Drilling tool and drilling device

A drilling tool and chamfering device technology, which is applied in metal processing and other directions, can solve the problems that drilling and pressing R angle cannot be carried out at the same time, the drilling device is not universal, and the drilling quality is poor, so as to avoid stress wear and Effects of material corrosion, cost reduction, and process reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

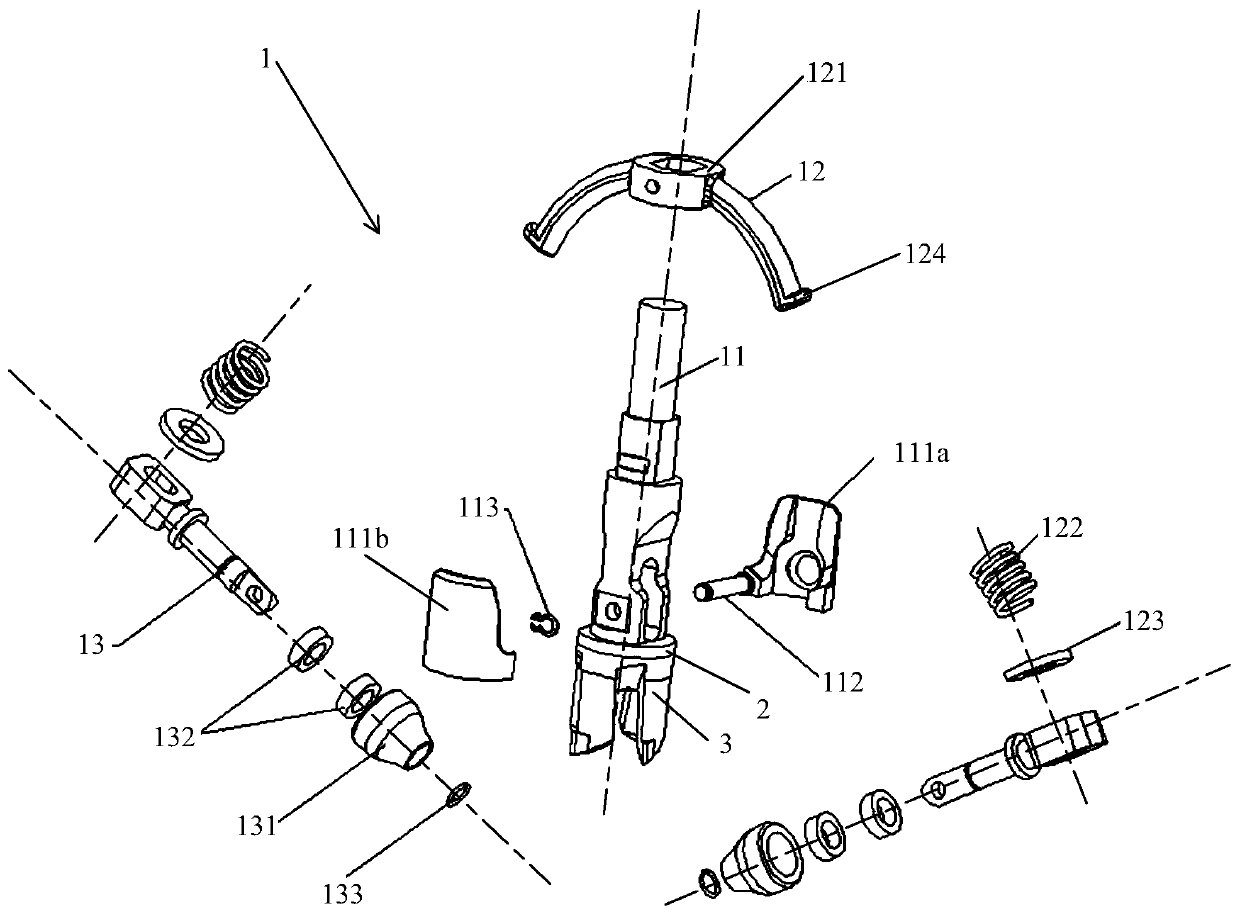

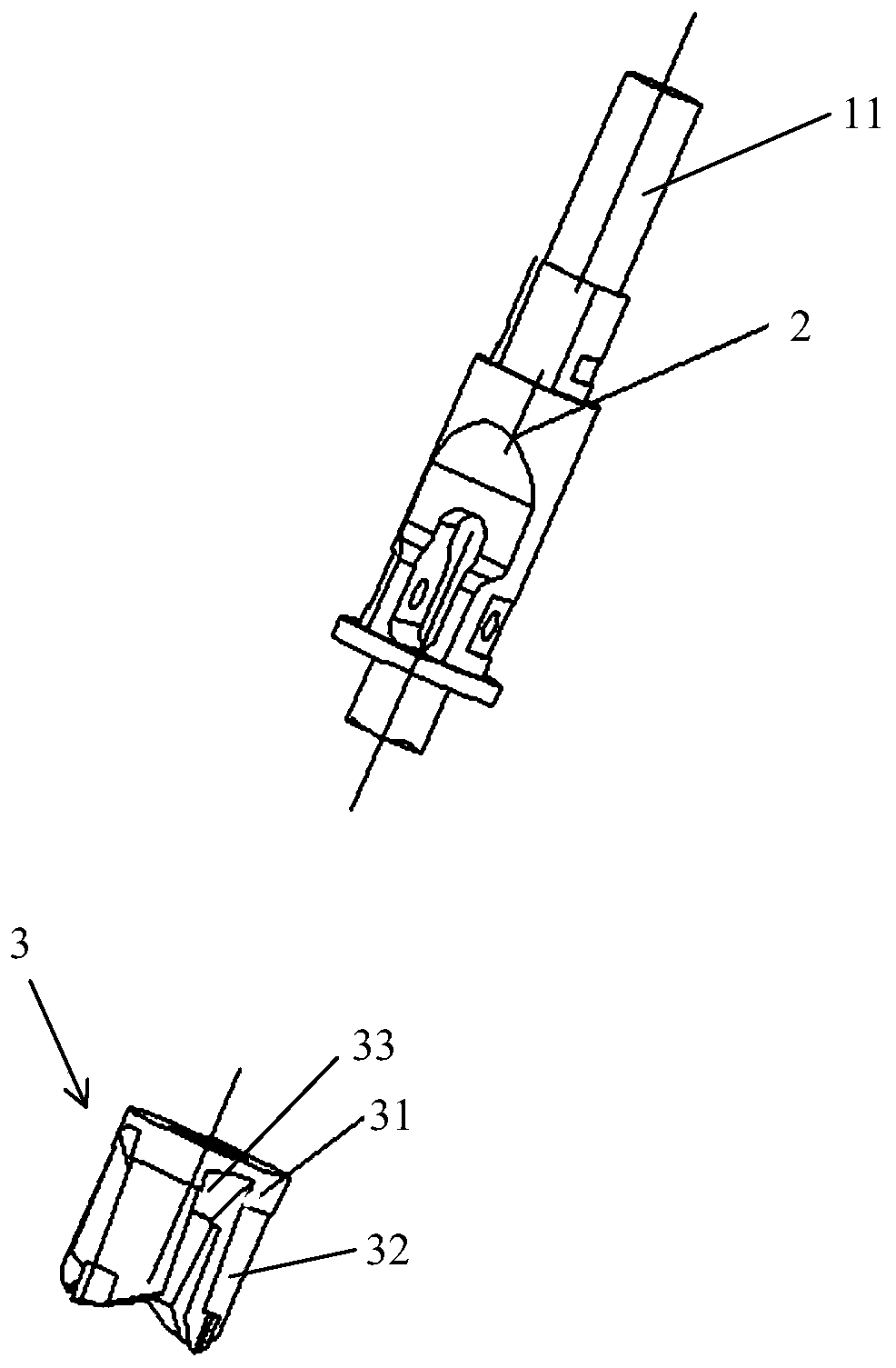

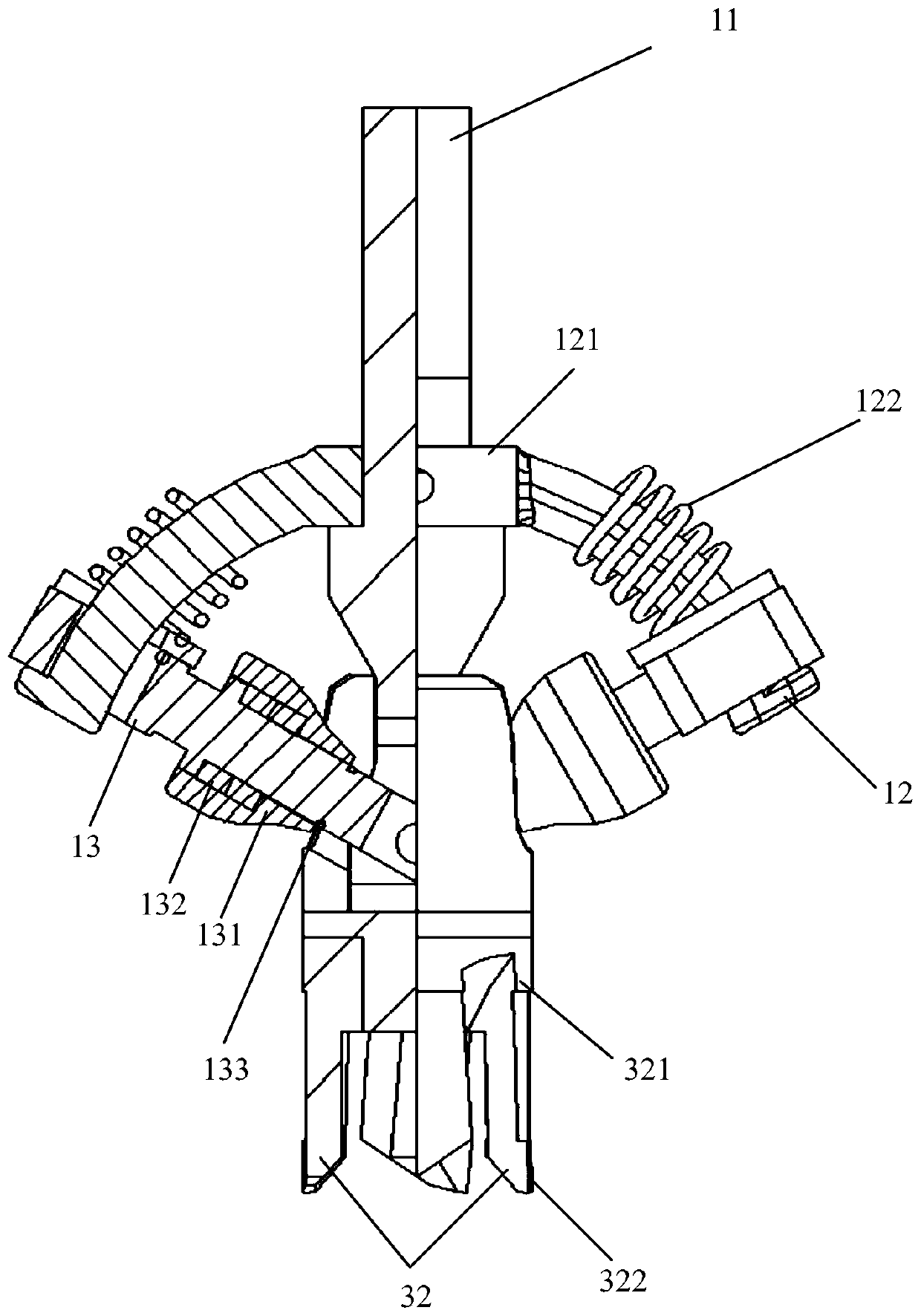

[0052] Such as figure 1 and 2 As shown, the embodiment of the present invention provides a drilling tool, including a chamfering device 1, a handle 2 and a cutter body 3, wherein the chamfering device 1 is used to press the R angle of the product (ie bumper), including a transmission