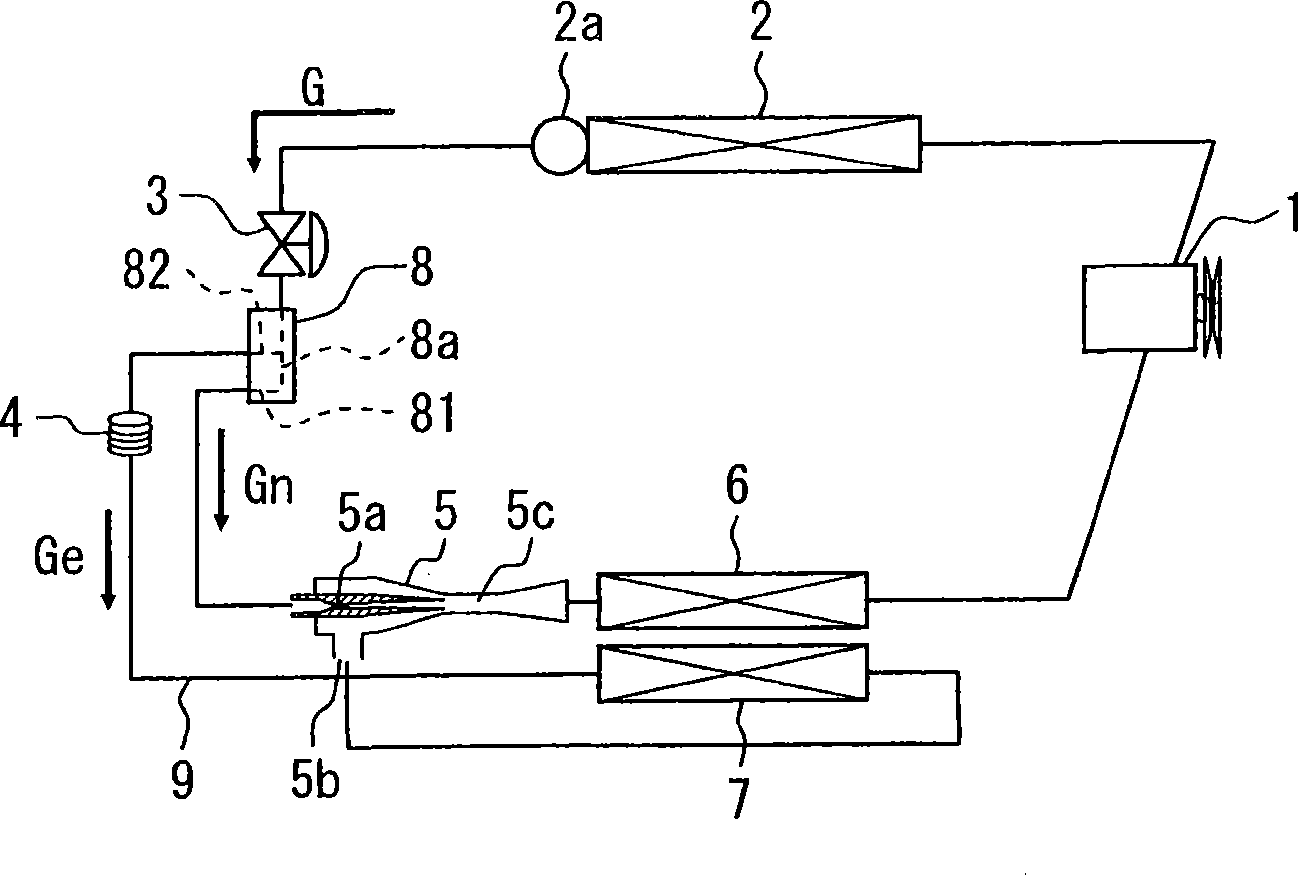

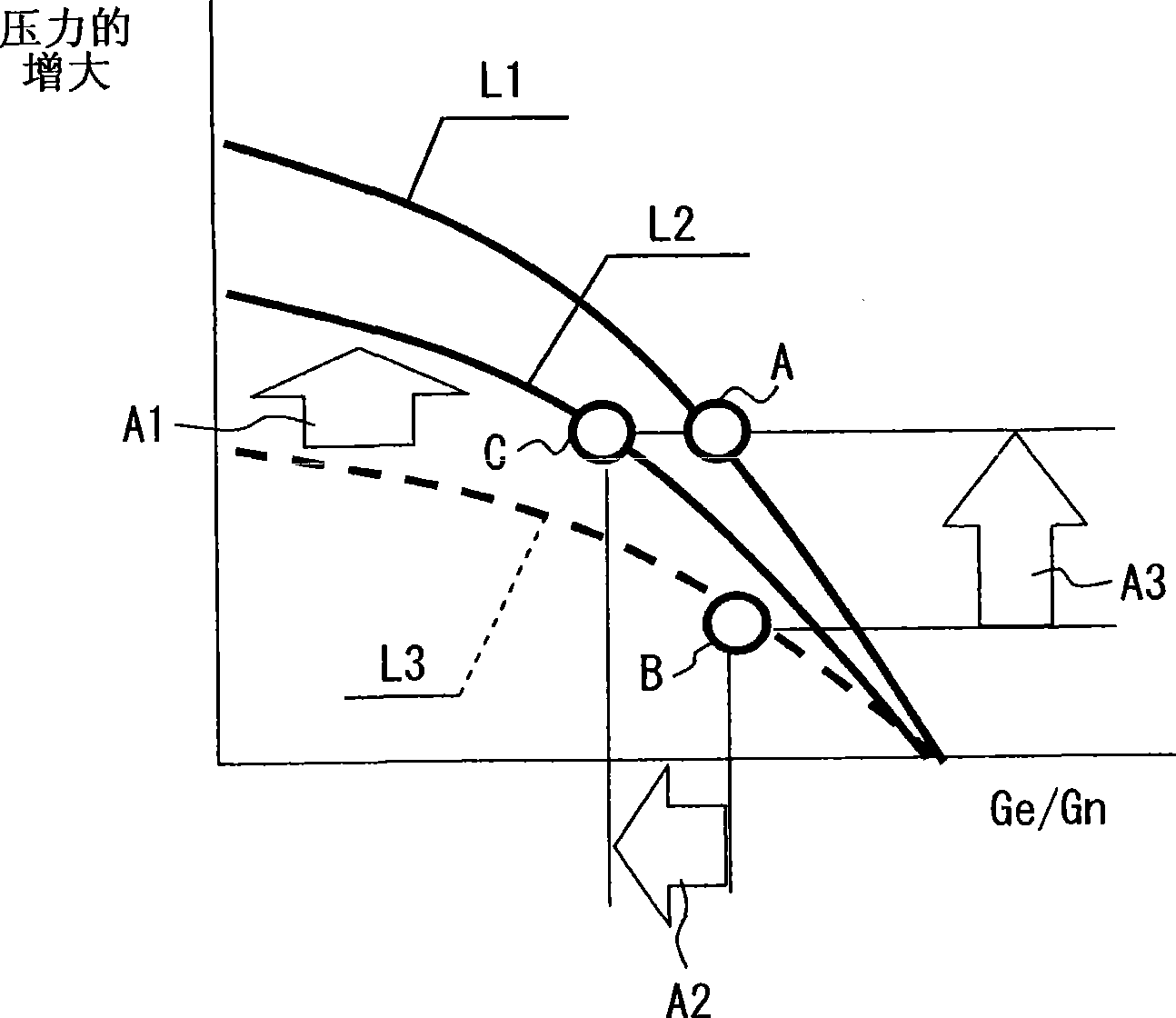

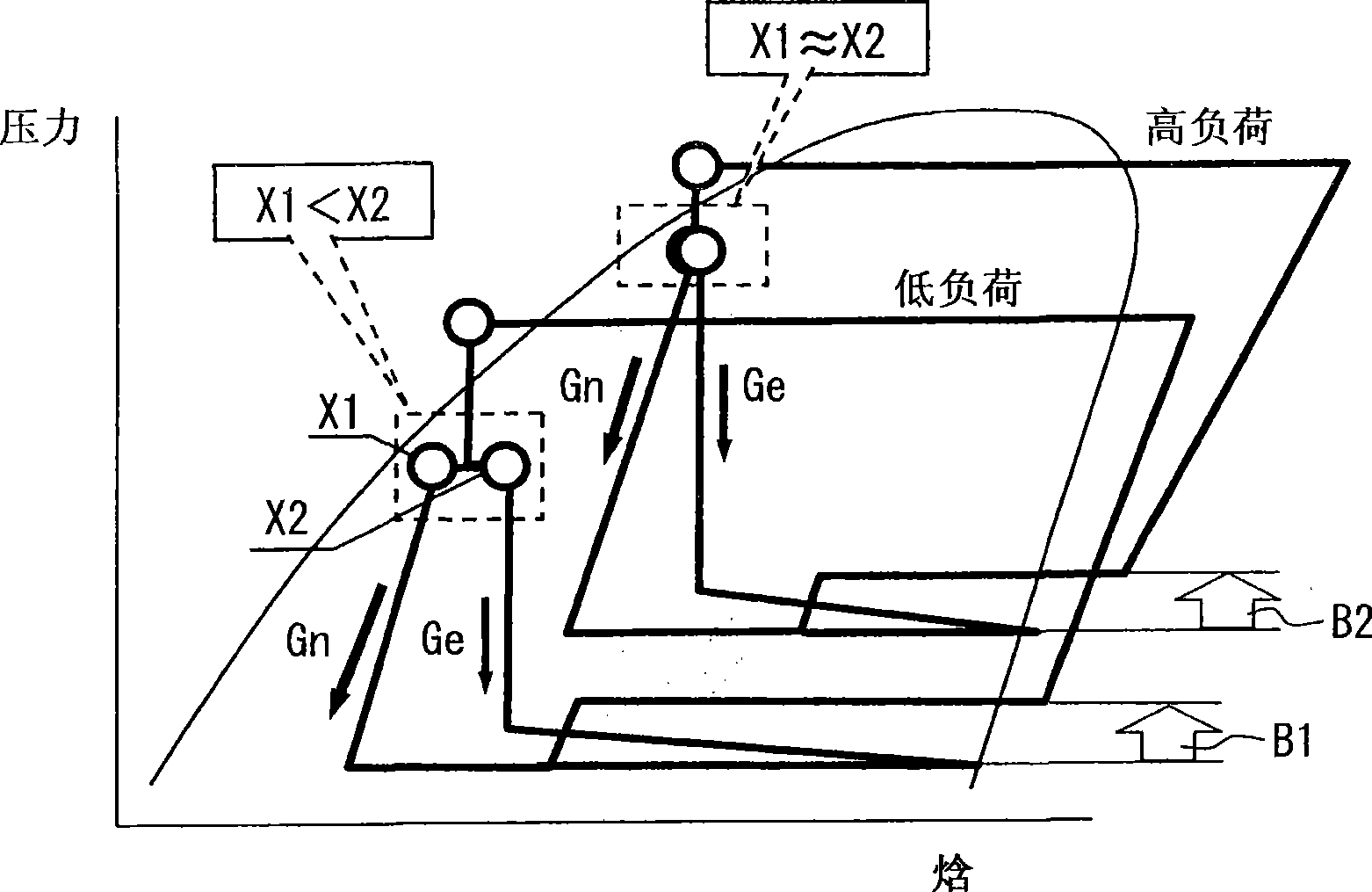

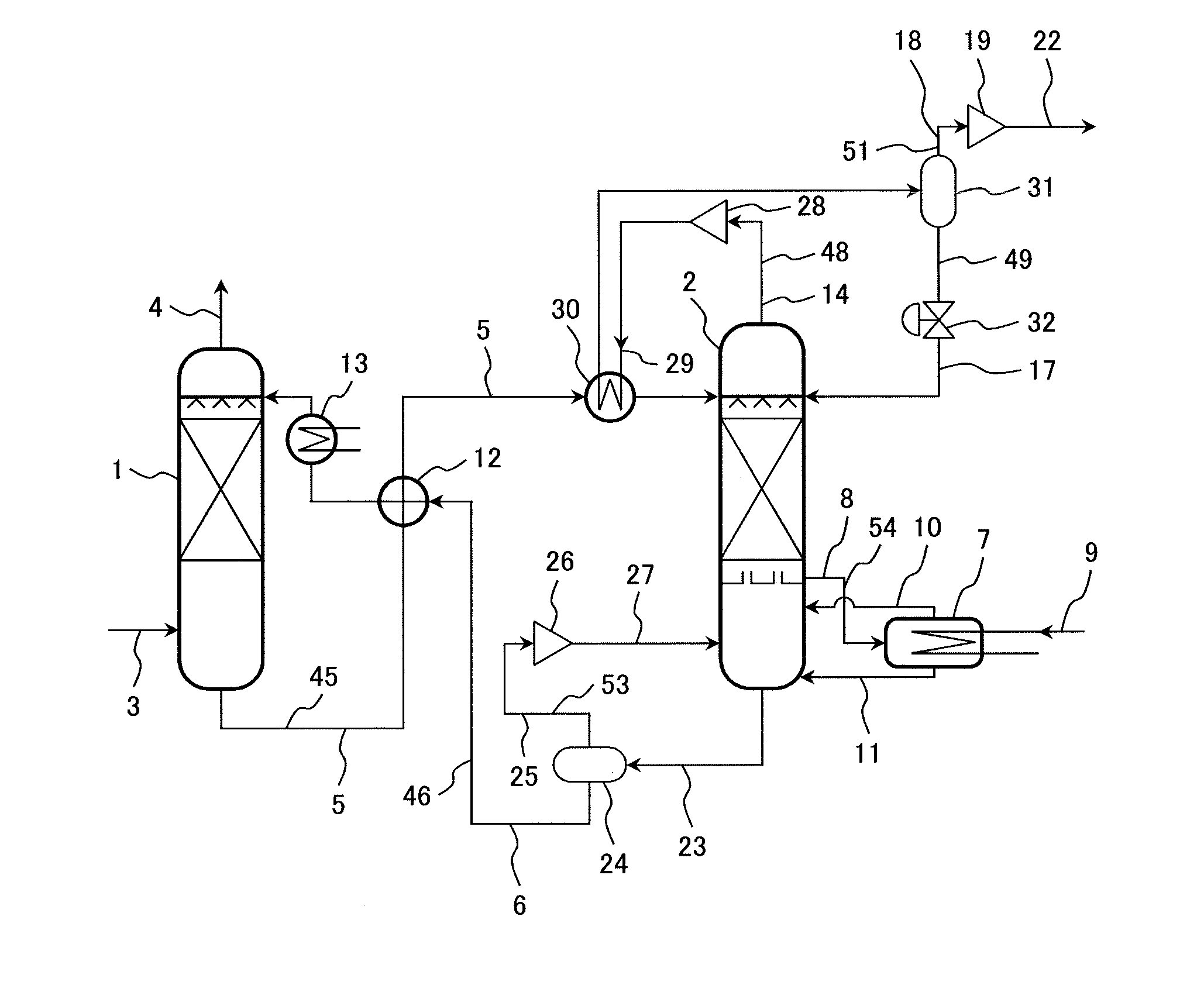

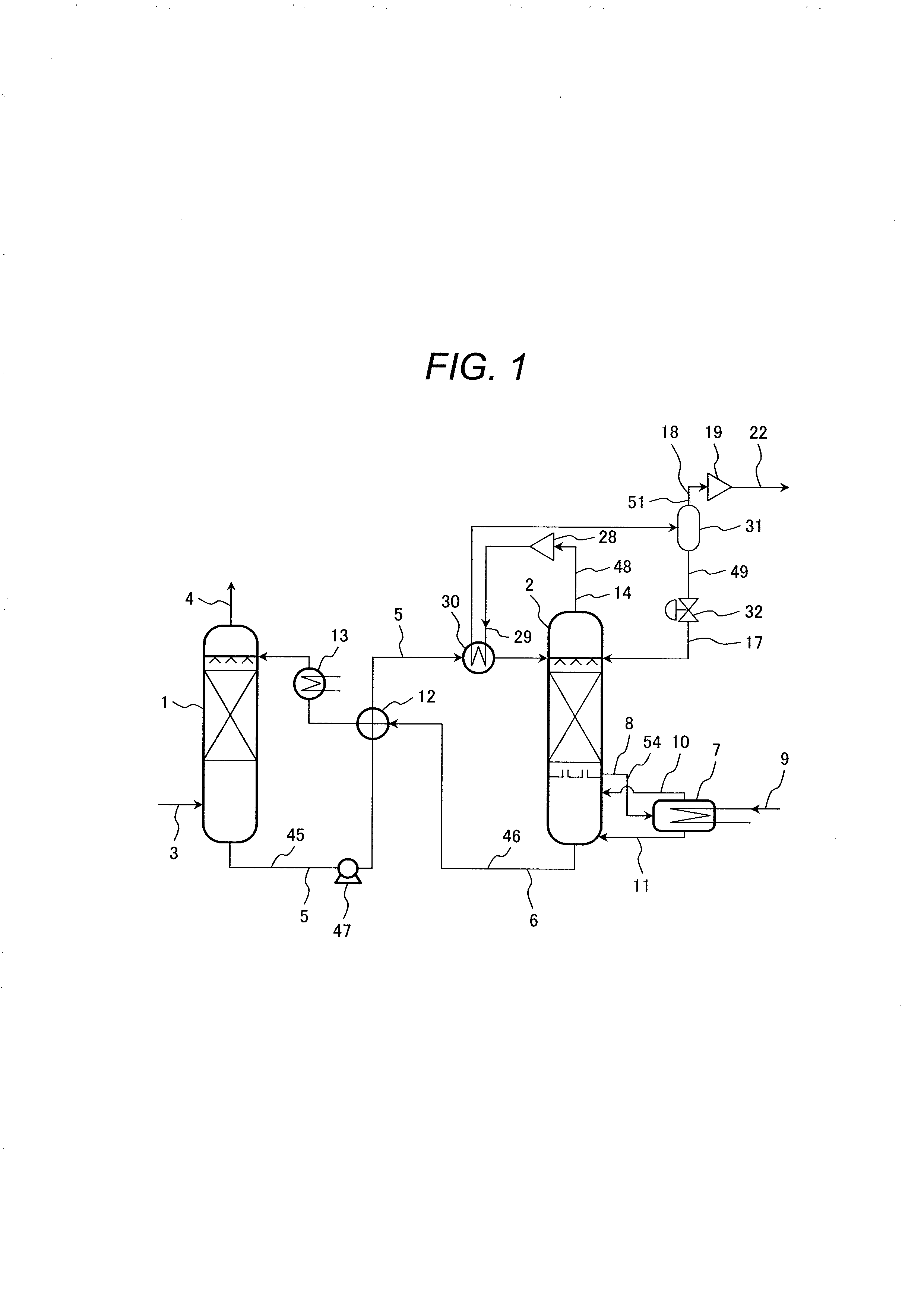

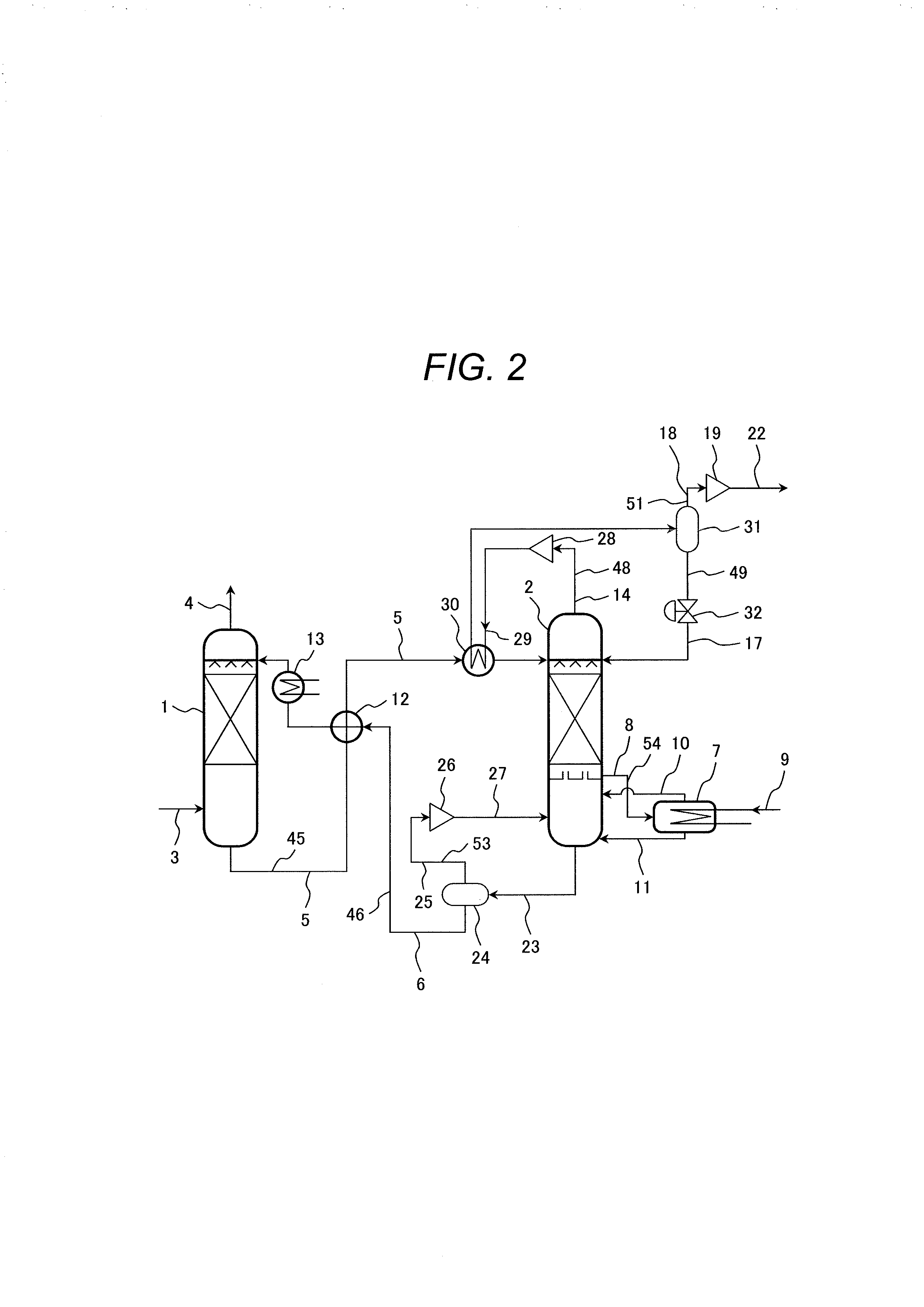

Vapor compression refrigerating cycle apparatus

ActiveUS20090229305A1Improve efficiencyIncrease pressureCompression machines with non-reversible cycleEvaporators/condensersEngineeringDistributor

A vapor compression refrigerating cycle apparatus includes a compressor, a radiator, first and second throttle devices, a flow distributor, an ejector, a suction passage, and first and second evaporators. The flow distributor separates refrigerant decompressed through the first throttle device into a first passage and a second passage. The first passage is in communication with a nozzle portion of the ejector. The second passage is in communication with a suction portion of the ejector through the suction passage. The second throttle device and the second evaporator are disposed on the suction passage. The flow distributor is configured to be capable of adjusting a ratio of a flow rate of refrigerant passing through the second passage to a flow rate of refrigerant passing through the first passage in accordance with a heat load of at least one of the radiator, the first evaporator and the second evaporator.

Owner:DENSO CORP

Self-resetting piezoelectric semi-active friction damper

InactiveCN103485436AAvoid the risk of breakingWith reset functionShock proofingElectricitySemi active

A self-resetting piezoelectric semi-active friction damper comprises a shell and sleeves, wherein the shell comprises a top cover and a small box. One end of each sleeve is arranged on a base at the bottom of the small box, the other end of each sleeve is arranged on a top seat below the bottom of the top cover, a certain gap is reserved between the top seat and the other end of the corresponding sleeve, piezoelectric ceramic drivers are placed in the sleeves, leads of the piezoelectric ceramic drivers extend out of the damper through small grooves in the side faces of the sleeves and long and narrow hole grooves in the side walls of the small box and are connected with an external power supply, gaskets are arranged at two ends of each piezoelectric ceramic driver, a baffle is fixed to one side wall of the small box through a fixing screw, pre-pressure is applied by pre-tightening screws on the top cover, a balancing pull rod penetrates the baffle and is connected with the outer wall of the left sleeve, a connecting pull rod is fixed to the left side wall of the small box through a hexagonal nut, an actuating pull rod penetrates one side wall of the small box and is connected with the right sleeve, and reset springs are arranged on the balancing pull rod and the actuating pull rod respectively. A control system of the self-resetting piezoelectric semi-active friction damper is simple, the performance of the piezoelectric ceramic drivers is stable, the pre-pressure is conveniently applied, output energy is less, power output is high, and a piston can automatically reset.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

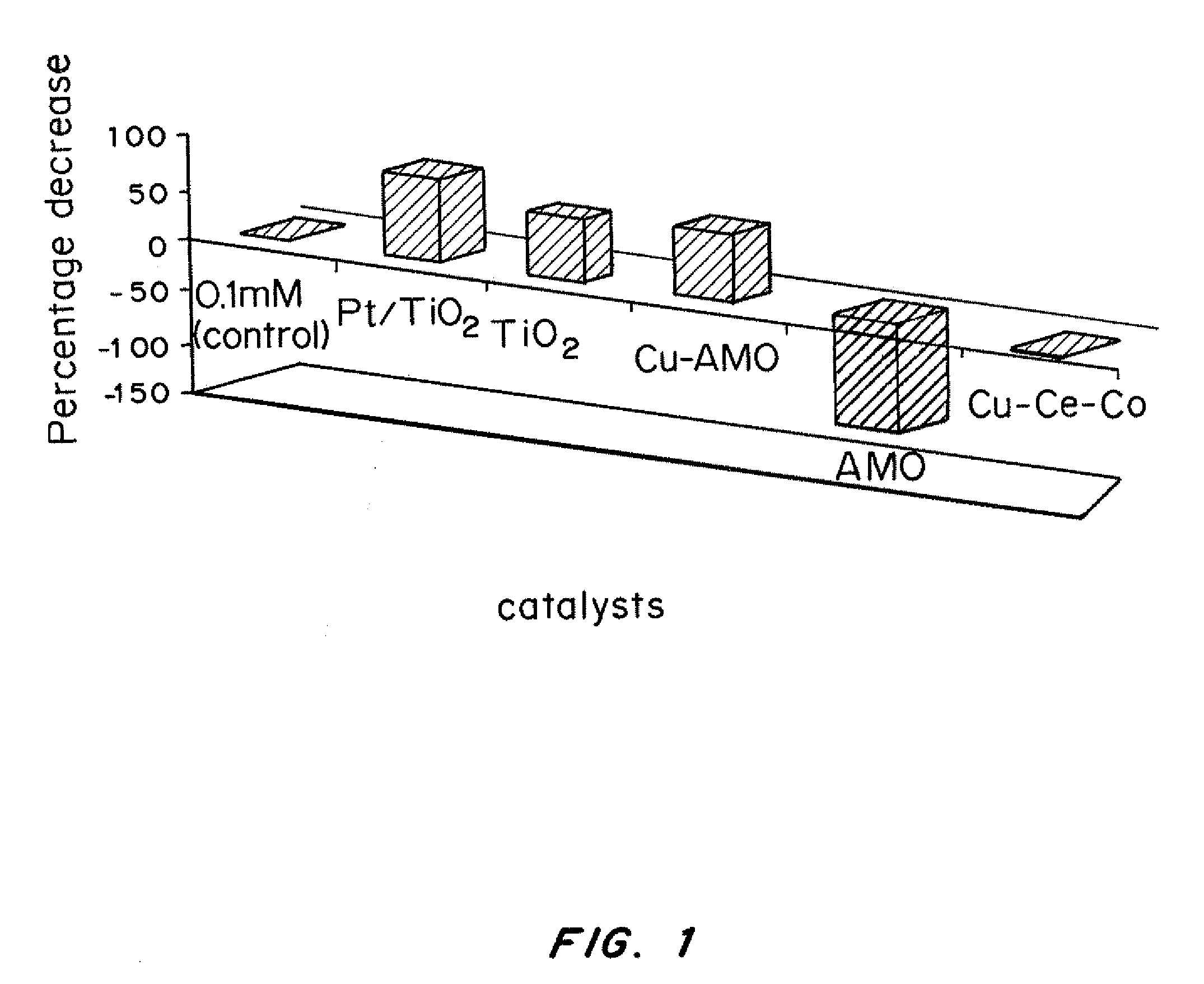

Methods for the treatment of ballast water

ActiveUS20130056648A1Low energy inputHigh selective energy outputAuxillariesSelf-bailing equipments/scuppersChemistryOxidation state

A process has been developed to selectively dissociate target molecules into component products compositionally distinct from the target molecule, wherein the bonds of the target molecule do not reform because the components are no longer reactive with each other. Dissociation is affected by treating the target molecule with light at a frequency and intensity, alone or in combination with a catalyst in an amount effective to selectively break bonds within the target molecule. Dissociation does not result in re-association into the target molecule by the reverse process, and does not produce component products which have a change in oxidation number or state incorporated oxygen or other additives because the process does not proceed via a typical reduction-oxidation mechanism. This process can be used for the remediation of water, particularly ballast water.

