Double-layer steel plate composite shear wall with corrugated web I-shaped steel components transversely arranged in staggered mode

A steel plate shear wall and combined shear wall technology, which is applied to building components, walls, building structures, etc., to achieve the effects of improving integrity, avoiding failure, and increasing elastic shear buckling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the embodiment of this patent is described in detail.

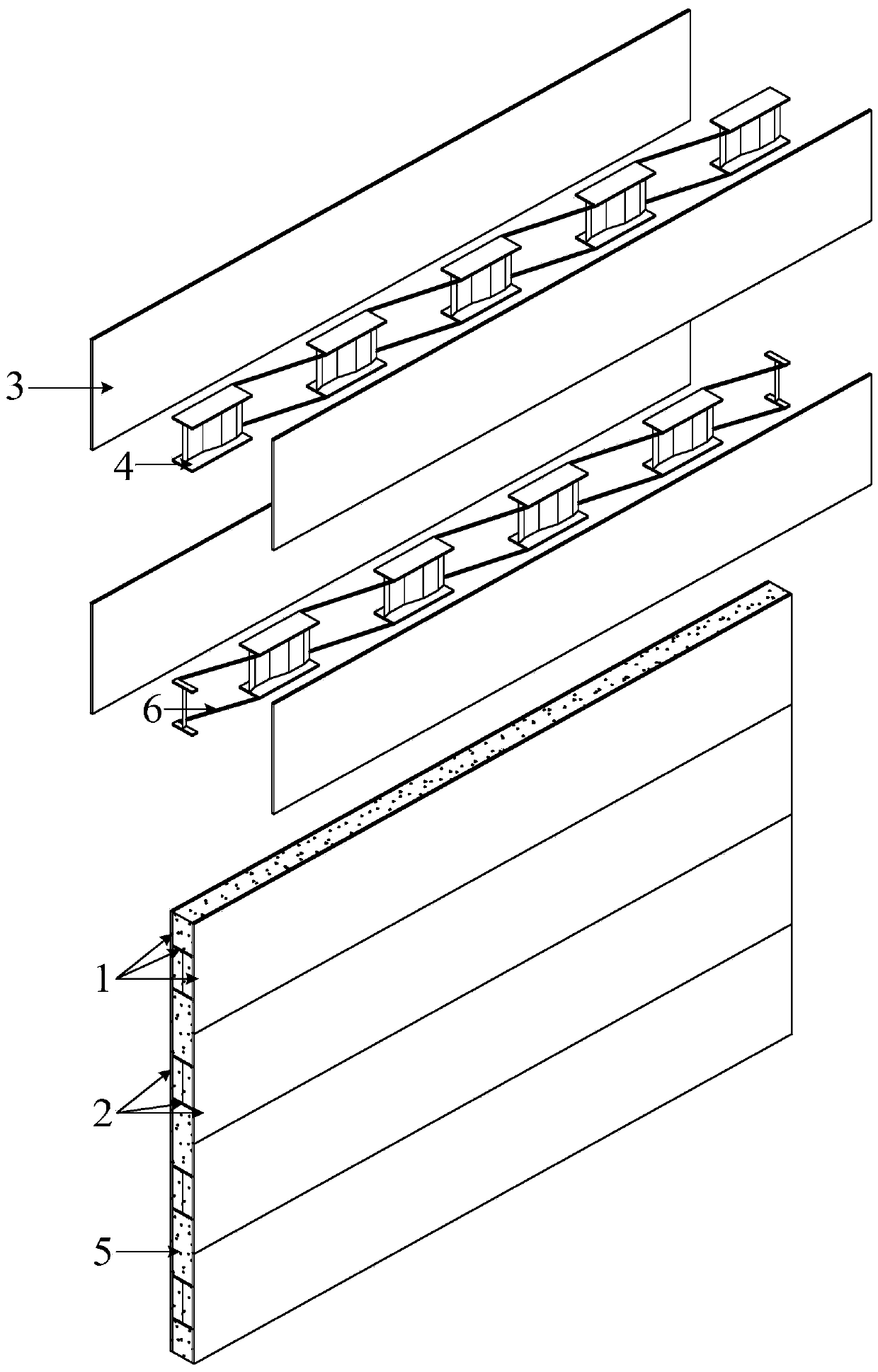

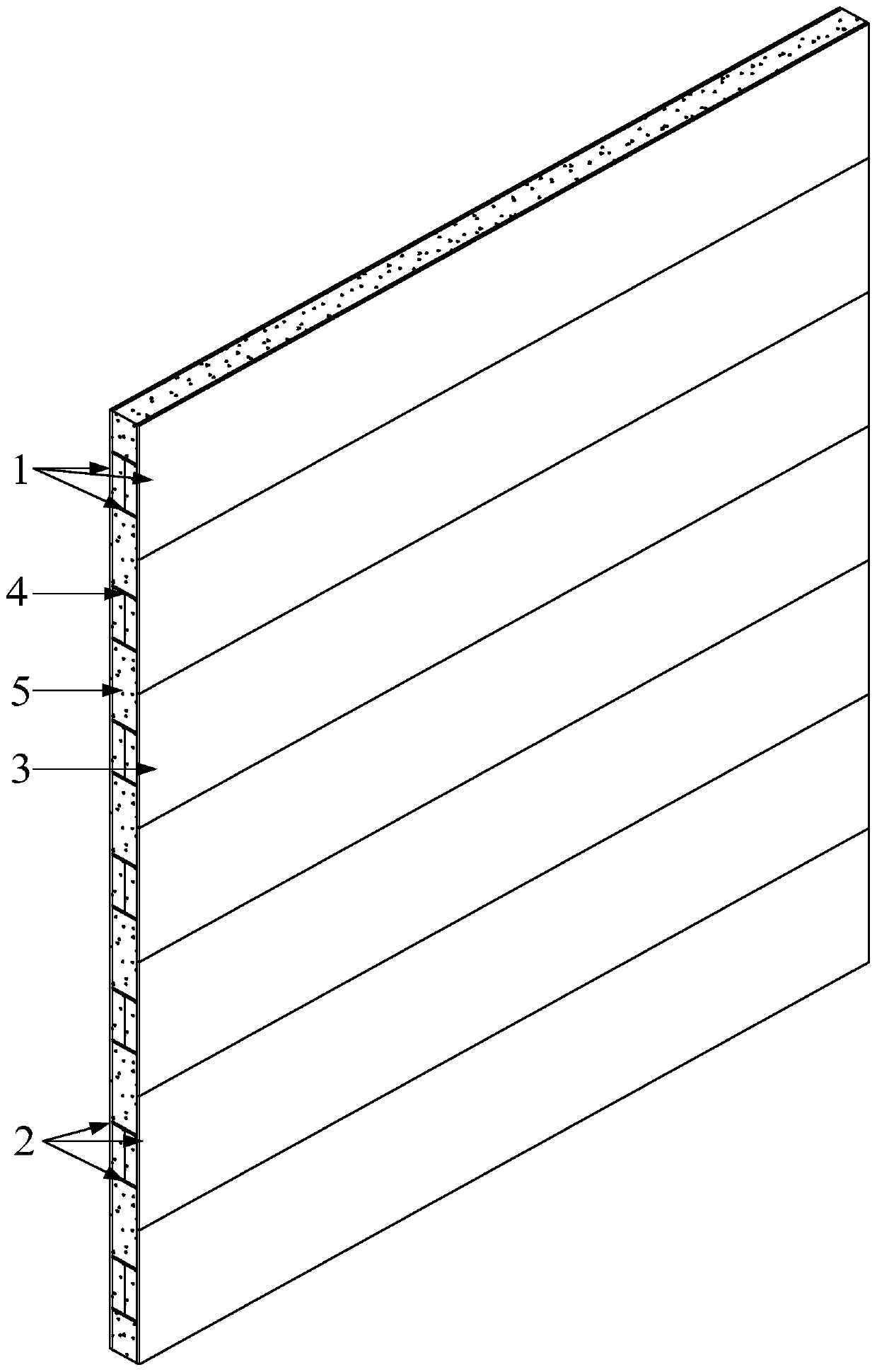

[0028] Such as Figure 1-7 As shown, a double-layer steel plate composite shear wall with horizontally staggered I-shaped steel members with corrugated webs includes the following members.

