Patents

Literature

39results about How to "To achieve the purpose of lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

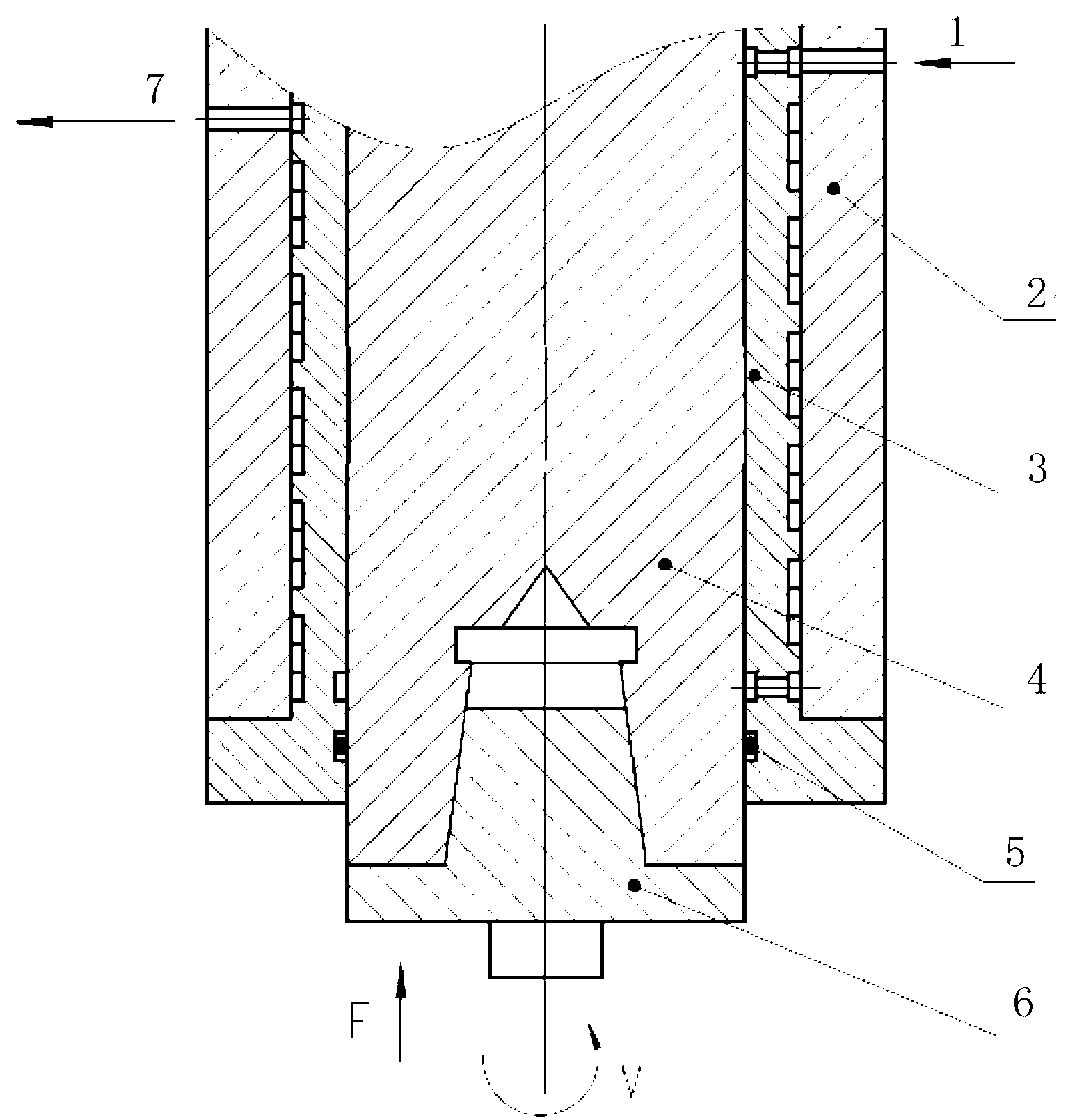

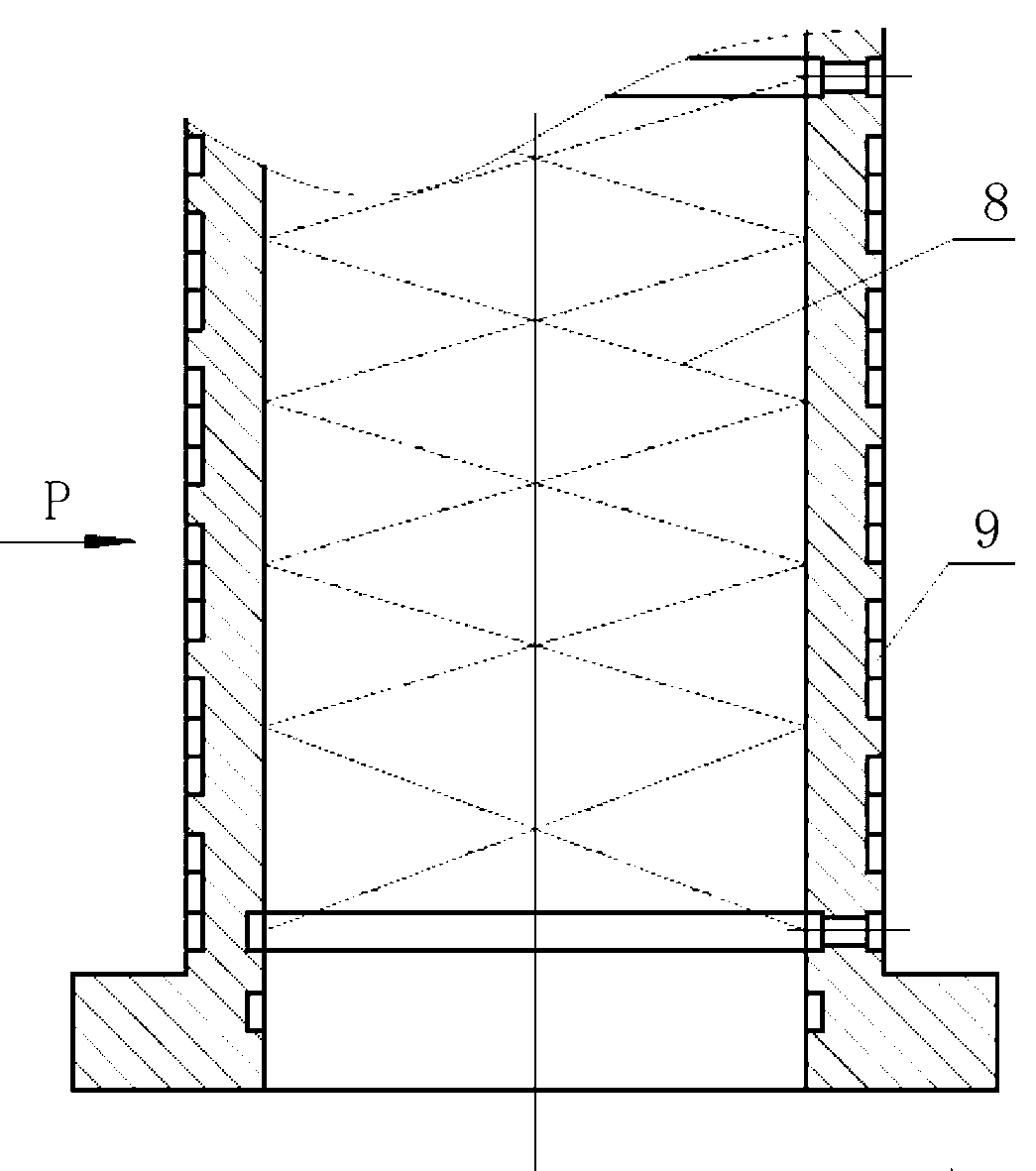

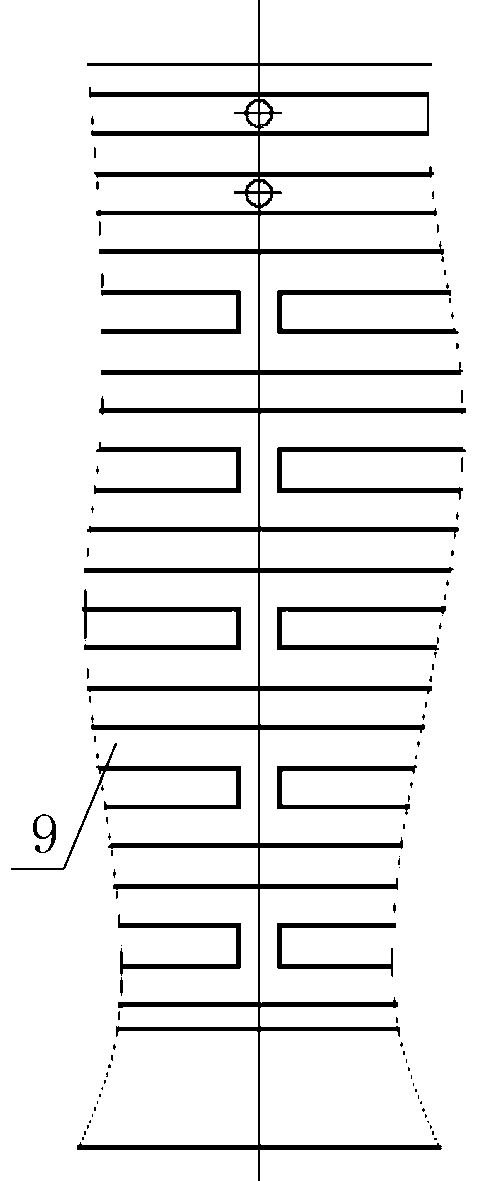

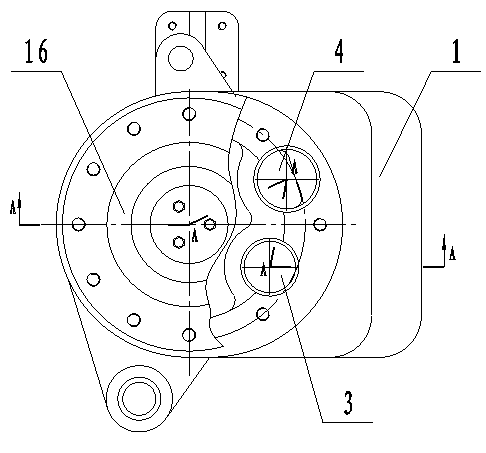