Owner:FAHS STAGEMYER

Vapor compression refrigerating cycle apparatus

InactiveCN101532741ASwell correctlyImprove COPCompression machines with several evaporatorsFluid circulation arrangementEngineeringDistributor

The invention provides a vapor compression refrigerating cycle apparatus includes a compressor, a radiator, first and second throttle devices, a flow distributor, an ejector, a suction passage, and first and second evaporators. The flow distributor separates refrigerant decompressed through the first throttle device into a first passage and a second passage. The first passage is in communication with a nozzle portion of the ejector. The second passage is in communication with a suction portion of the ejector through the suction passage. The second throttle device and the second evaporator are disposed on the suction passage. The flow distributor is configured to be capable of adjusting a ratio of a flow rate of refrigerant passing through the second passage to a flow rate of refrigerant passing through the first passage in accordance with a heat load of at least one of the radiator, the first evaporator and the second evaporator.

Owner:DENSO CORP

CO2 Capture System by Chemical Absorption

InactiveUS20130177481A1Increase energy efficiencyReduce cool exhaust heatGas treatmentLevel controlExhaust gasSolvent

The CO2 capture system by chemical absorption for removing CO2 from a combustion exhaust gas by a solvent, comprising: an absorber for absorbing CO2 by a solvent, a regenerator for heating a rich solvent absorbed CO2 thereby releasing CO2, a gas exhaust system for discharging gas from the regenerator, a gas compressor installed in the gas exhaust system, a heat exchanger disposed downstream of the gas compressor for exchanging heat between compressed gas and rich solvent to be supplied to the regenerator, a gas-liquid separator disposed downstream of the heat exchanger for separating gas from condensed water, a condensed water supply system for supplying condensed water from the gas-liquid separator to the regenerator, another gas exhaust system for discharging gas containing high-concentration CO2 from the gas-liquid separator, and a compressor disposed downstream of the gas-liquid separator in the another gas exhaust system for pressurizing the gas containing high-concentration CO2.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Laser-cladding repairing process for pump shaft of nuclear power station

InactiveCN105154874AImprove bindingEasy to operateMetallic material coating processesPower modeNuclear power

The invention discloses a laser-cladding repairing process for a pump shaft of a nuclear power station. The laser-cladding repairing process comprises the following steps: S1, determining the bending part of the pump shaft; S2, using high-energy laser to scan convex points at the bending part of the pump shaft, monitoring the pointer of a dial indicator and stopping laser scanning when the curvature of the pump shaft starts to stretch to the original position; S3, determining whether the pump shaft needs to be straightened, and removing a fatigue layer on the part, requiring treatment, on the pump shaft; S4, after determining that the damage surface of the pump shaft is free of abrasion scars, wiping off a flaw detection agent, repeatedly wiping off the flaw detection agent, which is not wiped off, with acetone, and cleaning the surface of the pump shaft by the low-power mode of a laser; and S5, performing laser cladding of the pump shaft till completion of cladding. According to the process, the pump shaft is straightened by laser and repaired by laser cladding, the operation is simple, the controllability of the implementation process is greatly improved in comparison with a method in the prior art, and the laser cladding material and substrate binding force of laser cladding is better than that of a traditional method.

