Aggregate drying drum and drying method for dry-mixed mortar production line

A dry-mixed mortar and production line technology, applied in drying, drying machines, drying solid materials, etc., can solve the problems of large chain operation noise, poor blade lifting effect, material strip wear on the cylinder wall, etc., to reduce energy consumption , Improve thermal efficiency, avoid the effect of sticking materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments.

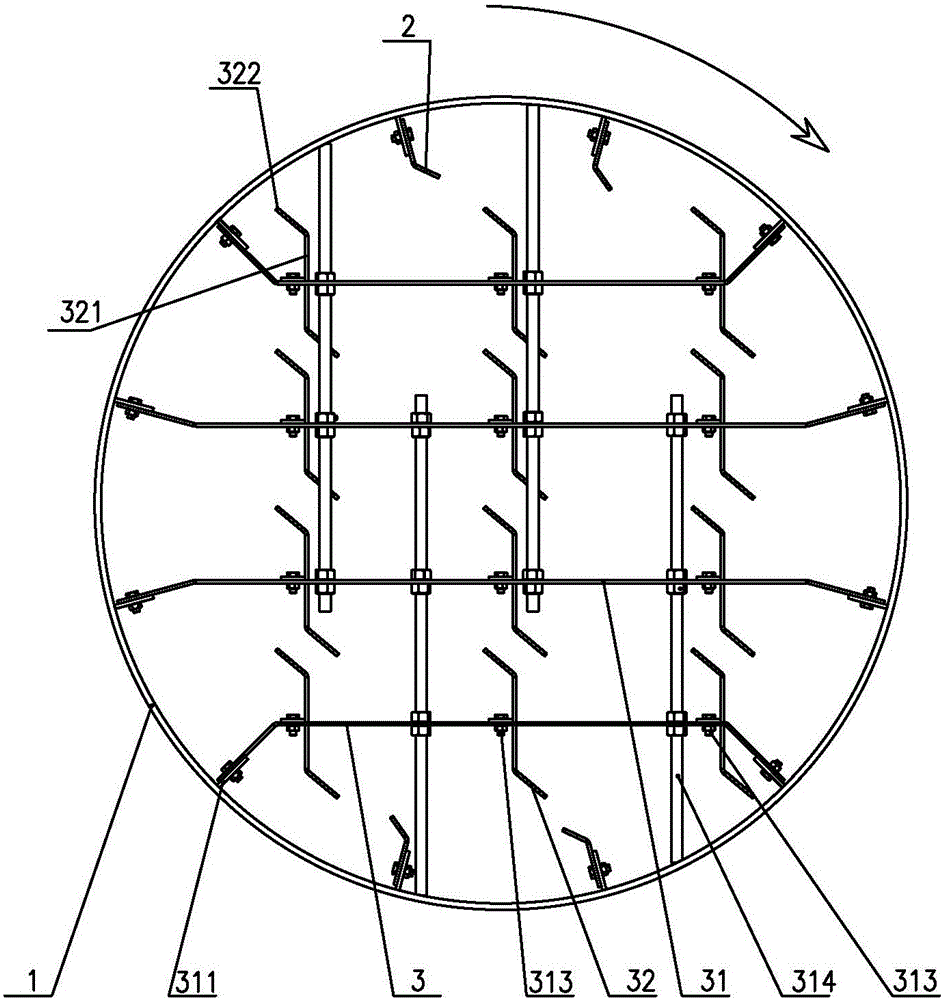

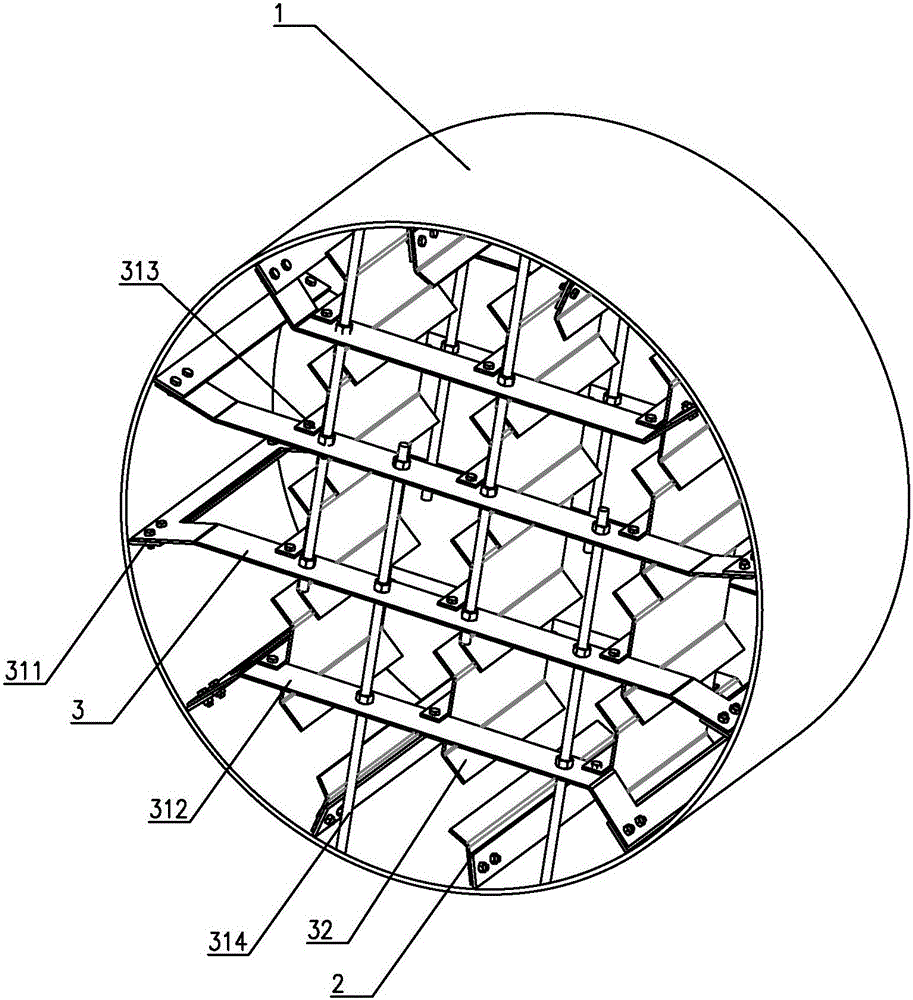

[0026] refer to Figure 1 to Figure 4 As shown, an aggregate drying drum used in a dry-mixed mortar production line includes a rotating cylinder 1, poplar blades 2, and an aggregate breaking device 3;