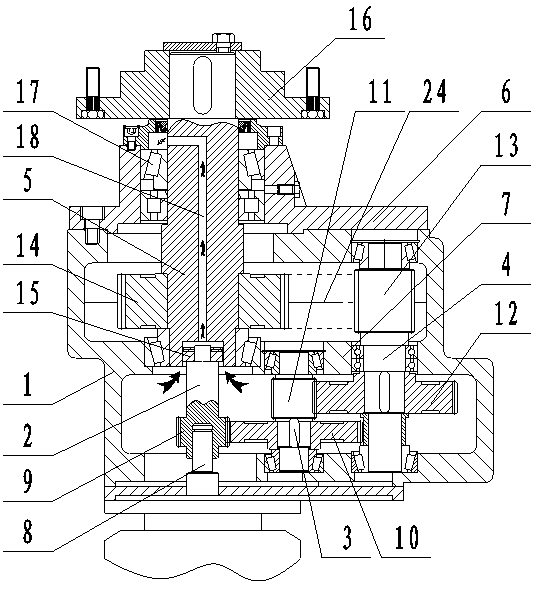

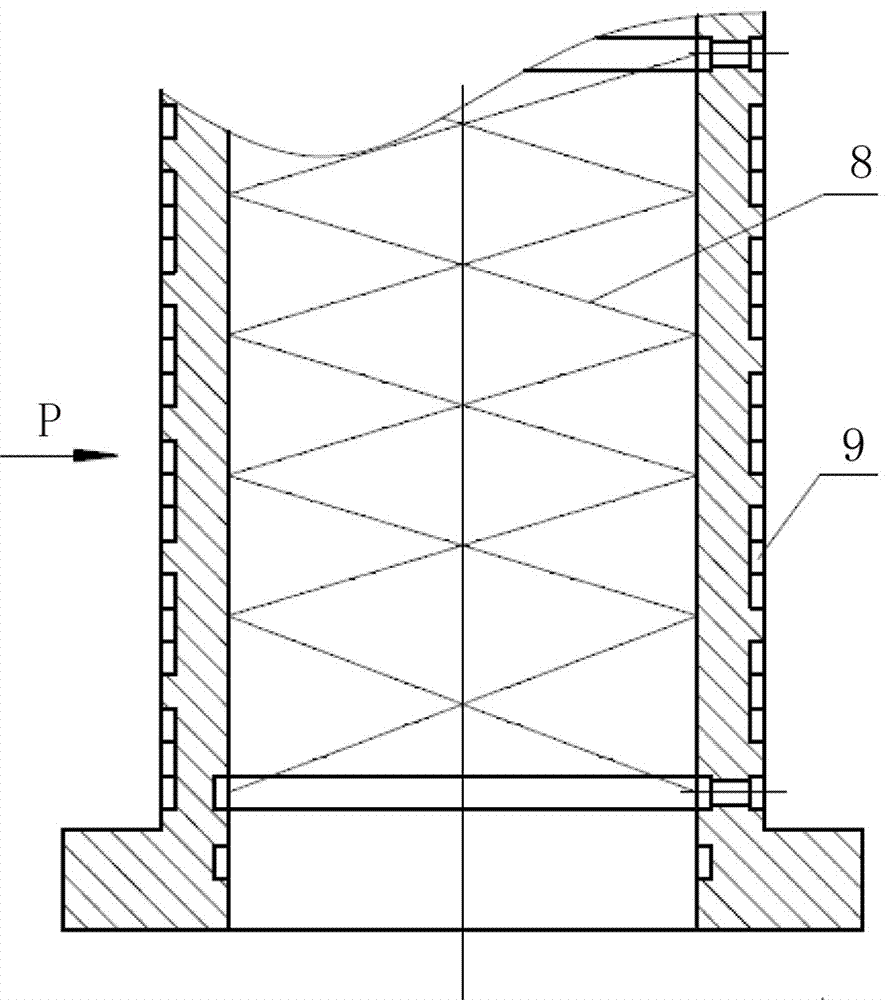

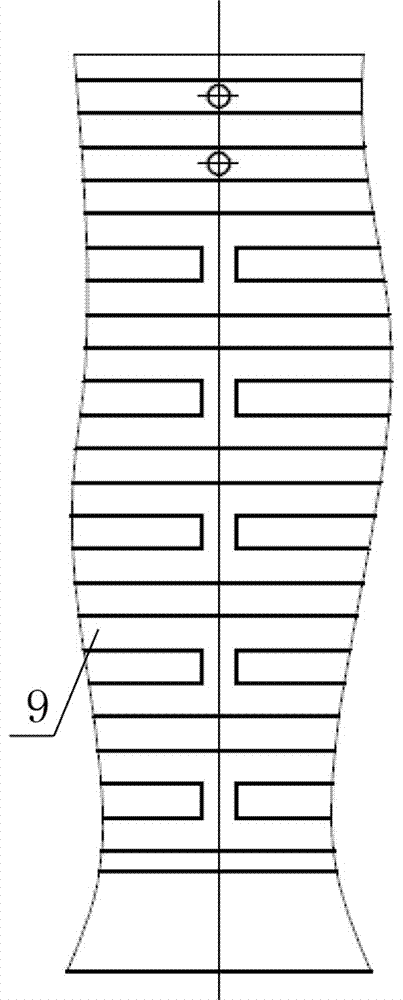

