Patents

Literature

37results about How to "Prevent wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

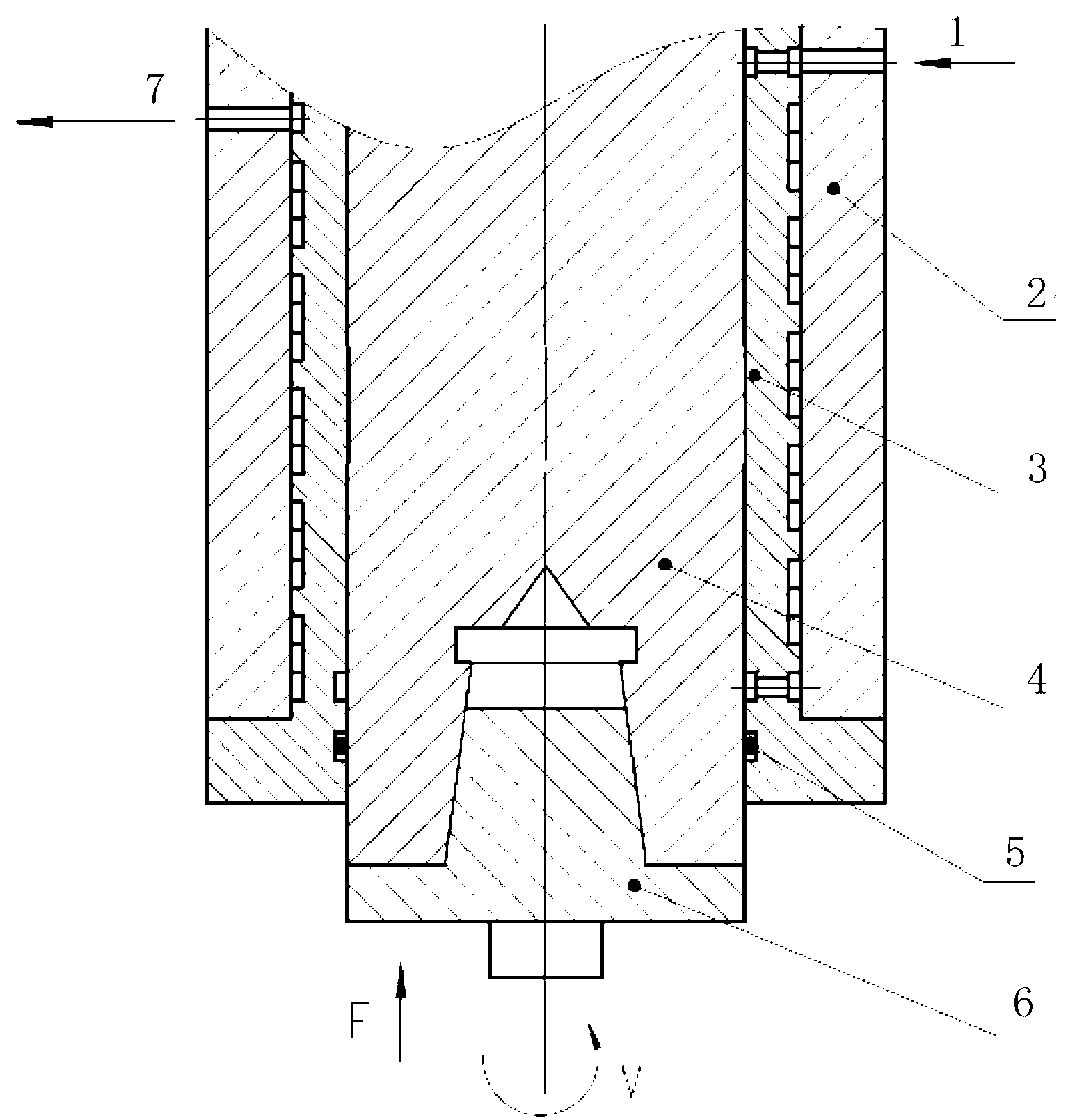

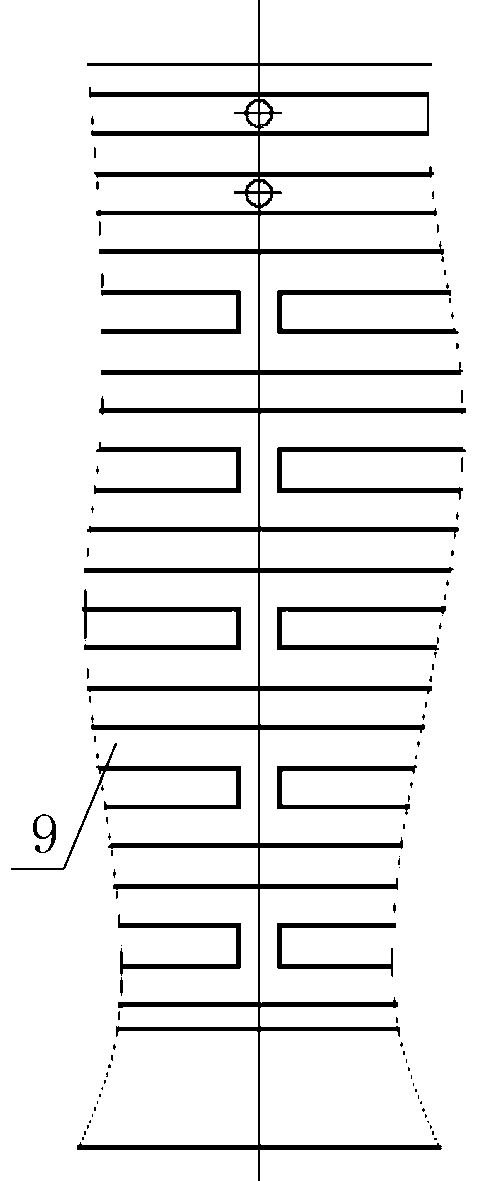

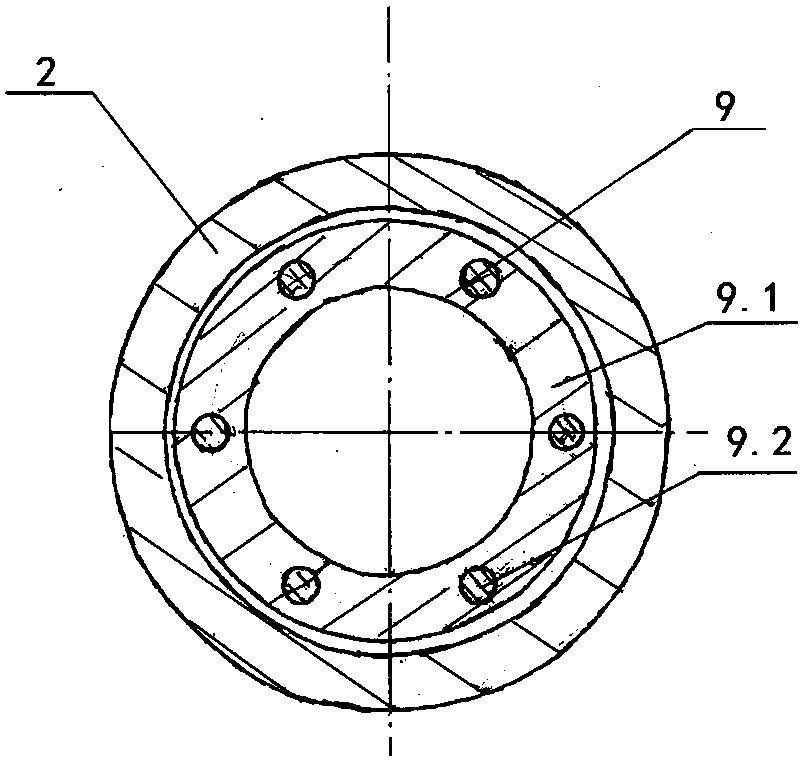

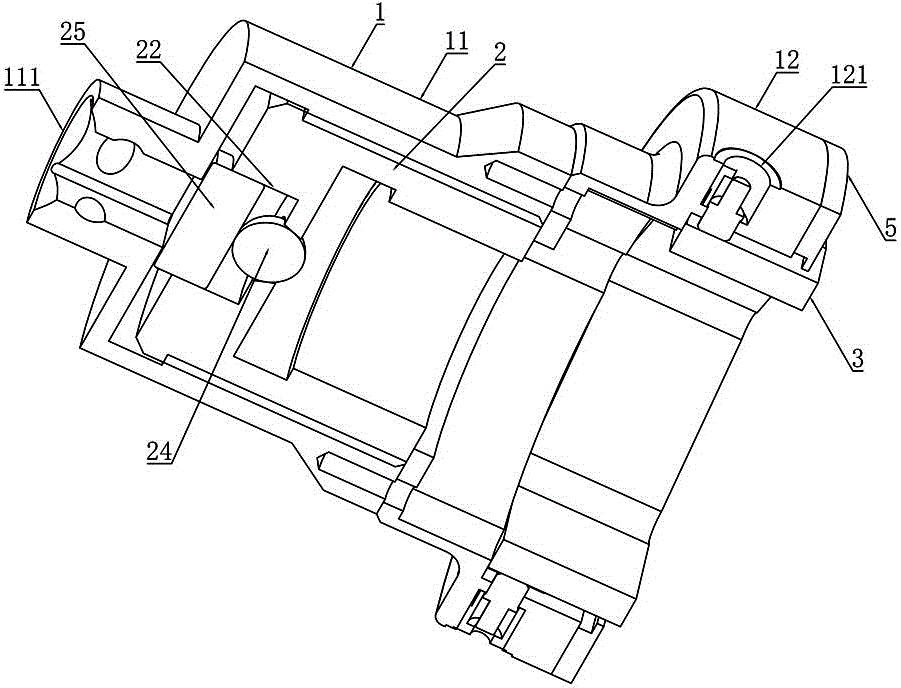

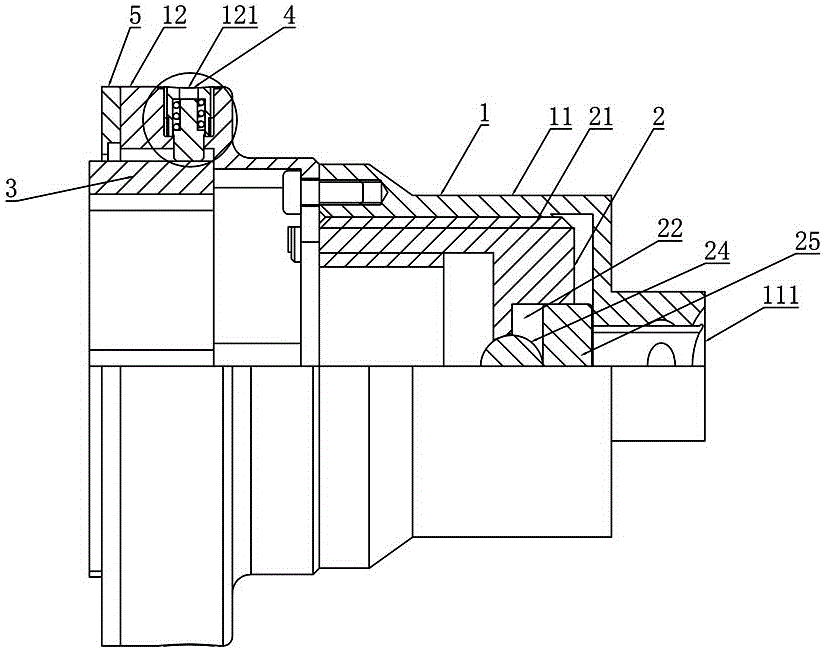

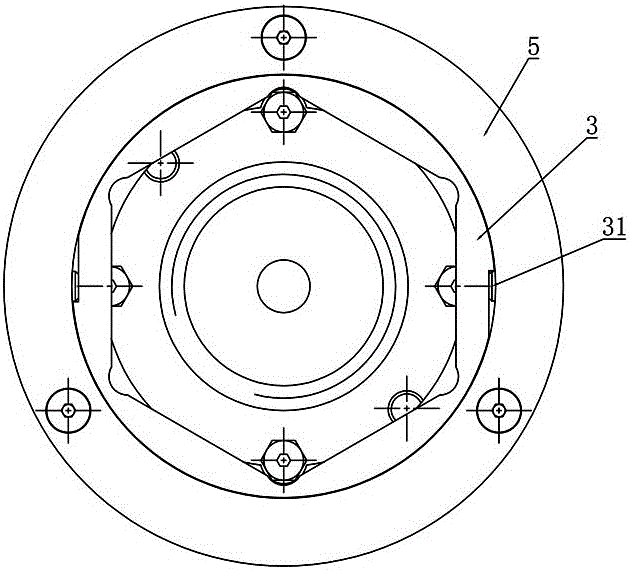

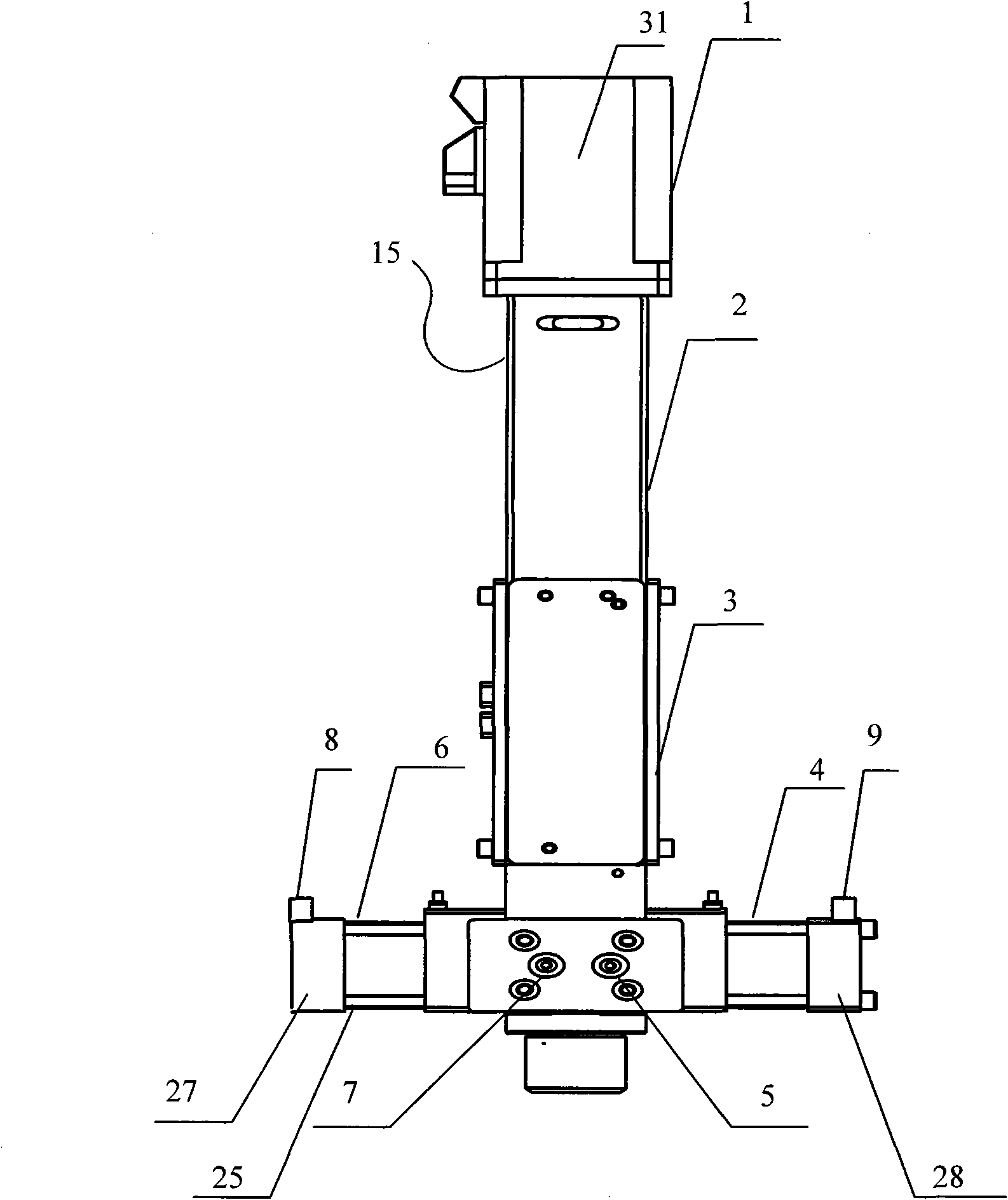

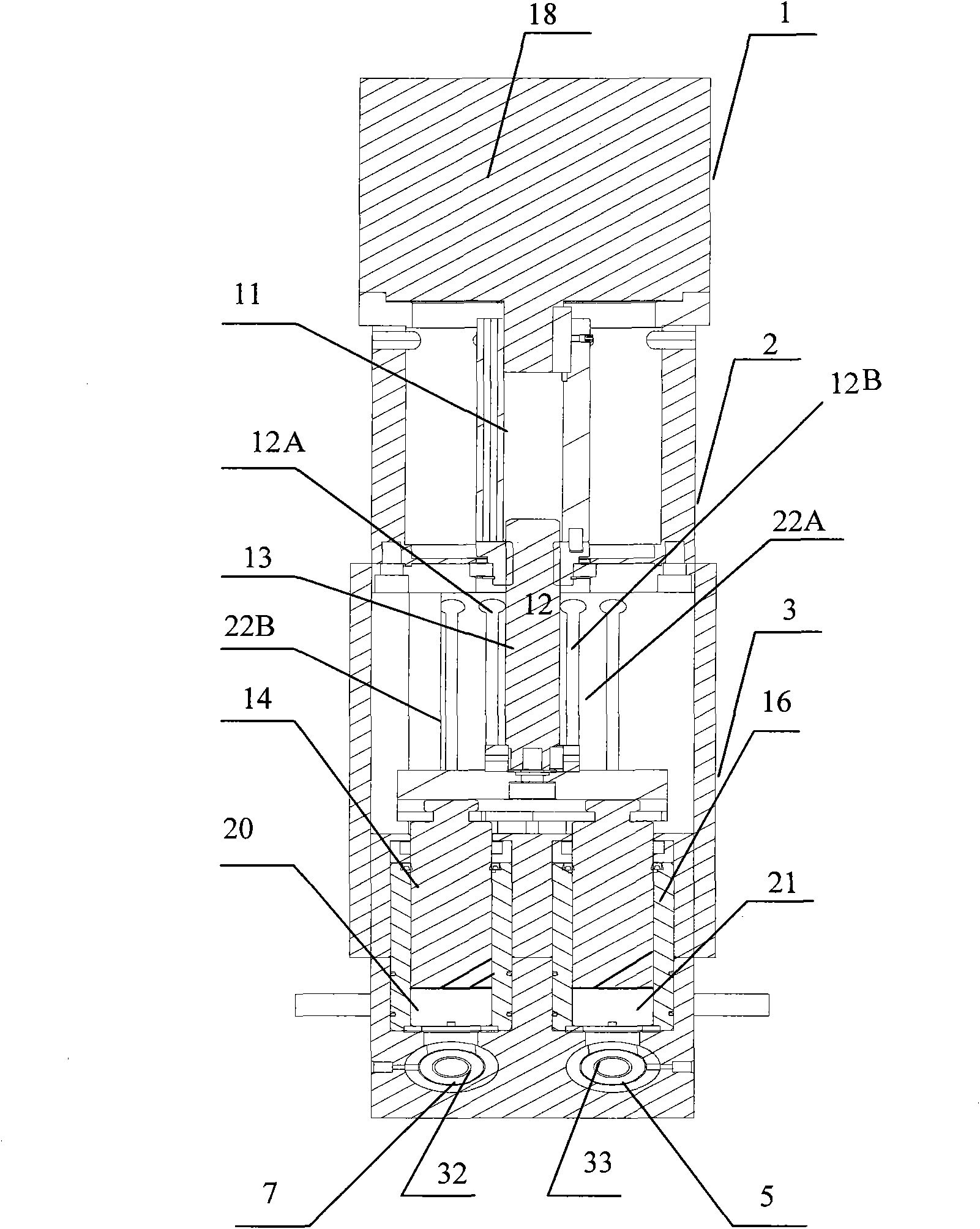

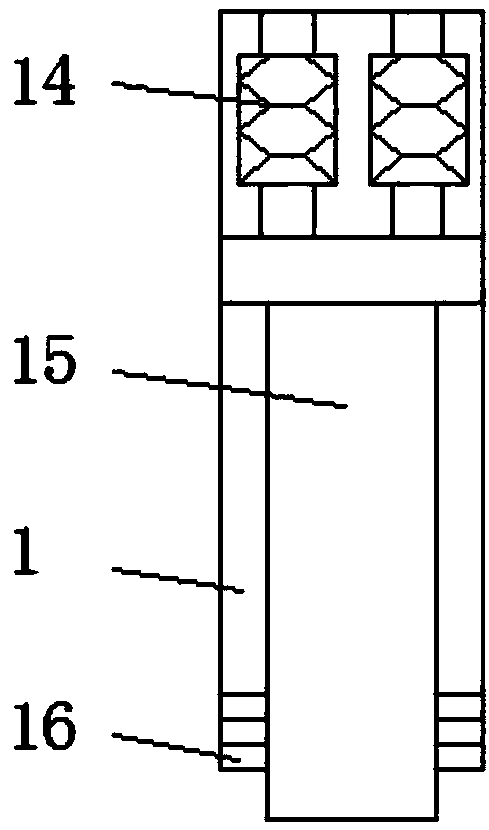

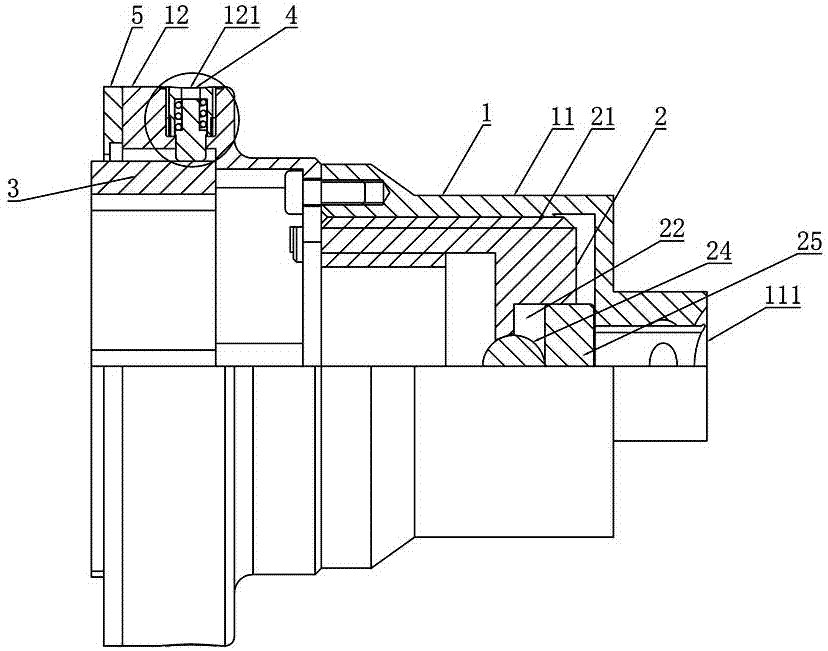

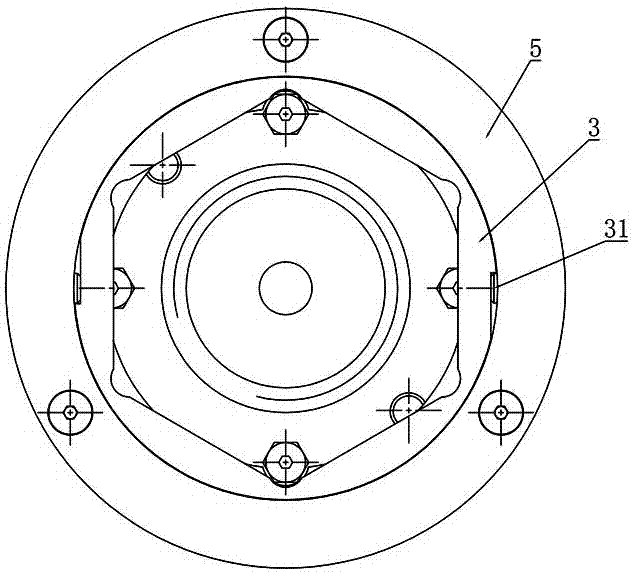

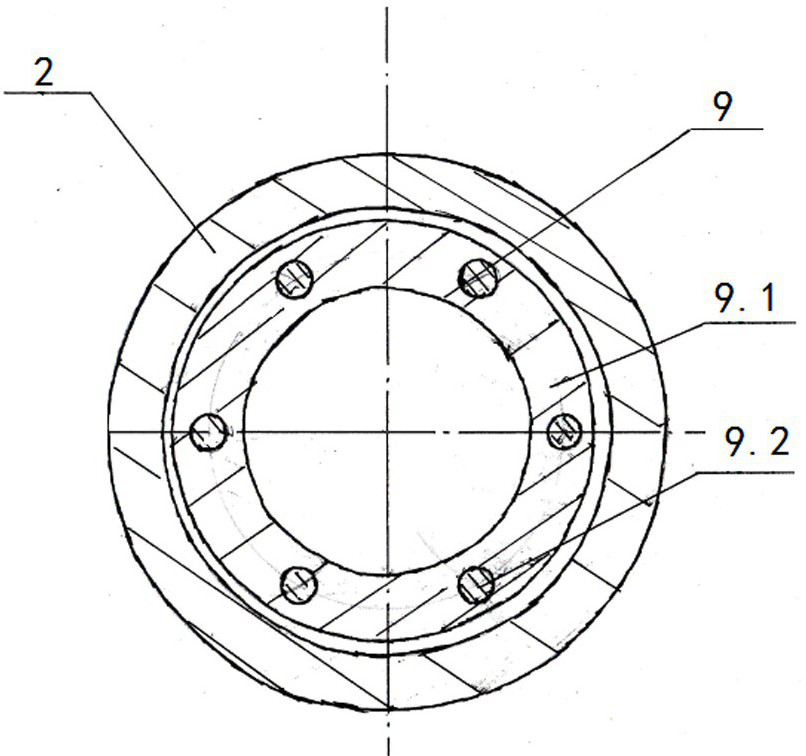

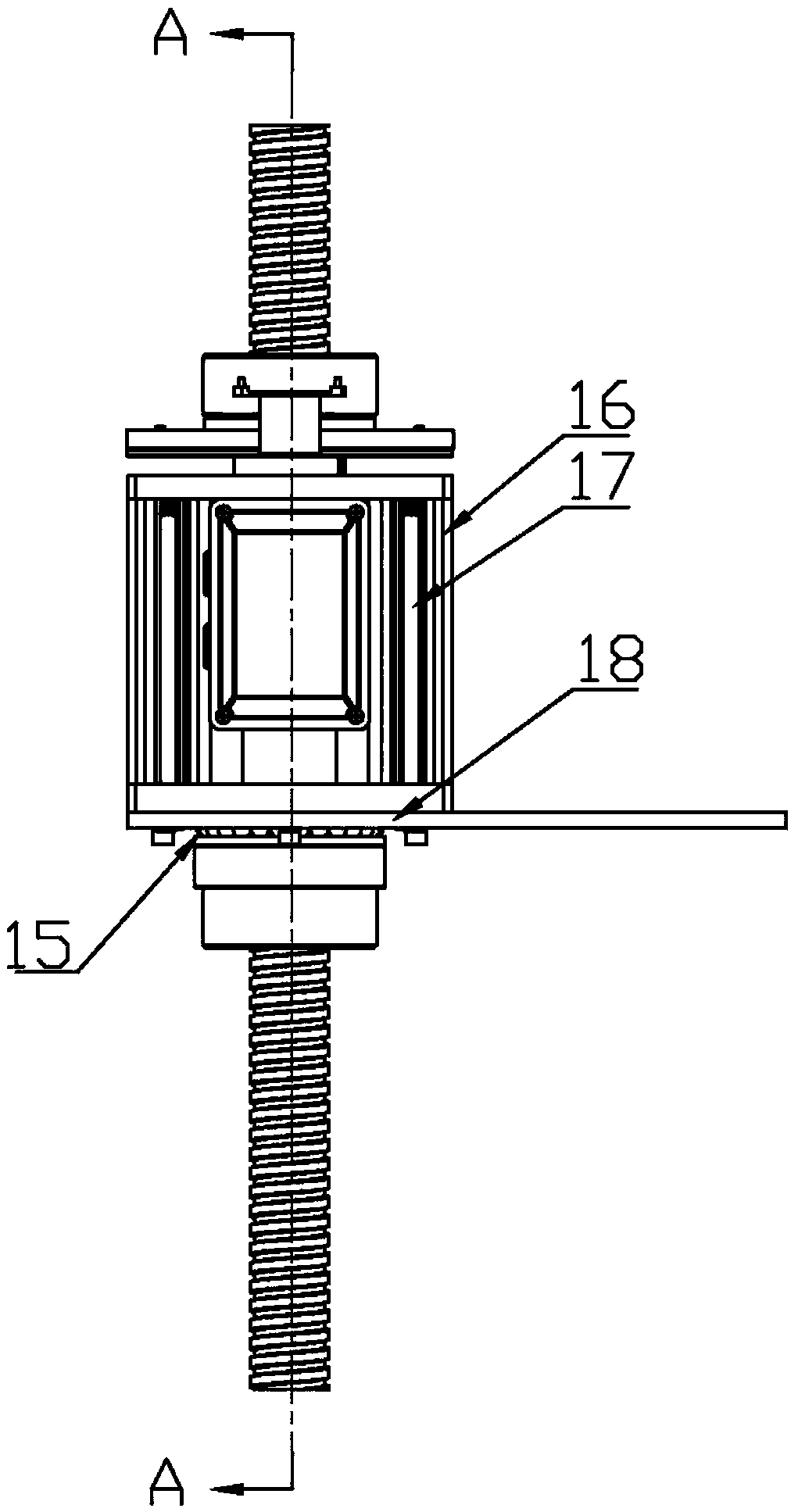

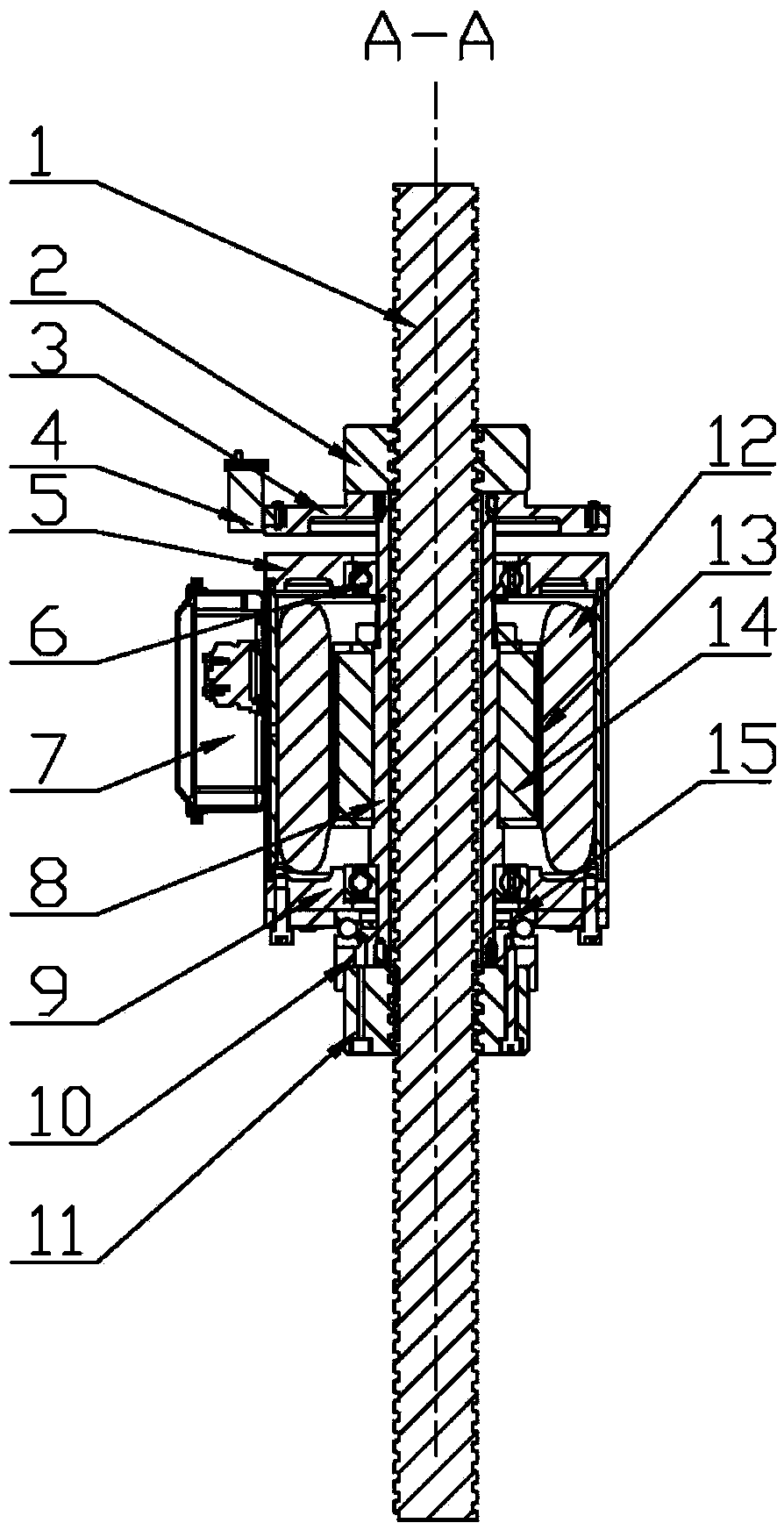

Self-lubrication cooled type gear shaper spindle structure

ActiveCN103302317APrevent wear and tearImprove cooling effectMaintainance and safety accessoriesReciprocating motionThermal deformation

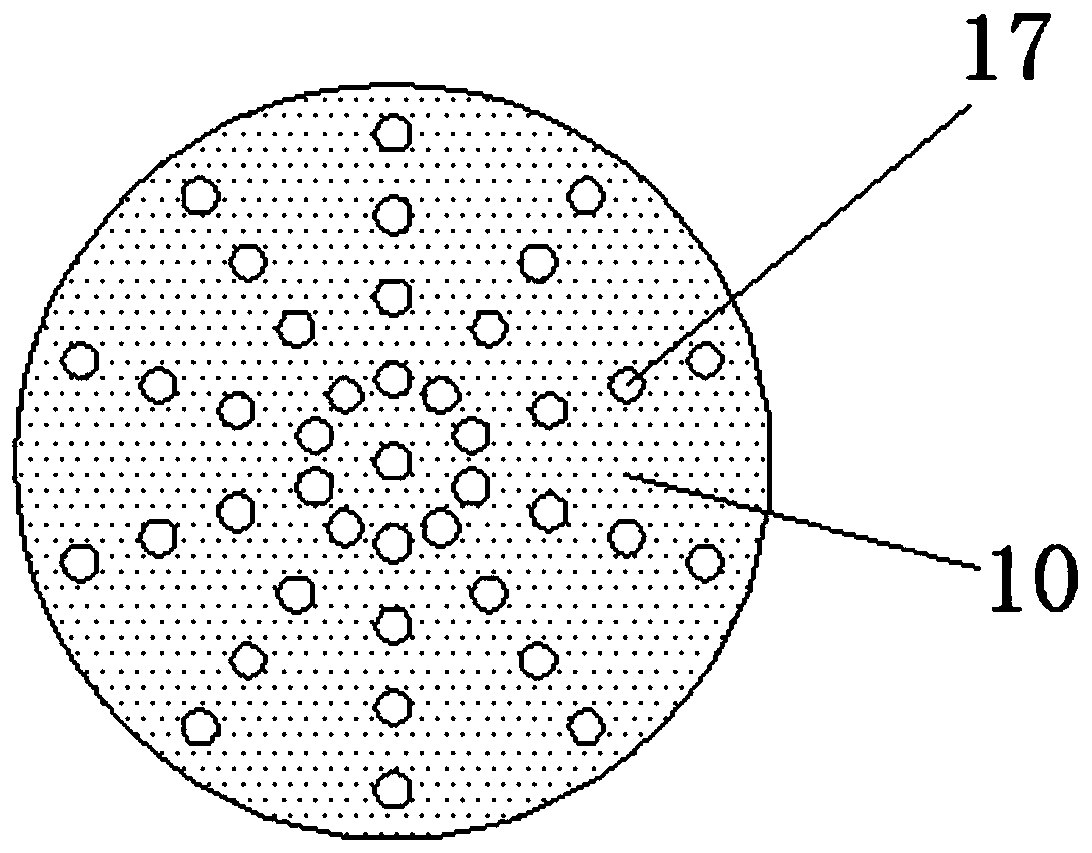

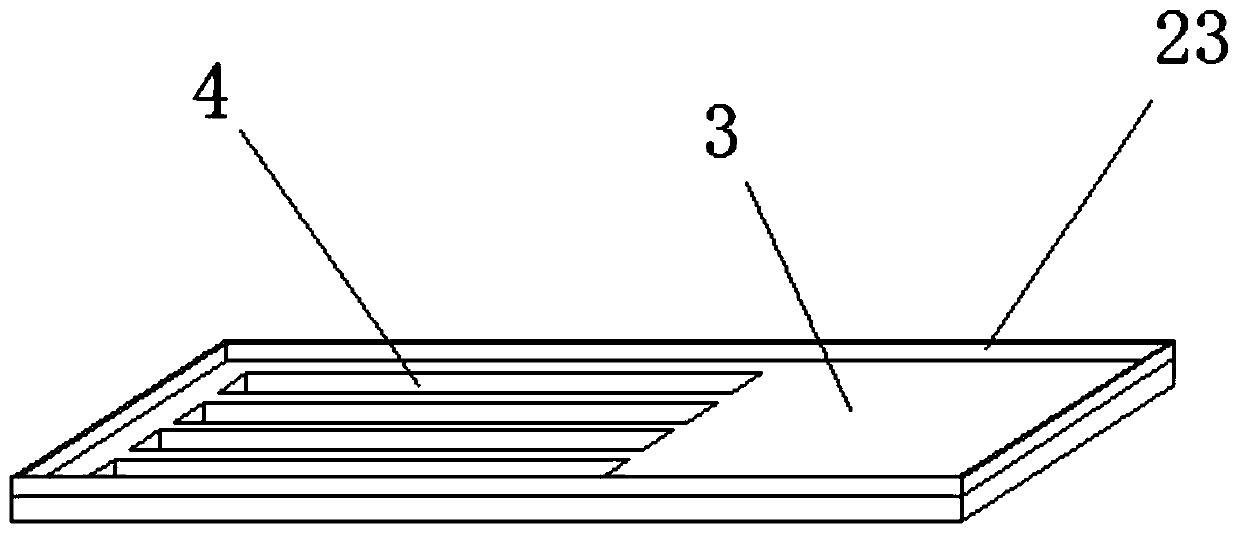

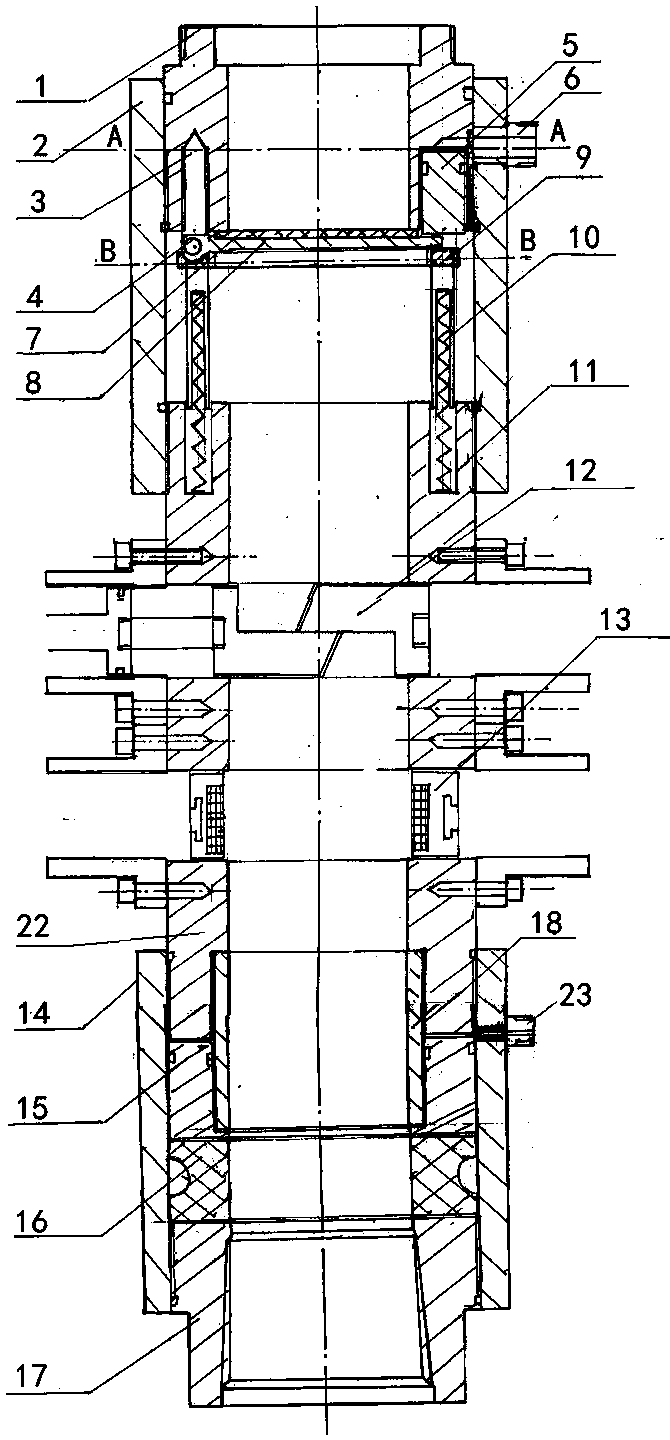

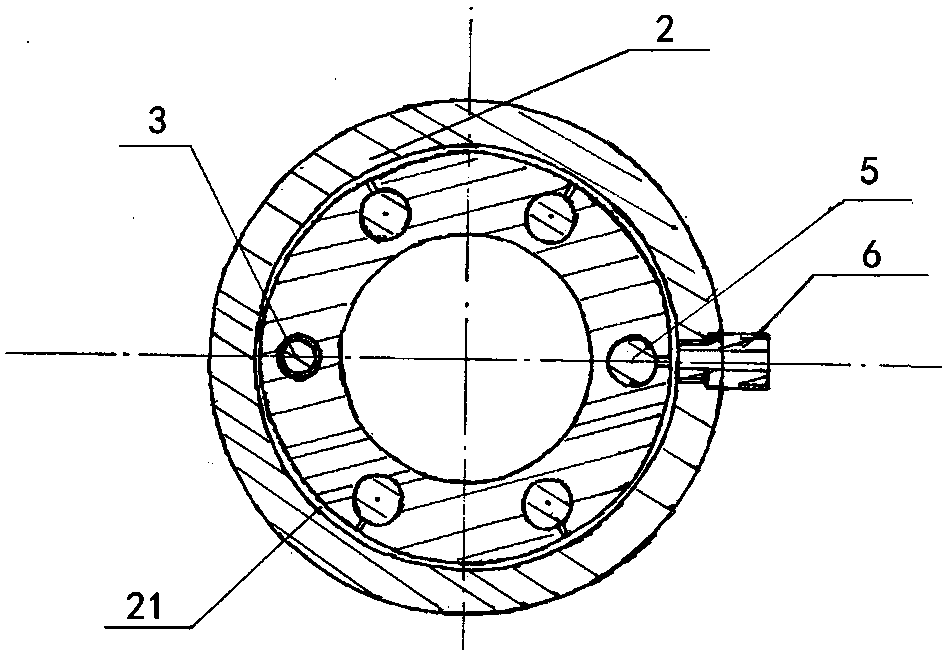

A self-lubrication cooled type gear shaper spindle structure comprises a spindle, wherein a spindle sleeve is arranged outside the spindle, and is embedded in a tool rest body; an oil inlet and an oil inlet are formed in the upper end of the spindle sleeve; spiral oil grooves are formed in the spindle sleeve; a plurality of ring-shaped cooling grooves are distributed on the excircle of the spindle sleeve; and the lower ends of the ring-shaped cooling grooves are communicated with the spiral oil grooves. According to the invention, the two spiral oil grooves are formed in the spindle sleeve, depending on the reciprocating movement of the spindle, oil is introduced into a friction zone to form a lubricating oil film so as to realize the purpose of lubrication and prevent grinding damage of the spindle; as the