Owner:JIANGSU SPRAY TECH

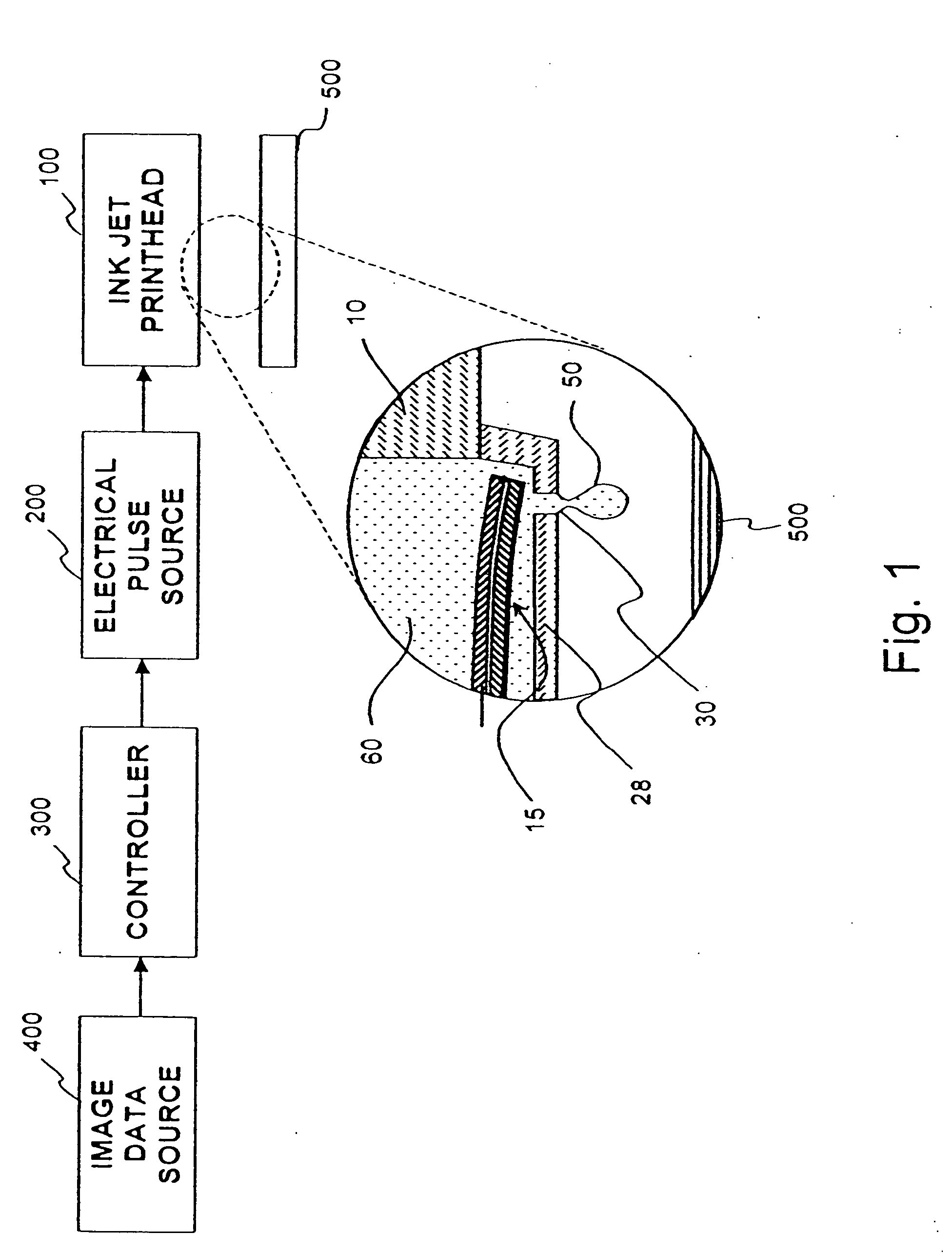

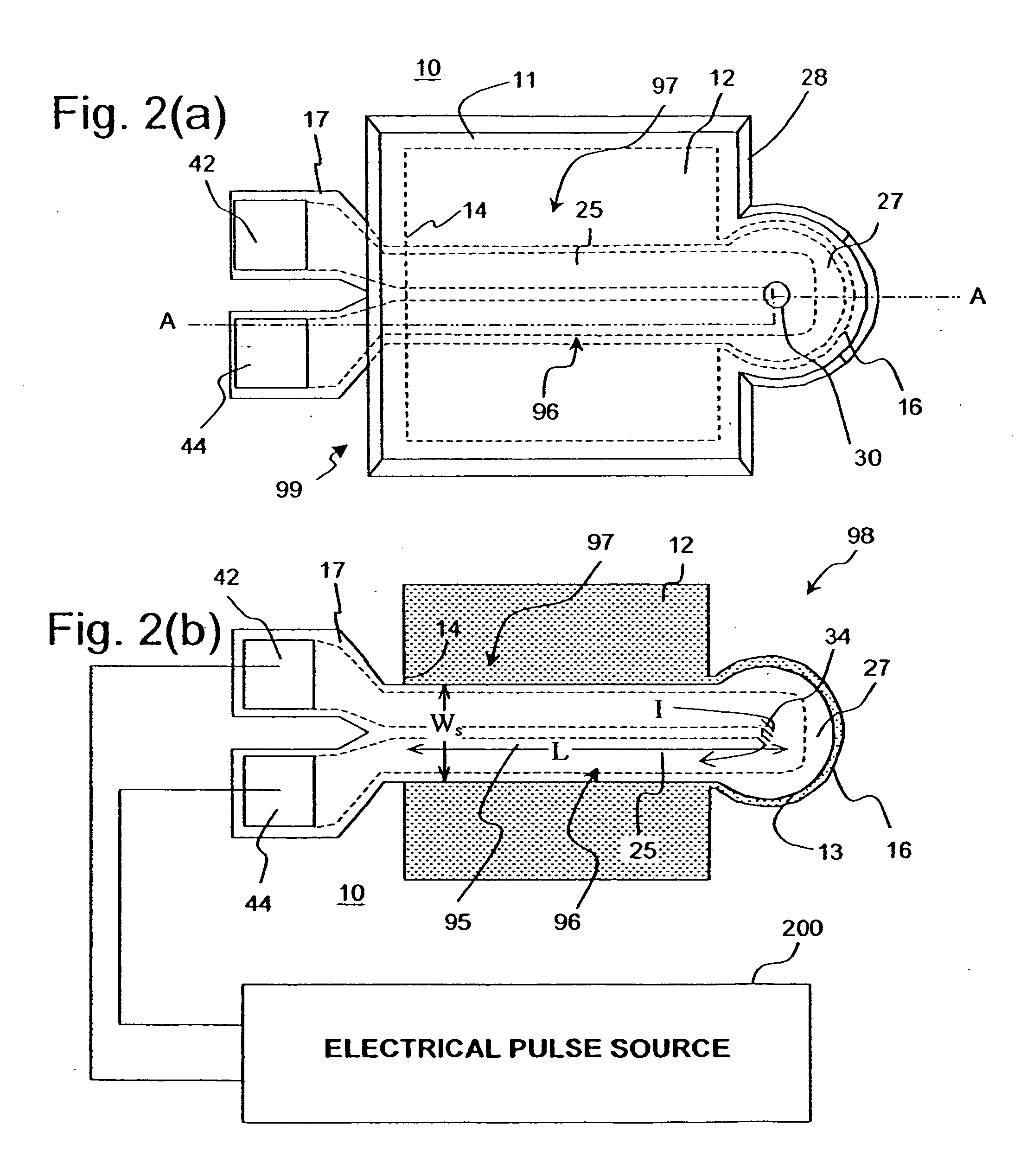

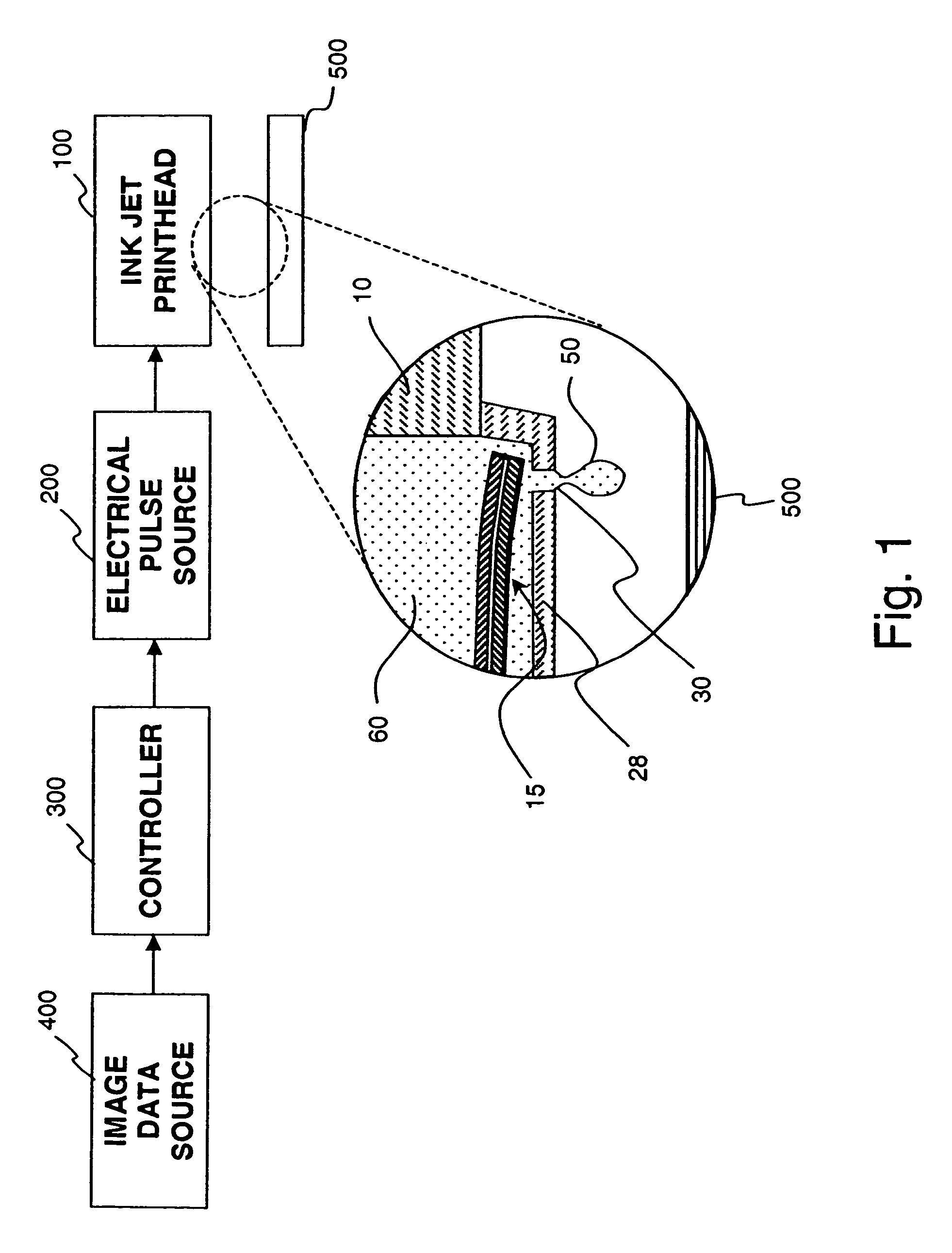

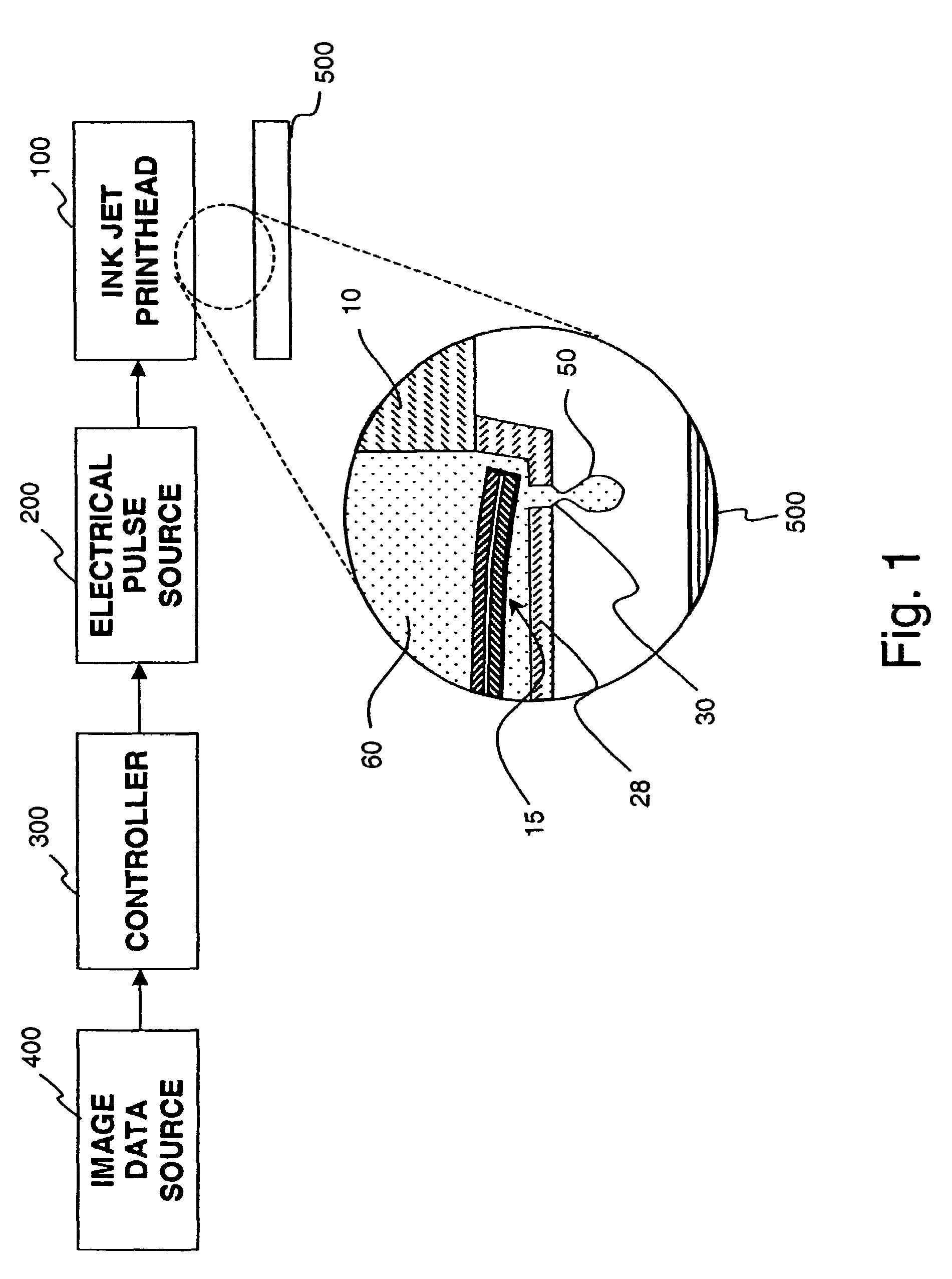

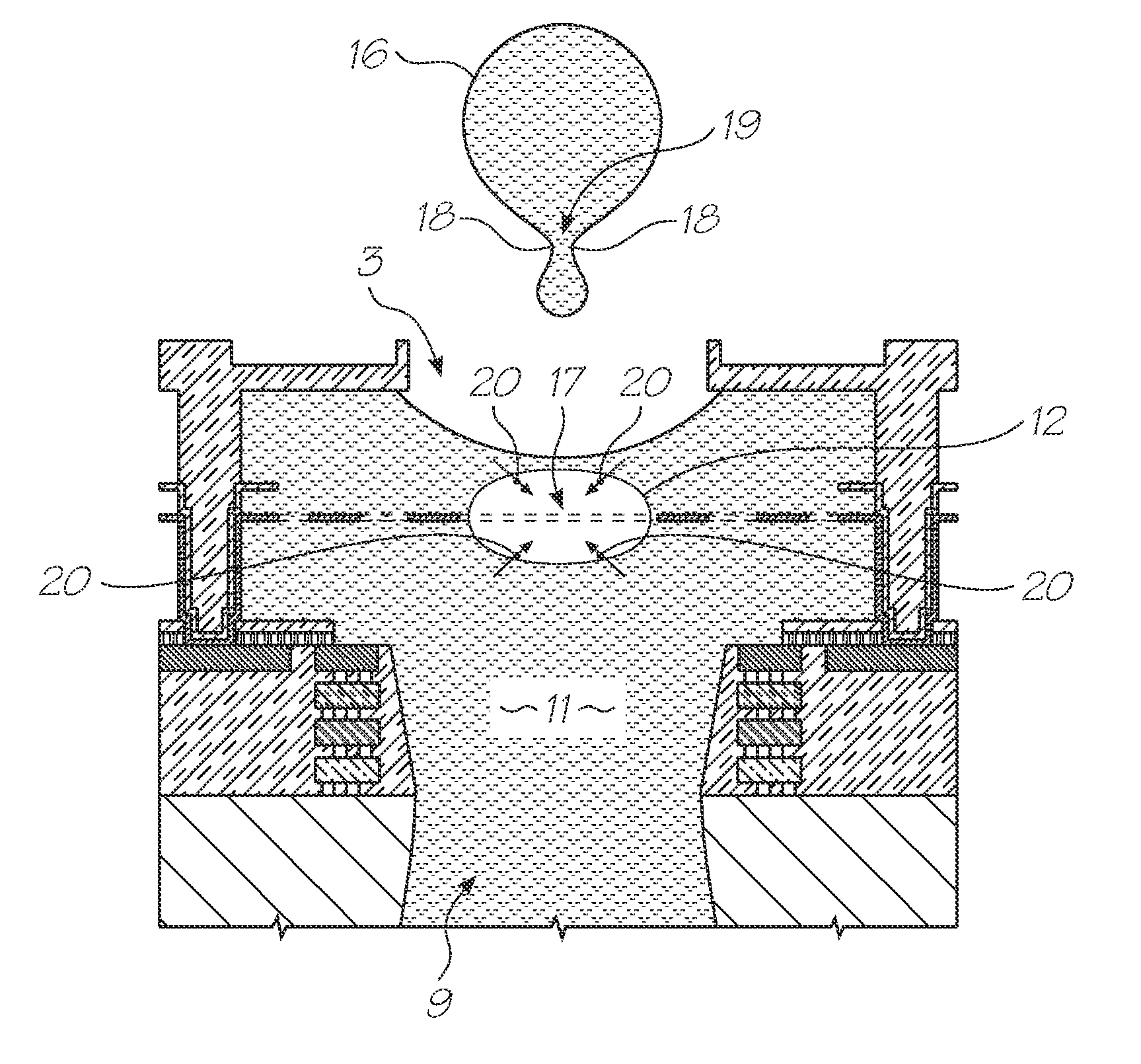

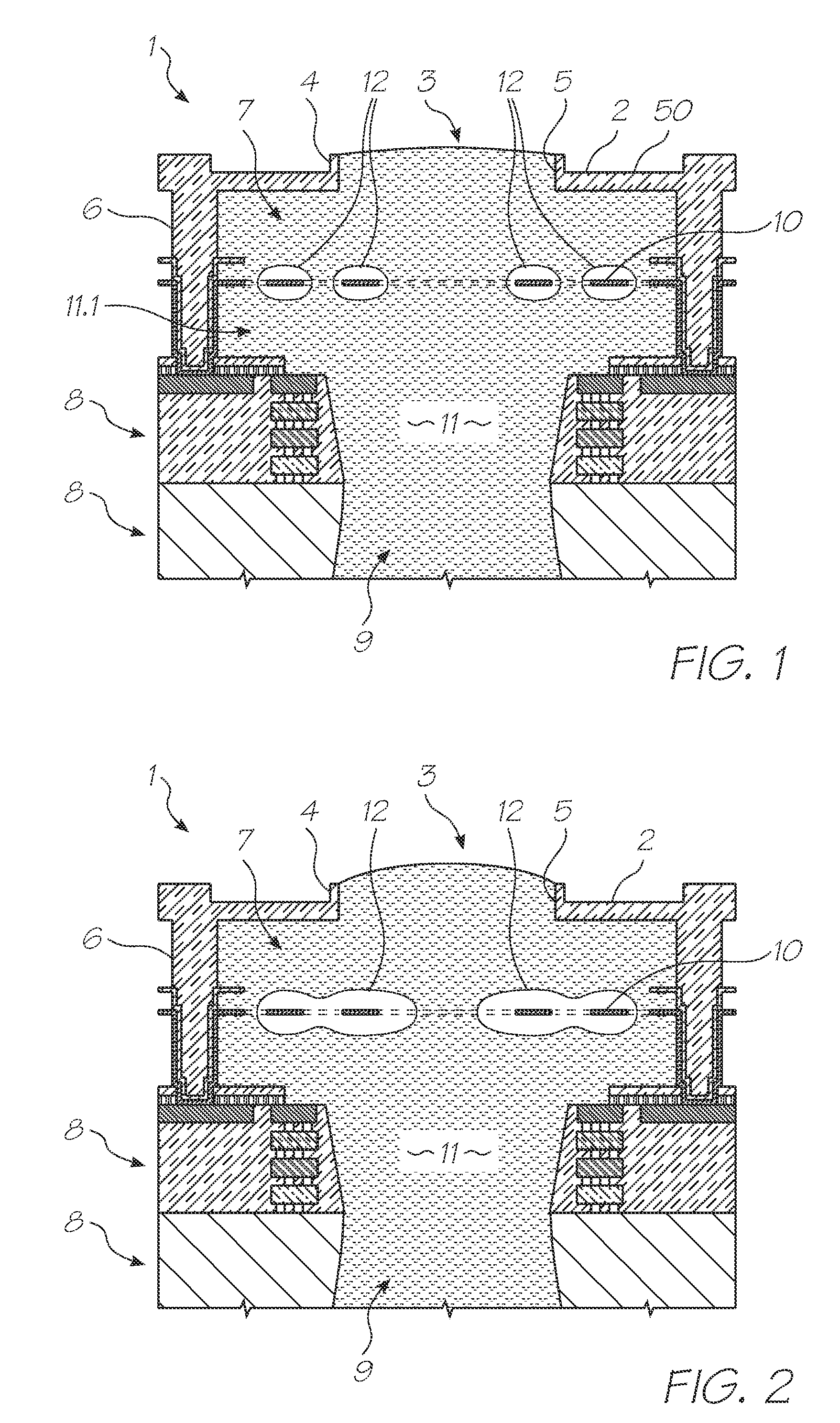

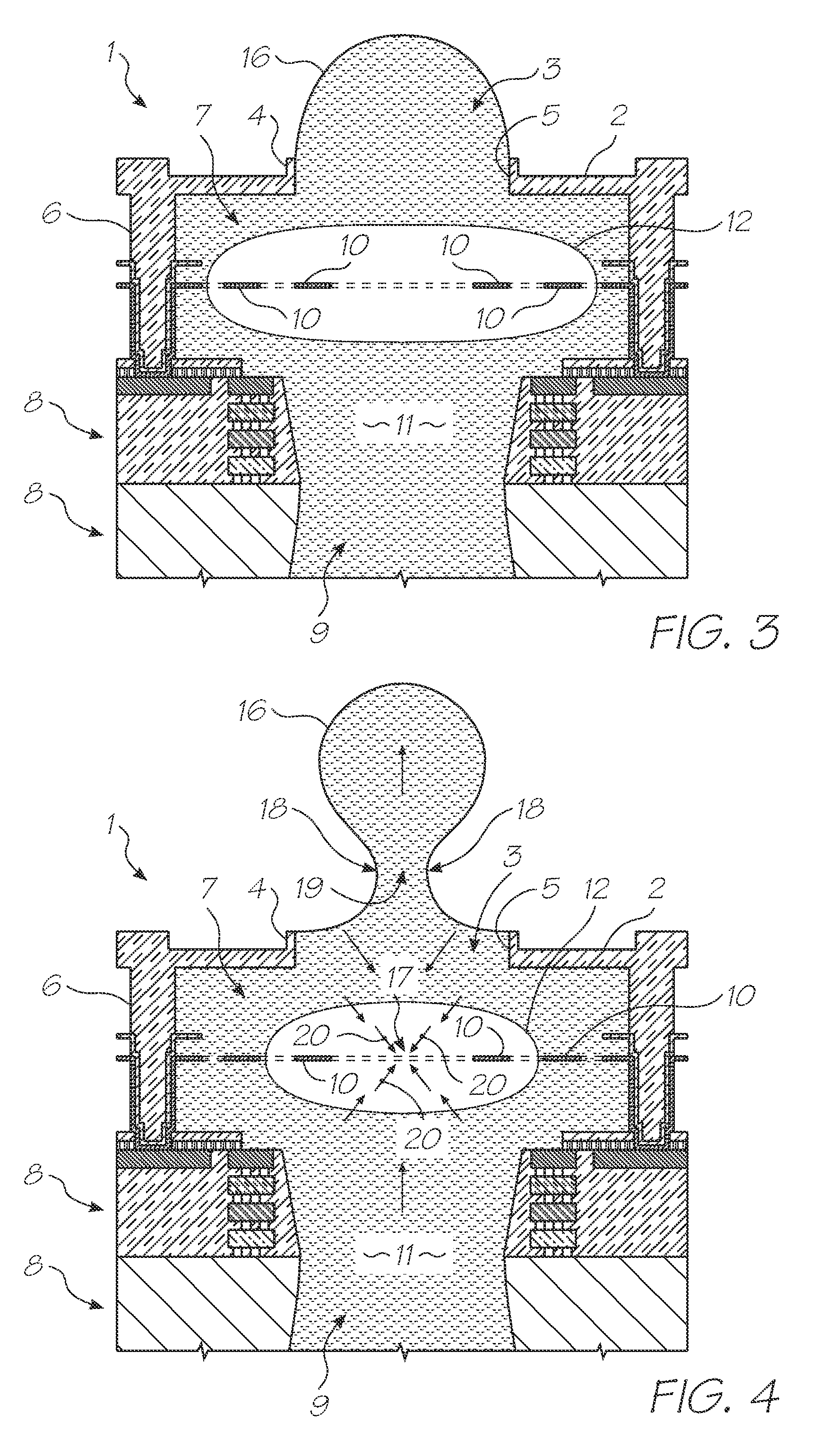

Liquid drop emitter with split thermo-mechanical actuator

InactiveUS20060082615A1Reduce resistanceLow energy inputPrintingElectrical resistance and conductanceThermal expansion

An apparatus for a liquid drop emitter, especially for use in an ink jet printhead, is disclosed. A chamber filled with a liquid, a nozzle and a thermo-mechanical actuator, extending into the chamber from at least one wall of the chamber is disclosed. A movable element of the thermo-mechanical actuator is configured with a bending portion which bends when heated, the bending portion having at least one actuator opening for passage of the liquid. Apparatus is adapted to apply heat pulses to the bending portion resulting in rapid deflection of the movable element, ejection of a liquid drop, and passage of liquid through the at least one actuator opening. A movable element configured as a cantilever or as a beam extending from anchor walls of the chamber is disclosed. The thermo-mechanical actuator may be formed as a laminate structure including a layer constructed of a deflector material having a high coefficient of thermal expansion and that is electrically resistive, for example, titanium aluminide. Apparatus adapted to apply heat pulses comprising a resistive heater formed in the deflector material in the bending portion is also disclosed.

