Sintering mixer cleaning device, rotary thorn roller thereof and thorn roller hanger

A technology for mixers and licker-in rollers, applied in mixers, mixers with rotating stirring devices, transportation and packaging, etc., can solve problems such as poor sealing effect of rotating bearings, failure of adjustment devices, and falling off of hanging devices, etc., to achieve extended The effect of service life, strong combination, and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

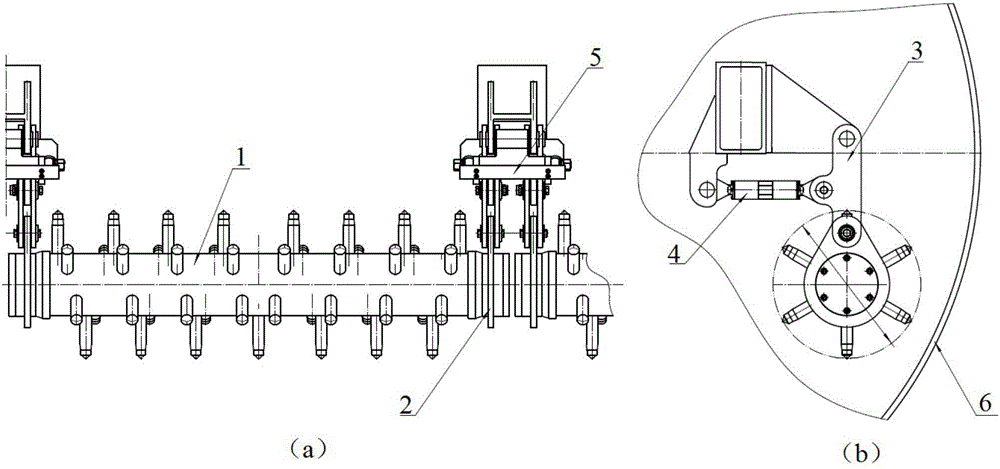

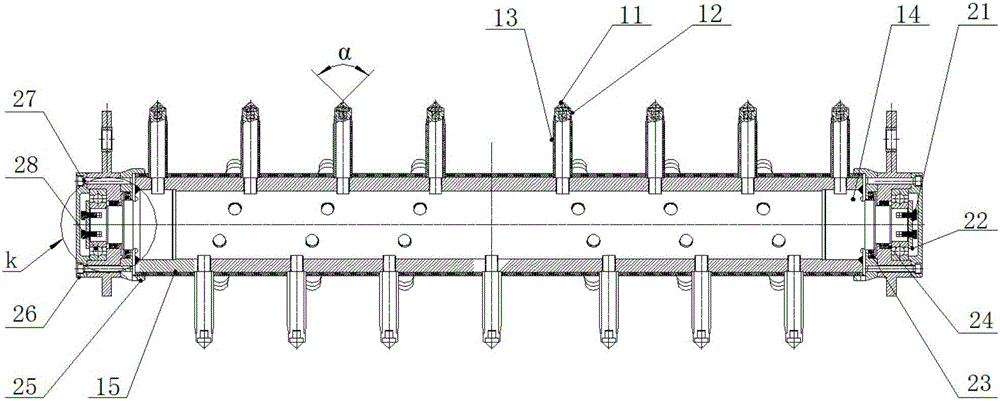

[0051] see figure 1 , figure 2 with image 3 A rotary licker-in roller of a sintering mixer cleaning device in this embodiment includes a licker-in mechanism 1 and a bearing rotation mechanism 2, and the licker-in mechanism 1 includes a licker-in head 11, a licker-in bar 12, and a licker-in bar bushing 13 , licker-in roller 14 and licker-in roller bushing 15. Wherein, the bearing rotating mechanism 2 is arranged at both ends of the licker-in roller 14, the licker-in roller 14 is equipped with a licker-in roller bushing 15 outside, and the licker-in roller 14 is provided with licker-in rods 12 arranged at intervals. In this embodiment, an external thread is provided at the bottom of the licker-in bar 12 , and an internal thread is correspondingly provided in the licker-in roller bushing 15 , so that the bottom of the licker-in rod 12 is connected with the licker-in roller bushing 15 through threads. The threaded connection between the stabbing bar 12 and the licker-in rolle...