[0029] 1——steel plate shear wall unit 1;

[0030] 2——steel plate shear wall unit 2;

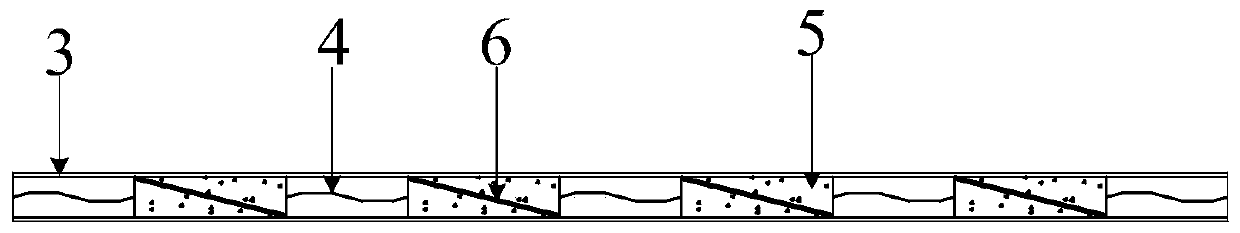

[0031] 3——outer steel plate;

[0032] 4——I-shaped steel member with corrugated web;

[0033] 5 - concrete;

[0034] 6 - tie rod.

[0035] Such as Figure 1-5As shown, the composite shear wall is composed of several steel plate shear wall unit one (1) and several steel plate shear wall unit two (2) cross-welded double-layer steel plate shear wall and integrally poured concrete. The steel plate shear wall unit one (1) and the steel plate shear wall unit two (2) are composed of two outer steel plates (3), several corrugated web I-shaped steel members (4) and several tie rods (6) Composition;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com