H-shaped steel bone-confined concrete column with round steel draw bars and fabrication method of column

A technology of confining concrete and I-shape, applied in the direction of columns, pier columns, pillars, etc., can solve problems such as buckling deformation, reduction of concrete restraint capacity, and reduction of bearing capacity of steel concrete columns, so as to achieve high bearing capacity, reduce maintenance costs, The effect of increased restraint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

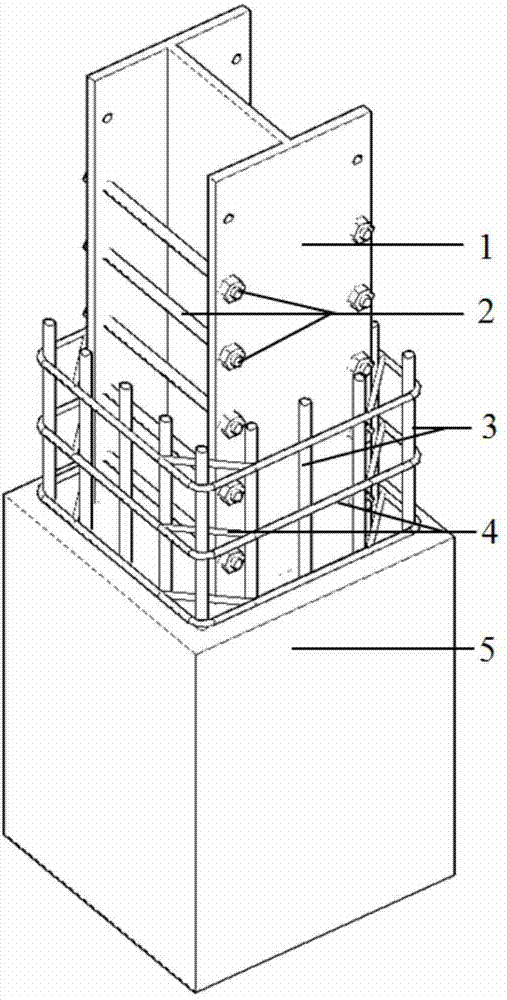

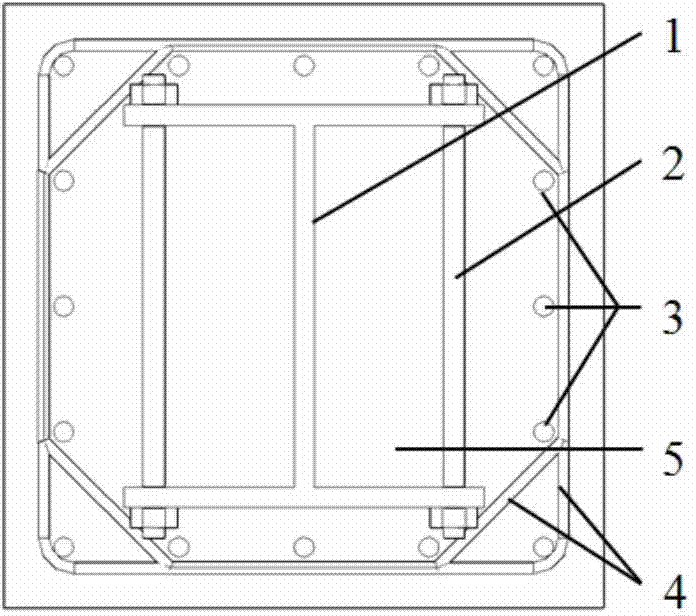

[0028] Such as figure 1 , figure 2 As shown, the I-shaped steel-reinforced concrete column with round steel tie rods includes I-shaped steel frame 1, round steel tie rods 2, longitudinal steel bars 3, composite stirrups 4, and concrete 5; On the basis, a round steel tie rod is added to form.

[0029] According to the technical solution of the present invention, the manufacturing steps of the I-shaped steel-framed concrete column with round steel tie rods are as follows:

[0030] 1) The factory prefabricated the I-shaped steel frame 1, and punched holes at the edge of the flange;

[0031] 2) Locate the round steel tie rod 2 and screw the nut on the outside of the flange of the I-shaped steel frame 1 to apply pre-tightening force;

[0032] 3) After the prefabricated and welded steel frame members are transported to the site and positioned, the longitudinal reinforcement 3 and the composite stirrup 4 are bound;

[0033] 4) Support the formwork and pour concrete 5 for mainten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com