Frequency-controllable airflow deflection control device

A technology of deflection control and air flow, which is applied in the direction of valve device, valve operation/release device, valve details, etc., can solve the problems of weakened anti-interference ability of solenoid valve, rubber aging, seal failure, etc., and achieve high deflection frequency range, Fewer joints and high airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be described in further detail below in conjunction with the accompanying drawings.

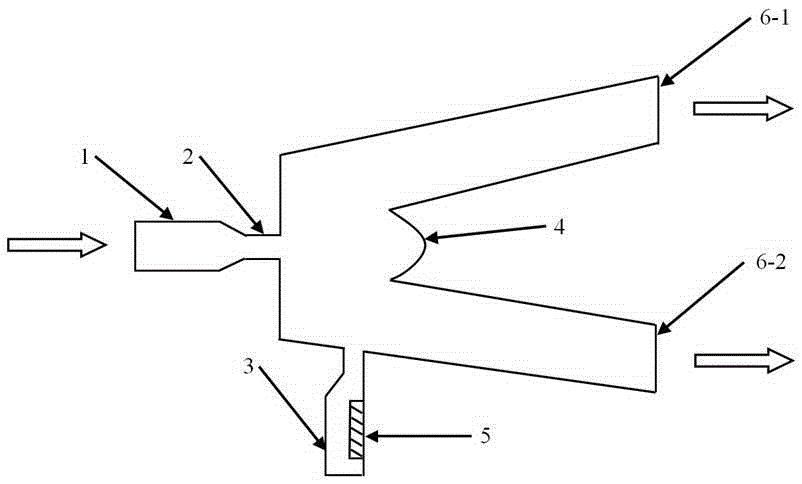

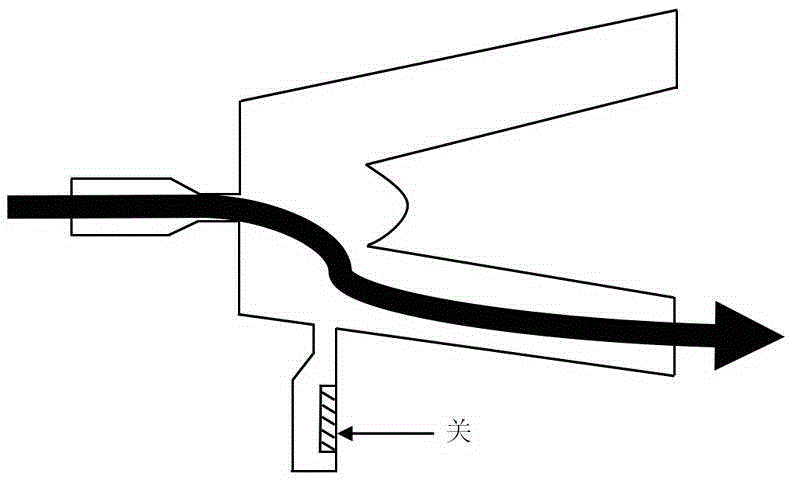

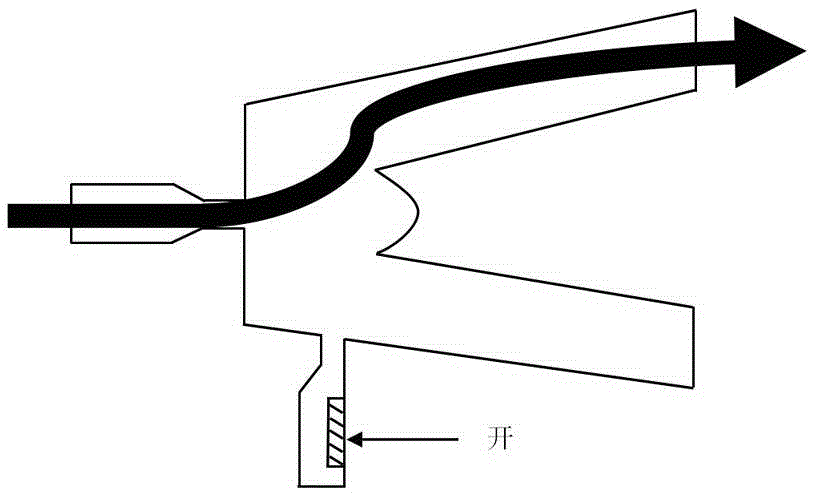

[0022] The inventive device such as figure 1 As shown, it includes a jet inlet 1, an inlet nozzle 2, a control port 3, a concave split splitter 4, an airflow deflection left outlet 6-1, and an airflow deflection right outlet 6-2. The airflow of jet inlet 1 is provided by a constant pressure air tank, and the flow rate of the inlet airflow is controlled by an airflow valve. The jet element is designed as a monostable wall-attached oscillating jet element. When there is no input to the control port 3, according to the Coanda effect, the airflow entering from the jet inlet 1 will always be attached to the side of the airflow deflection right outlet 6-2 port , the airflow flows out from the airflow deflection right outlet 6-2, such as figure 2 shown. When the control port 3 has an input, the airflow is deflected and attached to the port side of the left outlet 6-1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com