ring-shaped cooling grooves are distributed on the excircle of the spindle sleeve, and the lower ends of the ring-shaped cooling grooves are communicated with the spiral oil grooves, only one pair of openings are communicated between every two ring-shaped cooling grooves, and are distributed symmetrically, the lubricating oil flows to each cooling groove in the return process to take away heat of the spindle sleeve, which is generated by friction and impacting, so that the spindle sleeve is ensured to be fully cooled, the thermal deformation of the spindle sleeve becomes very small, and the grinding die of the spindle can be prevented.

Owner:宜昌长机科技有限责任公司

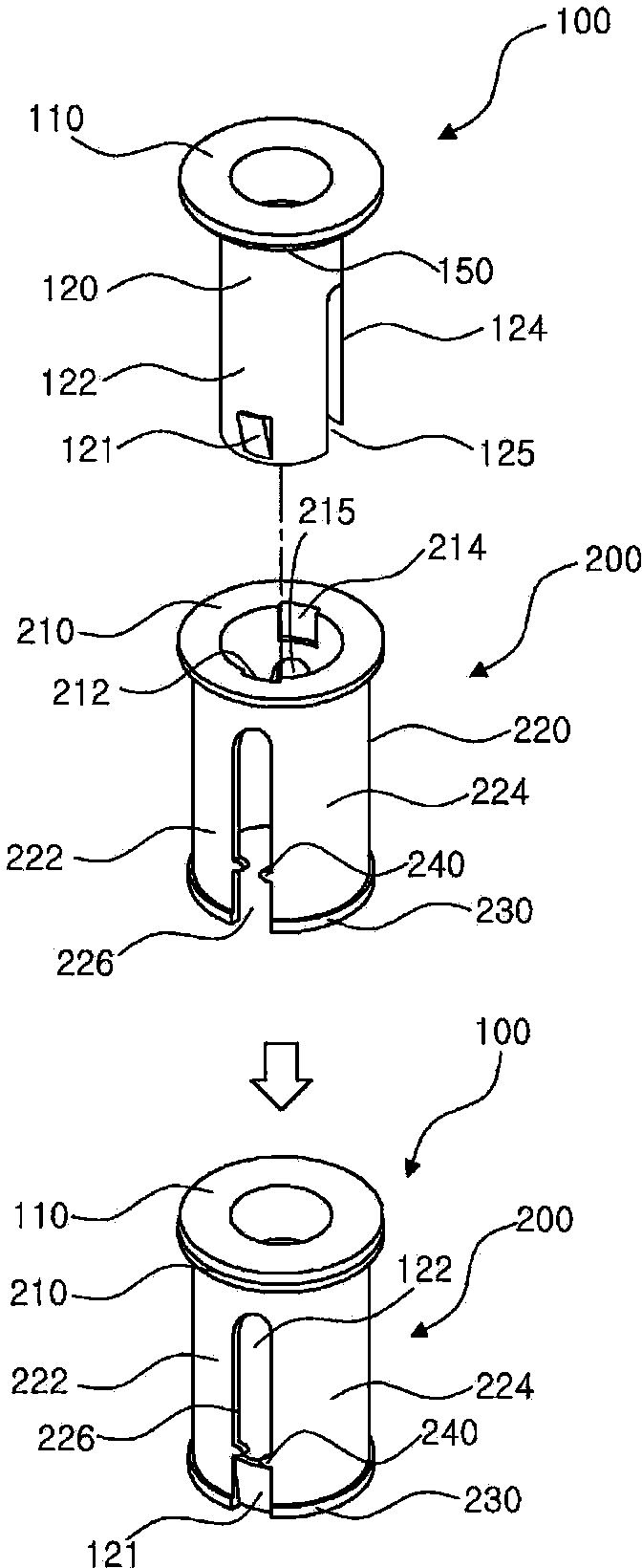

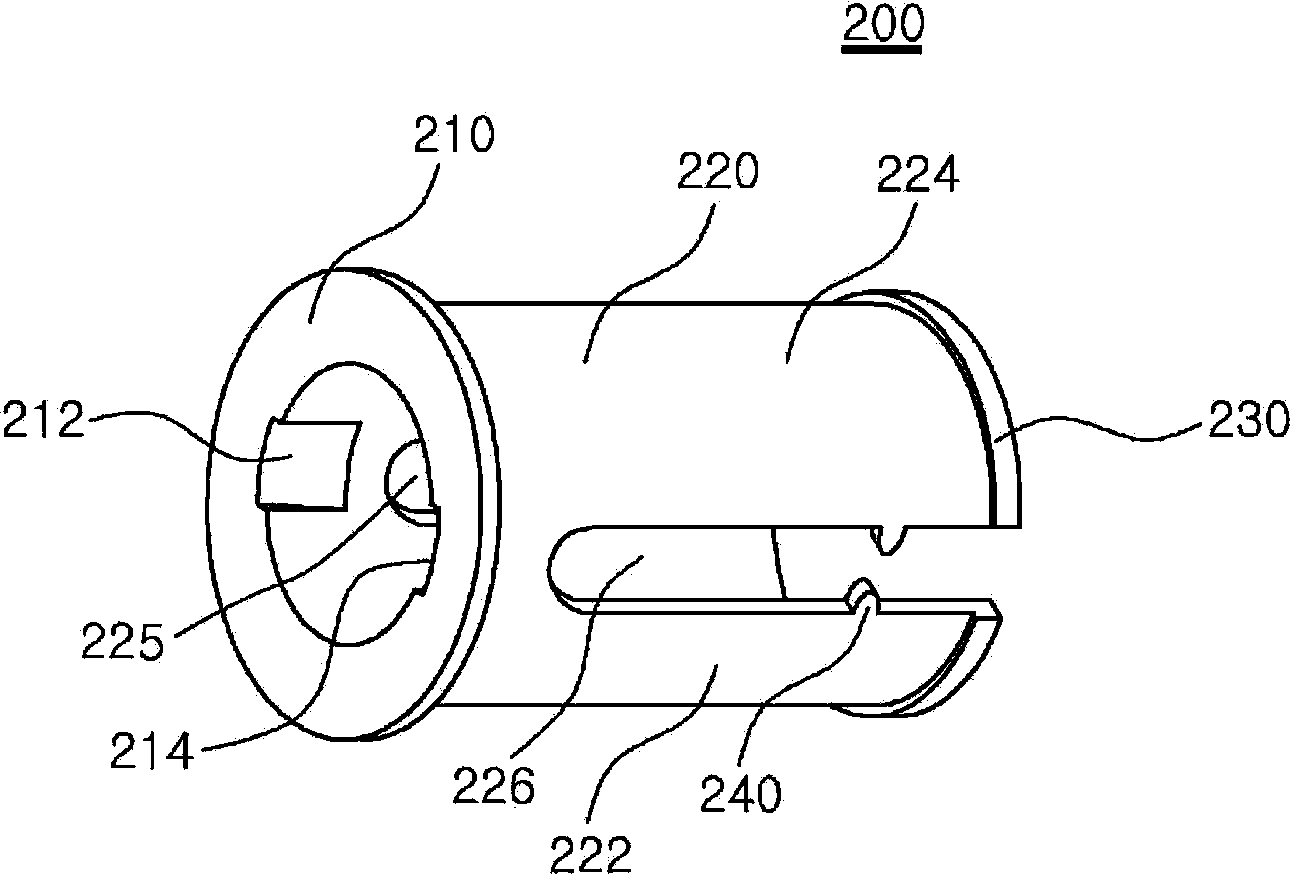

Elastic coupler having locking-unlocking function

An elastic coupler, according to one embodiment of the present invention, comprises: a hollow socket having an upper holding protrusion and a lower holding protrusion which are inserted into a first insertion hole and a second insertion hole which are respectively formed in a first object to be coupled and a second object to be coupled so as to couple the first object to be coupled and second object to be coupled and respectively protrude from an outer peripheral surface so as to be disposed on the upper end portion and the lower end portion of the hollow socket, and two or more guide slots which are formed on the outer peripheral surface from the lower end in a direction parallel to the direction of insertion; support pins which are inserted into the hollow socket so as to limit the movement of the upper holding protrusion and the lower holding protrusion towards the inside of the hollow socket; and fixing pins having two or more guide protrusions which protrude from the outer peripheral surfaces of the support pins and respectively move along the guide slots.