Owner:EASTMAN KODAK CO

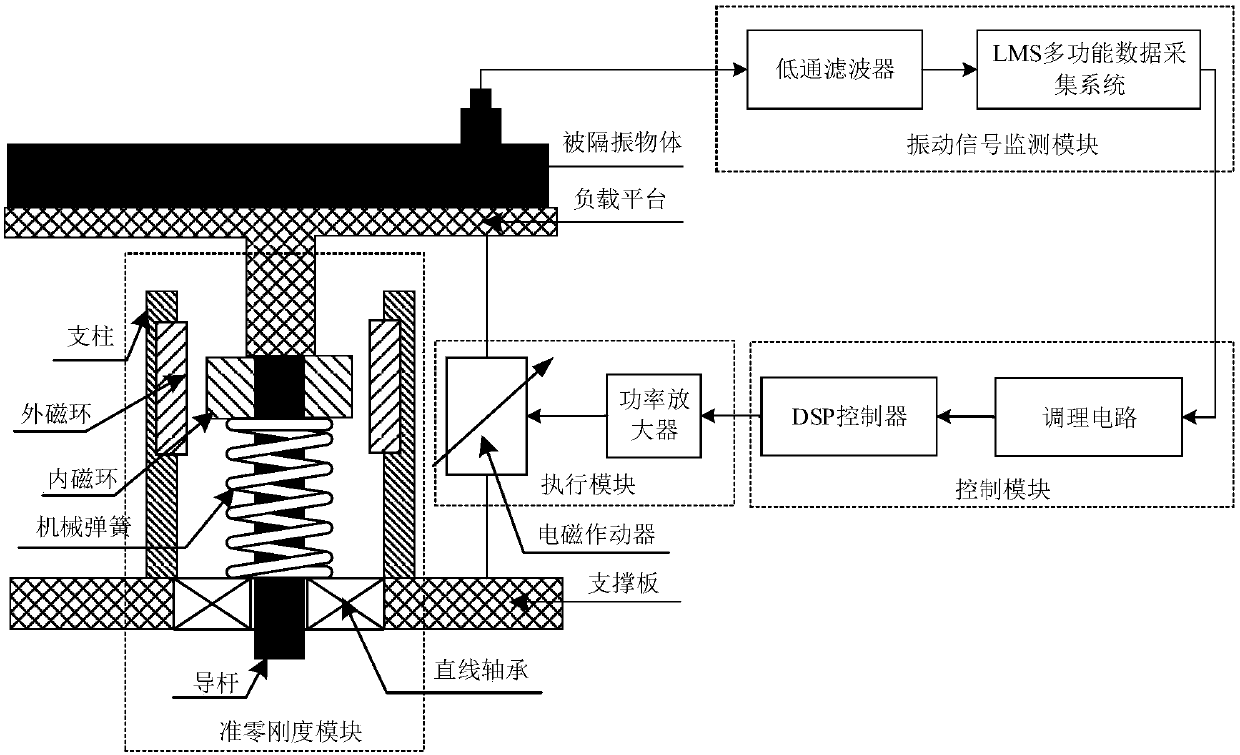

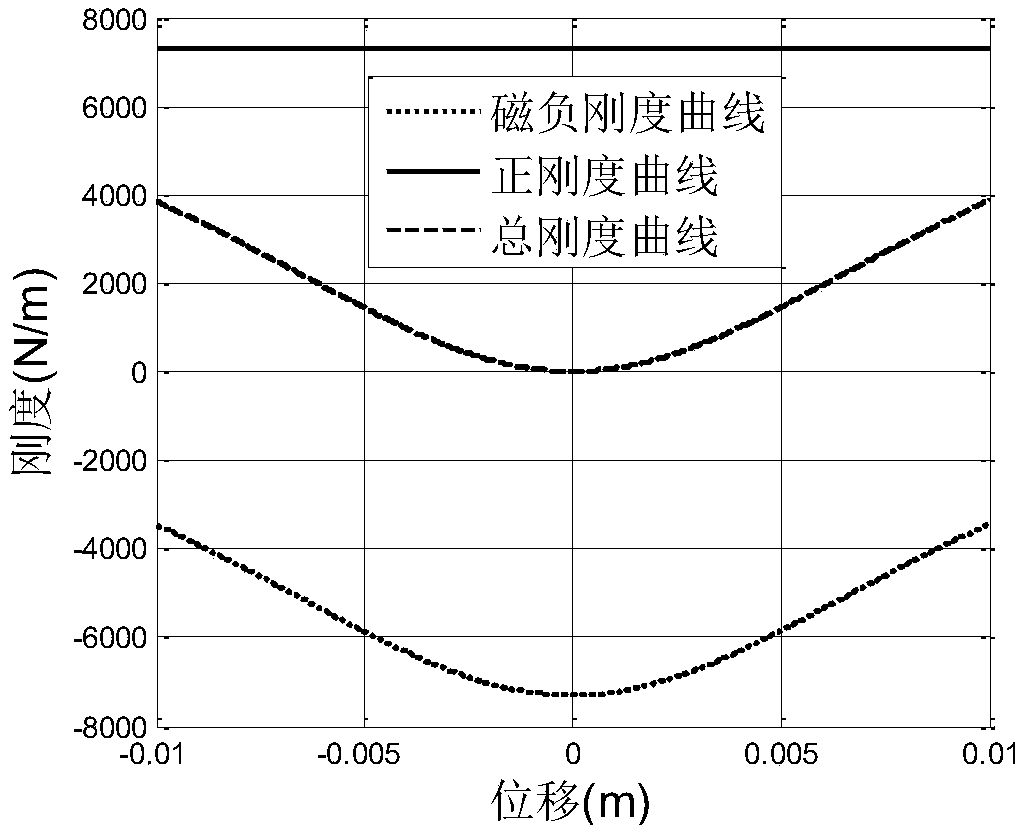

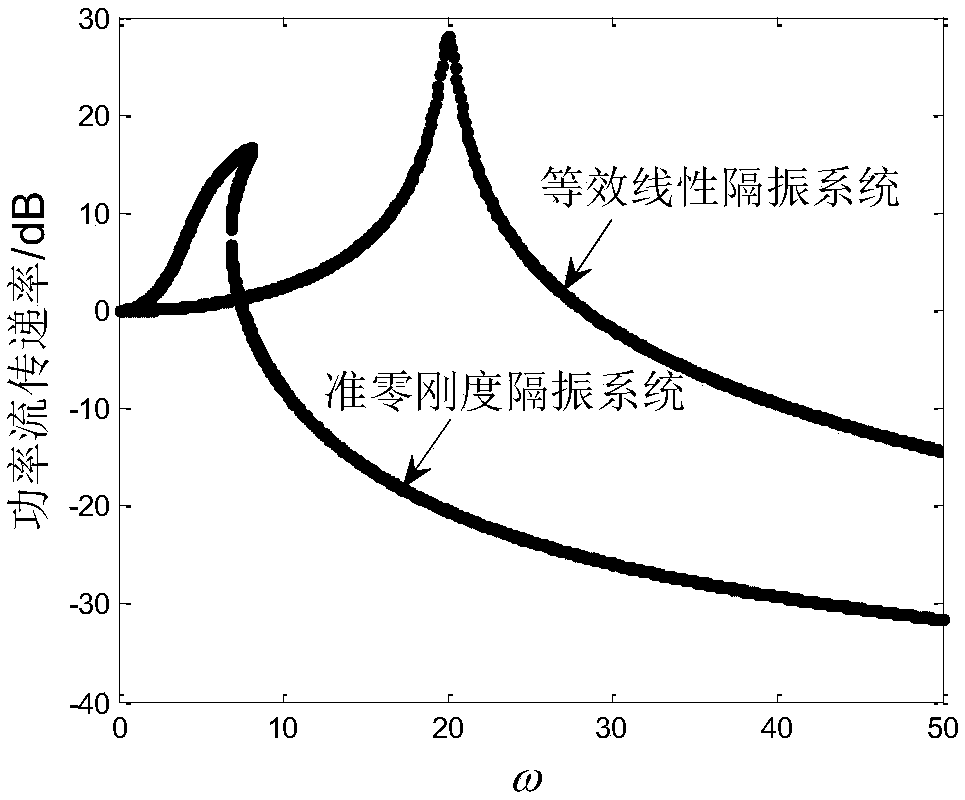

Low-frequency vibration isolation system and vibration reduction method

ActiveCN107807684AThe initial frequency of vibration isolation is lowImprove stabilityMechanical oscillations controlNoise controlControl signal

The invention belongs to the technical field of vibration and noise control and particularly relates to a high-performance low-frequency vibration isolation technology having stronger applicability. For solving the problem of low-frequency vibration isolation of mechanical devices, the invention provides a low-frequency vibration isolation system. The low-frequency vibration isolation system comprises a quasi-zero stiffness module, a vibration signal monitoring module, a control module and an execution module. Firstly, passive isolation of low-frequency vibration is achieved by utilizing the quasi-zero stiffness vibration isolation module, whether a control signal is output to the execution module through the control module or not is judged according to the motion state of the quasi-zero stiffness vibration isolation module, and accordingly the system has the advantage of always working on an attractor having the best whole vibration isolation effect. The system is good in operabilityand simple in identification and suitable for engineering practice application and provides an efficient and reliable new thought for low-frequency vibration control, required input energy is smaller,and the executed control times are fewer.