Positioning main shaft 11, guide shaft 12 and roller 13, guide shaft 12 is the arc-shaped structural part that has through hole in the middle part, the upper end of transmission positioning main shaft 11 passes through the middle part through hole of guide shaft 12, and roller 13 is two pairs, two One end of each is pivotally connected to the lower end of the transmission positioning main shaft 11, while the other ends of the two rollers 13 are respectively slidably connected to the arc sections of the guide shaft 12 that are separated on both sides of the through hole. The lower end of the transmission positioning main shaft 11 refers to It is the end away from the through hole of the guide shaf...

Embodiment 2

[0072] This embodiment provides a drilling device, which includes a driving member and the drilling tool as described in Embodiment 1. The driving shaft of the driving member is connected with the transmission and positioning spindle 11 of the drilling tool, and is used to drive the transmission and positioning spindle 11 to rotate. And vertical movement, so as to complete the work of drilling and pressing R angle.

[0073] Specifically, the driving member may be a motor, and the output shaft of the motor is connected with the transmission positioning main shaft 11 to drive its rotation and vertical movement.

[0074] In a feasible implementation, the driving part is a robot, and the mechanical arm of the robot is connected with the transmission positioning spindle 11 to drive its rotation and vertical movement. Meanwhile, the robot can also automatically control the drilling tool, thereby realizing automatic production.

[0075] The drilling device provided in the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com