Owner:株式会社乐博特思

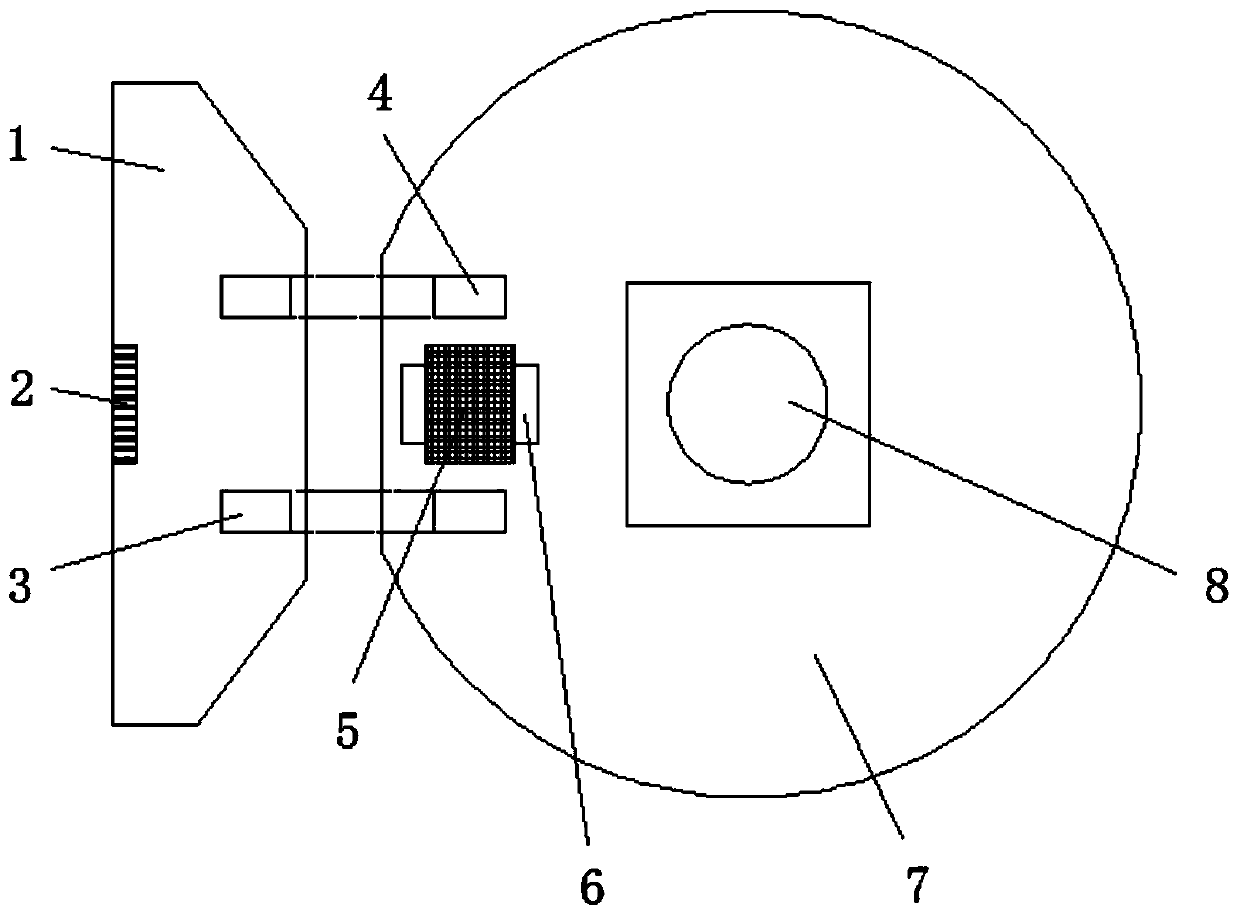

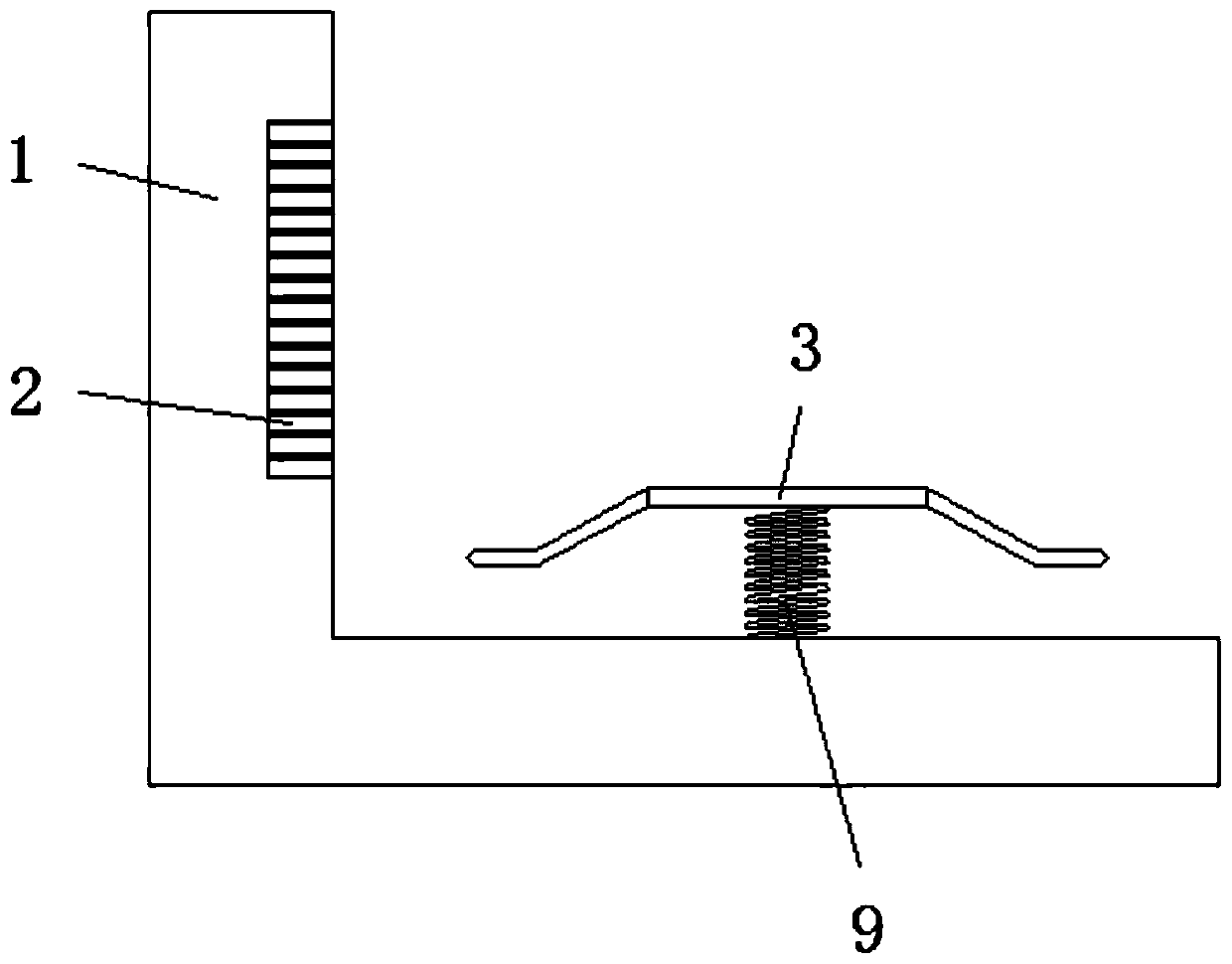

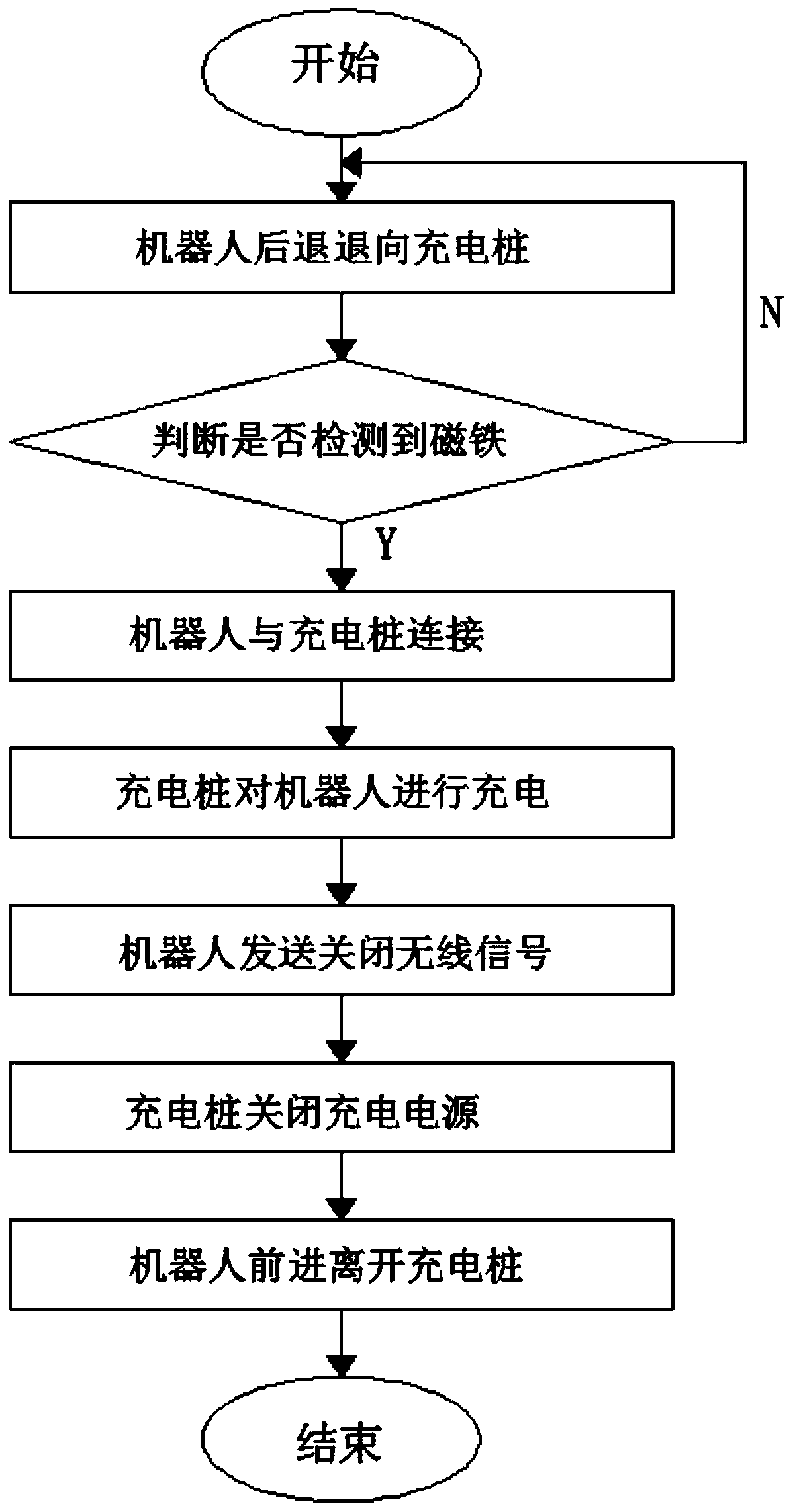

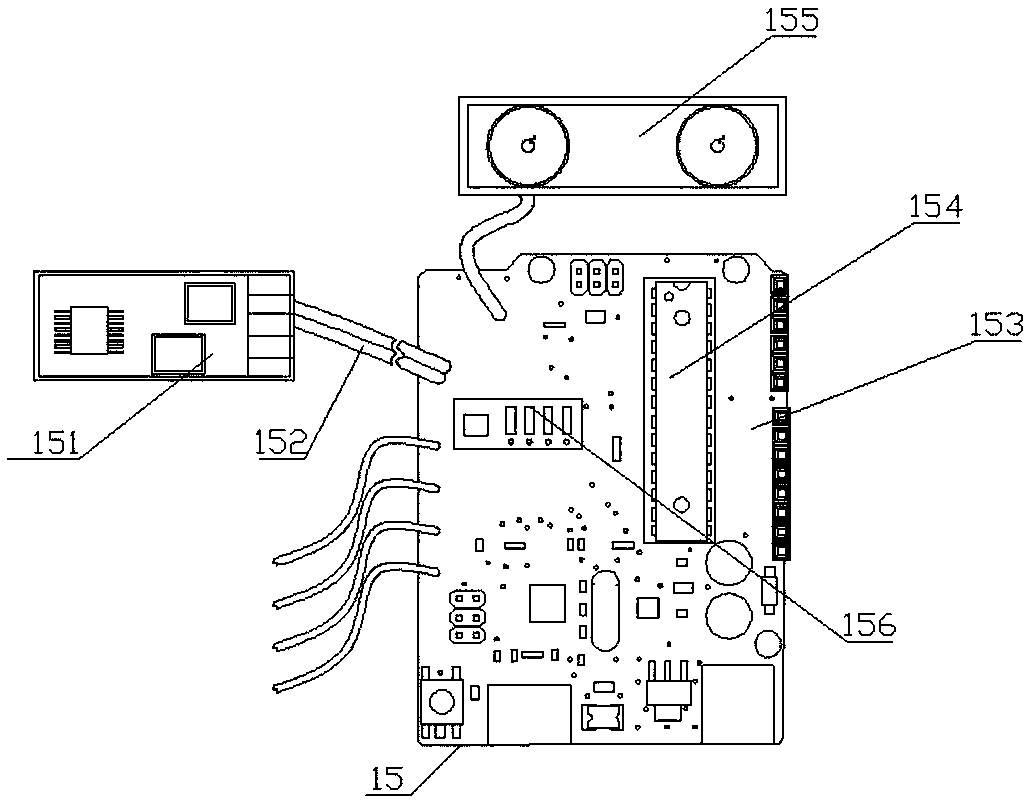

Robot automatic charging system

InactiveCN110690745AImprove securityEnsure charging safetyElectric powerSafety/protection circuitsSimulationMechanical engineering

The invention discloses a robot automatic charging system, comprising: a charging pile and a robot, wherein the vertical section of the charging pile is in an L shape; the outer wall of the horizontalend of the charging pile is provided with an electrode piece spring; a charging pile electrode piece is elastically connected the top of the electrode piece spring; a control main board is disposed inside the robot; and a robot electrode piece is disposed on the tail of the robot. In the present invention, the robot automatic charging system uses a charging method in which charging is performed before contact, thereby avoiding electric sparks caused by the friction of the electrode pieces in an energized state, ensuring the charging safety of the charging pile, and greatly improving the charging safety of the robot. Further, the robot automatic charging system uses a noncontact induction method to ensure the sufficient safety of the distance between the robot and the charging pile, avoidthe wear caused by the mechanical triggering mode of a contact micro switch, and avoid damage to both the robot and the charging pile caused by direct collision of the robot and the charging pile.

Owner:HANGZHOU AMY RONOTICS CO LTD

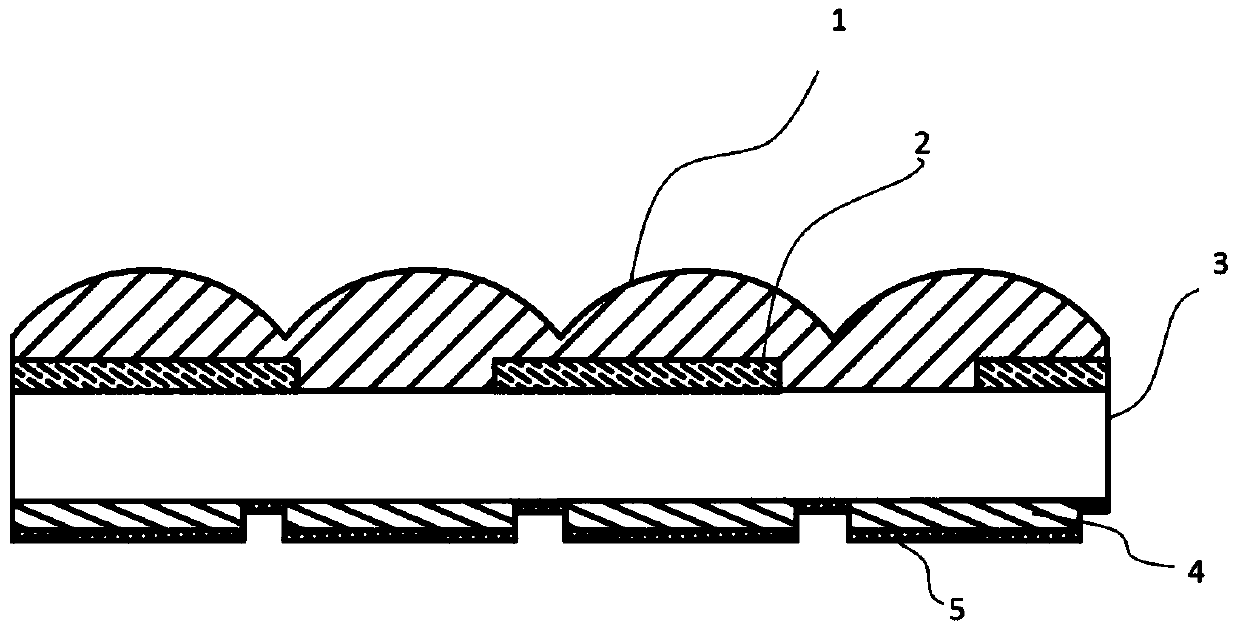

Image-text protection structure based on dynamic anti-counterfeiting film and preparation method thereof

PendingCN109979310AExtended service lifePrevent wear and tearStampsPhotomechanical apparatusTrademarkMicrograph

The invention provides an image-text protection structure based on a dynamic anti-counterfeiting film, and belongs to the technical field of anti-counterfeiting microstructures. The image-text protection structure comprises a microlens array layer, an organic thin film layer and a micrograph array layer in sequence from top to bottom, and further comprises an image-text layer. The invention also provides a preparation method of the image-text protection structure. The image-text protection structure can protect trademark image-text in an interlayer and prolong the service life of the trademarkimage-text; by combining dynamic graphs and image-text layer graphs for display, designed static trademark image-text can be displayed, besides, it can be seen that amplified micrograph arrays aroundthe image-text move dynamically along with the change of the visual angle, and thus the display mode is novel and has a strong visual appeal.

Owner:四川芯辰光微纳科技有限公司

Anti-wear synchronous belt

InactiveCN109466139ABarrier piercingPrevent wear and tearConveyorsSynthetic resin layered productsPolyurethane elastomerAdhesion process

The invention relates to an anti-wear synchronous belt which comprises a polyurethane base layer, wherein a core rope framework is arranged in the polyurethane base layer; a wear-resistant polyurethane layer is arranged on the surface of the polyurethane base layer; the wear-resistant polyurethane layer is an organosilicone modified polyurethane elastomer; the thickness of the wear-resistant polyurethane layer is 1-10mm. The preparation method of the anti-wear synchronous belt comprises the following steps: preparing and integrally molding the polyurethane and the core rope framework by virtueof extrusion molding so as to obtain the polyurethane base layer; adhering the wear-resistant polyurethane layer to the surface of the polyurethane base layer by virtue of a hot melt adhesion process. Compared with the prior art, the anti-wear synchronous belt disclosed by the invention has the advantages of being light in weight, excellent in impact resistance, wear-resistant, cut-resistant andthe like, and can be widely applied to the driving conveying industry.

Owner:AA IND BELTING (SHANGHAI) CO LTD

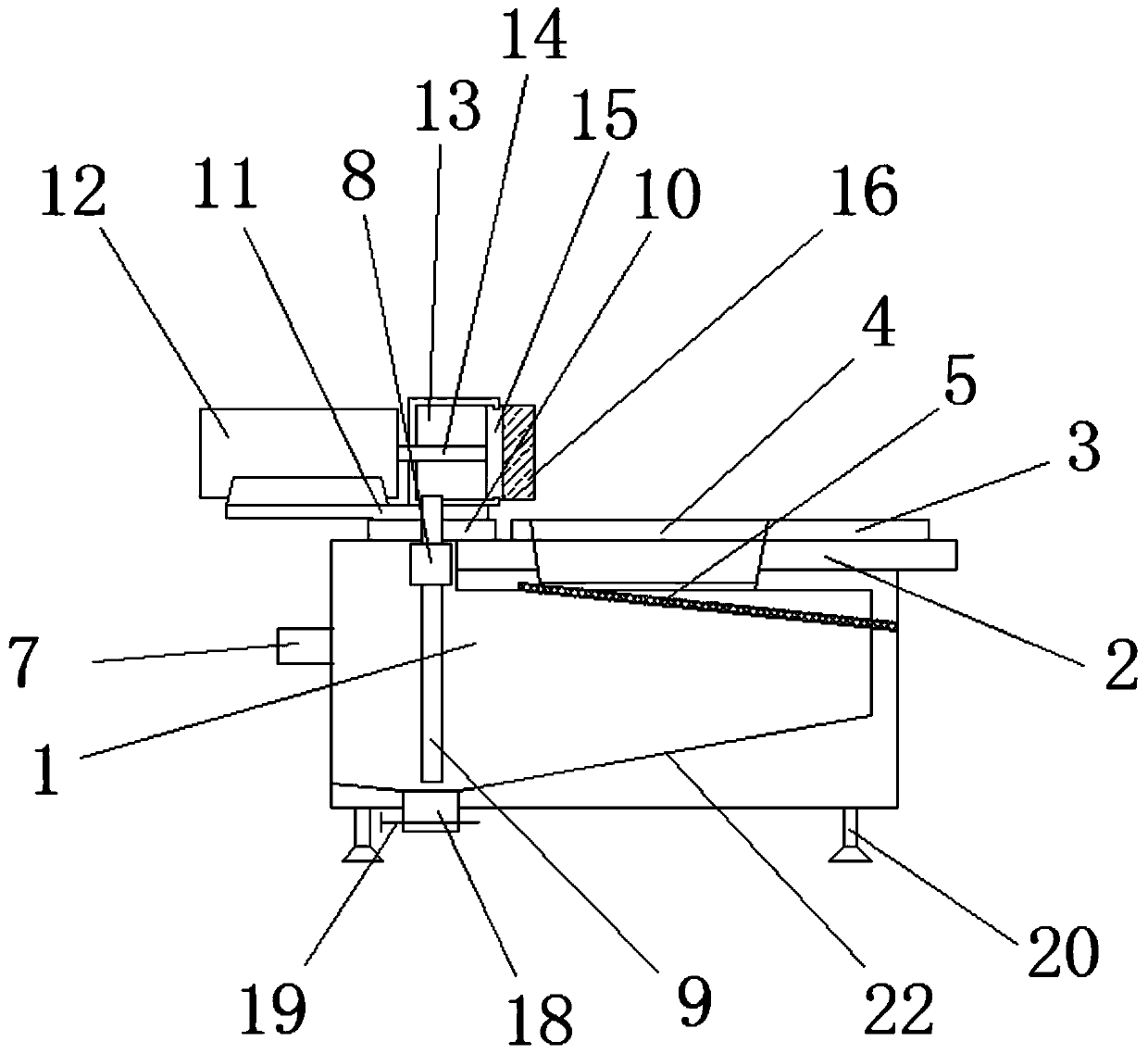

Cleaning device for threaded blade machining

The invention discloses a cleaning device for threaded blade machining. The cleaning device comprises a cleaning frame, a water collecting groove, a motor and mounting rods. The top of the cleaning frame is connected with a water inlet pipe in a penetrating mode, hydraulic telescopic columns are symmetrically installed on the two sides of the water collecting groove, and a water outlet pipe is fixed to one side of the water collecting groove. The motor is fixed to one side of the outside of the cleaning frame, the mounting rods are connected with the other side of the cleaning frame in a penetrating mode, one ends of the mounting rods are connected with connecting sleeves mutually, and elastic convex blocks are installed on the mounting rods. A rotating shaft is rotatably connected with aconnecting shaft penetrating through the inside of the cleaning frame through a transmission belt, inserting grooves and connecting grooves are reserved on the upper surface of the water collecting groove, a filter screen frame is installed in the water collecting groove, and connecting blocks are fixed to the two ends of the filter screen frame. According to the cleaning device for threaded blademachining, through the staggered arrangement of the mounting rods and cleaning rollers, threaded blades can be cleaned by the rotating cleaning rollers adjacent to the threaded blades after being installed on the mounting rods

Owner:KUNSHAN HIECISE PRECISION TOOL

C-Si-N silicon steel hearth roller sleeve and manufacture method thereof

InactiveCN101885615BImprove compactnessReduce porosityFurnace typesHeat treatment furnacesPorosityTar

The invention relates to a C-Si-N silicon steel hearth roller sleeve and a manufacture method thereof. The manufacture method comprises the following steps of: mixing 15-35 weight percent of carbon raw material granule, 20-40 weight percent of crude carbon raw material powder being smaller than or equal to 180 meshes, 40-55 weight percent of fine carbon raw material powder being smaller than or equal to 300 meshes and 1-15 weight percent of fine Si powder, additionally adding a bonding agent accounting for 5-18 weight percent of the mixture and mixing as well as grinding for 15-30 minutes; pressing and molding into a silicon steel hearth roller sleeve blank after mixing and grinding, loading the sleeve blank into a sintering furnace with an N2 atmosphere, preserving heat for 4-8 hours at 1,450-1,700 DEG C and sintering; maintaining the nitridized and sintered sleeve blank for 15-30 minutes under the condition of 10,000-20,000Pa, injecting tar and continuing to maintain for 15-30 minutes under the condition of 10,000-20,000Pa; preserving heat for 4-8 hours at 1,400-1,450 DEG C in a reducing atmosphere; and processing through a lathe and a grinder until the surface roughness is not larger than 12.5. The sleeve has the characteristics of good abrasive resistance, good oxidation resistance, high strength, low porosity, no nodules and long service life.

Owner:WUHAN UNIV OF SCI & TECH

Die-casting part shaping and grinding device

ActiveCN110253386APrevent wear and tearGood sealing effectGrinding carriagesGrinding machinesEngineeringLiquid storage

The invention discloses a die-casting part shaping and grinding device and relates to the field of die casting. The die-casting part shaping and grinding device comprises a liquid storage cavity. The top of the liquid storage cavity is fixedly provided with a platform. The top of the left side of the liquid storage cavity is fixedly provided with a rotary table. The top of the rotary table is fixedly connected with a bracket. A motor and a liquid spray cavity are fixedly mounted on the bracket. The right side of the motor is fixedly connected with a rotary shaft. The rotary shaft penetrates through the left sidewall of the liquid spray cavity to be fixedly connected with a rotary disk. The right side of the rotary disk is fixedly connected with a grinding disk. The grinding disk and the rotary disk are provided with a plurality of through holes. The bottom of the liquid spray cavity is fixedly connected with a liquid outlet pipe. The liquid outlet pipe penetrates through the bracket and the rotary table to extend to the bottom of an inner cavity of the liquid storage cavity. The upper portion of the liquid outlet pipe is fixedly provided with a liquid pump. The die-casting part shaping and grinding device can adjusting the angle of the grinding disk, can recover, filter and reutilize used grinding liquid, saves resources and is easy to apply and popularize.