Owner:NAVAL UNIV OF ENG PLA

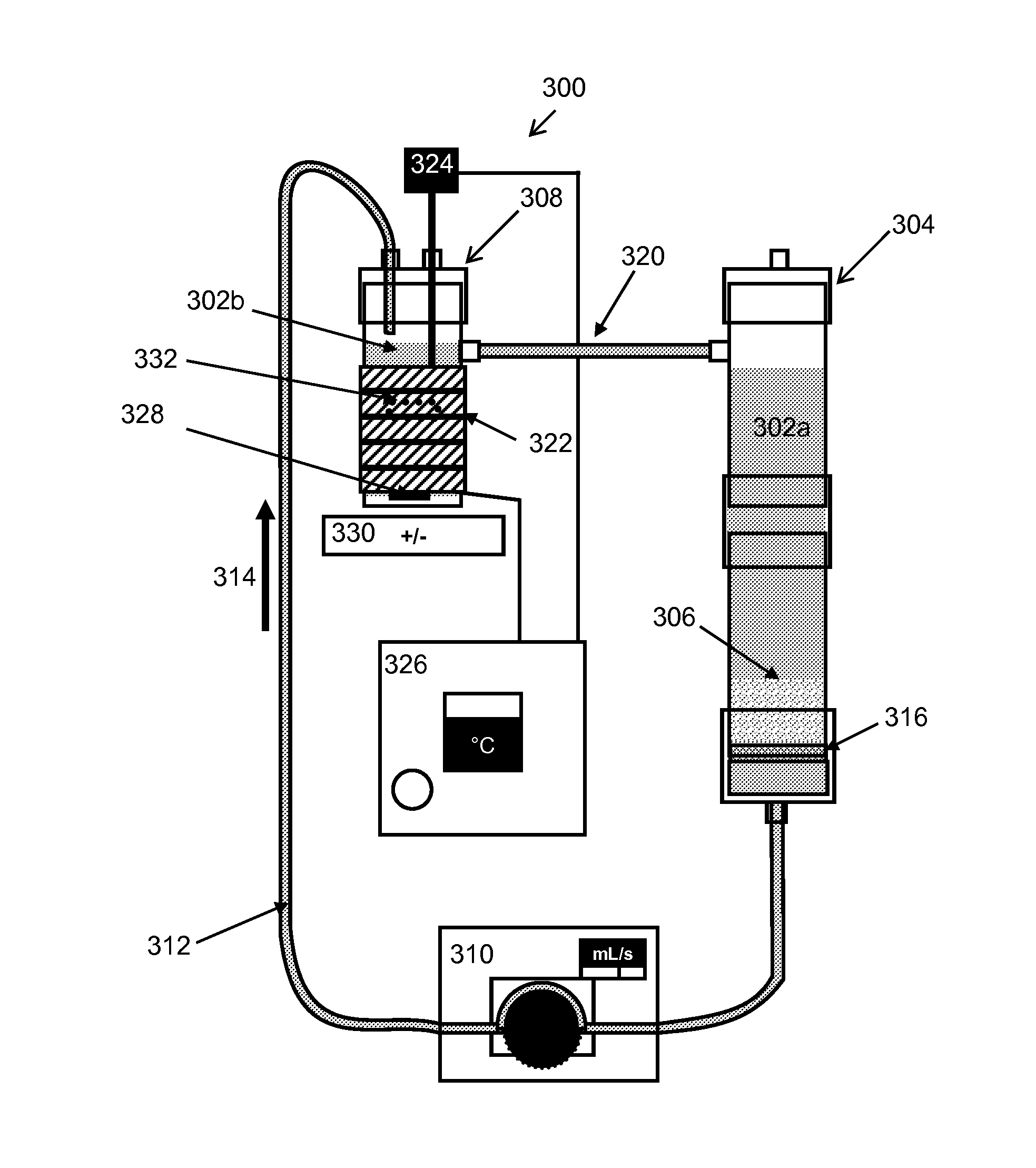

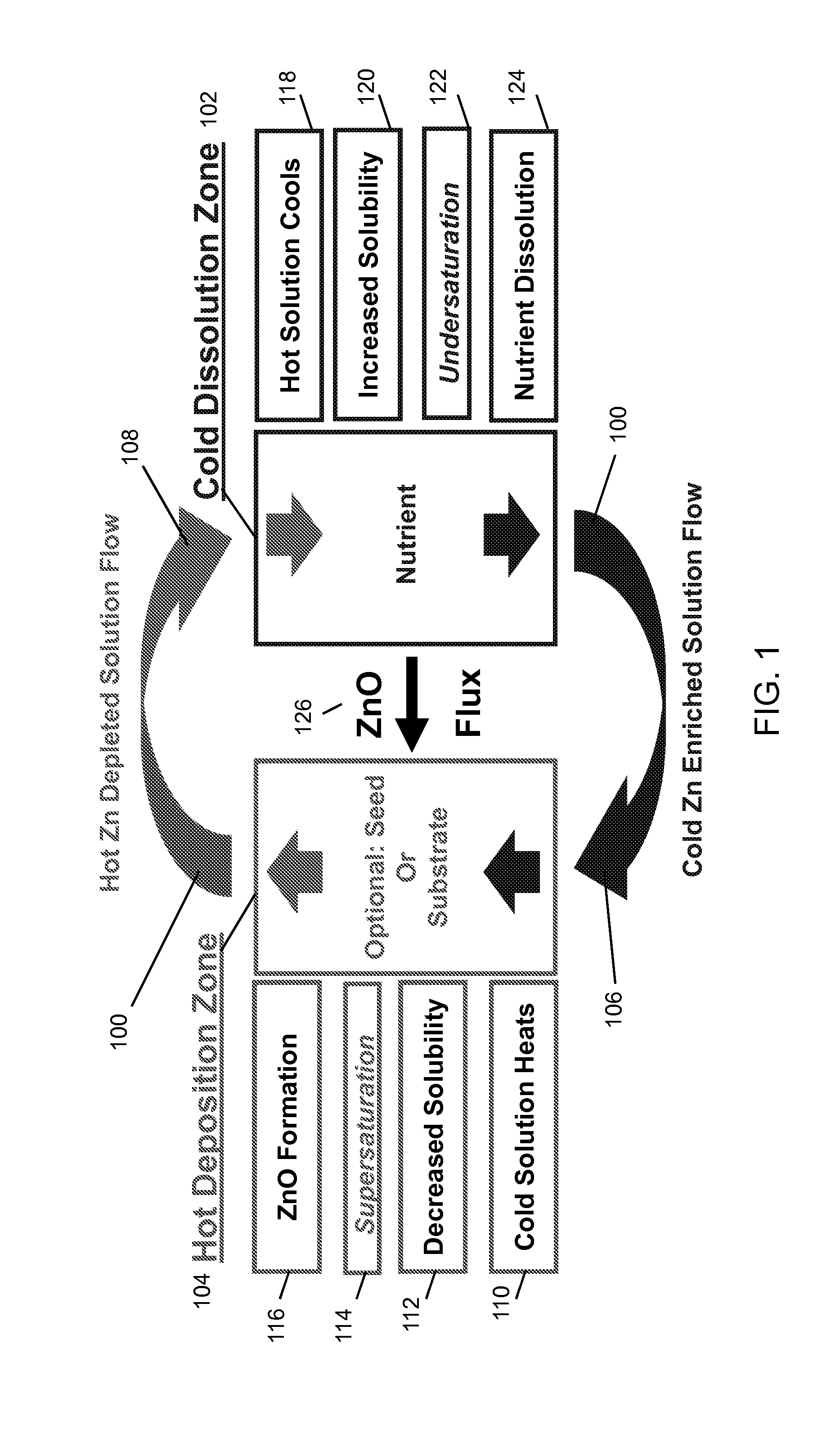

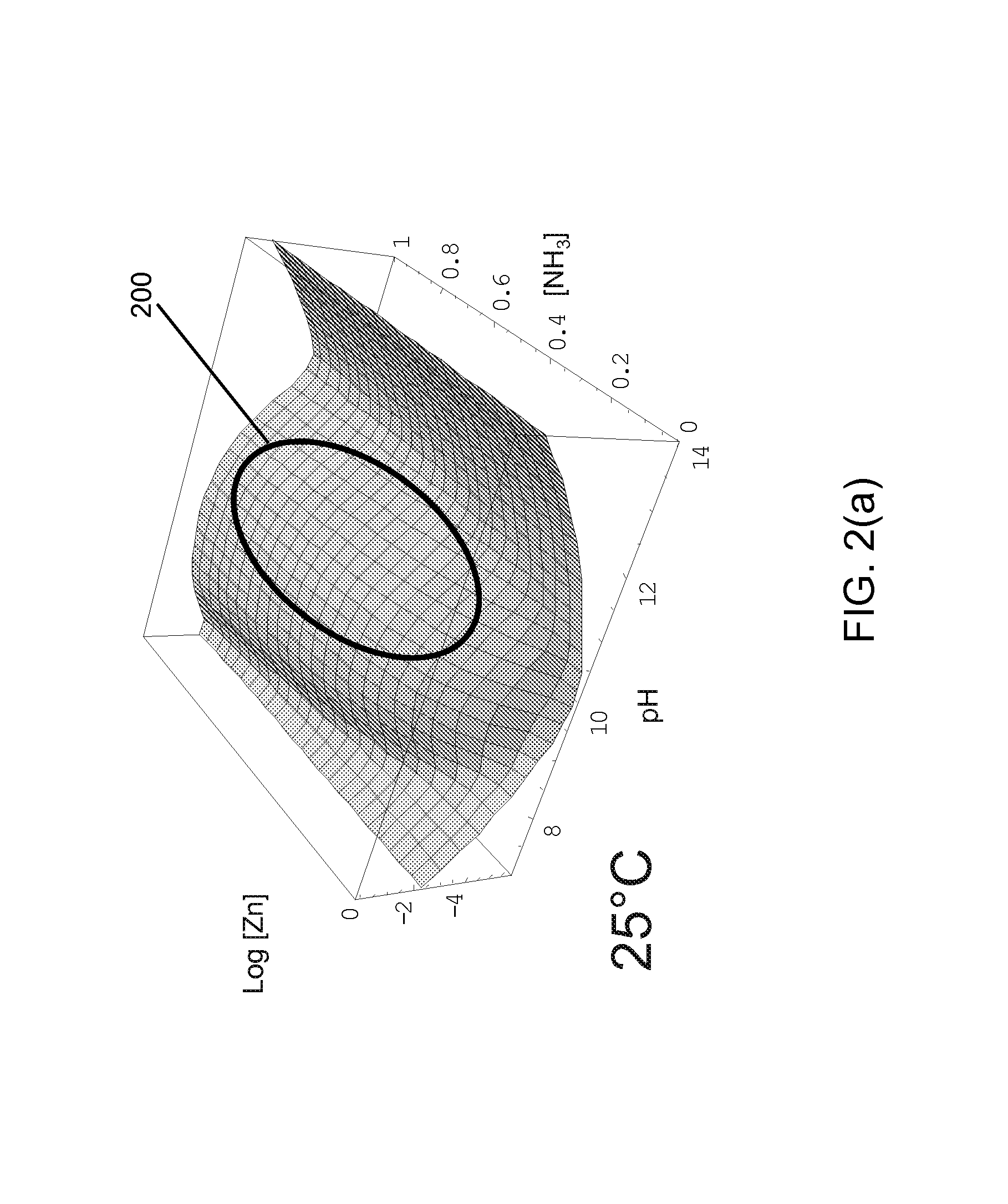

LOW TEMPERATURE CONTINUOUS CIRCULATION REACTOR FOR THE AQUEOUS SYNTHESIS OF ZnO FILMS, NANOSTRUCTURES, AND BULK SINGLE CRYSTALS

ActiveUS20140083352A1Improve compatibilityLowering environmental impact and costLiquid-phase epitaxial-layer growthZinc oxides/hydroxidesSource materialSingle crystal

A method for synthesizing ZnO, comprising continuously circulating a growth solution that is saturated with ZnO between a warmer deposition zone, which contains a substrate or seed, and a cooler dissolution zone, which is contains ZnO source material.