Embodiment 2

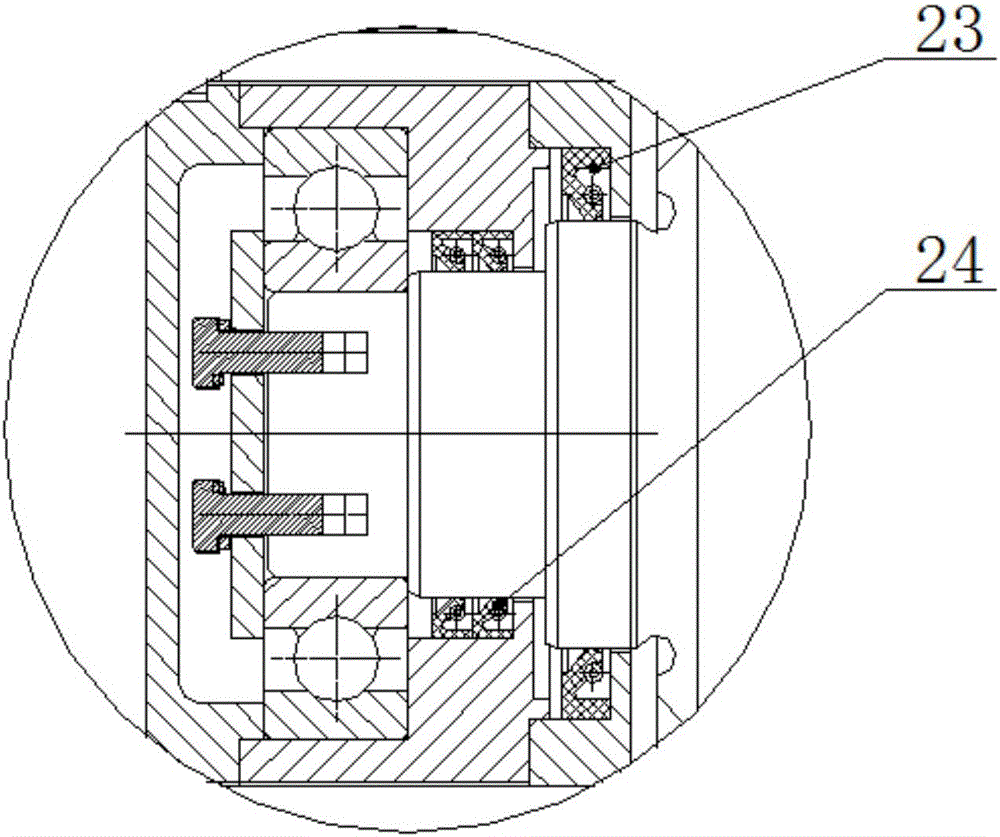

[0058] combine figure 1 , Figure 4 , Figure 5 with Image 6 , the licker-in roller suspension of a sintering mixer cleaning device in this embodiment includes a suspension mechanism 3, an adjustment mechanism 4 and a blind area cleaning mechanism 5, wherein the suspension mechanism 3 includes a suspension support 31, a licker-in roller pendant 33 and the bearing block 34, the hanging support 31 and the licker-in roller hanger 33 are movably connected by pin shafts, the bearing block 34 is used to connect the rotating licker-in roller, and the bearing block 34 and the licker-in roller hanger 33 are connected by a bearing The seat connection assembly 32 is connected.

[0059] The bearing seat connection assembly 32 includes an upper bush 321, a shaft sleeve 322, a lower bush 323, a fixing nut 324 and a second bolt 325. Both the bearing seat 34 and the licker-in roller hanger 33 are provided with hanging ear holes, and the second Bolts 325 pass through the hanging earholes ...

Embodiment 3

[0064] combine figure 1 , a material cleaning device for a sintering mixer in this embodiment, comprising a plurality of rotating licker-in rollers described in embodiment 1 and a plurality of licker-in rollers described in embodiment 2 hanging, two adjacent rotating licker-in rollers pass through the licker-in Roller suspension connection, more specifically, the licker-in mechanism 1 of the cleaning device is supported by the bearing rotation mechanism 2, the licker-in mechanism 1 and the bearing rotation mechanism 2 are jointly supported by the suspension mechanism 3, the licker-in mechanism 1 and the cylinder The distance between the internal walls is supported and adjusted by the adjustment mechanism 4 , the material cleaning mechanism 5 in the blind area is installed between the two licker-in roller mechanisms 1 , and the entire material cleaning device is installed in the barrel 6 of the mixer. The material cleaning device of the sintering mixer in this embodiment can wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com