Owner:田金举

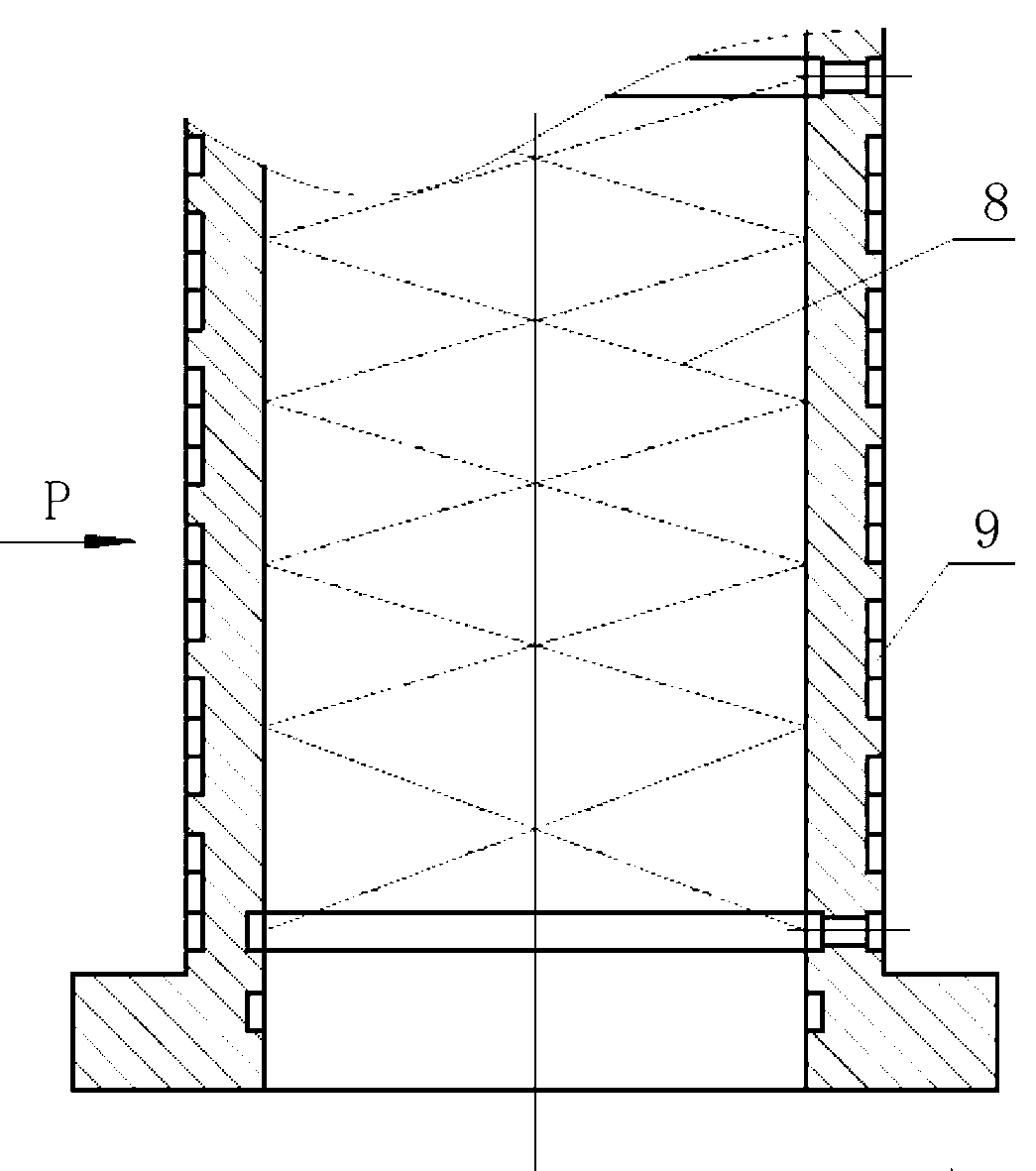

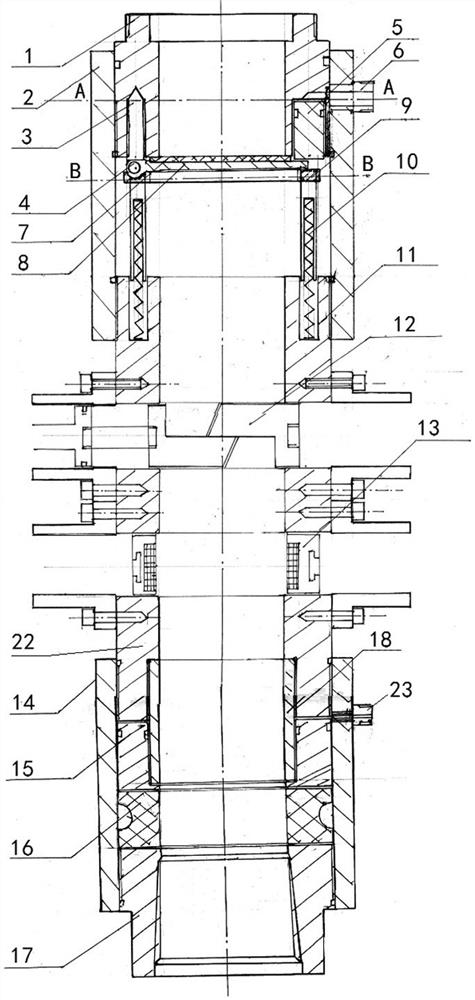

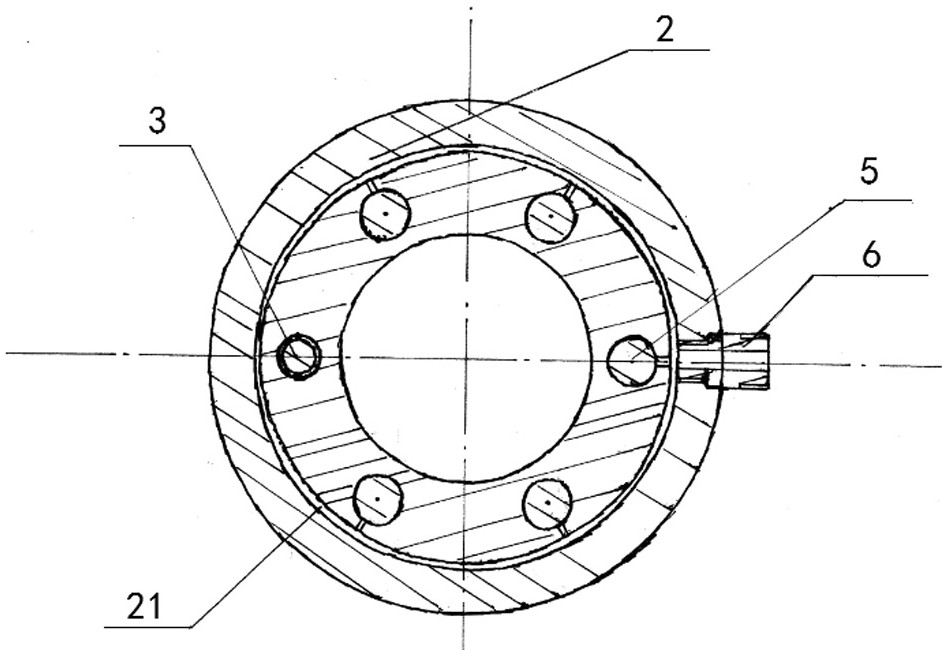

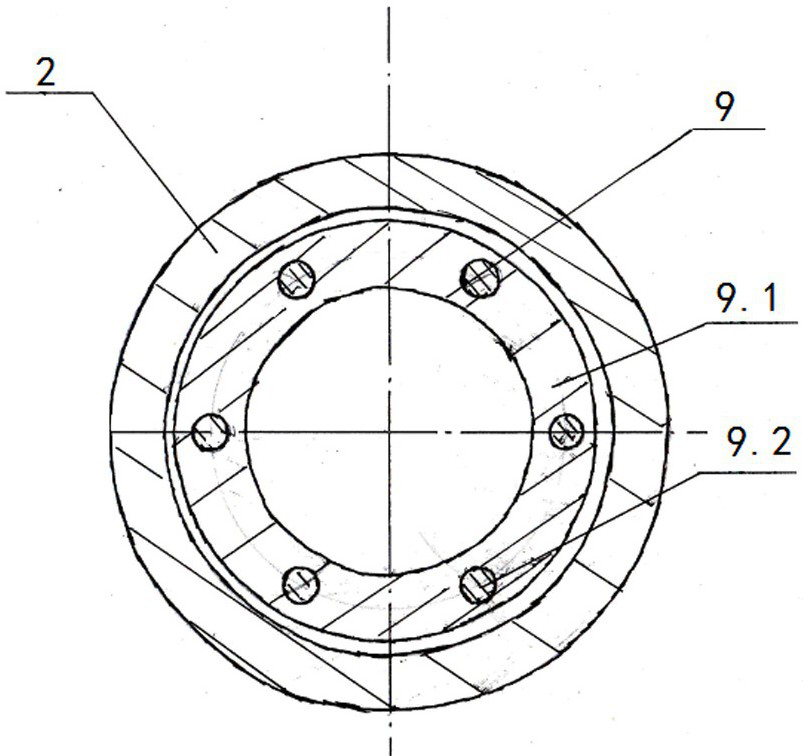

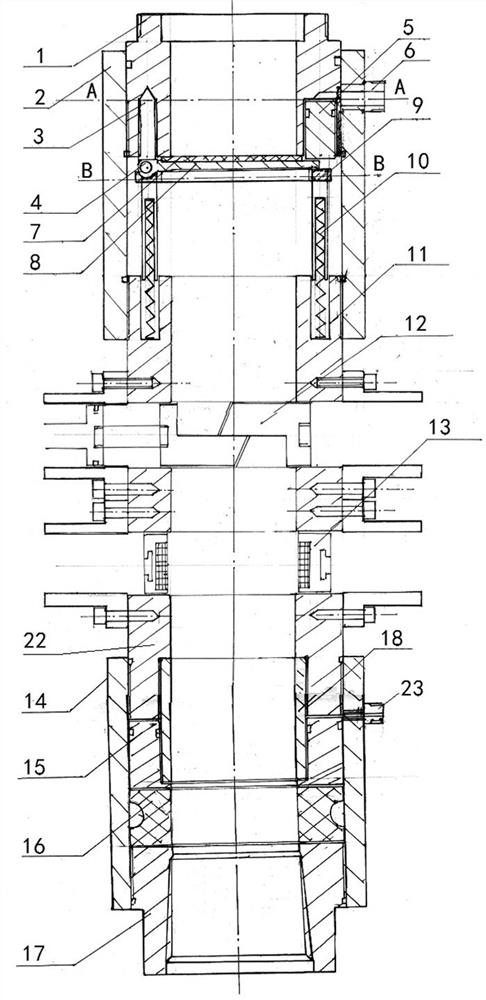

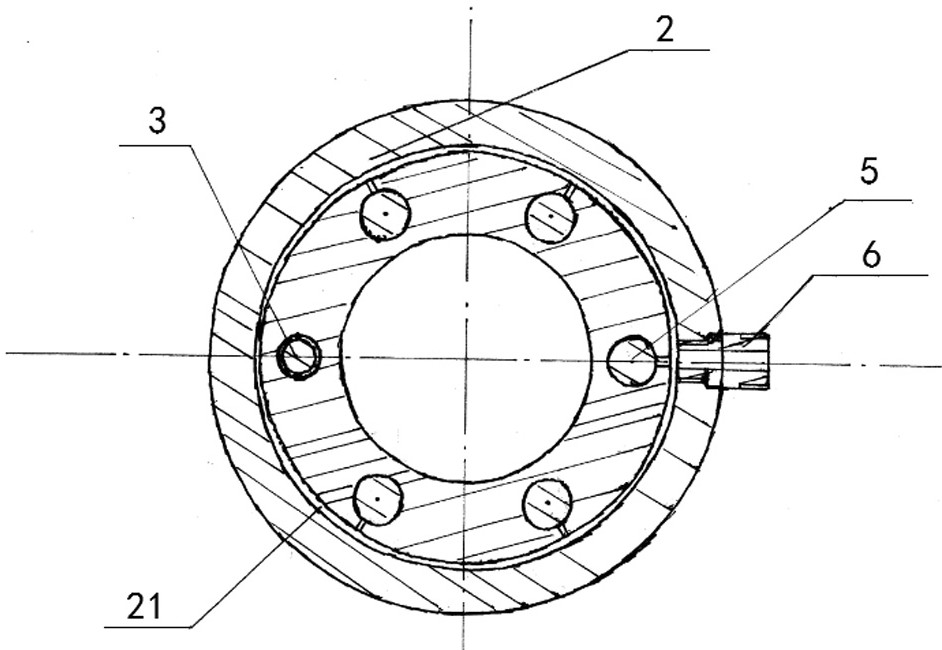

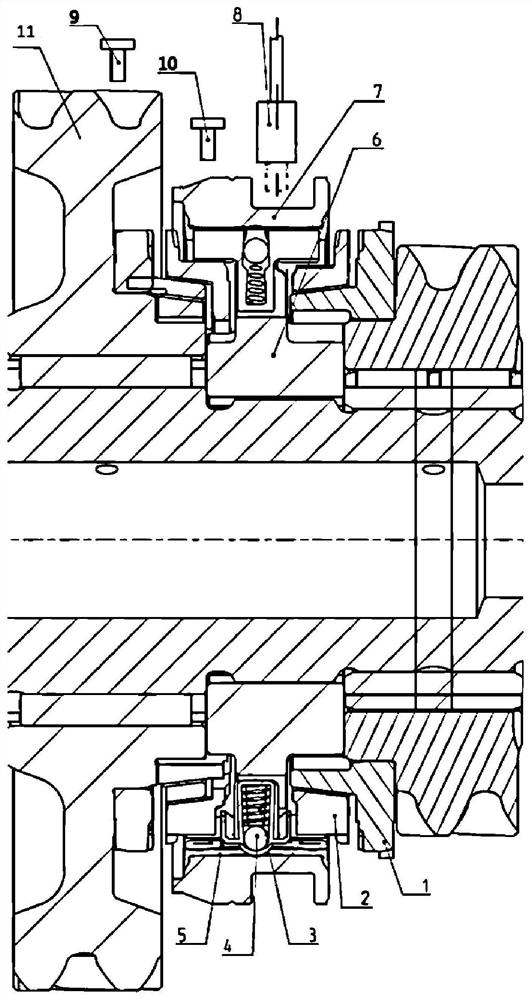

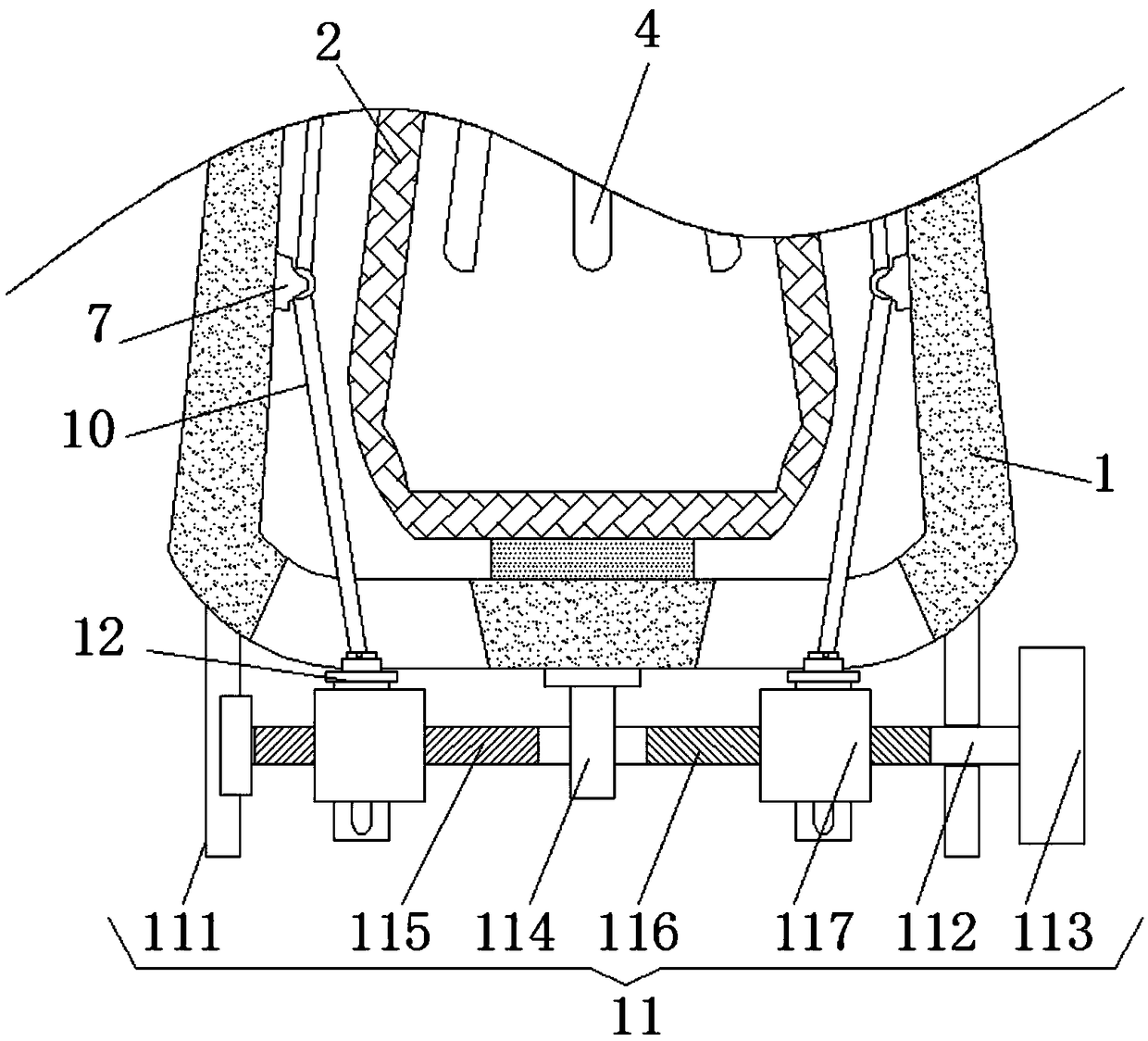

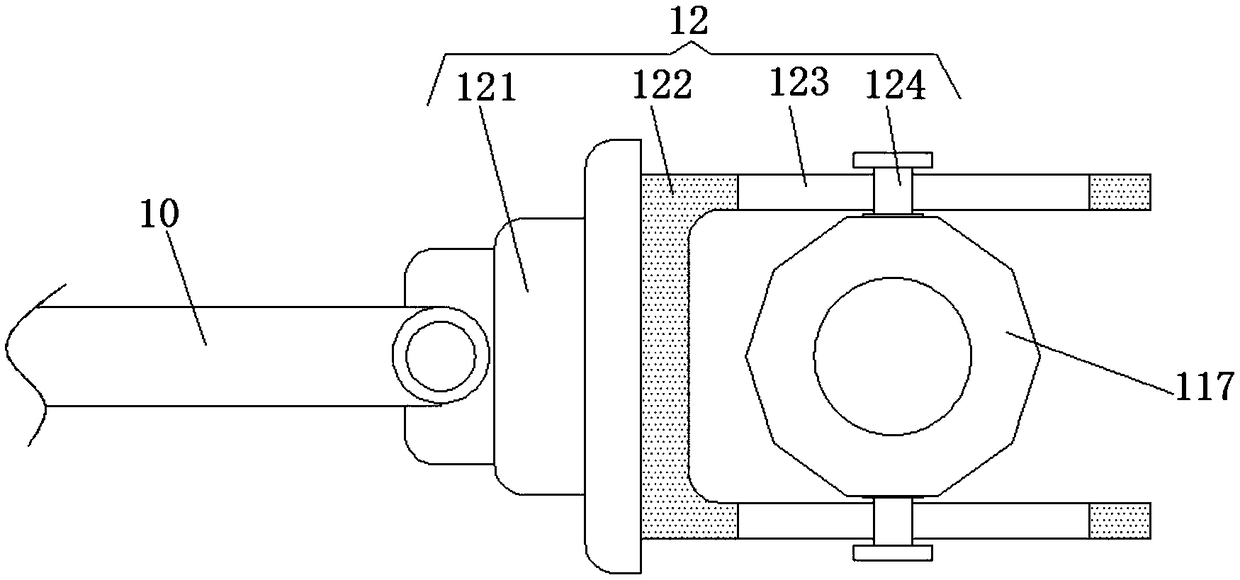

Four-gate continuous coiled tubing packer

The invention relates to a four-gate continuous coiled tubing packer. The packer comprises a main casing and a hydraulic cylinder, wherein the inner cavity of the main casing is sequentially providedwith a full sealing device, a shearing device, a suspension device and a semi-sealing device from top to bottom. During sealing, a support and a return spring are closed through gates to support a sealing carrier on the lower end surface of an upper joint to achieve the sealing. During repair, the gates are hydraulically driven to open to move a piston group down and push away the sealing carrierto further press the sealing carrier down and enable the sealing carrier to rotate around a gate rotating shaft, and coiled tubing can be lowered into a well along the upper joint inner cavity. The packer has the advantage that the operation space is expanded since the full seal is of a vertical structure, that is, at least one double wing is removed, the personal injury accident in the operationis greatly reduced, the weight of the whole device is greatly reduced, and the operation difficulty and the processing cost are reduced. The packer is safer and more reliable than the original 4FZ blowout preventer, more convenient to use, lower in processing cost and lighter in weight.

Owner:DAQING DANFENG PETROLEUM TECH DEV CO LTD

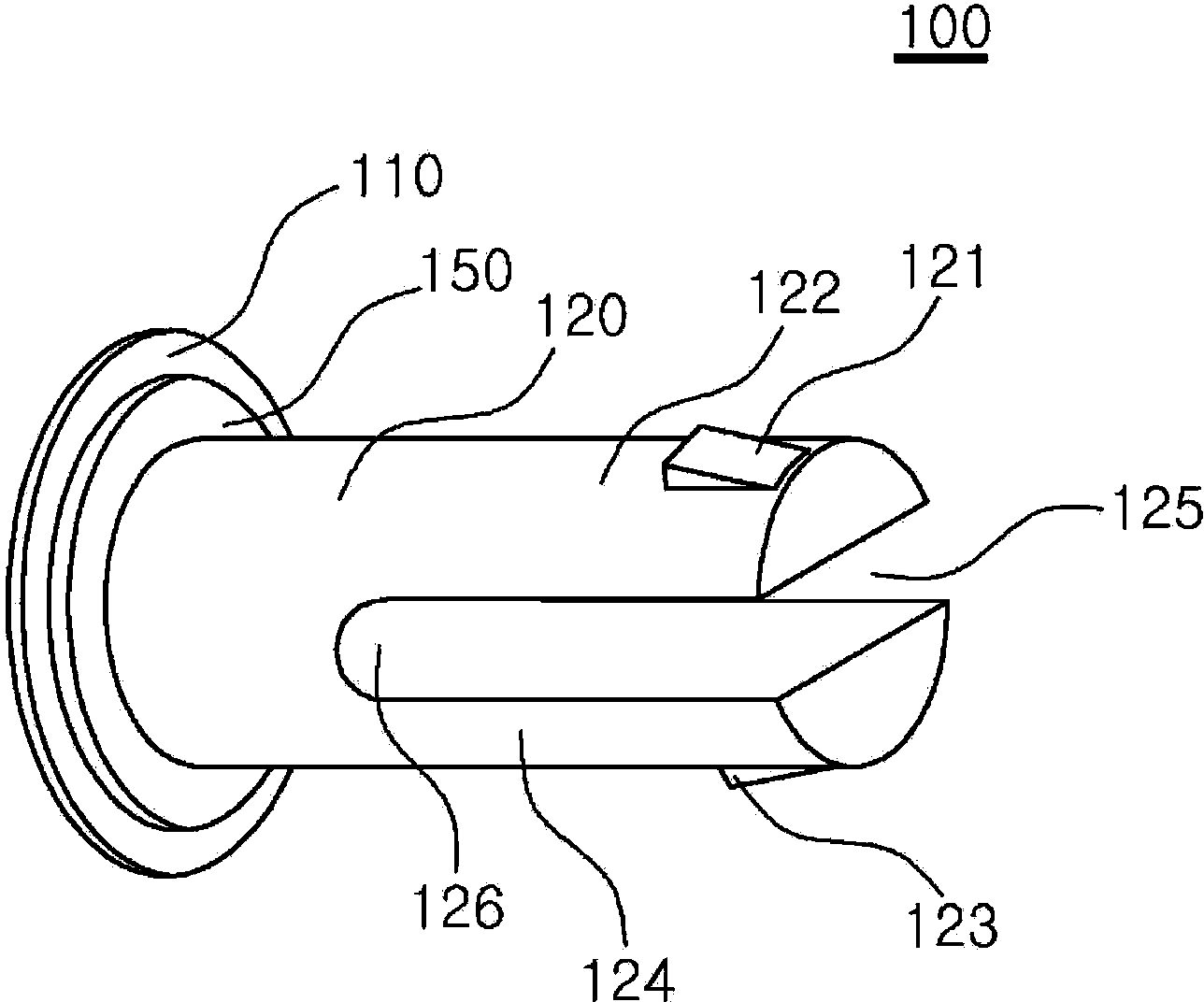

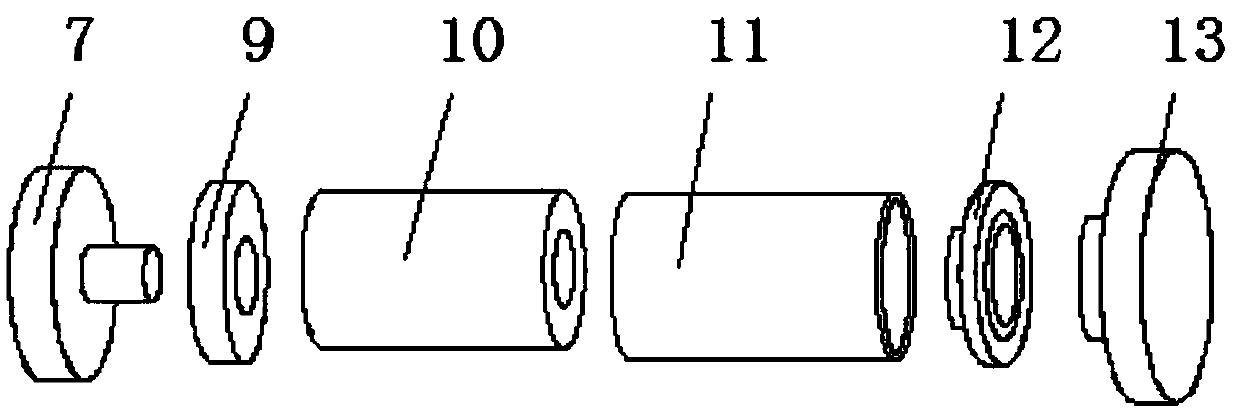

Embedding sleeve and embedding method of stud and nut

The invention discloses an embedding sleeve of a stud and a nut. The embedding sleeve comprises a shell, an inner sleeve and a nut loop, wherein the outer shell is provided with an inner cavity, a boss is arranged on one end of the inner cavity, the inner sleeve is in threaded connection with the inner cavity, and pushes against the boss, the inner sleeve is internally provided with internal threads matched with external threads of the stud, a connector butted with a driving end is arranged on one end, close to the boss, of the outer shell, the nut loop sleeves one end, far away from the boss, of the inner cavity, and a limiting assembly for limiting one-way rotation of the nut loop is arranged between the outer shell and the nut loop. The invention further correspondingly discloses an embedding method of the stud and the nut, in which the embedding sleeve is adopted for synchronously assembling the nut and the stud. The embedding sleeve and the embedding method have the advantages that operation is simple and convenient, the nut and the stud can be rapidly and synchronously assembled, and the like.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

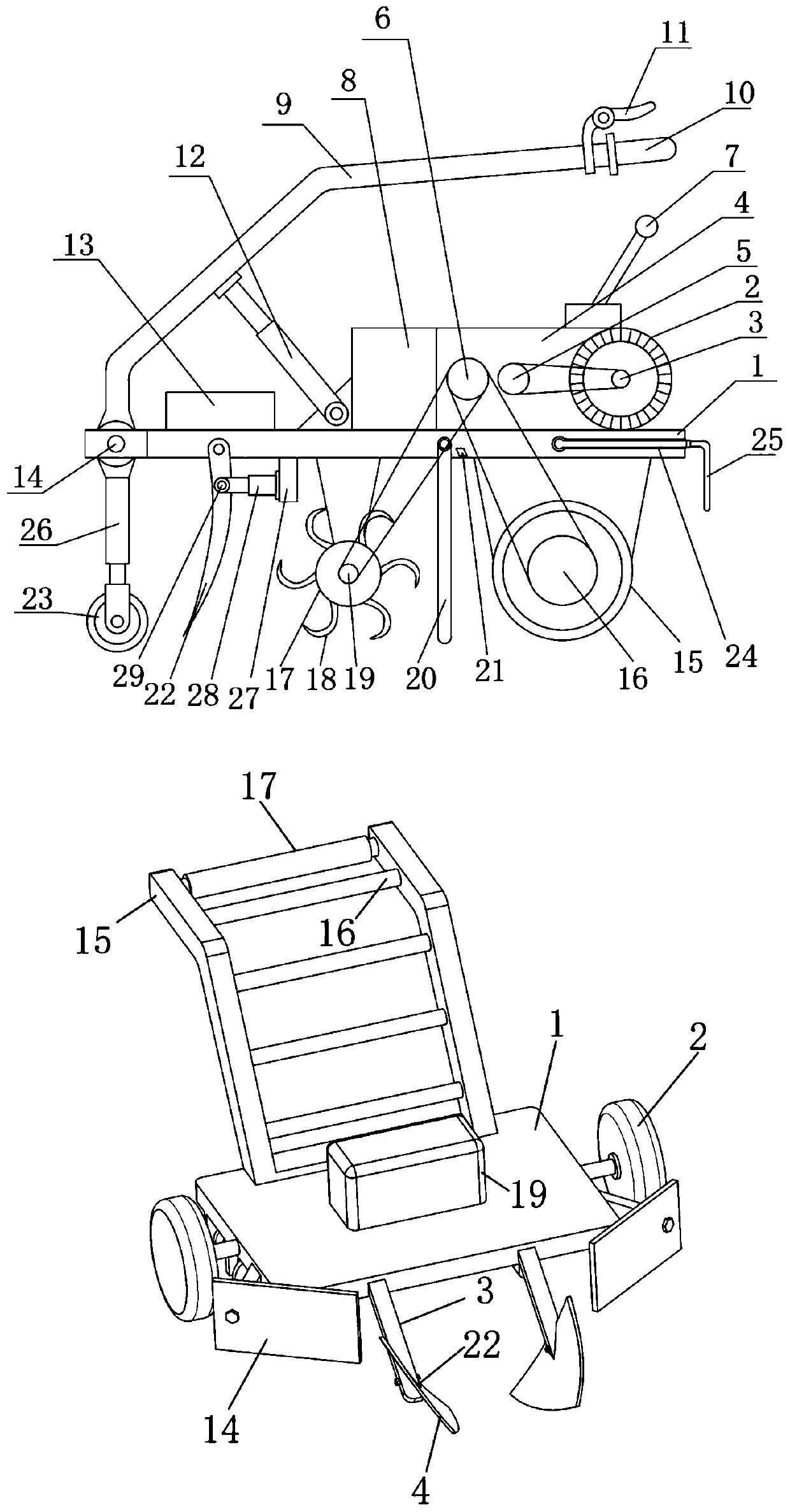

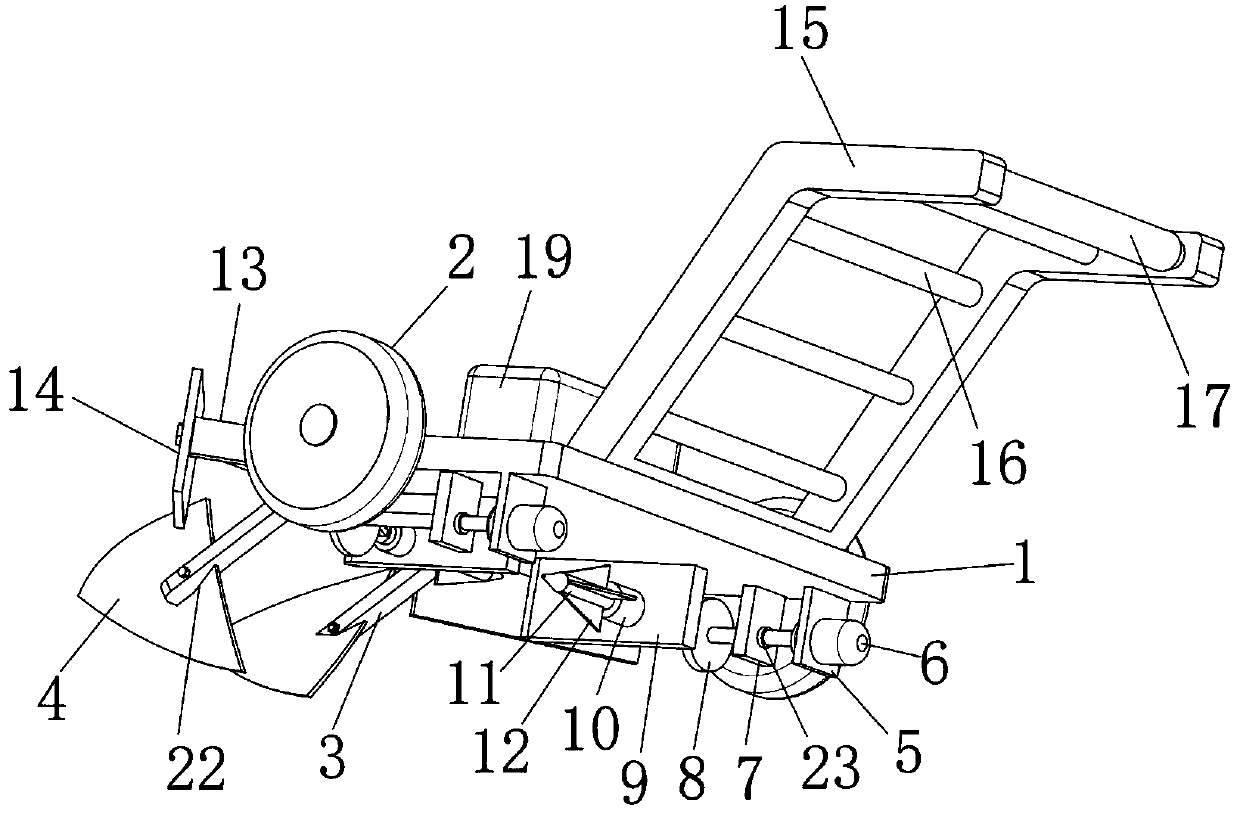

Efficient soil loosening device for fruit tree planting

The invention relates to the technical field of soil loosening devices, in particular to an efficient soil loosening device for fruit tree planting. The device comprises a bottom plate, two corresponding handlebars are fixedly welded to one side of the upper surface of the bottom plate, and corresponding wheels are fixedly installed on two corresponding side faces of the periphery of the bottom plate; two coulters are fixedly installed on the side face, away from the handlebars, on the periphery of the bottom plate; two corresponding first fixing plates are fixedly welded to the side, close tothe handlebars, of the lower surface of the bottom plate; motors corresponding to the coulters are fixedly arranged on the two first fixing plates, discs are fixedly arranged at the tail ends of theoutput ends of the two motors, and two third fixing plates corresponding to the discs are fixedly arranged on the portion, between the two discs, on the two sides of the lower surface of the bottom plate; the two third fixing plates are fixedly provided with sleeves corresponding to the discs respectively, telescopic columns are rotationally arranged in the two sleeves, and connecting rods are hinged between the tail ends, close to the discs, of the telescopic columns and the discs. The device has the advantage of being good in soil loosening effect.