Owner:RGT UNIV OF CALIFORNIA

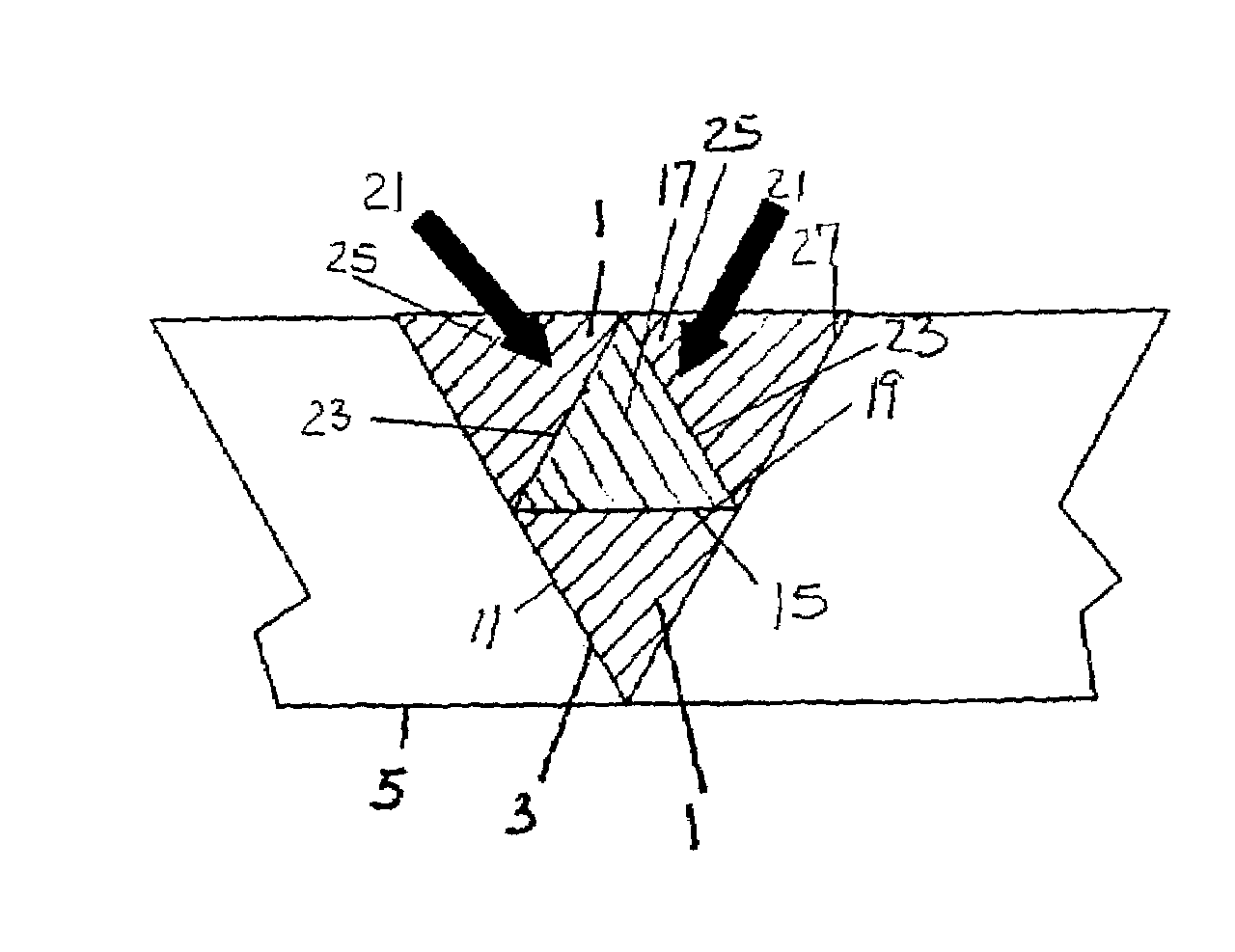

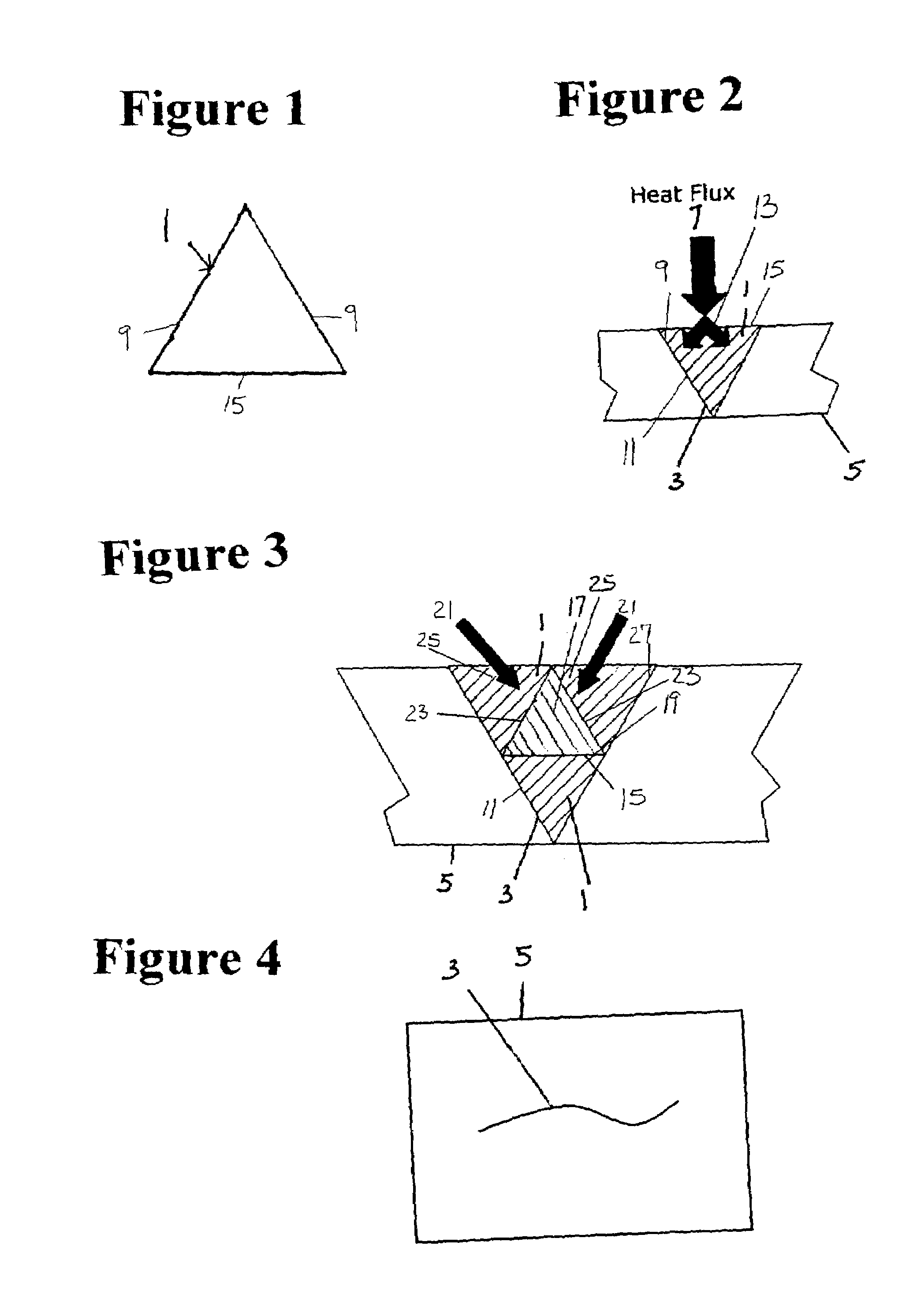

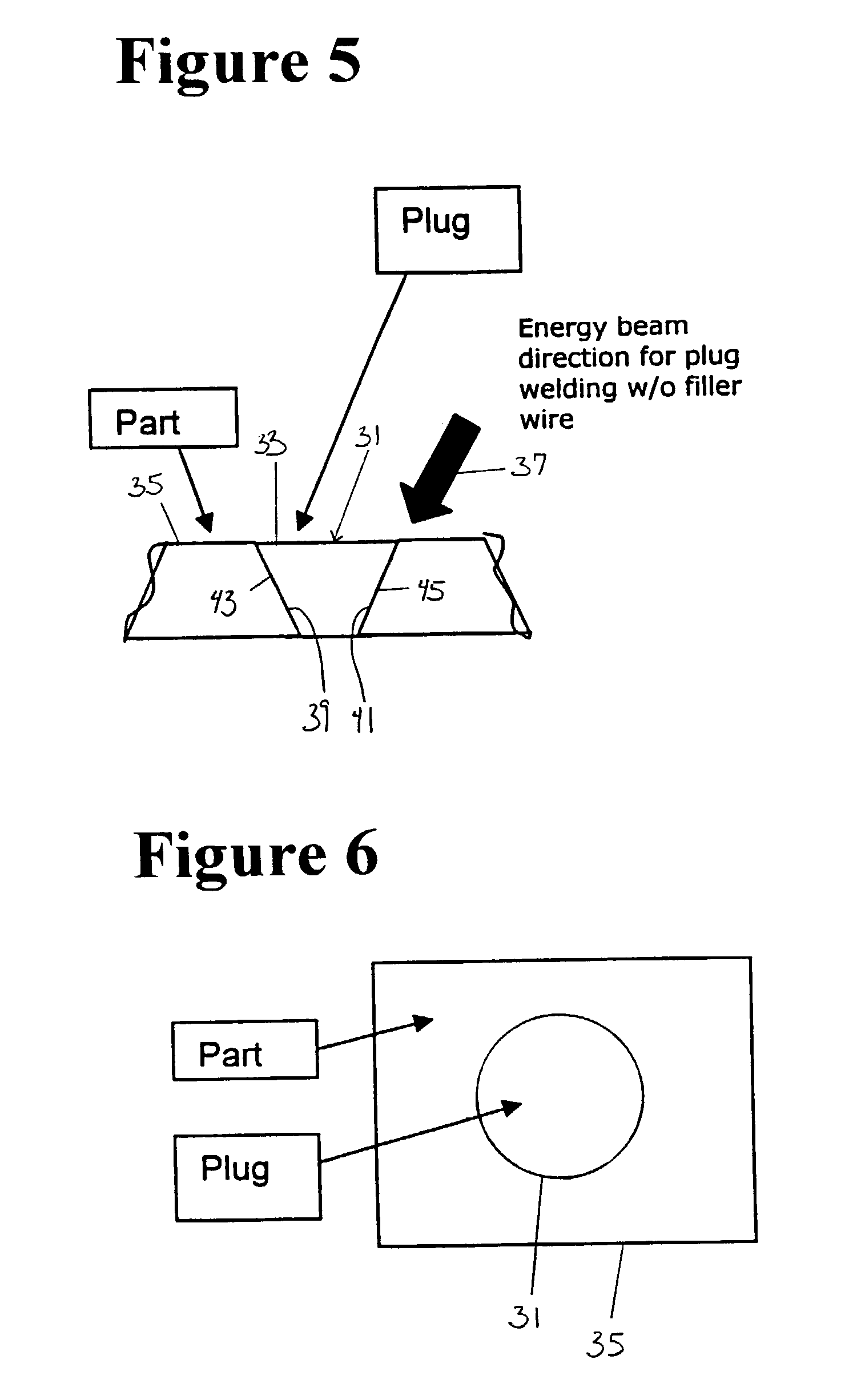

Repair with feedstock having conforming surfaces with a substrate

InactiveUS7600666B2Low energy inputReduce energy inputWelding/cutting media/materialsWelding/soldering/cutting articlesThin walledCorrosion

The present invention is a low heat energy input repair system. The system utilizes a V-shaped feedstock that conforms to the shape of grooves in damaged parts. The V-shape of the feedstock conforms closely to the damaged region of various components and reduces the heat input needed to bond the surfaces. The repair system is deployable onsite, at a military depot, industrial manufacturing facility or other location where a mobile repair system would be beneficial. The present system provides onsite, in-situ, low heat input repair of wear, fatigue and corrosion cracks, or impact surface damage of large components. The present invention is particularly useful for components with thin walls and results in low distortion.

Owner:RABINOVICH JOSHUA E

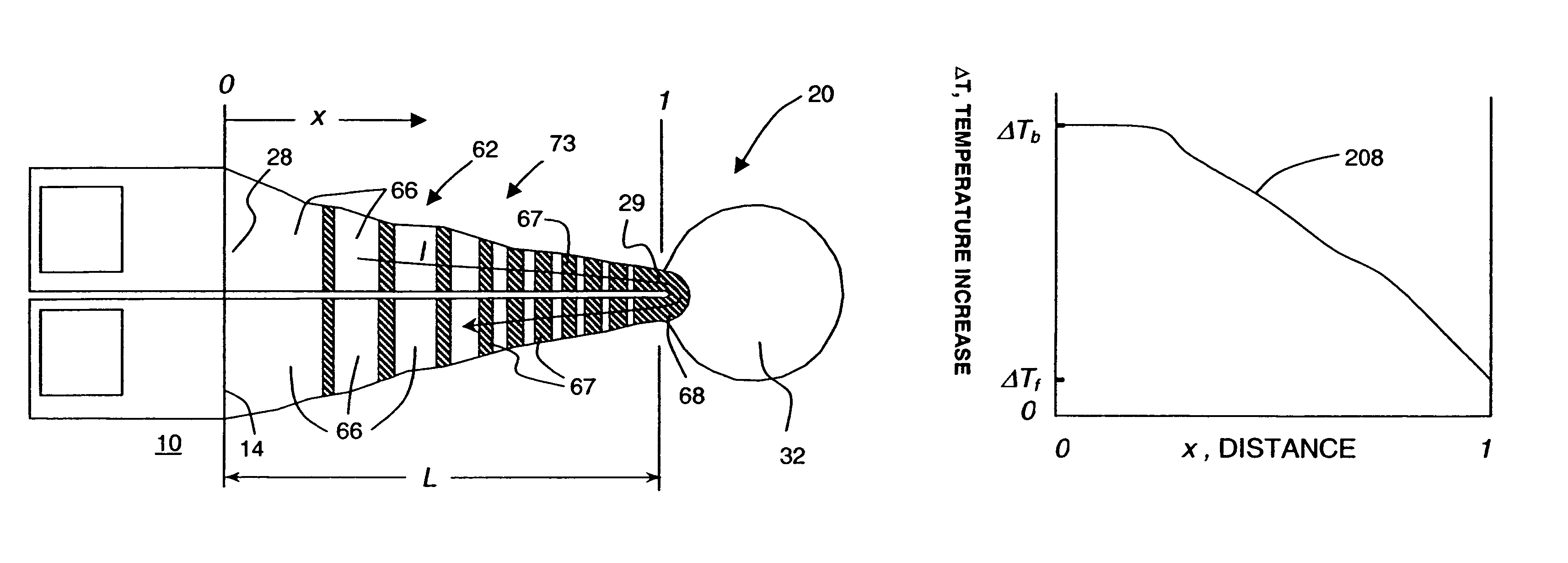

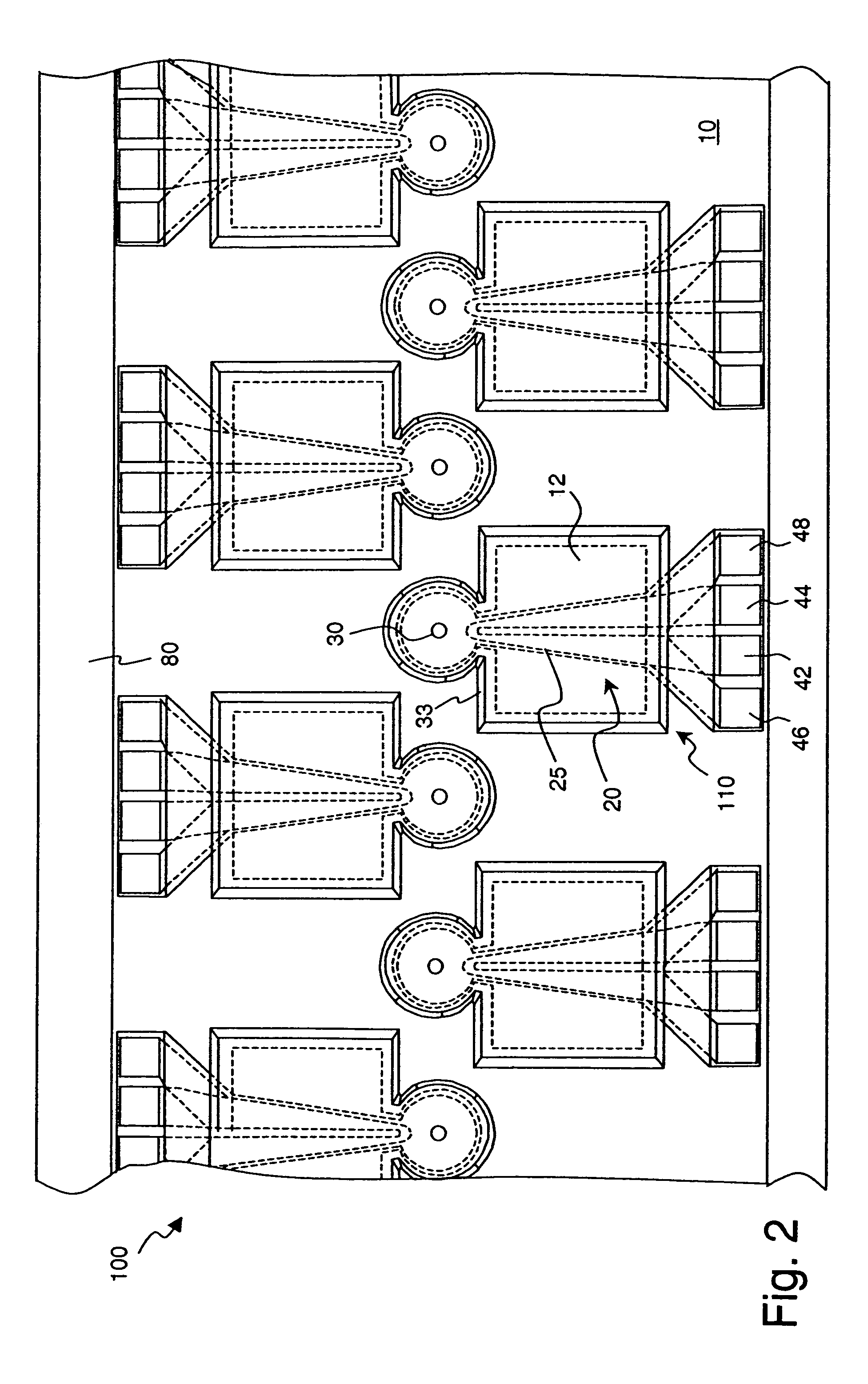

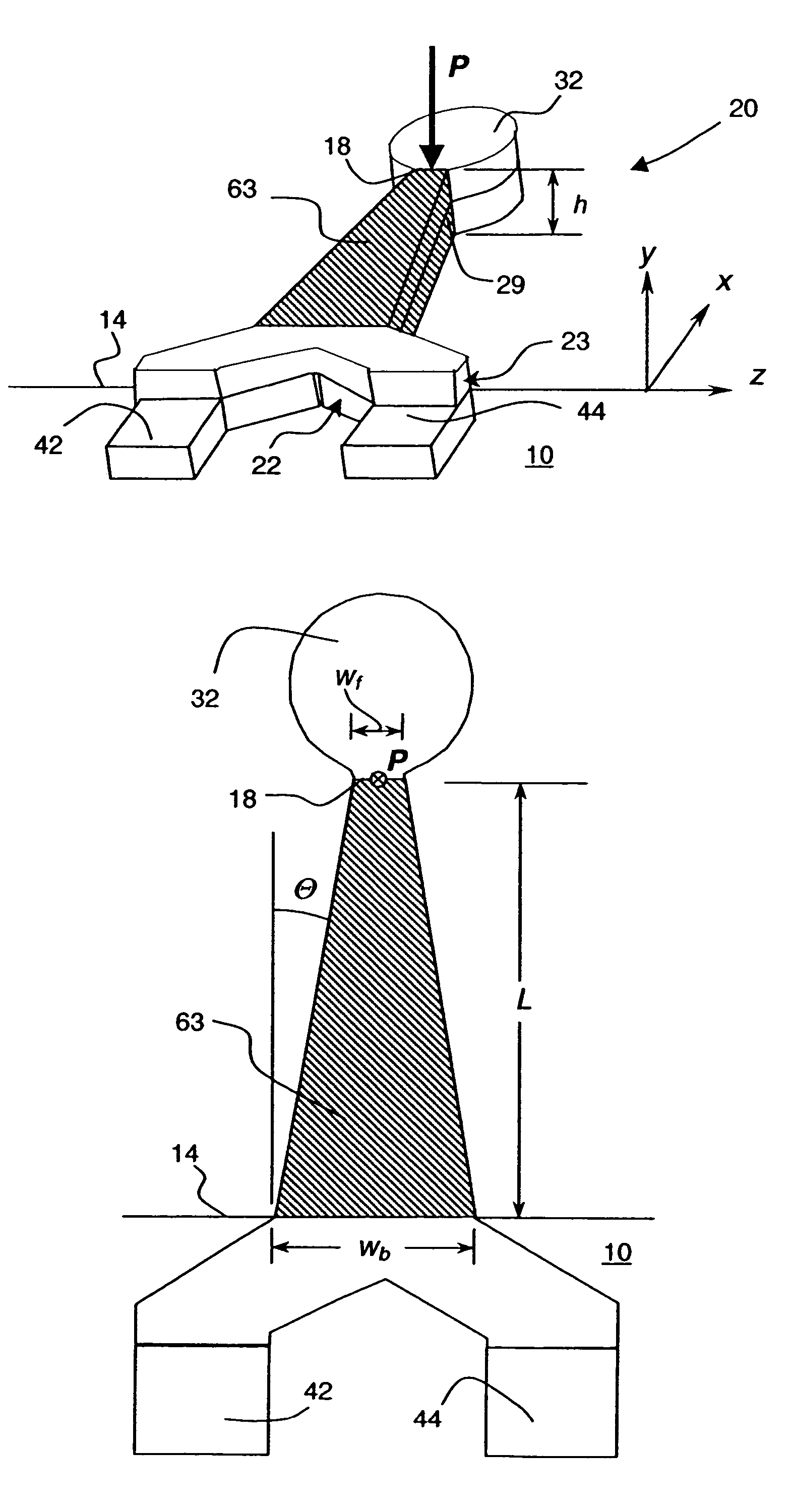

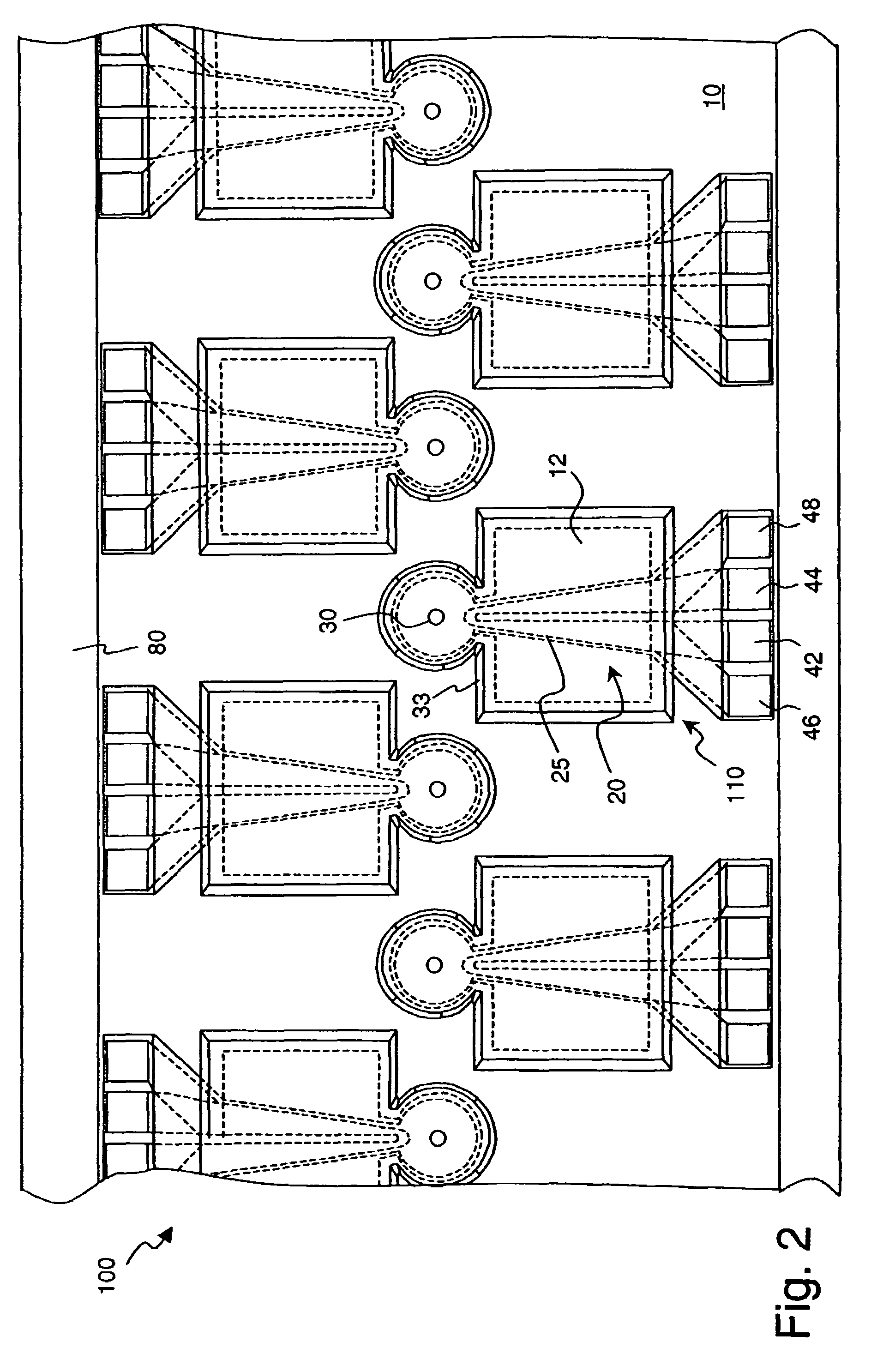

Tapered multi-layer thermal actuator and method of operating same

InactiveUS7033000B2Low energy inputRapid restoration of the actuatorLiquid surface applicatorsCoatingsElectrical resistance and conductanceThermal expansion

An apparatus for and method of operating a thermal actuator for a micromechanical device, especially a liquid drop emitter for use in an ink jet printhead, is disclosed. The disclosed thermal actuator includes a base element and a cantilevered element including a thermo-mechanical bender portion extending from the base element to a free end tip. The thermo-mechanical bender portion includes a barrier layer constructed of a dielectric material having low thermal conductivity, a first deflector layer constructed of a first electrically resistive material having a large coefficient of thermal expansion, and a second deflector layer constructed of a second electrically resistive material having a large coefficient of thermal expansion wherein the barrier layer is bonded between the first and second deflector layers.

