Vapor compression refrigerating cycle apparatus

A technology for compressing refrigeration and circulation devices, applied in compressors, compressors with multiple evaporators, fluid circulation arrangements, etc. The increase of the injector pressure is easy to reduce and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

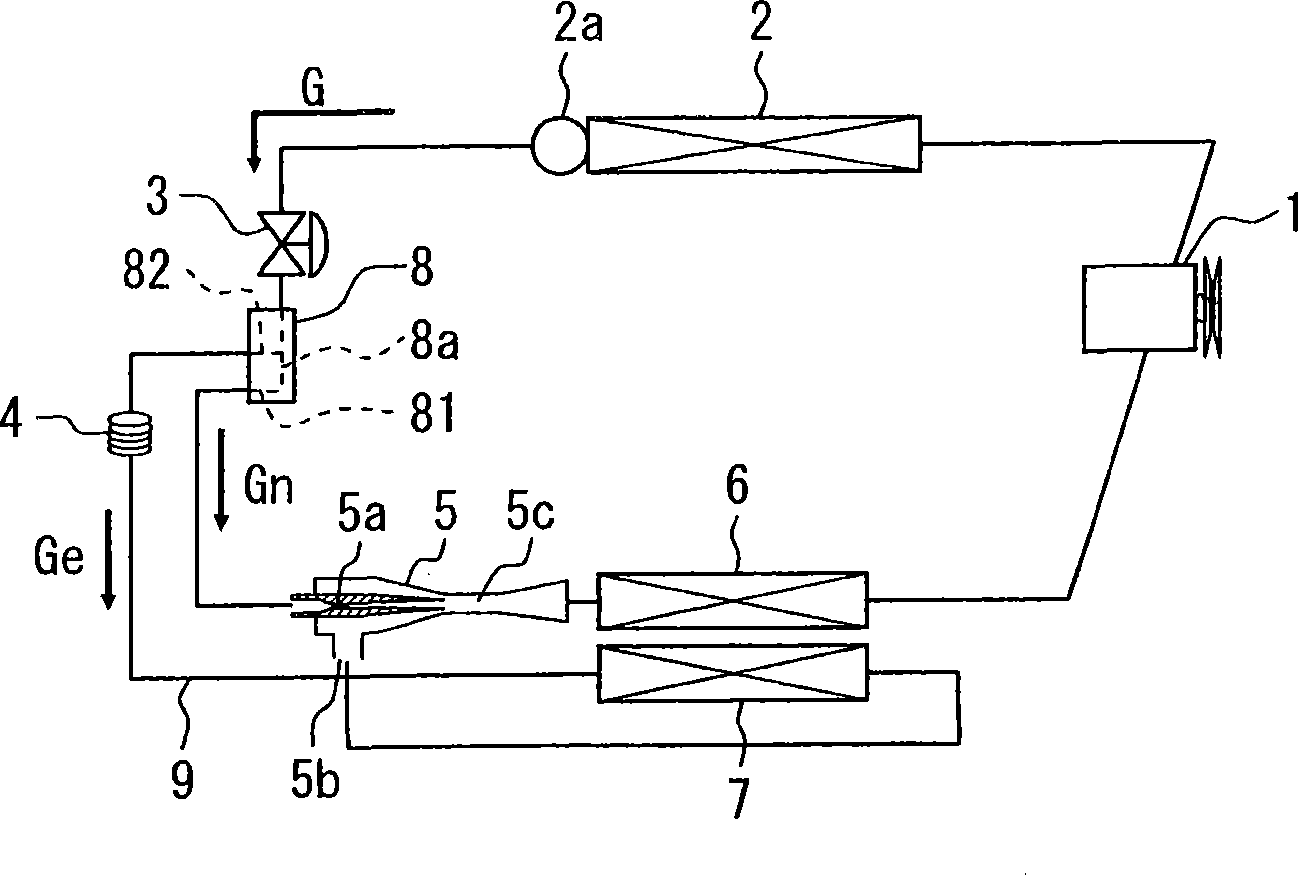

[0020] The following will refer to Figure 1 to Figure 5 A first embodiment of the present invention is described. figure 1 The vapor compression refrigeration cycle of the first embodiment is shown. The vapor compression refrigeration cycle device can be installed in vehicles for air conditioning, for example.

[0021] A vapor compression refrigeration cycle device generally includes a compressor 1, a radiator 2, a receiver 2a, a first throttle device 3, a flow distributor 8, an ejector 5, a first evaporator 6, a second evaporator 7 and a second evaporator Two throttling devices 4. The compressor 1, the radiator 2, the receiver 2a, the first throttle device 3, the flow distributor 8, the ejector 5 and the first evaporator 6 are connected in a loop form through refrigerant pipes. The refrigeration cycle device also includes a suction channel 9 branching from the flow distributor 8 and connected to the ejector 5 . The second throttle device 4 and the second evaporator 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com