Owner:银川瑞海陈技术咨询服务有限公司

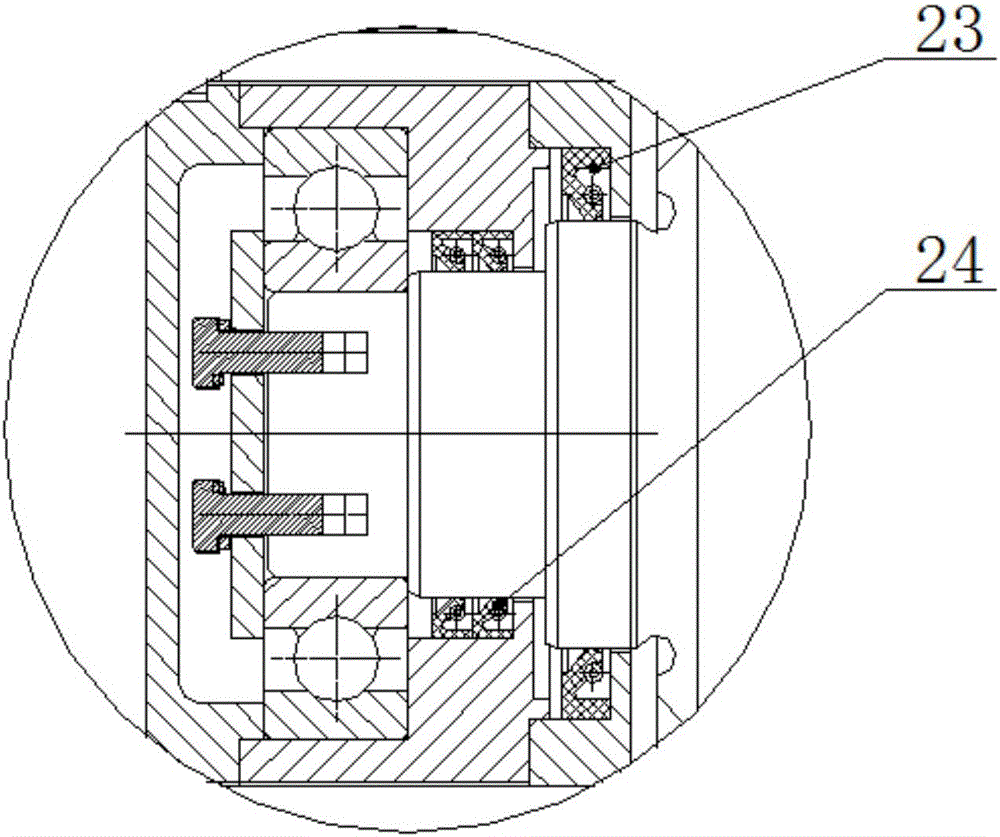

Two-component metering valve

ActiveCN102109046AGlue cleanVersatileOperating means/releasing devices for valvesMultiple way valvesEngineeringVALVE PORT

The invention relates to a two-component metering valve. A valve body comprises an upper valve body, a lower valve body and a metering device; the upper valve body comprises an upper valve body shell and a driving device arranged in the upper valve body shell; a cavity is formed in the upper part of the lower valve body; at least two piston channels are parallelly formed at the bottom in the cavity; a glue outlet is formed on the tail part of each piston channel; a piston is arranged in the middle of each piston channel; at least one part of the sealed end of each piston is arranged in each corresponding glue outlet; at least one sealing device is arranged between each piston and each corresponding piston channel; the top ends of the parallelly arranged pistons are fixed on the same connecting plate; a connecting device is connected with the driving device through at least one transmission device; and the at least one transmission device is arranged in a transmission device channel formed between the upper valve body and the lower valve body. The glue dispensing two-component metering valve dispenses glue quickly and accurately, breaks the glue completely, and has a sealing structure which is difficult to damage.

Owner:SHENZHEN AXXON AUTOMATION

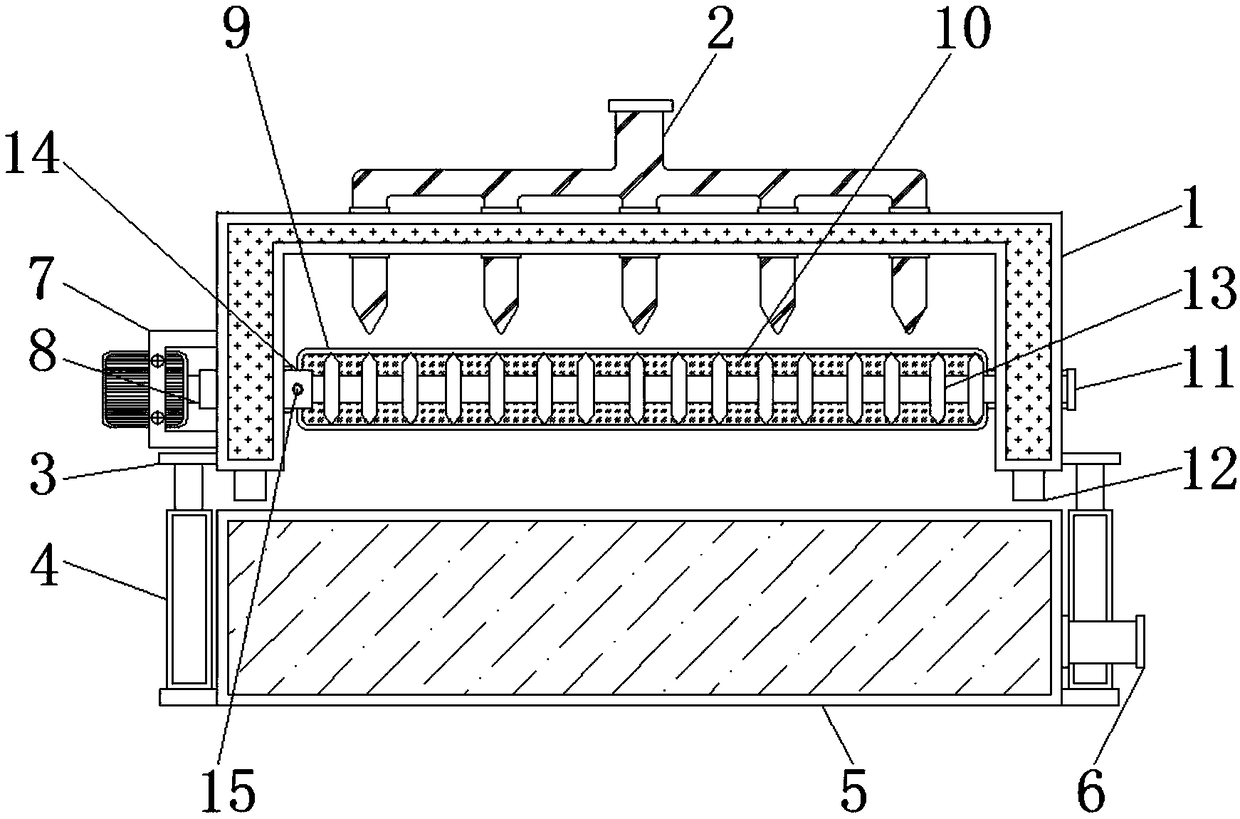

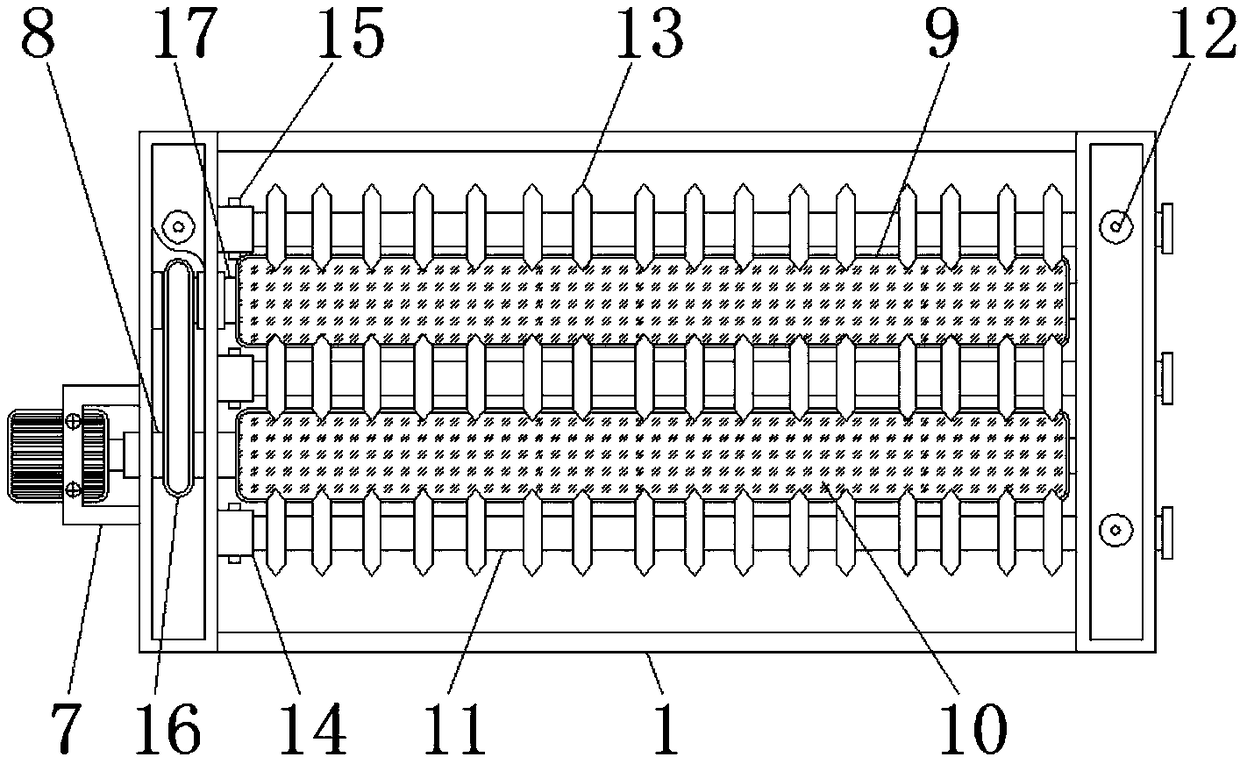

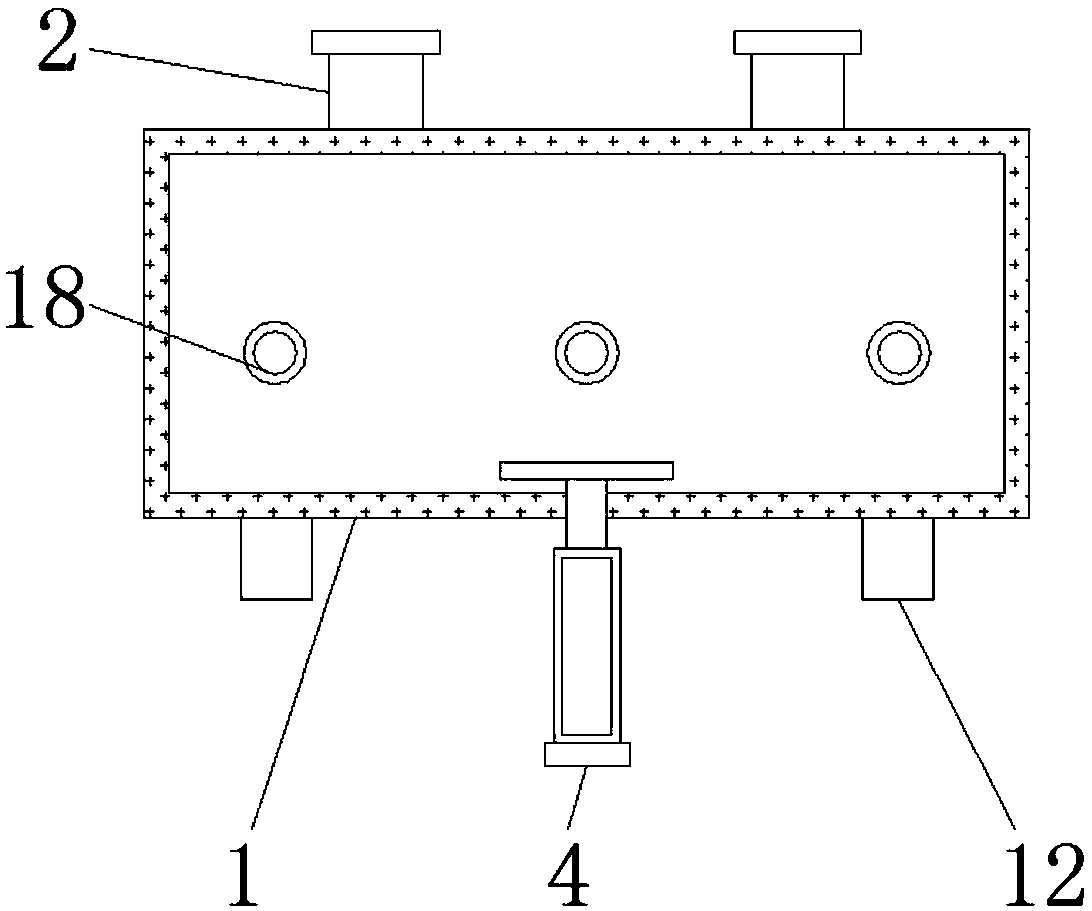

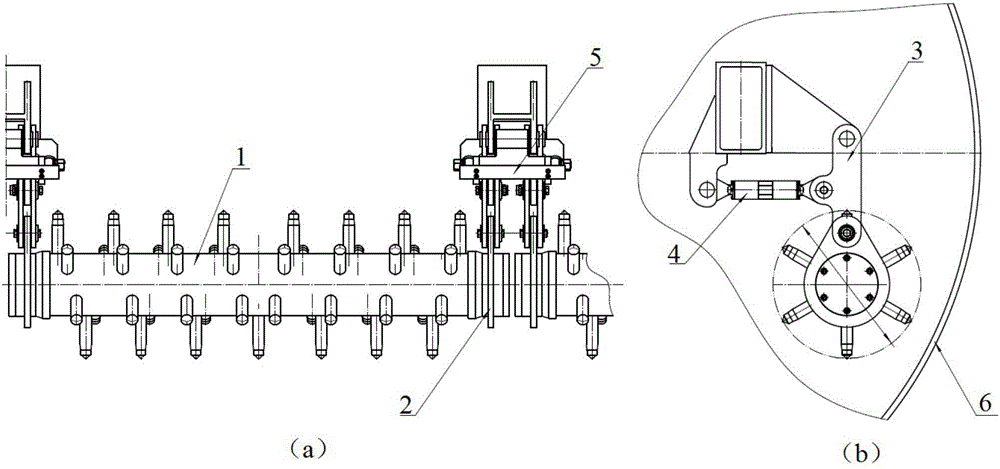

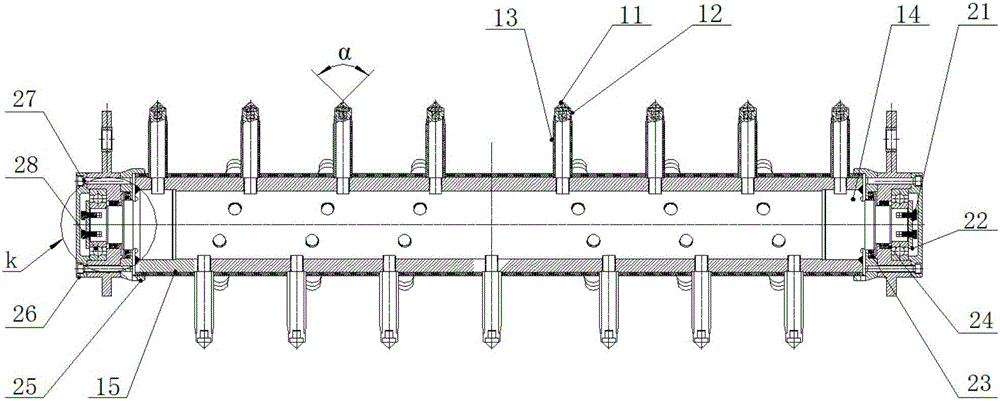

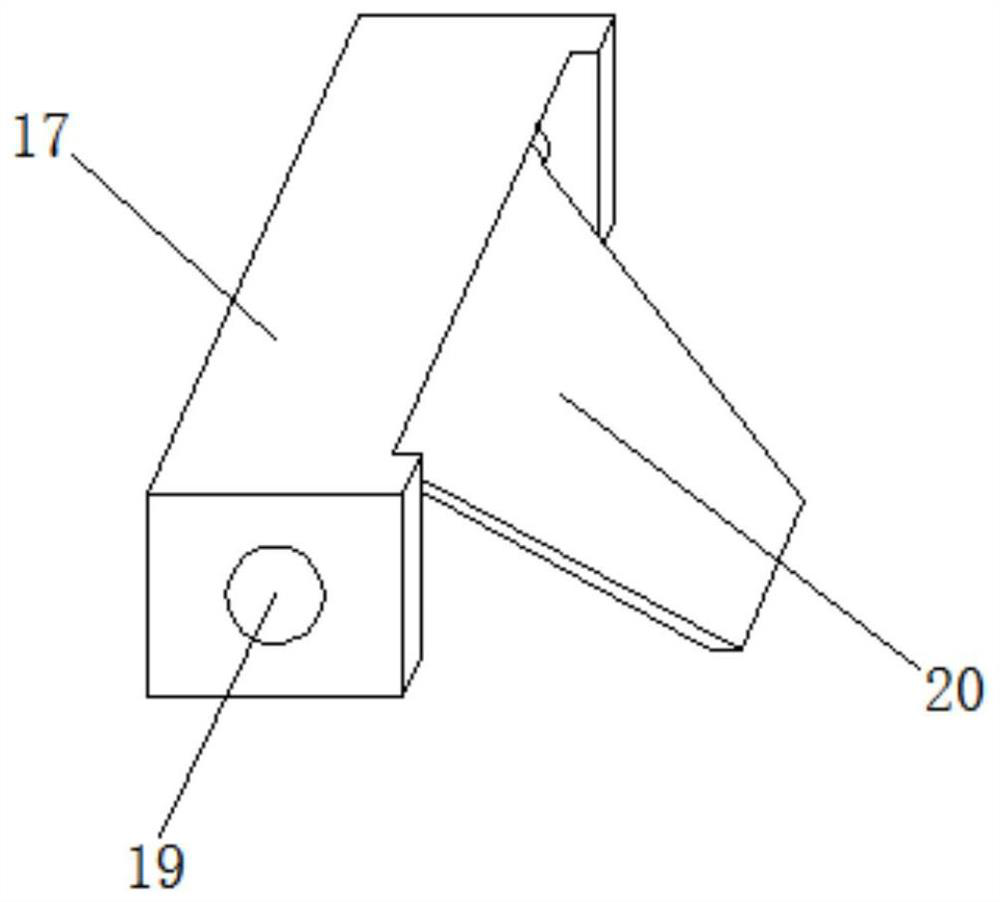

Sintering mixer cleaning device, rotary thorn roller thereof and thorn roller hanger

ActiveCN106040046ASolve the sticky problemOptimize the connection methodRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a sintering mixer cleaning device, a rotary thorn roller thereof and a thorn roller hanger and belongs to the technical field of sintering mixers. The sintering mixer cleaning device, the rotary thorn roller thereof and the thorn roller hanger have the advantages that the connecting manner of thorn rods and a thorn roller body is improved, special sleeves are arranged on the thorn roller and the thorn rods in an embedded manner, the material adhering problem of the cleaning device is solved thoroughly, and the thorn roller, thorn heads and the thorn rods are allowed to be exposed, a beating rotating mechanism adopts a multistage combined sealing structure, external materials and steam can be effectively prevented from corroding bearings, and the service life of the cleaning device is prolonged; an scraper cleaning mechanism is added between thorn rollers, materials adhered to the wall of a cylinder can be cleaned completely, and cleaning blind areas are eliminated; the sintering mixer cleaning device can effectively and reliably work for a long time, equipment maintenance workload is relieved greatly, the replacement cycle of main parts is prolonged from the original half a year to two years, and equipment performance is increased evidently.

Owner:马鞍山市方正机械制造有限责任公司

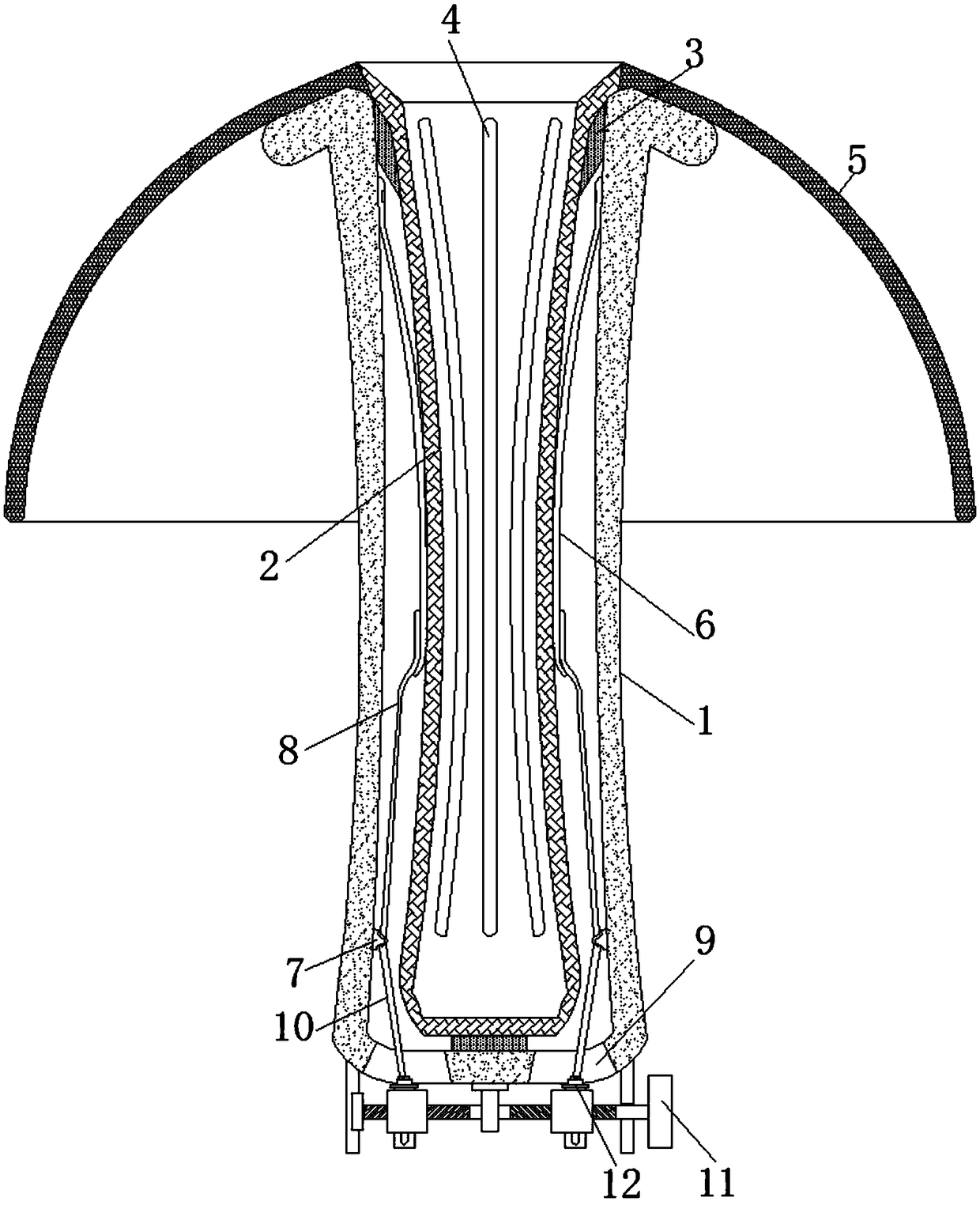

Oil-leakage-proof atomizer and aerosol generating device

The invention relates to the field of aerosol generating devices, and in particular, relates to an oil-leakage-proof atomizer and an aerosol generating device. A convex part is arranged at one end ofa shell; a matched concave part is correspondingly arranged on the peripheral side of an oil cup base; when the oil cup base is inserted and positioned on the shell, the convex part is arranged in theconcave part, so one end, close to the oil cup base, of the shell is fixed by the concave part; when a sealing silicone rubber applies an outward acting force to the inner surface of the shell, one end of the shell is based on the concave part, so that the convex part abuts against and is fixed in the concave part, the position, corresponding to the convex part, of the shell is prevented from being turned outwards under the action of acting force, the stability of interference fit between the sealing silicone rubber and the shell is improved, the sealing effect on the shell is improved, and oil leakage is prevented. Meanwhile, the problem that the oil cup base is loosened due to the fact that the convex part corresponding to the shell is turned outwards under the acting force of the sealing silicone rubber is solved, and the inserting stability of the oil cup base is improved.