[0027] The two ends of the rotating cylinder 1 are the screw inlet and the outlet respectively;

[0028] The poplar blade 2 is a bent blade arranged on the inner wall of the rotating cylinder 1;

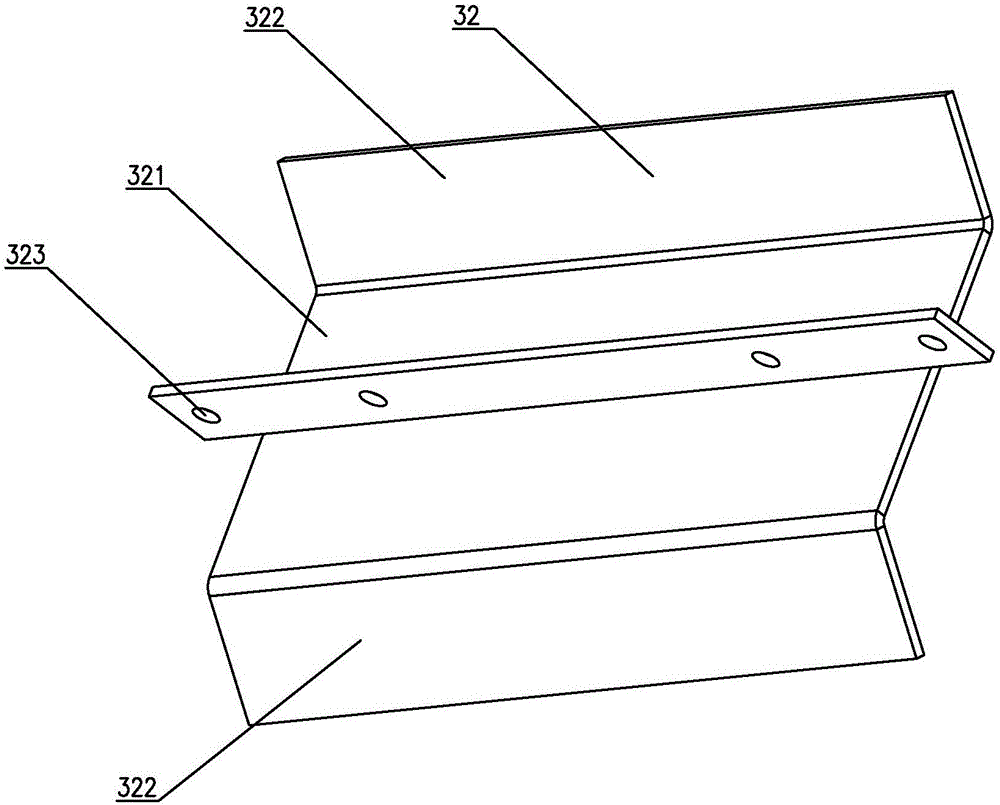

[0029] The aggregate breaking device 3 is arranged on the circumferential section of the rotating cylinder 1 and connected to the screw feed inlet. The aggregate breaking device 3 includes a support assembly 31 and a number of bending blades 32. The bending blades 32 With the supporting components 31 evenly arranged on the circumferential section of the rotating cylinder 1, each bending blade 32 carries out material holding and lifting actions respectively as the cylinder 1 rotates, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com