Owner:EASTMAN KODAK CO

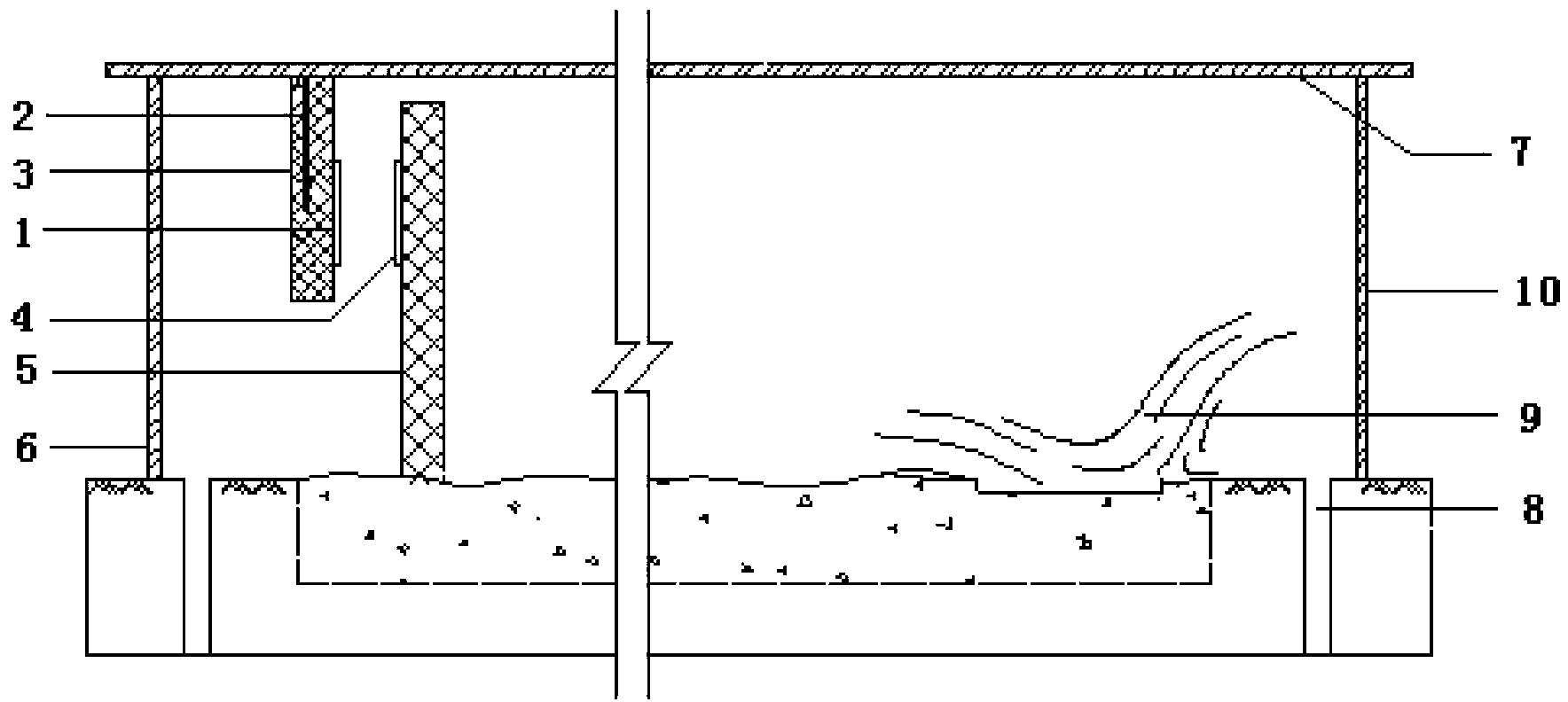

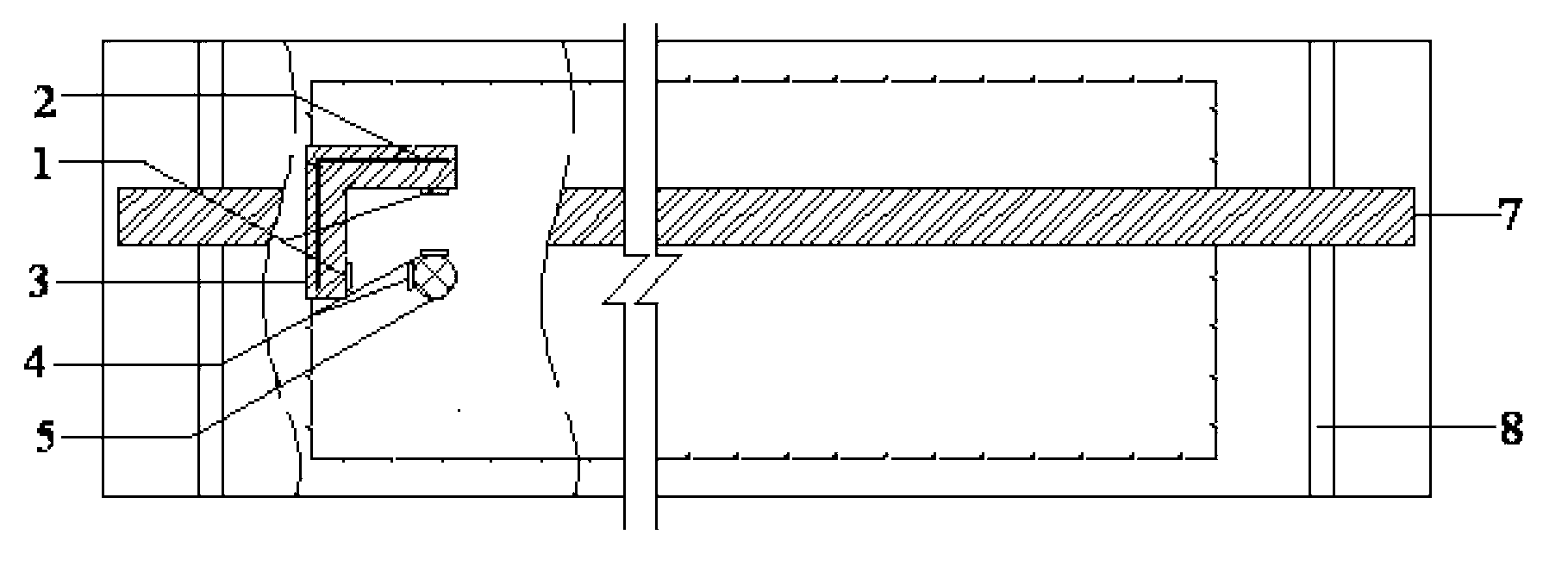

Introduced capacitive device for measuring horizontal ground micro-vibration

ActiveCN103017890AImprove the shortcoming of only testing displacement in one directionNo contact measurement errorSubsonic/sonic/ultrasonic wave measurementUsing electrical meansLow-pass filterEngineering

The invention discloses an introduced capacitive device for measuring horizontal ground micro-vibration. The device comprises a standard signal generator (11), an introduced capacitive sensor (12), a negative feedback operational amplifier (13) and a low-pass filter and display system (14). The introduced capacitive sensor comprises an introduced copper cylinder (5) and a capacitor piece (4), wherein the introduced copper cylinder (5) is arranged on the ground, and the capacitor piece (4) is arranged at the top end of the introduced copper cylinder (5). A vibration isolation ditch (8) is arranged at a 2m<2> position surrounding the periphery of the copper cylinder, a steel cylinder A (6) and a steel cylinder B (10) are arranged on the outer side of the vibration isolation ditch, a steel beam (7) is arranged at the top ends of the two steel cylinders, a measuring electrode (1), a shielding electrode (2) and a shielding electrode shell (3) are arranged below the steel beam, and an excitation source (9) is arranged within an enclosed scope of the vibration isolation ditch (8). The introduced capacitive device is simple in structure and convenient to use, facilitates simultaneous measurement of horizontal vibration in two vertical directions, and can be specially used for precisely measuring horizontal ground micro-vibration.

Owner:TIANJIN UNIV

Printhead with increasing drive pulse to counter heater oxide growth

ActiveUS20090066742A1Increases drive pulse energyDecrease in levelInking apparatusOther printing apparatusPulse energyEngineering

An inkjet printer that has a printhead with an array of ejection devices for ejecting drops of liquid onto a media substrate. Each of the ejection devices having a chamber for holding liquid, a nozzle in fluid communication with the chamber and a heater positioned in the chamber for contact with the liquid such that resistive heating of the heater generates a vapour bubble that ejects a drop of the liquid through the nozzle. The printer also has a controller for receiving print data and generating drive pulses to energize the heaters in accordance with the print data. The controller increases the drive pulse energy during the printhead lifetime.

Owner:MEMJET TECH LTD +1

Inkjet printhead with titanium aluminium alloy heater

Owner:SILVERBROOK RES PTY LTD

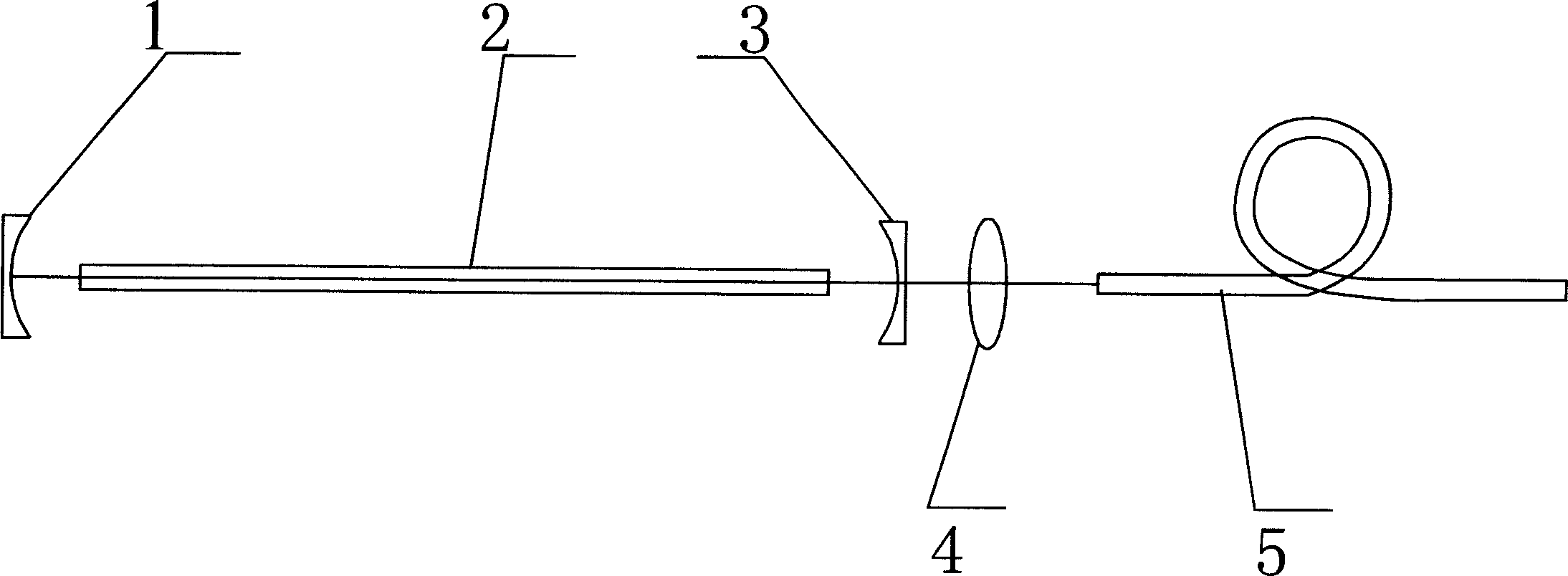

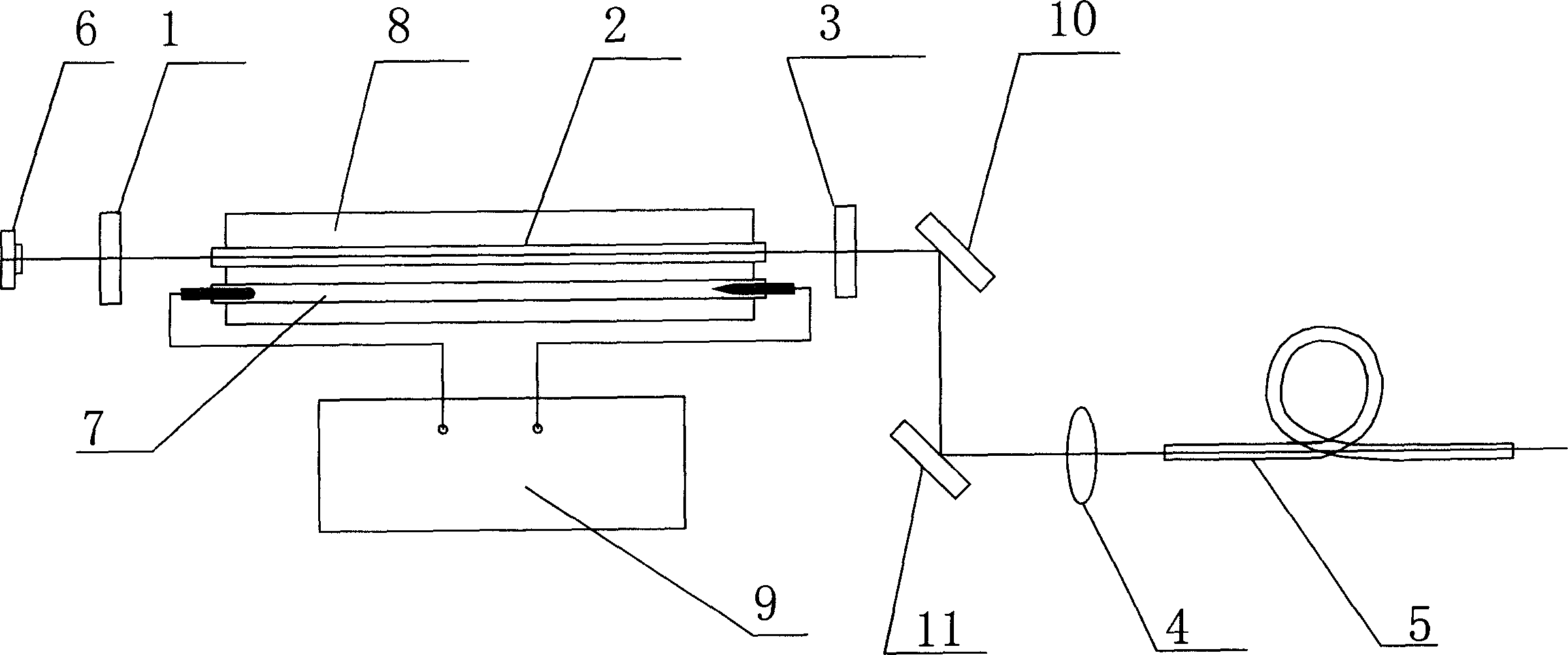

1.444 micron nd: YAG laser therapeutic apparatus

InactiveCN1618410AIncrease powerOperational securityOptical resonator shape and constructionSurgical instrument detailsFluorescenceNd:YAG laser

A 1.444-micron Nd:YAG laser therapy apparatus for laser operation with high staltic effect and high safety to human eyes is composed of a laser oscillator, a laser pump system, a cooling system and an optical fibre coupling system. Its dual-elliptical cavities has the reflecting Ag layer on its inner surface. The Eu doped quartz glass tube is used to filter out the pumping UV and long-wave band fluorescence from pumping lamp.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