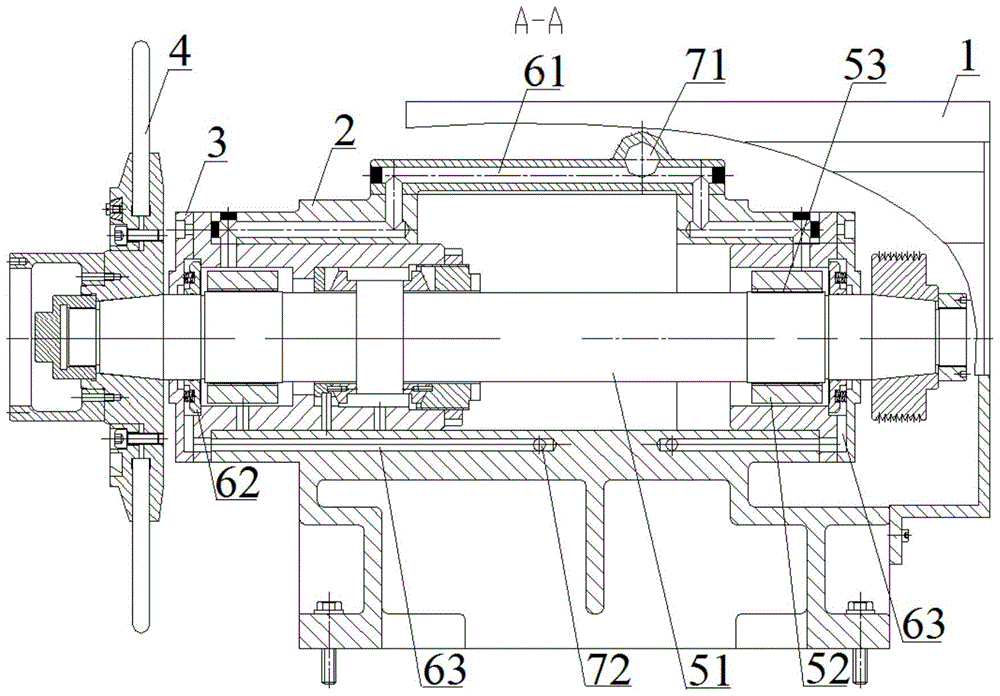

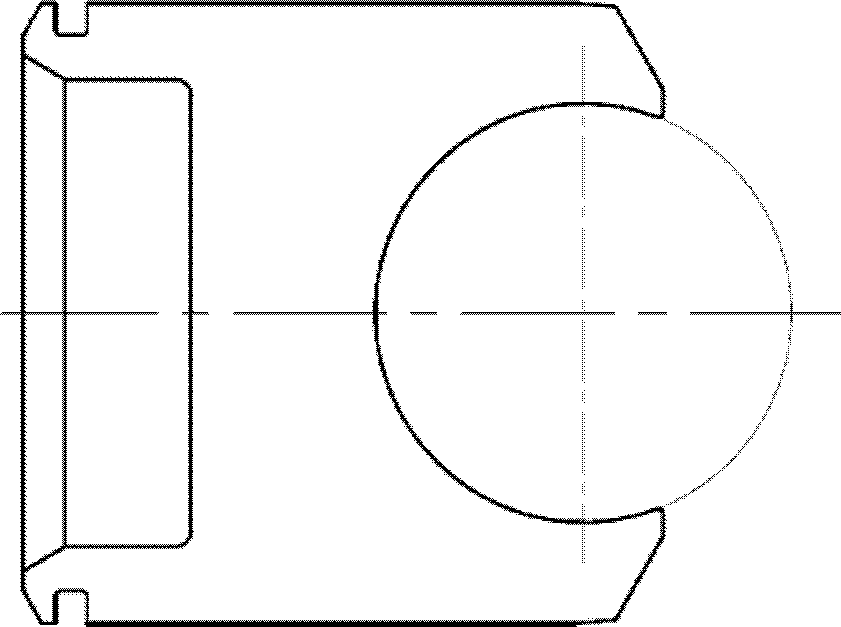

Self-lubrication cooled type gear shaper spindle structure

ActiveCN103302317APrevent wear and tearImprove cooling effectMaintainance and safety accessoriesReciprocating motionThermal deformation