Owner:SHENZHEN JIYOU TECH CO LTD

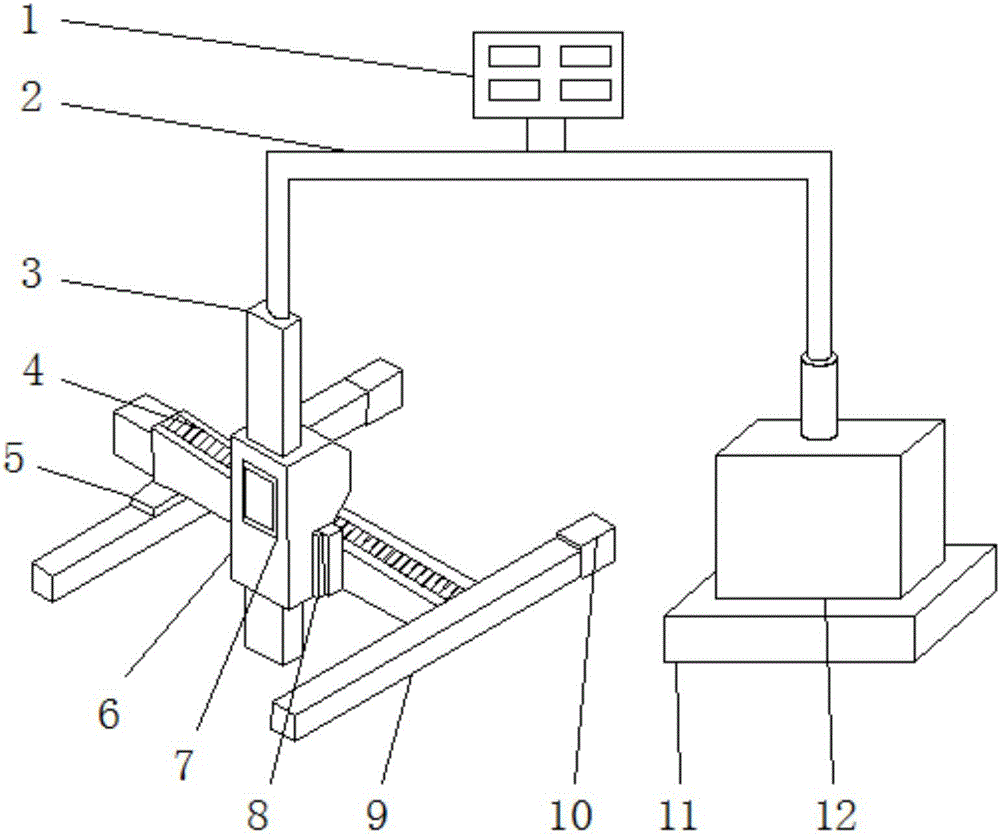

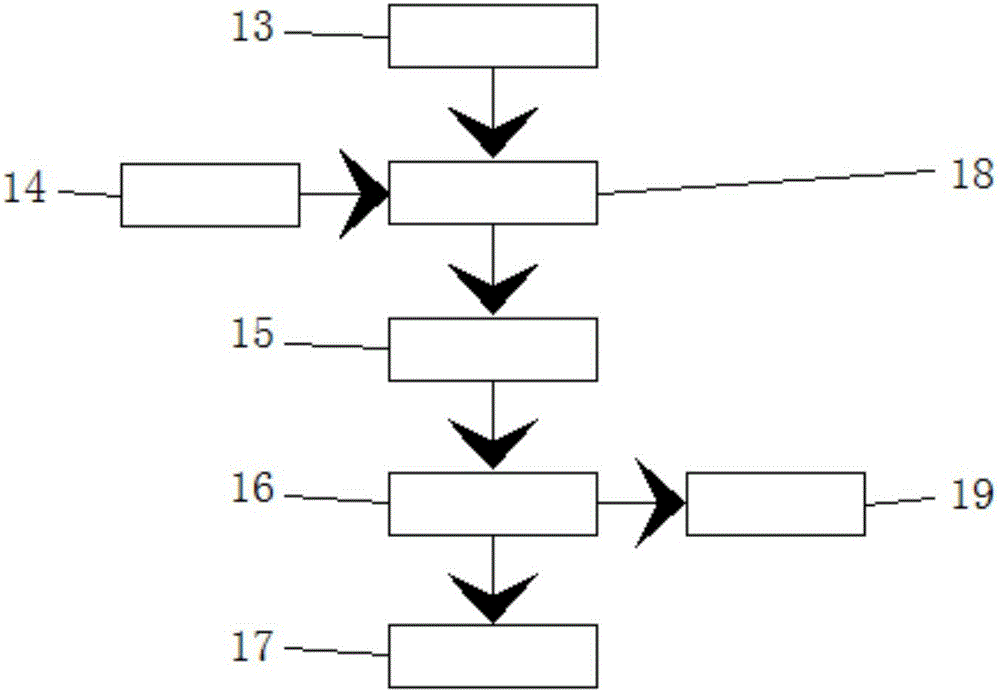

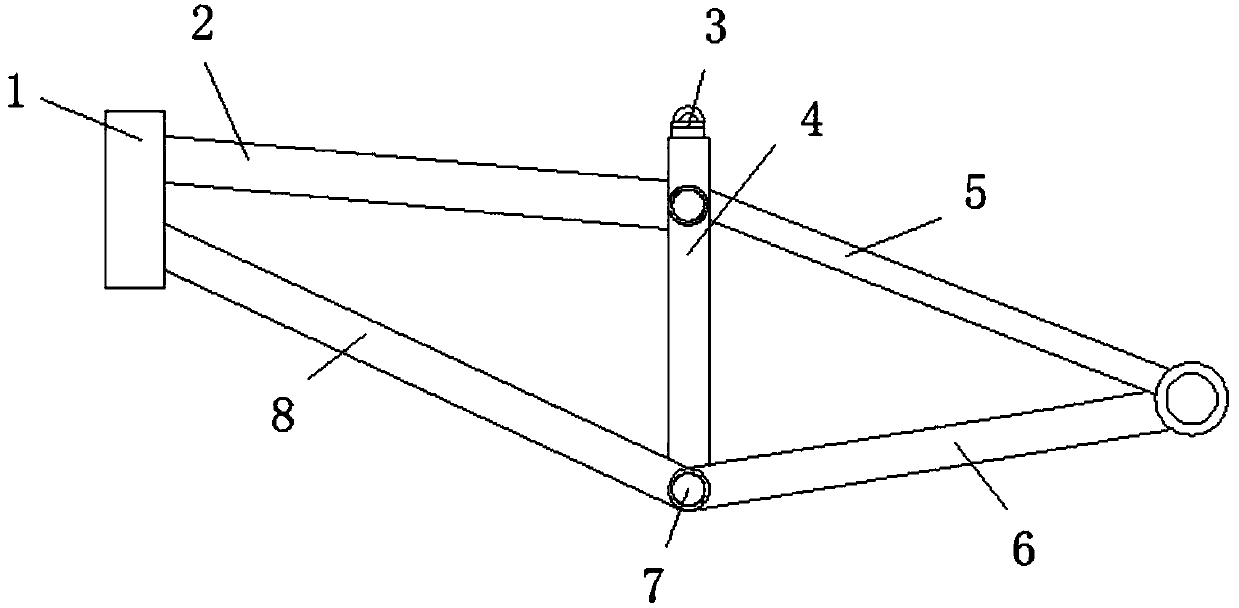

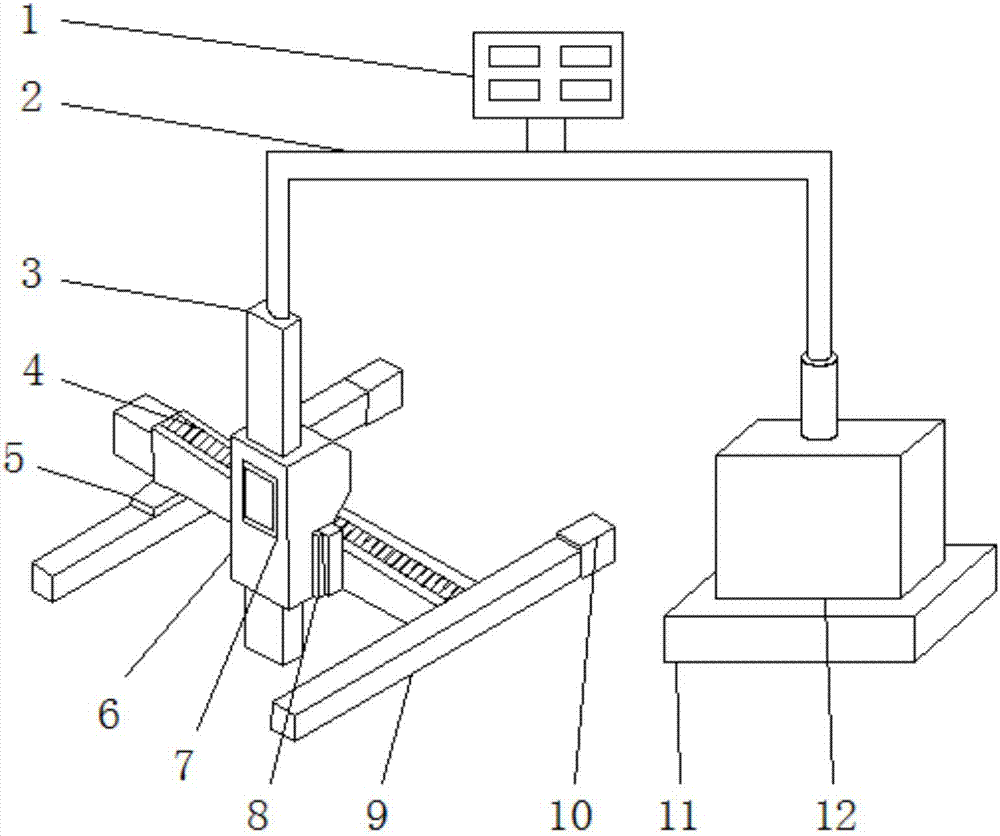

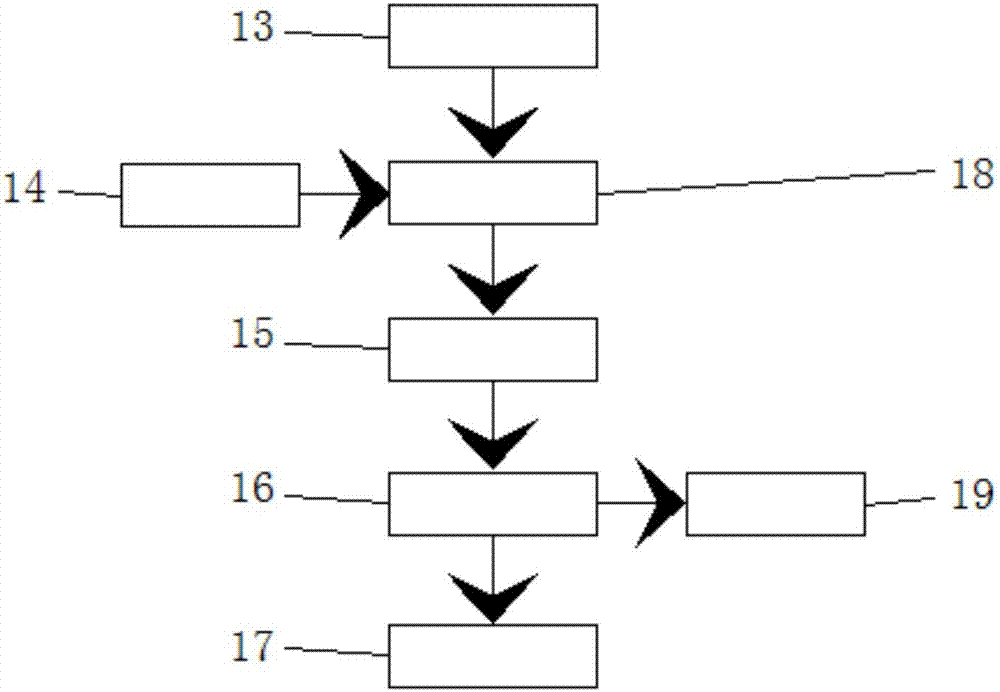

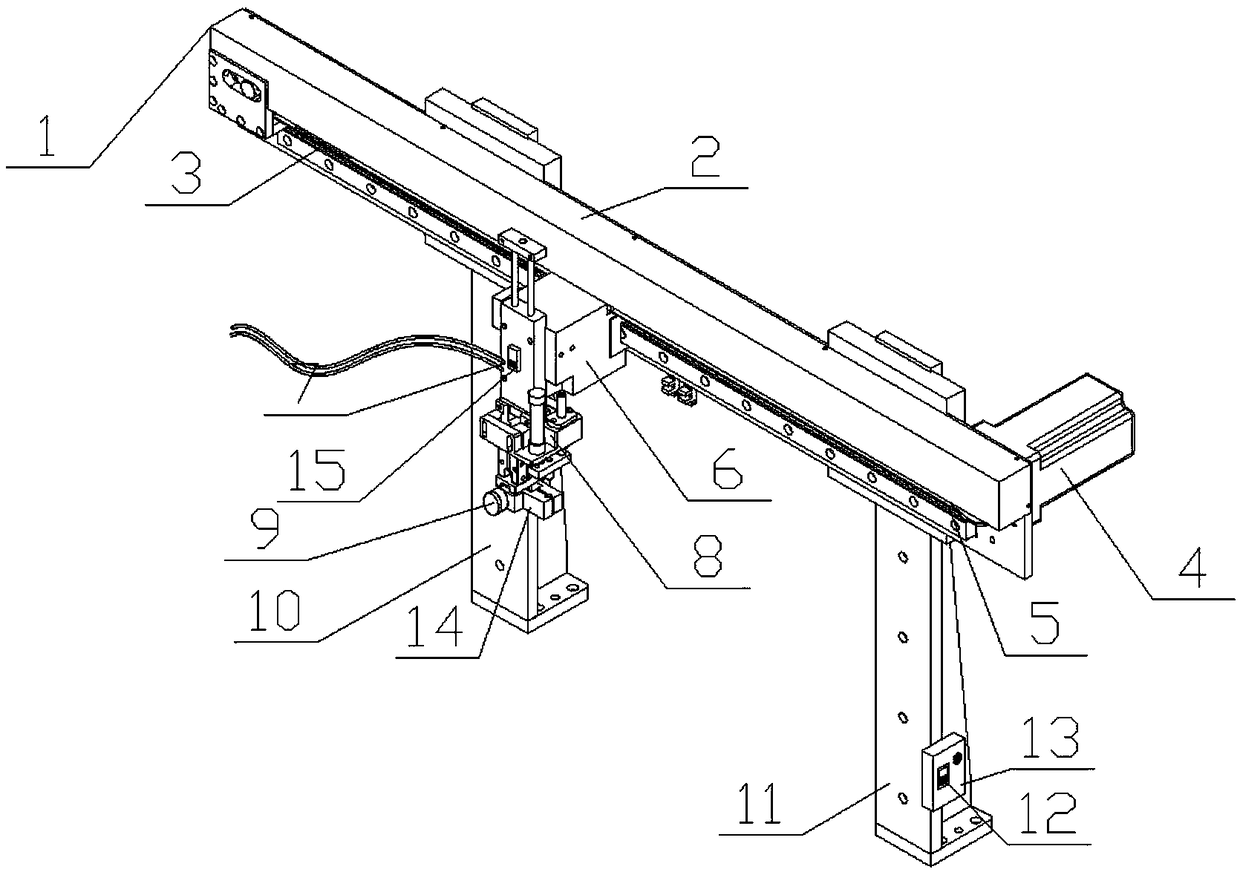

Control system for gantry truss robot and control method for control system for gantry truss robot

ActiveCN106315413AStable and safe operation statusPrevent wear and tearLoad-engaging elementsControl systemRobot control system

The invention discloses a control system for a gantry truss robot. The control system for the gantry truss robot comprises a machine body, an X shaft, a command processing module and a command positioning module. A display screen is mounted on the front surface of the machine body. The X shaft is mounted on the right side of the machine body. A Y shaft is mounted on the right side of the X shaft. A shaft spacer is mounted below the Y shaft. A Z shaft is mounted above the machine body. A controller is mounted above the Z shaft. The input end of the command positioning module is electrically connected with the output end of an initial command module and the output end of an external input module. The output end of the command positioning module is electrically connected with the input end of a command drive module. The output end of the command processing module is electrically connected with the input end of a command recovery module. The invention further provides a control method for the control system for the gantry truss robot. The mounted machine body is of a stainless steel corrosion-resisting structure, so that the machine body can be kept in the stable and safe operation state for a long time, meanwhile excessive use wear to the machine body is avoided, and thus the service life of the system is prolonged.

Owner:宁夏巨能机器人股份有限公司

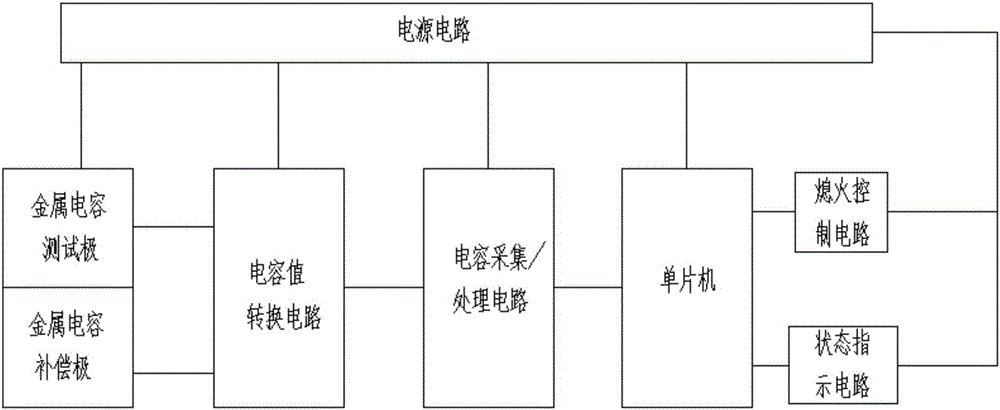

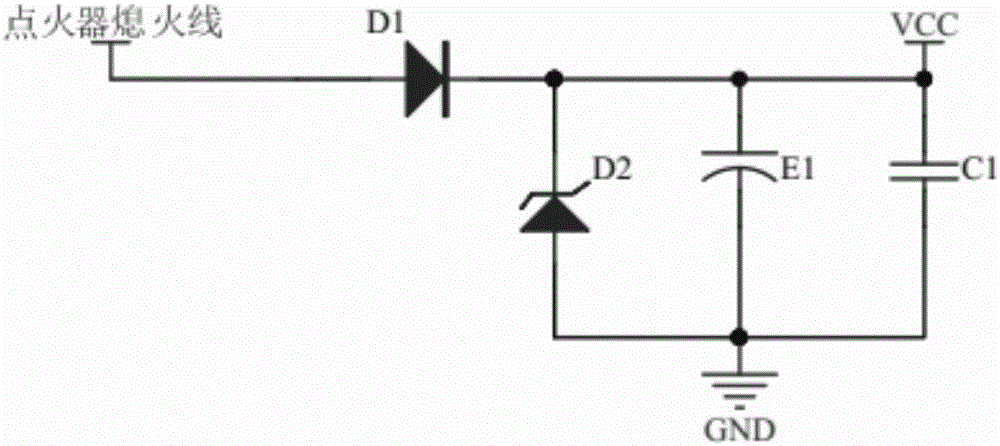

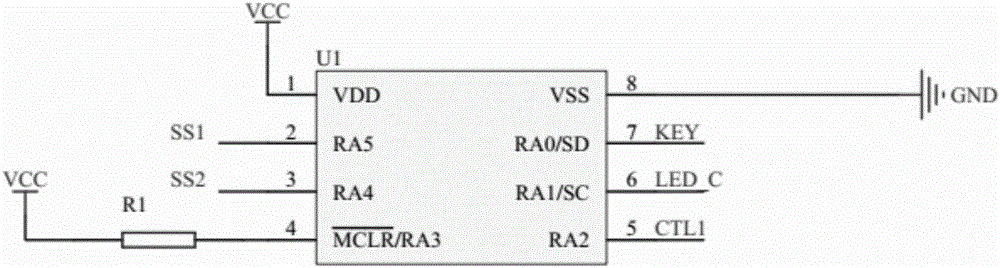

Four-in-one intelligent engine oil sensor

PendingCN106640267ACompact structureEasy to installMachines/enginesLubrication indication devicesSignal processing circuitsGasoline

The invention discloses a four-in-one intelligent engine oil sensor. The four-in-one intelligent engine oil sensor comprises a sensor body mounted in the position of an engine oil level gauge, and a measurement signal processing circuit. The four-in-one intelligent engine oil sensor has the beneficial effects that firstly, the sensor is compact in structure and convenient to mount and replace; secondly, the sensor does not have a mechanical moving structure, usage abrasion caused by long-term floating is eliminated, the service life is effectively prolonged, and the sensor failure phenomenon caused by clamping stagnation hidden danger is avoided; thirdly, the sensor is wide in application range and can be directly used for existing gasoline engine oil measuring and alarming systems without being modified; fourthly, due to the fact that a circuit part is completely isolated from fuel oil, potential safety hazards caused by electronic device damage are avoided, and the sensor is safer and more reliable than traditional products; fifthly, the functions of four traditional parts such as a flame rollout switch, an engine oil alarming device, an engine oil sensor body and the engine oil level gauge are integrated, and miniature design is facilitated; and sixthly, the sensor adopts the single-chip microcomputer principle, and infinite functions can be given to the sensor.

Owner:重庆沃奥机电有限公司

How to use four ram coiled tubing sealer

ActiveCN109519144BImprove sealingEasy to useWell/borehole valve arrangementsSealing/packingHydraulic cylinderUpper joint

The invention relates to a method for using a four-gate continuous coiled tubing packer. The packer comprises a main casing and a hydraulic cylinder, wherein the inner cavity of the main casing is sequentially provided with a full sealing device, a shearing device, a suspension device and a semi-sealing device from top to bottom. During sealing, a support and a return spring are closed through gates to support a sealing carrier on the lower end surface of an upper joint to achieve the sealing. During repair, the gates are hydraulically driven to open to move a piston group down and push away the sealing carrier to further press the sealing carrier down and enable the sealing carrier to rotate around a gate rotating shaft, and coiled tubing can be lowered into a well along the upper joint inner cavity. The packer has the advantage that the operation space is expanded since the full seal is of a vertical structure, that is, at least one double wing is removed, the personal injury accident in the operation is greatly reduced, the overall weight is greatly reduced, and the operation difficulty and the processing cost are reduced. The packer is safer and more reliable than the original4FZ blowout preventer, more convenient to use, lower in processing cost and lighter in weight.

Owner:大庆市顺康石油科技开发有限公司

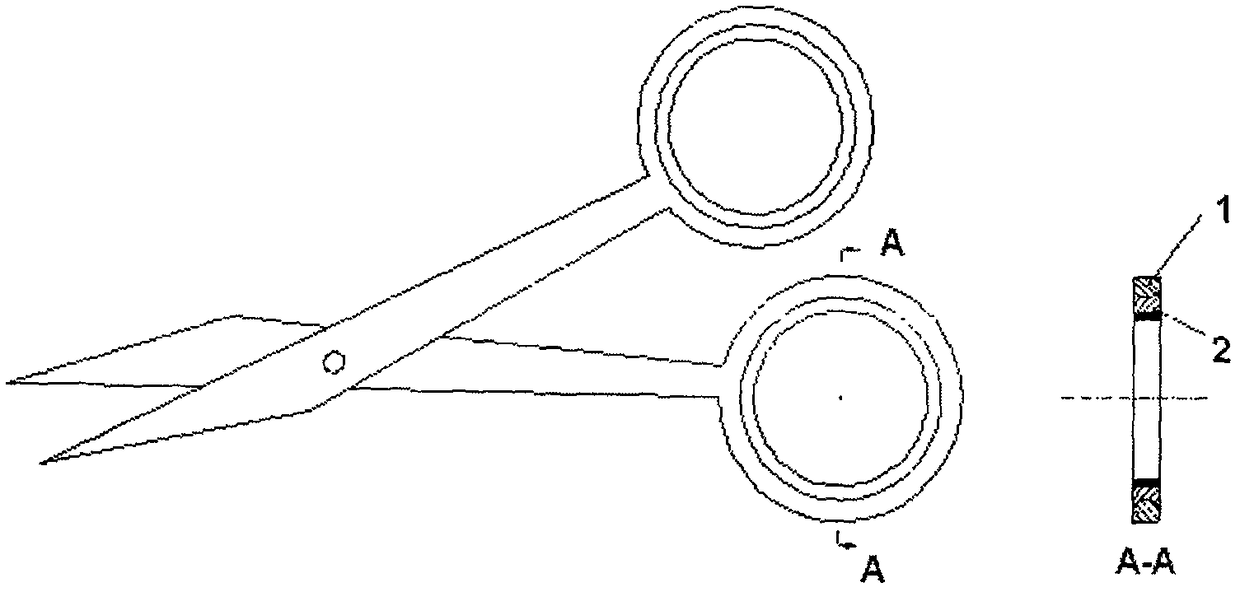

Scissors hand shank preventing finger from being abraded

InactiveCN108789505ASimple mechanical structurePrevent wear and tearMetal working apparatusLubricationEngineering

The invention discloses a scissors hand shank preventing the finger from being abraded. The scissors hand shank preventing the finger from being abraded is structurally composed of a scissors hand shank body and an anti-wear ring. The inner side of the hand shank body protrudes to the inner side and is inlaid in an outer groove of the anti-wear ring. Graphite is sprayed onto two contact surfaces to achieve the lubrication effect. The hand shank body and the anti-wear ring can rotate freely and relatively. The inner side of the anti-wear ring is coated with a layer of rubber. When the finger makes contact with the inner side of the anti-wear ring, the rubber achieves the antiskid effect. The scissors hand shank is simple in mechanical structure and can prevent the finger from being abradedwhen a pair of scissors is used repeatedly for a long time.

Owner:QIQIHAR UNIVERSITY

Dual-damping bicycle frame

InactiveCN109866859AImprove securityRotary folding is easy and convenientFoldable cyclesVehicle frameEngineering

The invention discloses a dual-damping bicycle frame which comprises a frame body; a fixed buckle plate is welded to the top of the frame body; the bottom end of the frame body is rotationally connected with a front support arm and a rear support arm by means of an outer sleeve; the upper end of the frame body is rotationally connected with a front rack and a rear rack by means of the outer sleeve; a handlebar fixing frame is welded on one side of the front frame and one side of the front support arm; a connecting column is arranged in the handlebar fixing frame; a damping spring is arranged at the top end of the connecting column; damping cushions are arranged on two sides of the lower surface of the connecting column; an inner sleeve is arranged on one side of the outer sleeve, and is connected with a front sealing plate in a buckling manner by means of a press-fit gasket; an embedded backing ring is arranged on the other side of the outer sleeve; and a rear sealing plate is arrangedon one side of the embedded backing ring. The bicycle frame is simple and reasonable in integral structure and design, small in size, convenient to carry and transport, firm and durable, and convenient to fold, and has high practicability.

Owner:任冰

A control system and control method for a gantry truss robot

ActiveCN106315413BStable and safe operation statusPrevent wear and tearProgramme-controlled manipulatorLoad-engaging elementsControl systemRobot control system

The invention discloses a control system for a gantry truss robot. The control system for the gantry truss robot comprises a machine body, an X shaft, a command processing module and a command positioning module. A display screen is mounted on the front surface of the machine body. The X shaft is mounted on the right side of the machine body. A Y shaft is mounted on the right side of the X shaft. A shaft spacer is mounted below the Y shaft. A Z shaft is mounted above the machine body. A controller is mounted above the Z shaft. The input end of the command positioning module is electrically connected with the output end of an initial command module and the output end of an external input module. The output end of the command positioning module is electrically connected with the input end of a command drive module. The output end of the command processing module is electrically connected with the input end of a command recovery module. The invention further provides a control method for the control system for the gantry truss robot. The mounted machine body is of a stainless steel corrosion-resisting structure, so that the machine body can be kept in the stable and safe operation state for a long time, meanwhile excessive use wear to the machine body is avoided, and thus the service life of the system is prolonged.