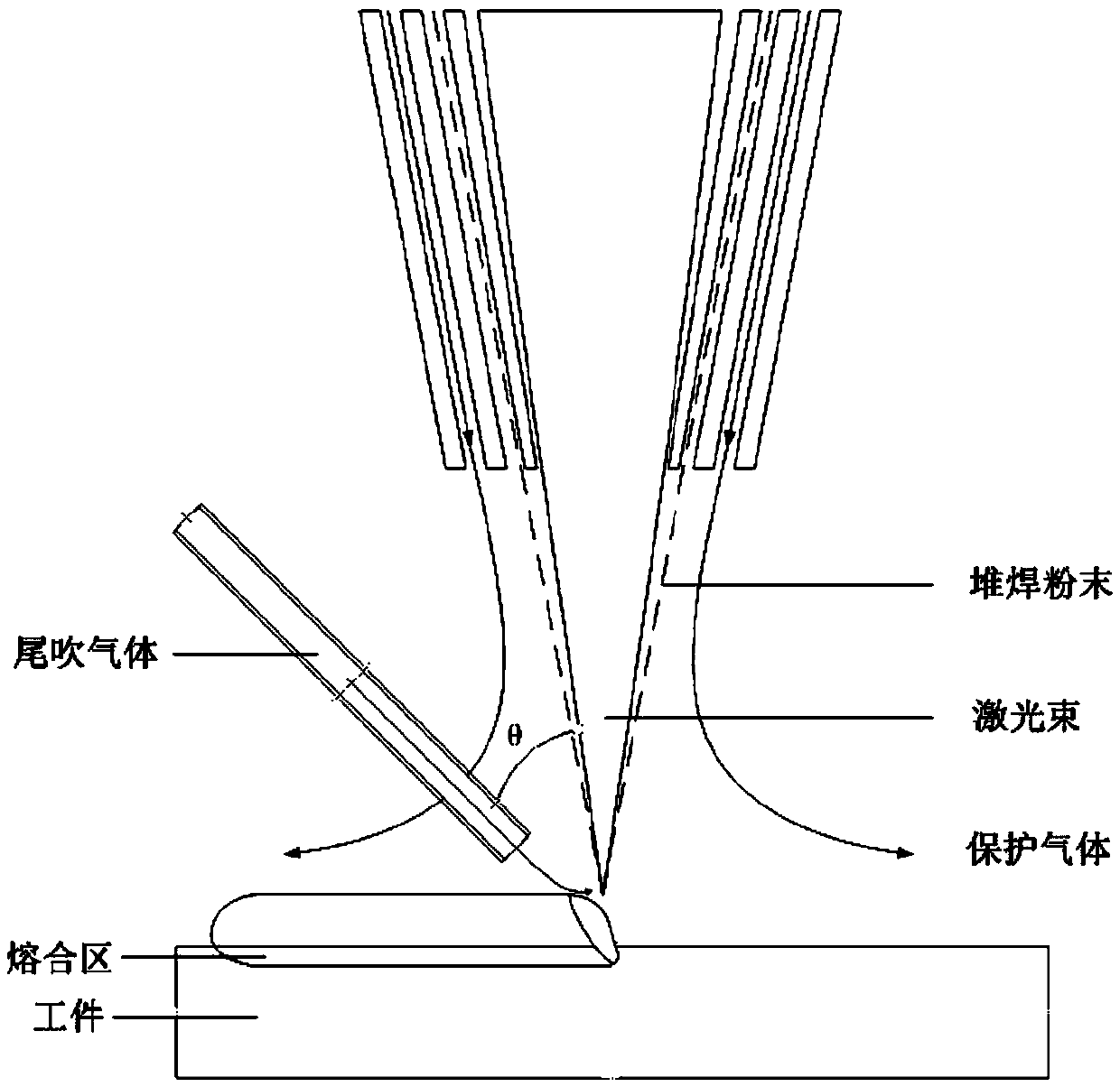

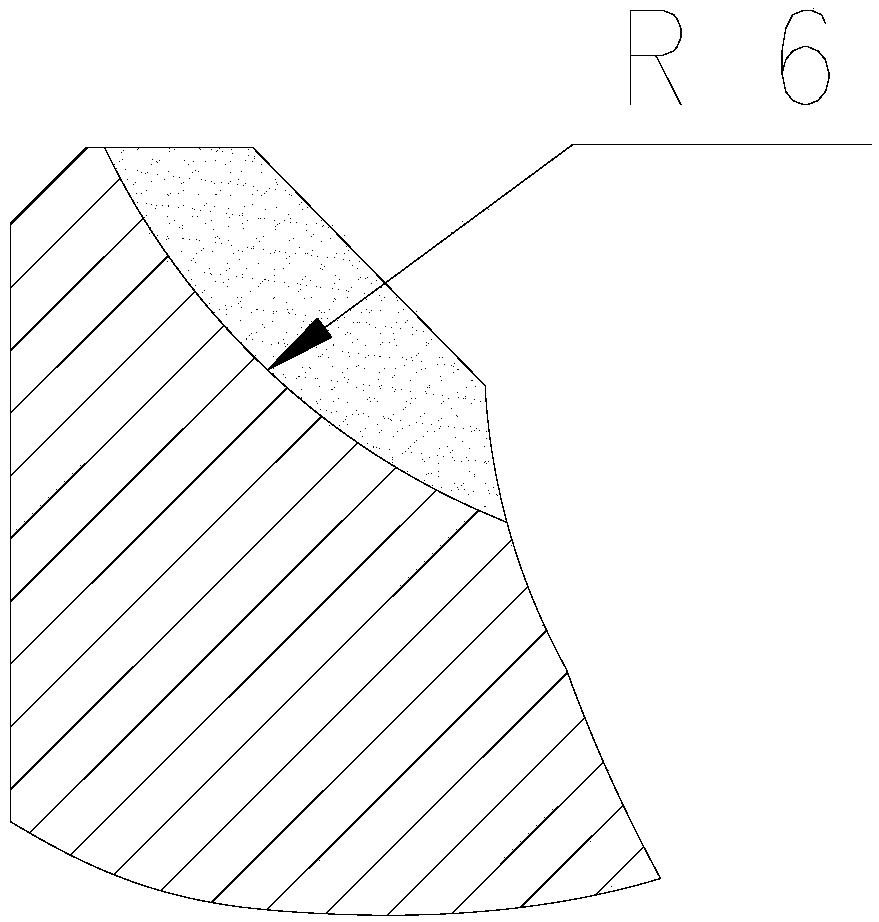

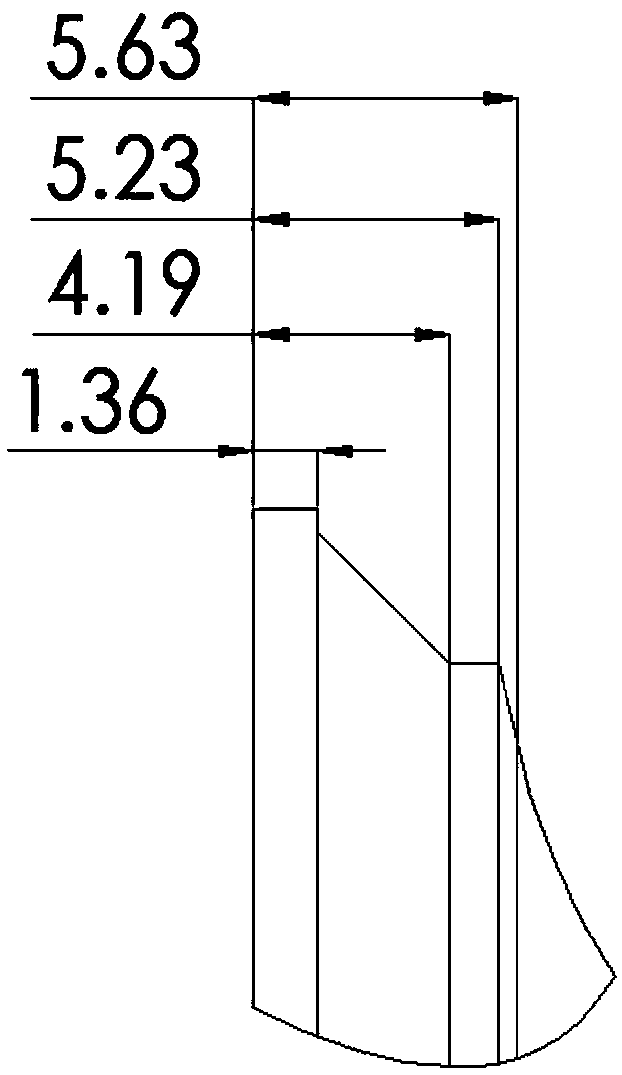

Laser overlaying method for engine valve conical surfaces

InactiveCN109570764AAvoid generatingGreat heat effectAdditive manufacturing apparatusLaser beam welding apparatusShielding gasEngineering

The invention discloses a laser overlaying method for engine valve conical surfaces. Valve workpieces to be overlaid are formed through machining, and are preheated in a heat treatment furnace; the preheating temperature is 200-300 DEG C; the preheating time is 15-30 min; the valve workpieces to be overlaid are fixed by using a tool; the tool is mounted on a rotating shaft, and is used for drivingthe valve workpieces to be overlaid to rotate; the valve workpieces are overlaid by laser through a laser overlaying machine; due to self rotation of the valve workpieces, a scanning trajectory of laser beams emitted by the laser overlaying machine is spiral; and the laser overlaying machine comprises the following parameters: 5-8 mm of the light spot diameter, 2000-3000 W of the laser power, 5-15 mm / s of the scanning speed, 10-16 g / min of the powder feeding speed, 5-15 L / min of the flow of tail blowing gas, 5-10 L / min of the flow of protective gas, and 35-45% of the joint rate. The method not only can effectively reduce the loss of overlaying powder and increase the utilization rate of the overlaying powder, but also can effectively reduce thermal stress.

Owner:HUAI JI DENG YUE VALVE CO LTD

Tapered multi-layer thermal actuator and method of operating same

InactiveUS7029101B2Low energy inputRapid restoration of the actuatorLiquid surface applicatorsCoatingsElectrical resistance and conductanceThermal expansion

An apparatus for and method of operating a thermal actuator for a micromechanical device, especially a liquid drop emitter for use in an ink jet printhead, is disclosed. The disclosed thermal actuator includes a base element and a cantilevered element including a thermo-mechanical bender portion extending from the base element to a free end tip. The thermo-mechanical bender portion includes a barrier layer constructed of a dielectric material having low thermal conductivity, a first deflector layer constructed of a first electrically resistive material having a large coefficient of thermal expansion, and a second deflector layer constructed of a second electrically resistive material having a large coefficient of thermal expansion wherein the baffler layer is bonded between the first and second deflector layers.

Owner:EASTMAN KODAK CO

Composite coating of ceramic-metal compound and its prepn

The present invention is composite coating of ceramic-metal compound and its preparation process. The preparation process includes the following five steps: preparing heat reaction powder, preparing, preparing, turning off all switches and arranging the processed workpieces. The heat reaction powder is one Fe-Al-TiO2-B2O3 system comprising Fe powder, Al powder and TiO2 powder of 150-200 mesh fineness as well as B2O3 powder of 100-150 mesh fineness. Under the action of plasma heat excitation and the auxiliary action, the powder system takes chemical reaction in plasma flow to form metal phase and intermetallic compound phase on the surface of the workpiece to combine metallurgically with the substrate surface in micro melting state. The coating may have regulated hardness and controlled thickness, and the process has less deformation of workpiece and high efficiency.

Owner:崔洪芝

Self-maintenance rolling bearing and assembling method thereof

InactiveCN103423297ATransport stableEasy to installRoller bearingsBearing componentsSelf maintenanceRolling-element bearing

The invention relates to a self-maintenance rolling bearing. The self-maintenance rolling bearing comprises a roller ring and a first bearing sleeve ring (2) with two ribs (6, 8) which extend along a radial direction (32) to first rib height (34). The self-maintenance rolling bearing also comprises a second bearing sleeve ring. A first rib which extends along the radial direction to the first rib height is arranged at a first axial end of a roller path of the second bearing sleeve ring, and a second rib which extends along the radial direction to second rib height is arranged at a second axial end of the roller path of the second bearing sleeve ring. The second rib height is less than the first rib height. In assembling, the second bearing sleeve ring or the roller ring is heated to an assembling temperature form an environment temperature. At the assembling temperature, the second rib of the second bearing sleeve ring can move relatively to the roller ring along the axial direction because of second bearing sleeve ring or roller ring diameter variation caused by the temperature.

Owner:AB SKF

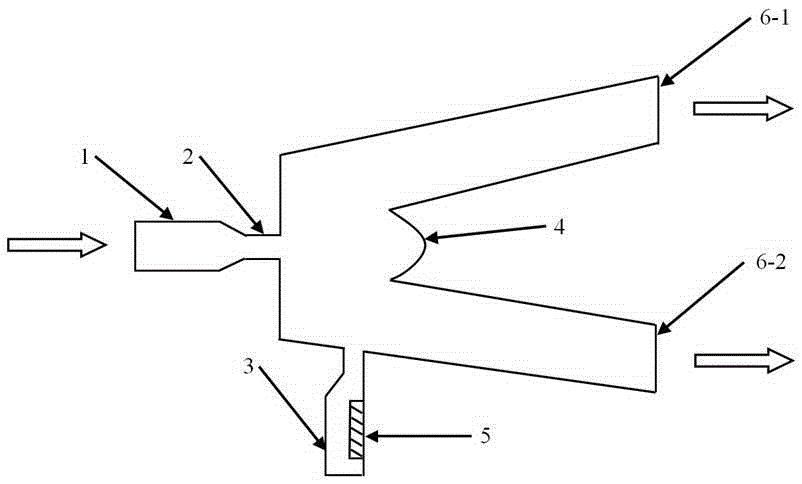

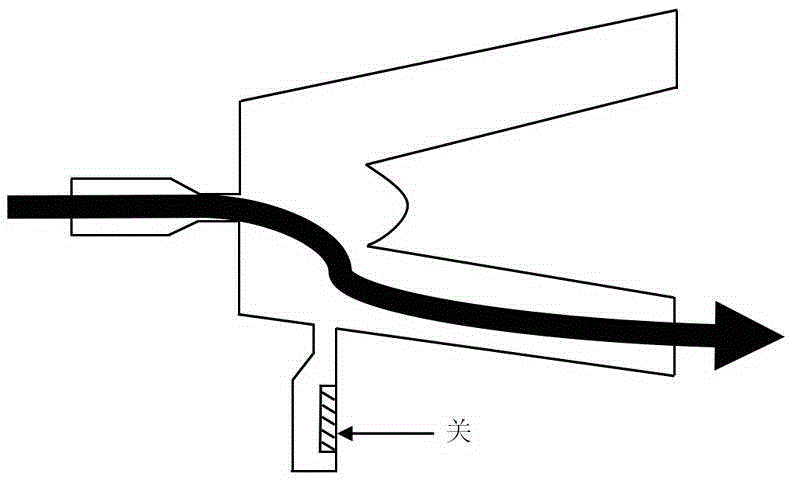

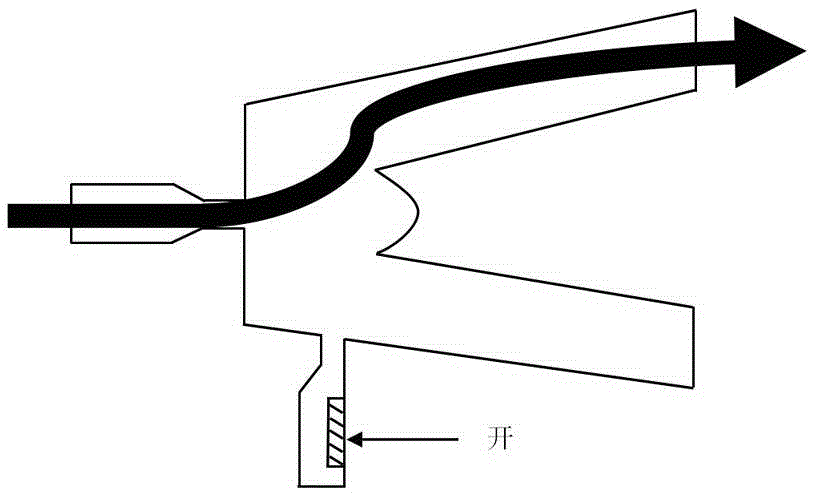

Frequency-controllable airflow deflection control device

InactiveCN105402464ASimple mechanical structureReduce processing difficultyOperating means/releasing devices for valvesMultiple way valvesJet flowFluid control

The invention discloses a frequency-controllable airflow deflection control device and belongs to the technical field of fluid control. The control device comprises a monostable wall-attached oscillating efflux element and a plasma exciter (5). The monostable wall-attached oscillating efflux element comprises an efflux inlet (1), an inlet nozzle (2), a concave flow distribution wedge (4), a control port (3), a left airflow deflection outlet (6-1) an a right airflow deflection outlet (6-2). The frequency-controllable airflow deflection control device has the advantages that the size is small, the structure is simple, continuous adjustment can be achieved, the service life is long, the deflection frequency is high, and the control energy needing to be input is low.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Printhead with increasing drive pulse to counter heater oxide growth

ActiveUS7901056B2Decrease in levelImprove efficiencyInking apparatusOther printing apparatusVapor bubblePulse energy

An inkjet printer that has a printhead with an array of ejection devices for ejecting drops of liquid onto a media substrate. Each of the ejection devices having a chamber for holding liquid, a nozzle in fluid communication with the chamber and a heater positioned in the chamber for contact with the liquid such that resistive heating of the heater generates a vapor bubble that ejects a drop of the liquid through the nozzle. The printer also has a controller for receiving print data and generating drive pulses to energize the heaters in accordance with the print data. The controller increases the drive pulse energy during the printhead lifetime.

Owner:MEMJET TECH LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com