Owner:宁夏巨能机器人股份有限公司

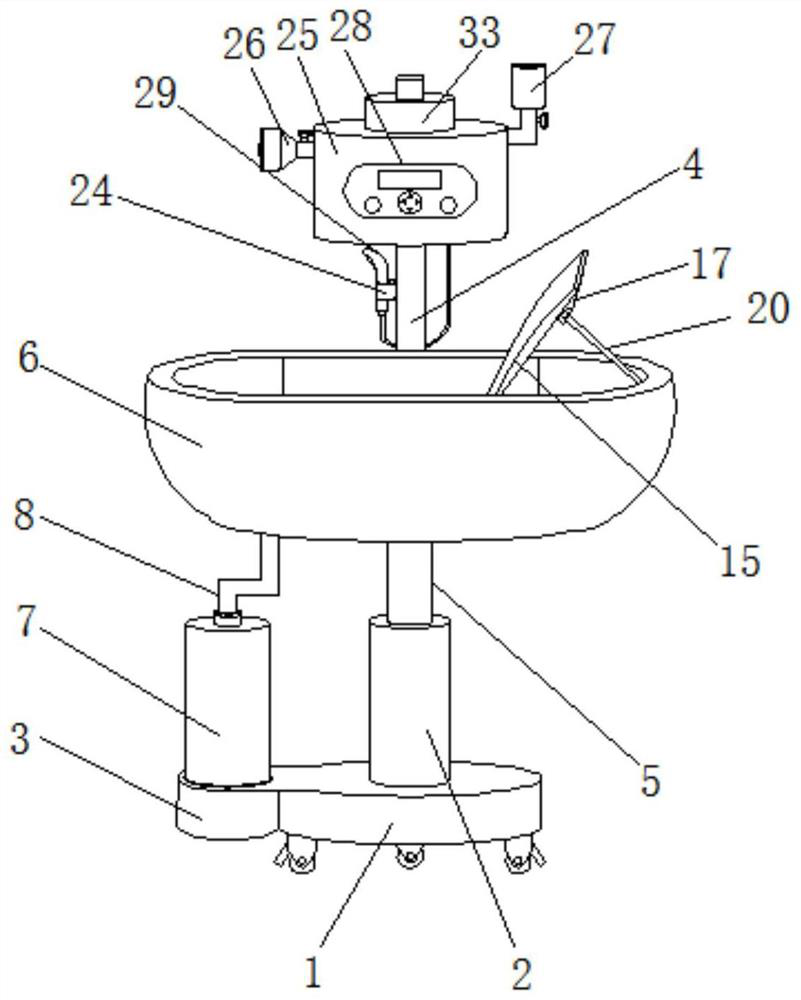

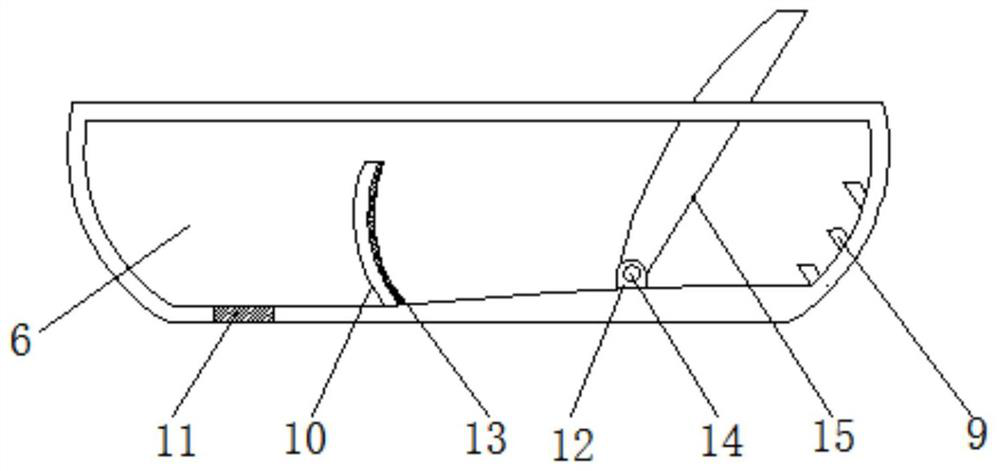

Pediatric nursing anus cleaner convenient to use

InactiveCN113018561AEasy to useReduce occupancyCannulasEnemata/irrigatorsPediatric nursingNursing care

A Pediatric nursing anus cleaner convenient to use, disclosed in the invention,structurally comprises a fixing seat, an electric push rod, a containing frame and a supporting rod are arranged on the fixing seat, the electric push rod is fixedly connected with the middle of the upper end of the fixing seat through a screw, the containing frame is welded to the left end of the fixing seat, the lower end of the supporting rod is fixedly connected with the back face of the fixing base through a screw, and the electric push rod is connected with a cleaning basin through a push rod. A waste liquid collecting barrel is arranged in the containing frame, and a liquid guide pipe is arranged at the upper end of the waste liquid collecting barrel. The anus cleaner can be conveniently used at different positions, the using range of the anus cleaner is enlarged, the space occupied by the anus cleaner is reduced, the height of the cleaner can be adjusted according to the height of medical staff, the phenomenon that medical staff bend down or are not enough in height when cleaning the anus of the baby is avoided, and the flexibility of the anus cleaner in the using process is improved.

Owner:习子林

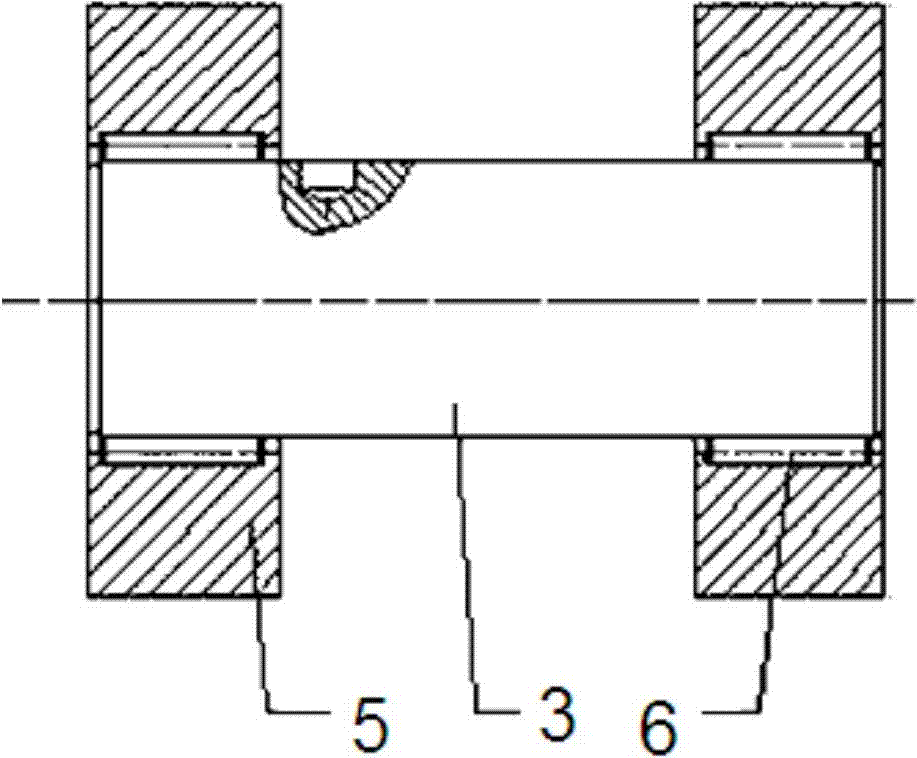

Internal roller of marking machine

InactiveCN104747589AExtended service lifeEasy assembly, disassembly and maintenanceShaft and bearingsBall bearingPulp and paper industry

The invention relates to an internal roller of a marking machine, which coats a pin shaft. The roller comprises a roller body and a ball bearing, wherein the roller body is arranged on the pin shaft through the ball bearing. Compared with the prior art, the internal roller of the marking machine has such advantages as long service life and convenience for disassembly and maintenance.

Owner:SHANGHAI ANDELAI AUTO PARTS

A kind of stud nut pre-embedded sleeve and pre-embedded method

The invention discloses an embedding sleeve of a stud and a nut. The embedding sleeve comprises a shell, an inner sleeve and a nut loop, wherein the outer shell is provided with an inner cavity, a boss is arranged on one end of the inner cavity, the inner sleeve is in threaded connection with the inner cavity, and pushes against the boss, the inner sleeve is internally provided with internal threads matched with external threads of the stud, a connector butted with a driving end is arranged on one end, close to the boss, of the outer shell, the nut loop sleeves one end, far away from the boss, of the inner cavity, and a limiting assembly for limiting one-way rotation of the nut loop is arranged between the outer shell and the nut loop. The invention further correspondingly discloses an embedding method of the stud and the nut, in which the embedding sleeve is adopted for synchronously assembling the nut and the stud. The embedding sleeve and the embedding method have the advantages that operation is simple and convenient, the nut and the stud can be rapidly and synchronously assembled, and the like.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

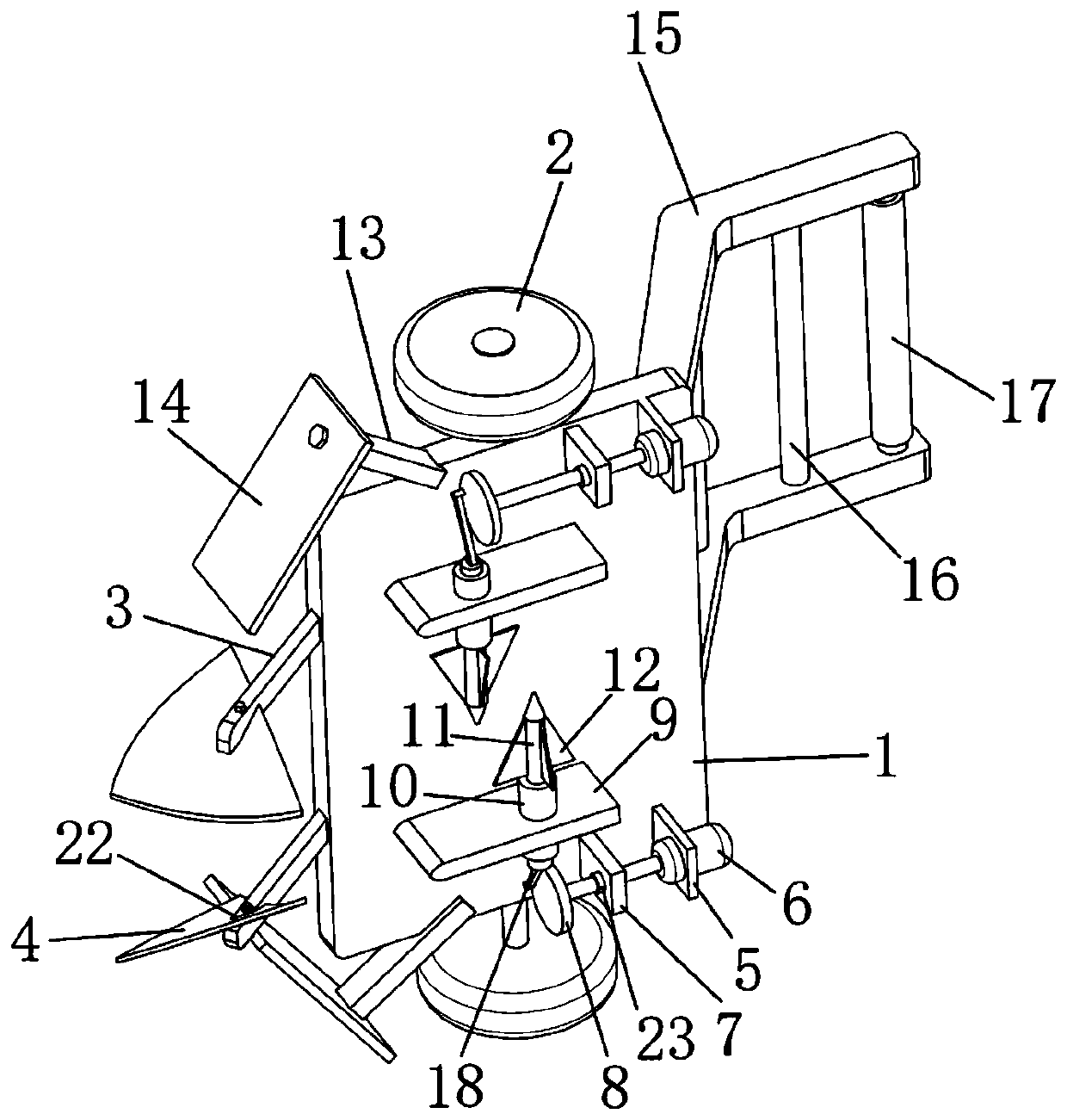

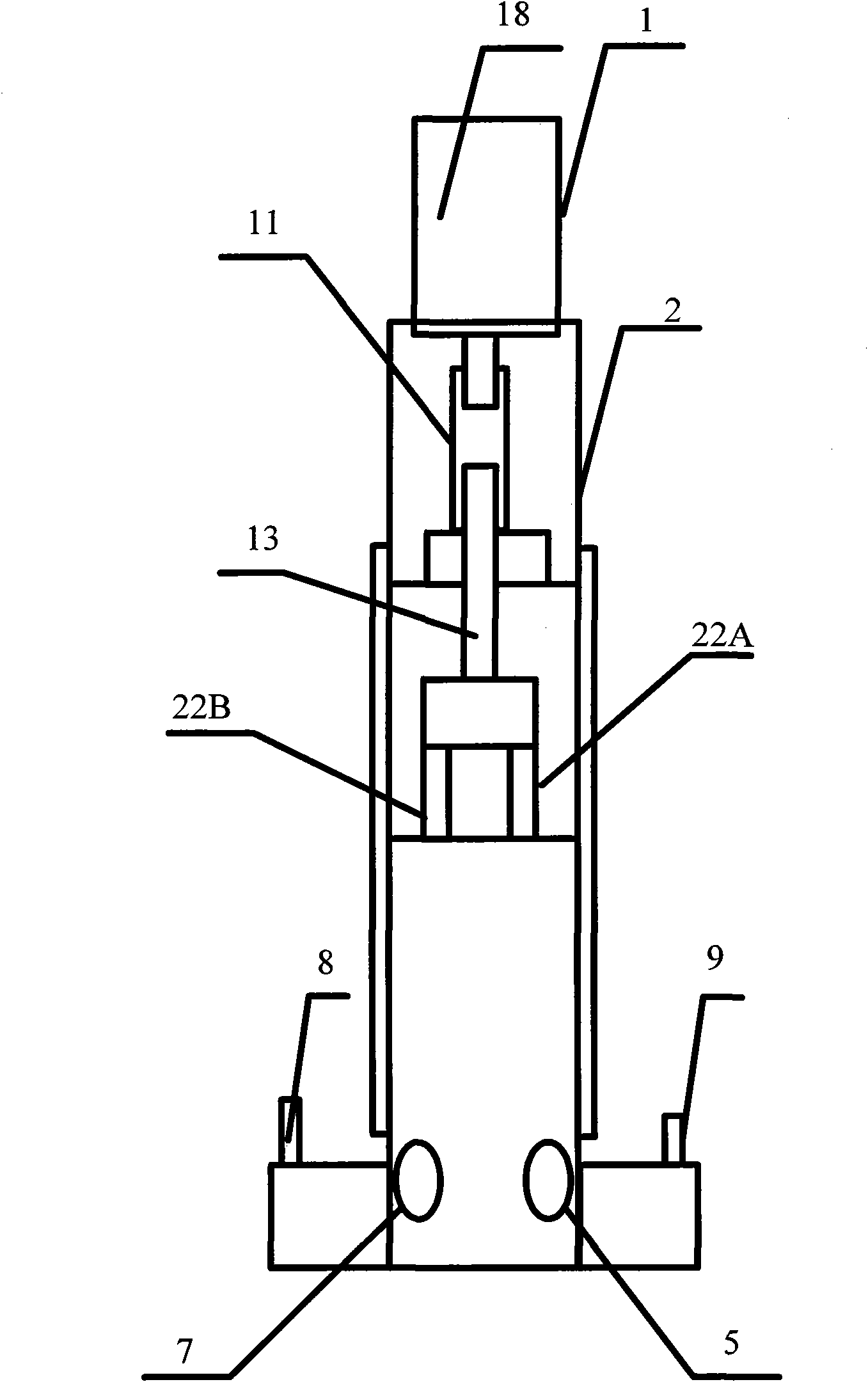

Four ram coiled tubing sealer

The invention relates to a four-ram coiled tubing sealer. The technical solution is: including the main shell and the hydraulic cylinder, install the full sealing device, the shearing device, the suspension device and the semi-sealing device in the inner cavity of the main shell from top to bottom. When sealing the well, close the bracket through the gate The seal carrier is supported on the lower end surface of the upper joint by the return spring and the return spring to realize the seal; during the workover, the piston group is driven down by hydraulically driving the ram, and the seal carrier is pushed away, and further pressed down, so that the seal carrier rotates around the ram shaft , the coiled tubing can be run downhole along the inner cavity of the upper joint. The beneficial effect of the present invention is: because the whole seal is a vertical structure, that is, at least one double wing is removed, the working space is expanded, and the personal trauma accidents in the working are greatly reduced; the weight of the whole device is also greatly reduced, In this way, the difficulty in the operation reduces the processing cost, and it is safer and more reliable than the original 4FZ blowout preventer, more convenient to use, lower in processing cost and lighter in weight.

Owner:DAQING DANFENG PETROLEUM TECH DEV CO LTD

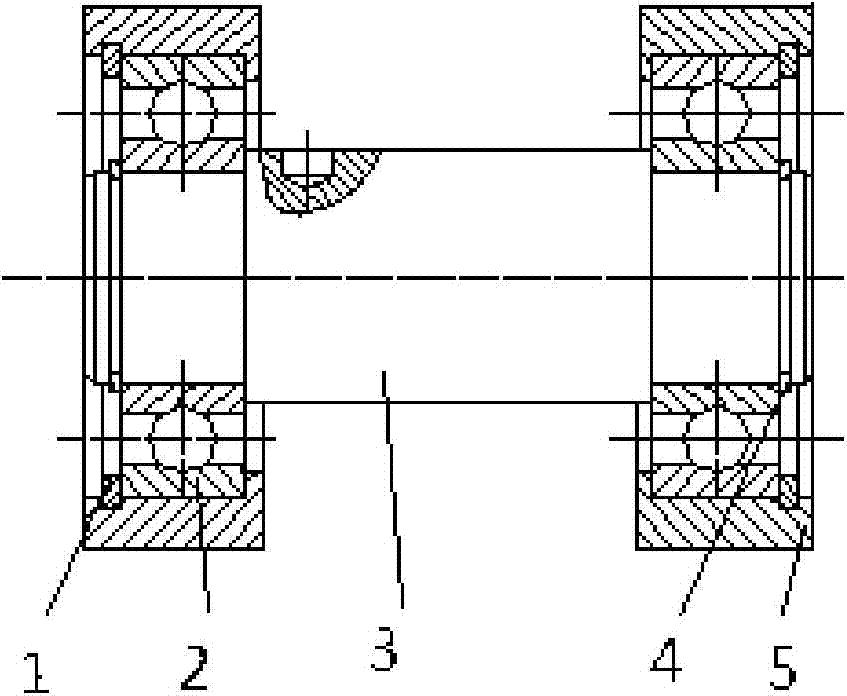

Vehicle synchronizer assembly and vehicle

ActiveCN112392868AAvoid teethingPrevent wear and tearMechanical actuated clutchesGearing controlAutomotive engineeringMechanical engineering

The invention provides a vehicle synchronizer assembly and a vehicle. The vehicle synchronizer assembly comprises a gear hub sleeving a working shaft of a vehicle, a gear sleeve sleeving the gear huband at least one hydraulic rod device arranged in the circumferential direction of a shifting fork groove of the gear sleeve and spaced from the shifting fork groove. Each hydraulic rod device comprises a hydraulic rod and a driving mechanism for driving the hydraulic rods to reciprocate between a working state of being clamped in the shifting fork groove and a non-working state of exiting from the shifting fork groove. The driving mechanisms are configured to drive the hydraulic rods to be in the working state to prevent the gear sleeve from being connected with the gear-position gear when the rotating speed of the working shaft is different from the rotating speed of the gear-position gear to be connected with the gear sleeve, and when the rotating speed of the working shaft is the sameas that of the gear-position gear, the hydraulic rods are driven to be in the non-working state to enable the gear sleeve to be connected with the gear-position gear. According to the scheme of the vehicle synchronizer assembly, the technical problem of incomplete meshing after gear engagement due to the fact that the locking angles of the gear sleeve and joint gears are abraded is solved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +4

Auxiliary taking handle equipment for medicine pot with straight handle

ActiveCN109044832AReduced direct transfer of heatPrevent wear and tearPharmaceutical product form changeThermal insulationEngineering

The invention relates to the technical field of medicine pot auxiliary equipment, and discloses auxiliary taking handle equipment for a medicine pot with a straight handle. The equipment comprises a cylinder body, a flexible glue cylinder matched with the shape of the inner side wall of the cylinder body is arranged on the inner side of the cylinder body, and the top side surface of the flexible glue cylinder is mutually and fixedly connected with the top of the inner side of the cylinder body, the bottom surface of the flexible glue cylinder and the bottom of the inner side of the cylinder body through bonding layers; a thermal insulation layer piece is connected with the inner side of the flexible glue cylinder, an opening of the top of the cylinder body is in a taper shape sinking inward, a taper protective sleeve adheres to the surface of the top of the cylinder body, and arc elastic pressing pieces are fixedly connected to the tops of the left and right inner side walls of the cylinder body. According to the auxiliary taking handle equipment for the medicine pot with the straight handle, by arranging the flexible glue cylinder, the arc elastic pressing pieces, a hinged movablepiece and a second pressing piece, the length of the heat conduction is extended, the area of heat conduction is reduced, and therefore the purpose of achieving thermal insulation and scald prevention on the cylinder body is achieved.

Owner:山东酷品智能科技有限公司

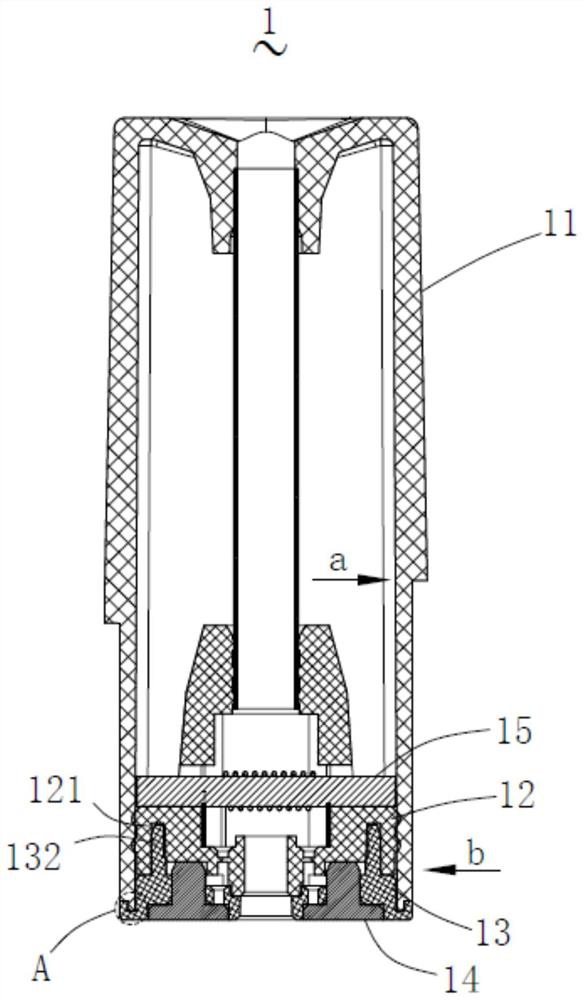

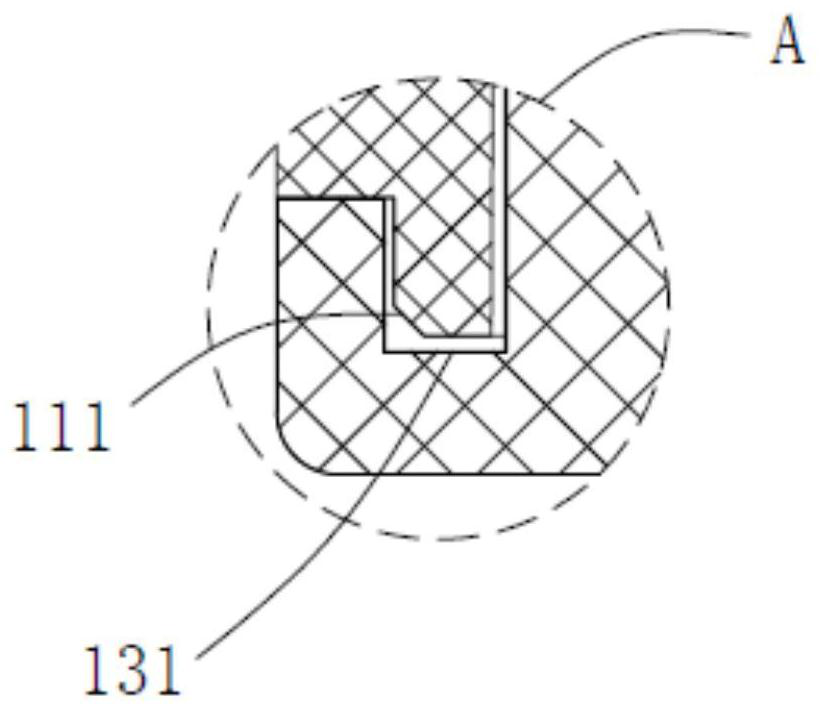

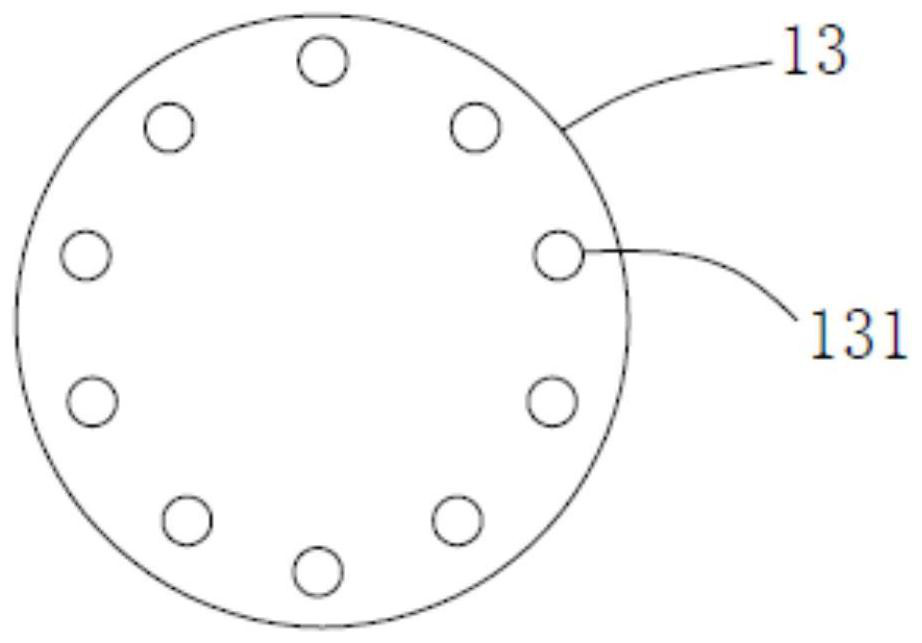

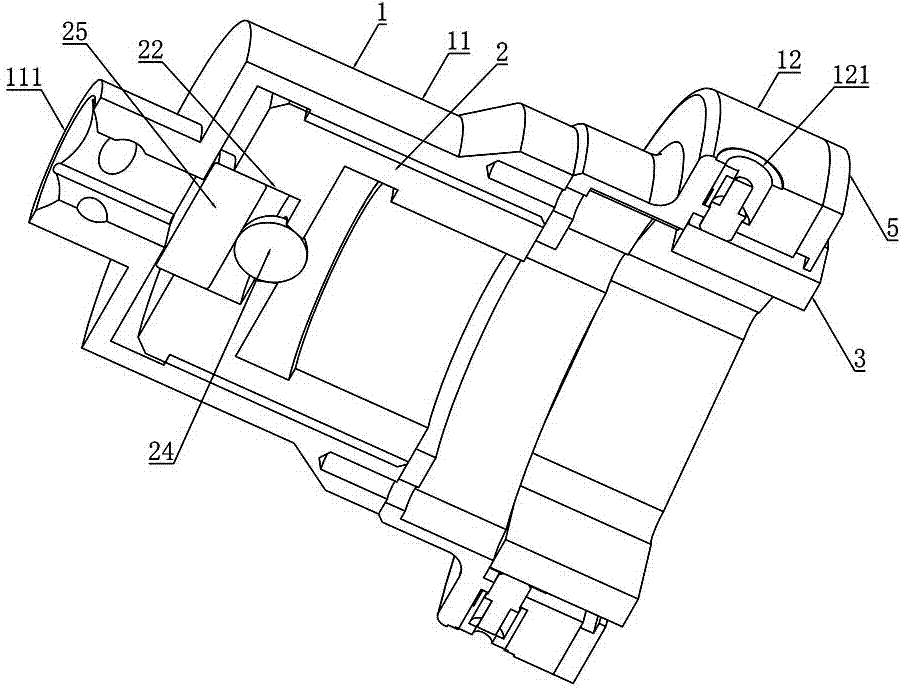

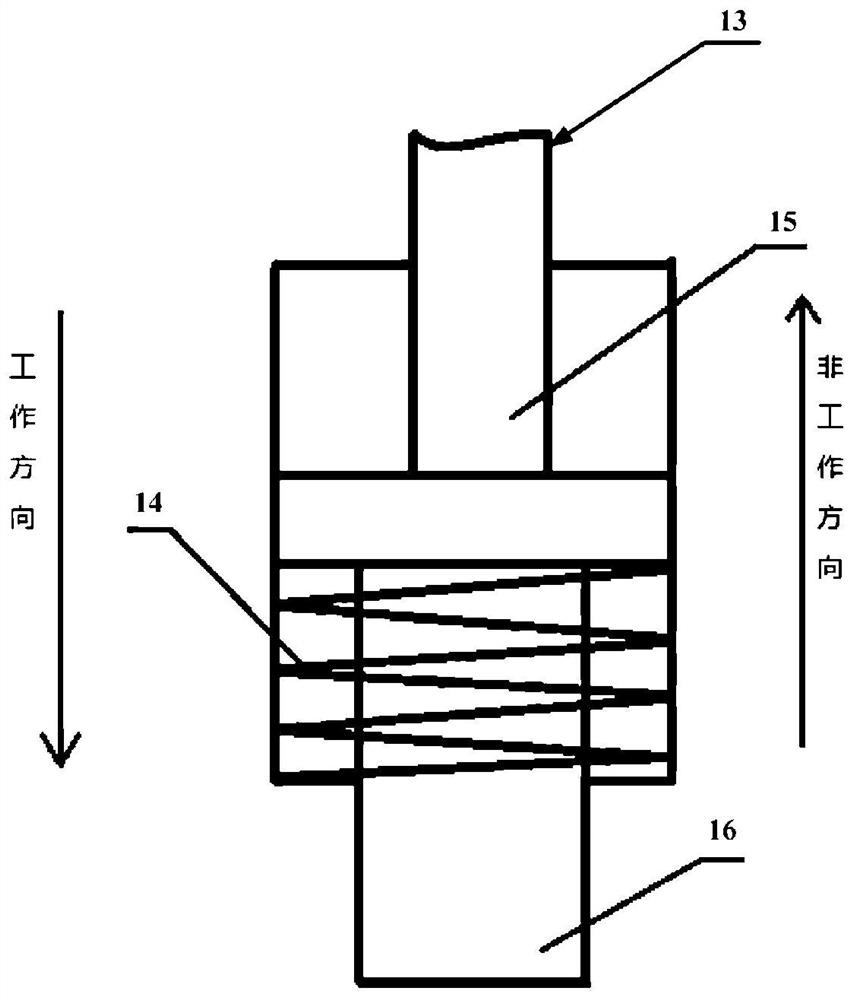

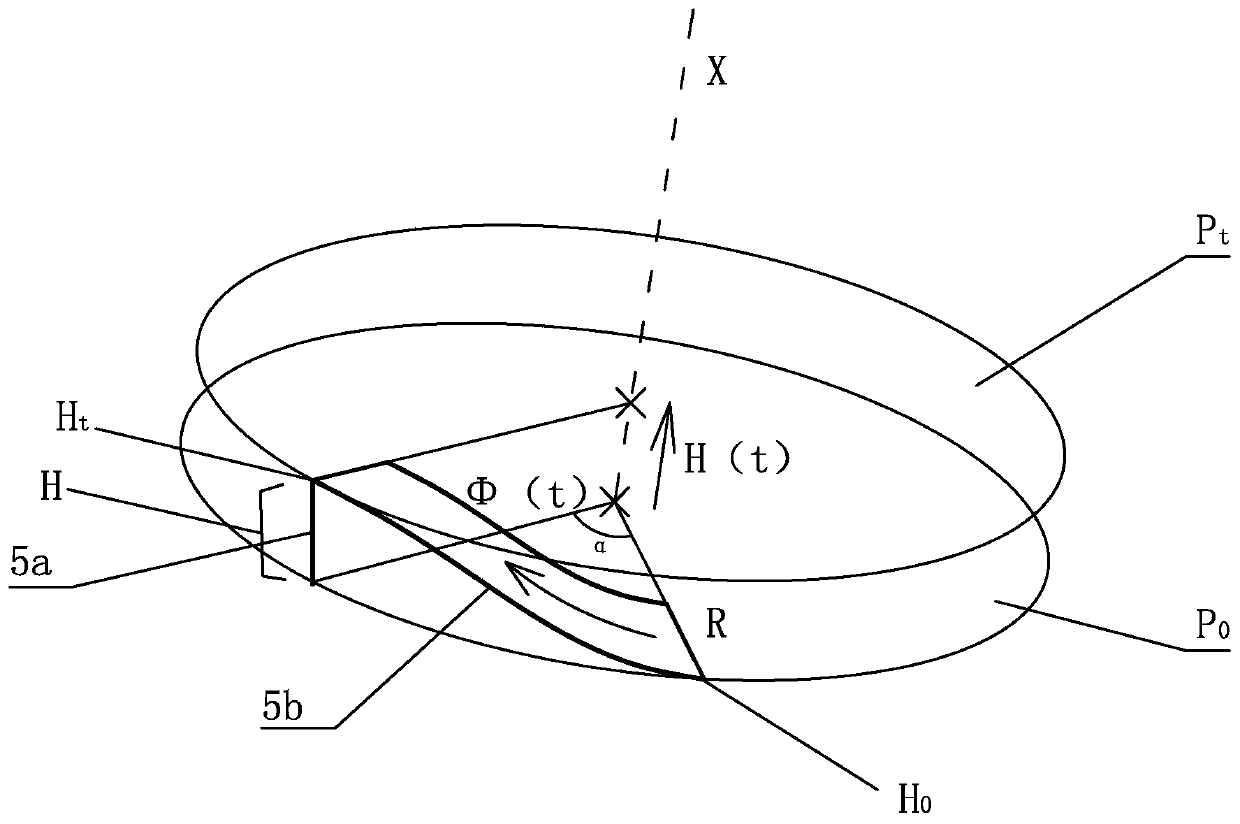

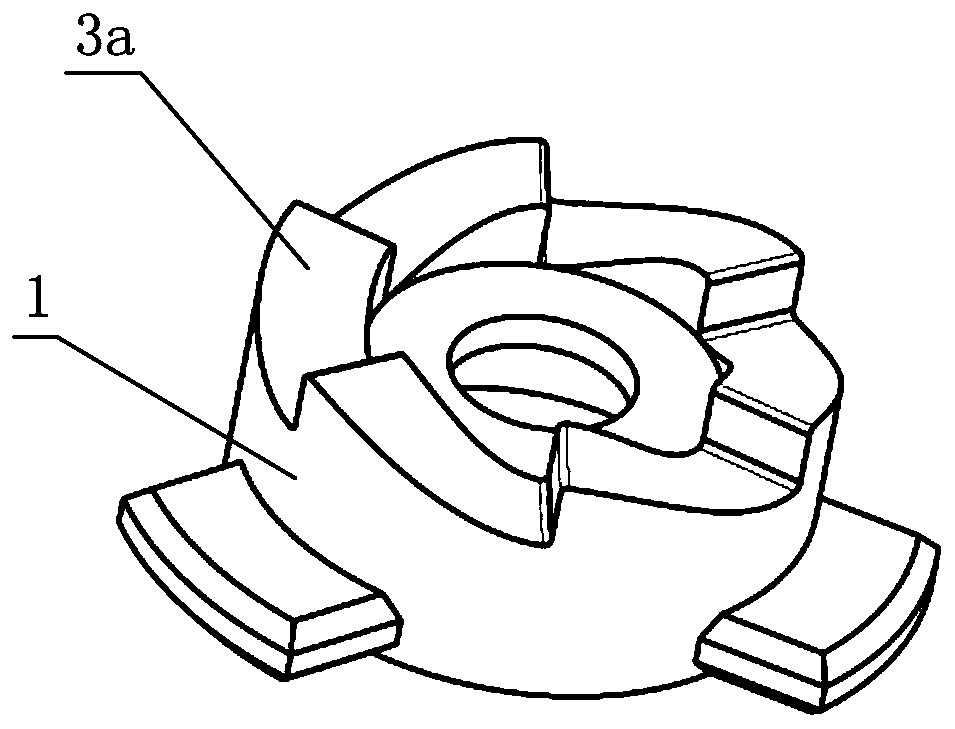

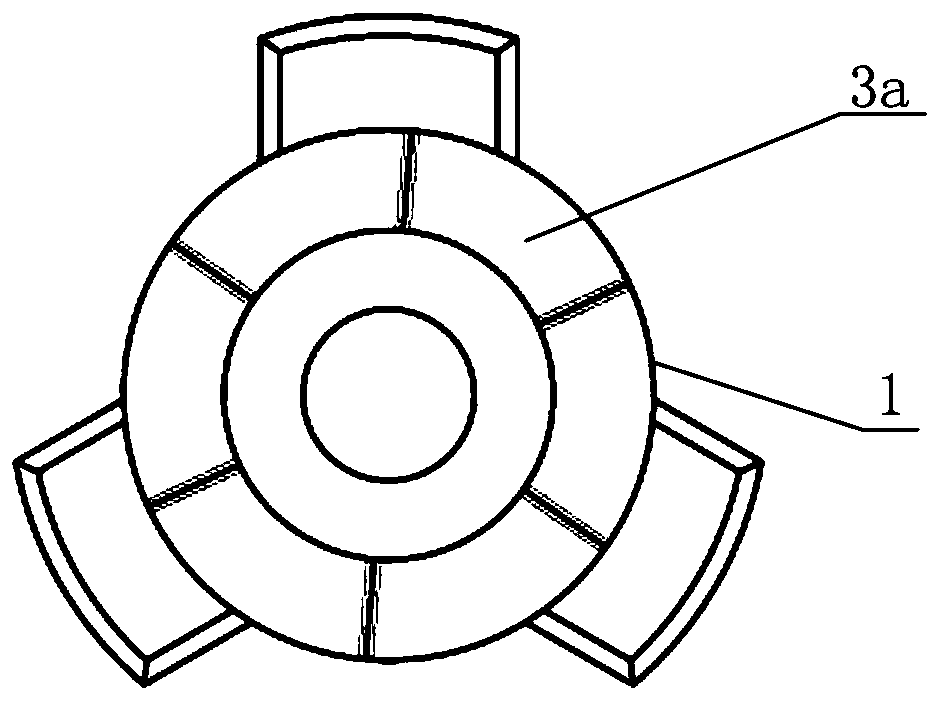

Coaxial vibration gear used for vibration drug supply unit of reservoir-type dry powder inhalation drug supply device

ActiveCN110464930ADifferent vibration effectsImprove powder flowabilityInhalatorsRelative displacementCircular disc

The invention relates to a coaxial vibration gear used for a vibration drug supply unit of a reservoir-type dry powder inhalation drug supply device, and belongs to the field of inhalation type drug supply devices. A first gear and a second gear are in a circular-disc shape; vibrating teeth of the first gear and vibrating teeth of the second gear are opposite to each other; according to tooth shapes of the vibrating teeth, first sides are a vertical straight surface, and second sides are an inclined surface, a curved surface or the combination of the inclined surface and the curved surface; and the first gear and the second gear have a relative rotation relationship in the working state. When first gear and the second gear are relatively rotated to the helical tooth surface, the first gearand the second gear slide in the axial direction from the first position to the second position to generate relative displacement, and the relative displacement becomes zero at the moment of relativerotation to the straight tooth surface, so that relative vibration is produced between the first gear and the second gear. The vibration gears can be prevented from being worn and stuck, and the service life of the vibration gears can be significantly prolonged, so that the service life of the entire drug supply device is effectively prolonged, and the coaxial vibration gear used for the vibration drug supply unit of the reservoir-type dry powder inhalation drug supply device can be widely used in the field of designing and manufacturing of the vibration drug supply unit of the reservoir-typedry powder inhalation drug supply device

Owner:SHANGHAI SINE YELLOW RIVER PHARMA CO LTD

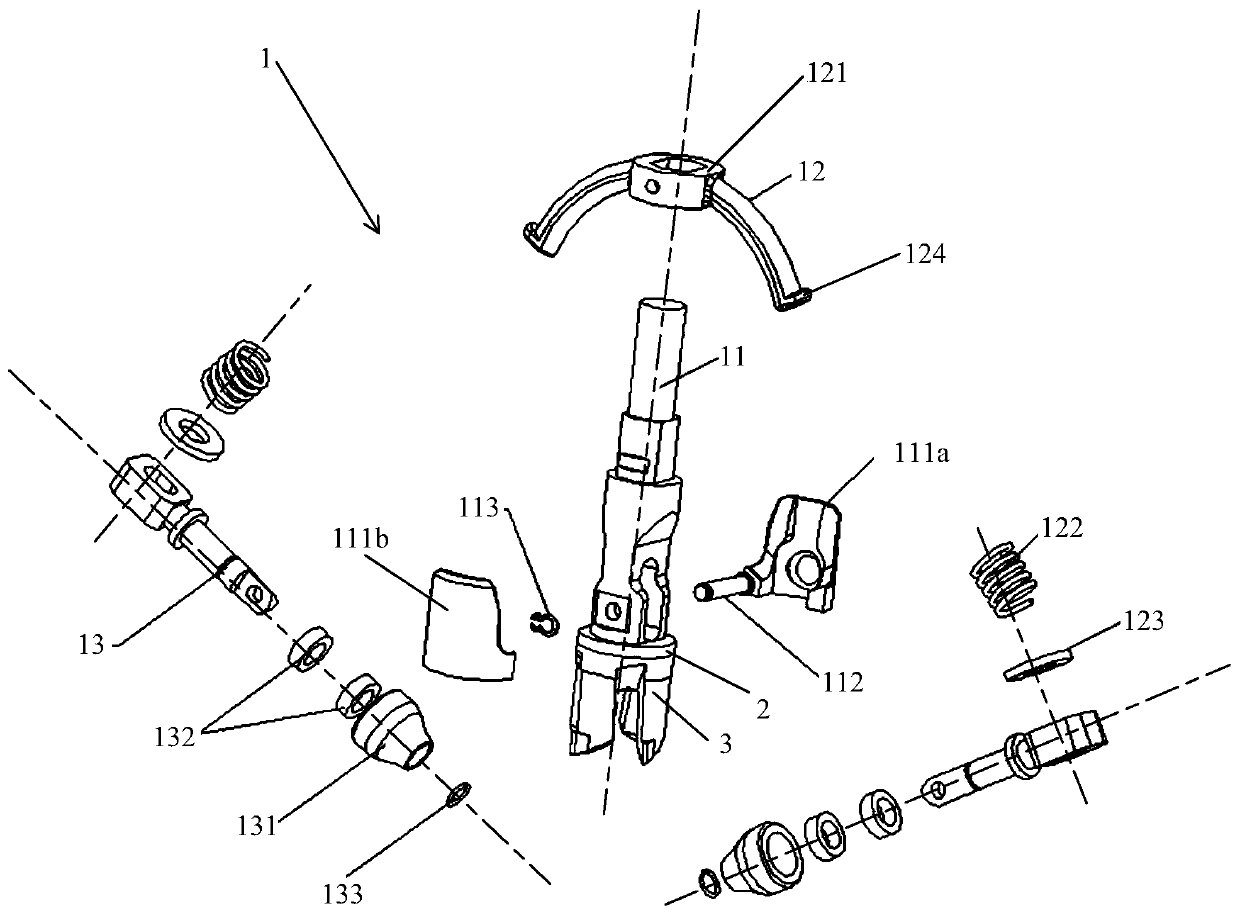

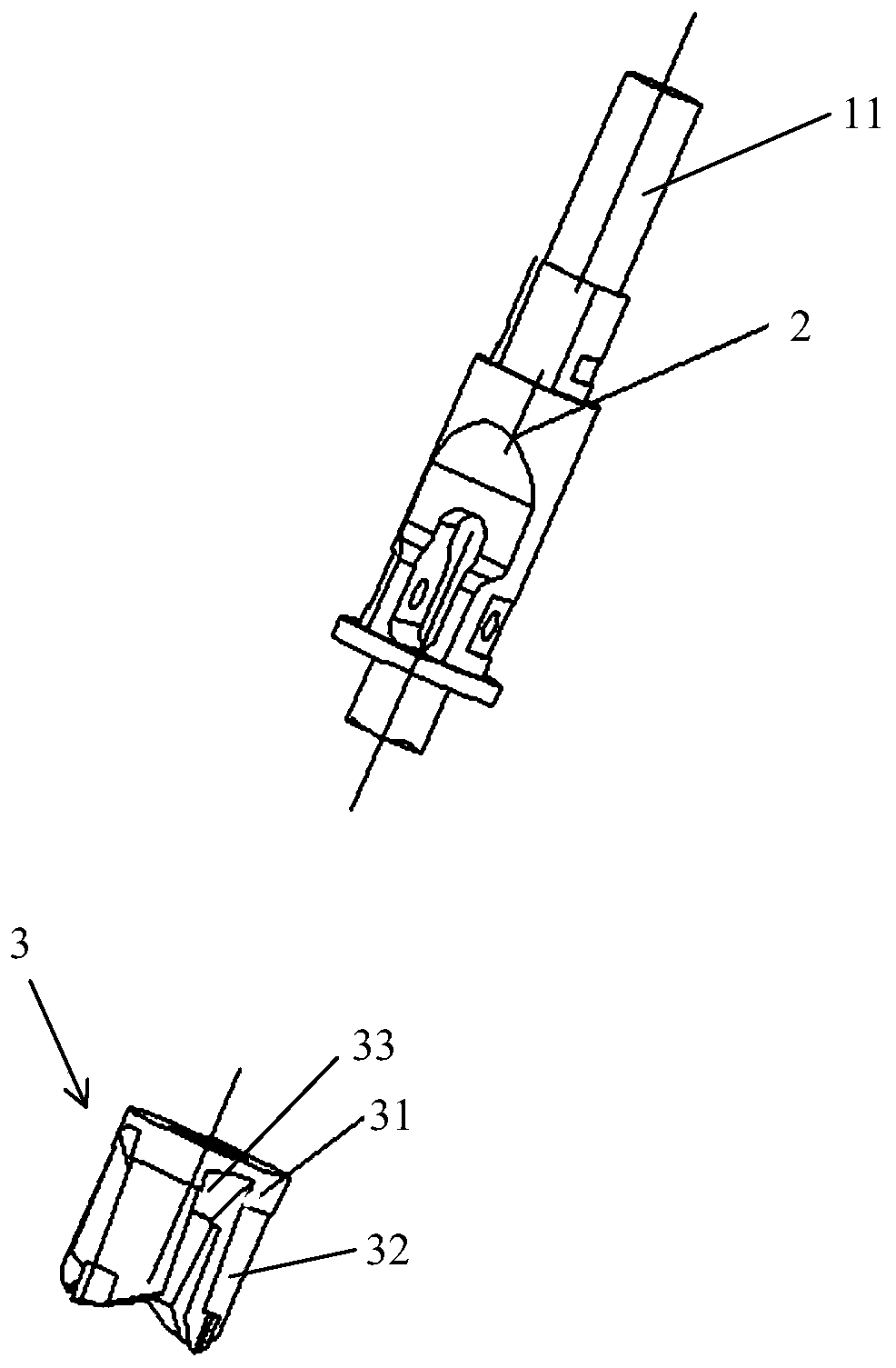

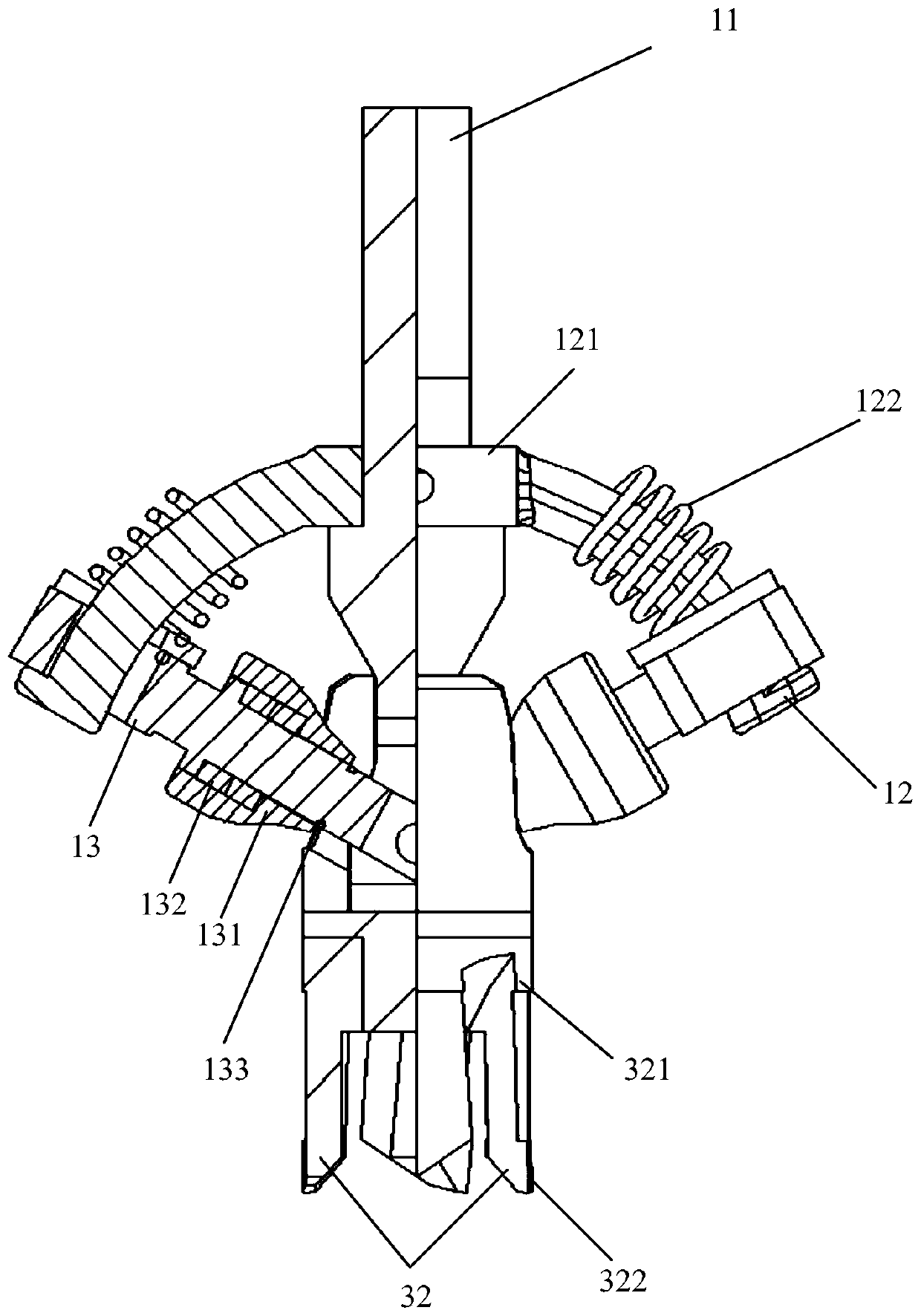

Drilling tool and drilling device

The invention relates to a drilling tool and a drilling device. The drilling tool comprises a tool body, a tool handle connected with the tool body and a chamfering device, wherein the chamfering device comprises a guide shaft, a transmission positioning main shaft and pin rollers; the guide shaft is an arc-shaped piece with a through hole formed in the middle; the upper end of the transmission positioning main shaft penetrates through the through hole; the lower end of the transmission positioning main shaft is connected with one ends of the two symmetrically-distributed pin rollers in a pivoted mode; and the other ends of the two pin rollers are connected with the arc-shaped sections, positioned on the two sides of the through hole, of the guide shaft in a sliding mode correspondingly. According to the drilling tool and the drilling device, the chamfering device, the tool handle and the tool body are organically combined together, drilling and R angle pressing are synchronously conducted, drilling and R angle pressing can be completed only through one device, the production cost is greatly reduced, and the production efficiency is improved.

Owner:YANFENG PLASTIC OMNIUM AUTOMOTIVE EXTERIOR SYST

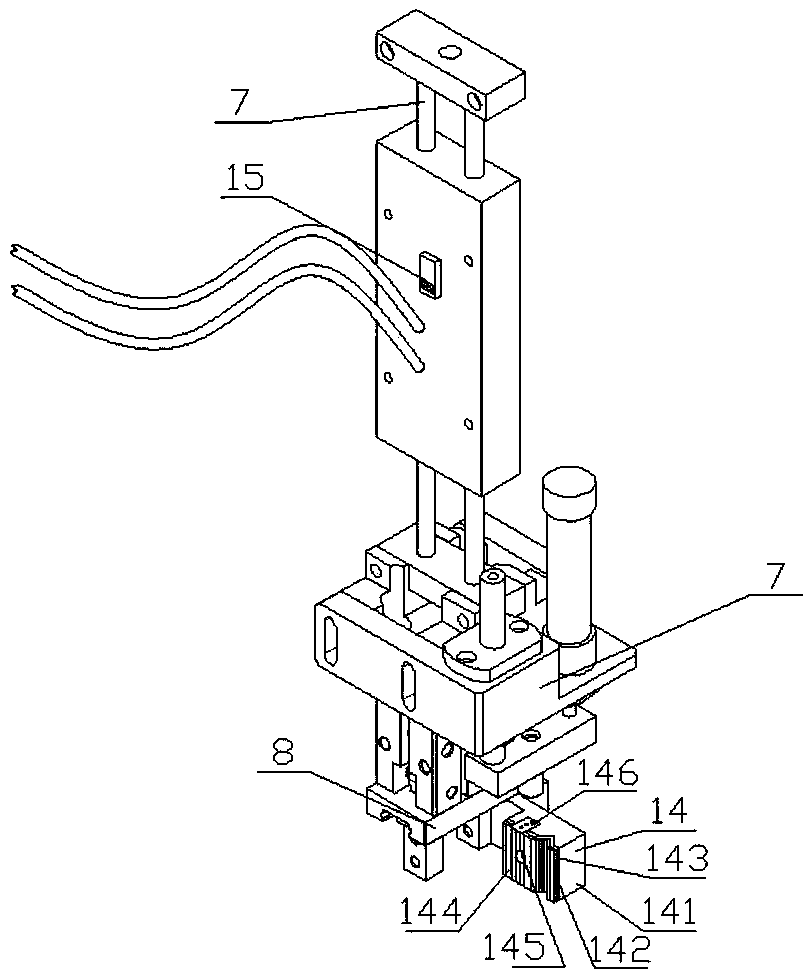

A novel screw driving device and a preparation method thereof

PendingCN109194019AReduce wearSmall footprintMechanical energy handlingBuilding liftsControl theoryMotor shaft

The invention provides a novel screw driving device, comprising: a motor assembly, a screw, an upper nut and a lower nut; a motor assembly includes a motor housing, a motor stator, a magnet, a motor rotor, and a screw motor shaft. The screw motor shaft is sleeved outside the screw by a hollow structure. The motor rotor is sleeved outside the screw motor shaft and fixed on the screw motor shaft. The screw motor shaft and the motor rotor rotate synchronously; a magnet steel is sleeve on that rotor of the motor. The stator of the motor is sleeved outside the magnet steel. The motor housing is sleeved outside the motor stator, and the motor housing is fixedly connected with the motor stator; Both ends of the screw motor shaft extend out of the motor housing. The upper nut and the lower nut arerespectively fixed on both ends of the screw motor shaft; and the upper nut and the lower nut are respectively engaged with the screw. The invention has the advantages that the double nuts are directly positioned and the hollow shaft of the motor directly drives the nuts at both ends to run, thereby saving the space occupied by the traction machine, improving the transmission efficiency, reducingthe vibration of the whole machine, reducing the wear caused by the eccentricity of the nuts, and prolonging the service life of the whole machine.

Owner:SHANGHAI FAXI DRIVE TECH

Discharge device of industrial mechanical claw

InactiveCN108792604AAvoid using wear and tearSmart Reminder ReachedConveyor partsLoudspeakerEngineering

The invention discloses a discharge device of an industrial mechanical claw. The discharge device is characterized by structurally comprising a machine body, a reinforcing claw block and an intelligent reminding device. The discharge device of the industrial mechanical claw solves the problems that shaking is caused by material grabbing when wind in regions such as a seaside is strong, the machinebody generates shake as a shaking angle is too great, and the safety influence problem caused by reminding and alarm are not performed; a deviation angle signal is detected by a gyroscope sensor, andis converted into an electric signal by an a / d converter for being sent to a single chip microcomputer; and after a detected deviation angle exceeds 25 degrees, the single chip microcomputer controlsa loudspeaker to emit buzzer reminding. A reinforcing claw block design is designed, so that the problem that later-stage damage and maintenance cost is high as wear damages are caused after long-term use of the inner side surface of the mechanical claw and protection is not performed is solved; surface anti-sliding rubber is used for increasing clamping force of the inner side surface of a clawblock; and moreover, an inner side connecting bolt is fixed with a top fixed plate reinforcing plate and the claw block, so that the reinforcing plate is in direct contact with the top end of a clamped object when the claw block is clamped.

Owner:陈沛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com