A self-lubrication cooled type gear shaper spindle structure comprises a spindle, wherein a spindle sleeve is arranged outside the spindle, and is embedded in a tool rest body; an oil inlet and an oil inlet are formed in the upper end of the spindle sleeve; spiral oil grooves are formed in the spindle sleeve; a plurality of ring-shaped cooling grooves are distributed on the excircle of the spindle sleeve; and the lower ends of the ring-shaped cooling grooves are communicated with the spiral oil grooves. According to the invention, the two spiral oil grooves are formed in the spindle sleeve, depending on the reciprocating movement of the spindle, oil is introduced into a friction zone to form a lubricating oil film so as to realize the purpose of lubrication and prevent grinding damage of the spindle; as the ring-shaped cooling grooves are distributed on the excircle of the spindle sleeve, and the lower ends of the ring-shaped cooling grooves are communicated with the spiral oil grooves, only one pair of openings are communicated between every two ring-shaped cooling grooves, and are distributed symmetrically, the lubricating oil flows to each cooling groove in the return process to take away heat of the spindle sleeve, which is generated by friction and impacting, so that the spindle sleeve is ensured to be fully cooled, the thermal deformation of the spindle sleeve becomes very small, and the grinding die of the spindle can be prevented.

Owner:宜昌长机科技有限责任公司

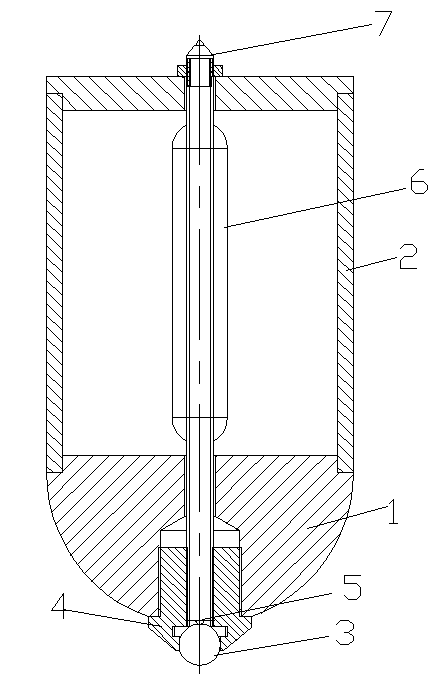

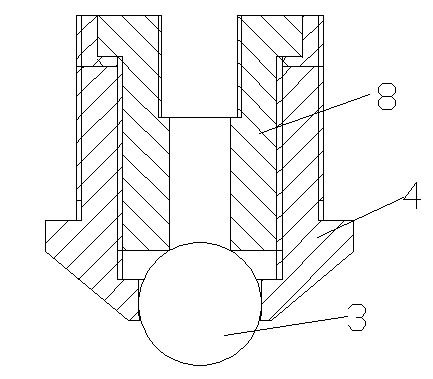

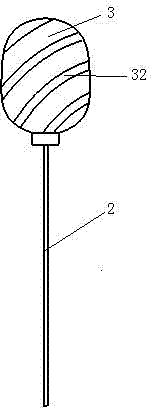

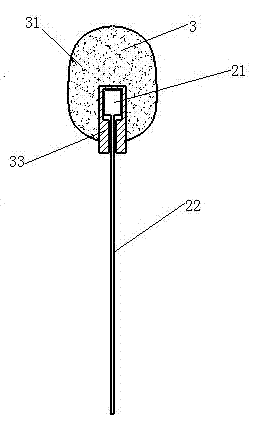

Self-lubricating gyroscope

The invention discloses a self-lubricating gyroscope, comprising a hollow barrel, a hemispheric gyroscope head, a ball and an oil supply device, wherein the ball is embedded in the top of the gyroscope head, and the oil supply device for lubricating the ball is arranged inside the gyroscope. The delivery valve port of the oil supply device is in contact with the ball, the ball is arranged in the top of the gyroscope head through a ball seat, and the ball is arranged inside the ball seat. The rotary part of the gyroscope, contacting with the ground, namely the ball does not rotate, the oil supply device rotates at high speed along with a shell under the twitching of an external force, a throttle valve rotates at high speed along with the gyroscope and generates heat energy, so as to heat and melt lubricating oil, and the lubricating oil seeps along the ball to lubricate. Not only is the abrasion problem of the gyroscope head solved, but also the wear-resisting property of the gyroscope rotating head is improved, at the same time, the friction force between the gyroscope head and the ground is greatly reduced, the abrasion damage to the ground is avoided, and a city square is protected. According to the self-lubricating gyroscope, solid lubricating grease is used, only little grease seeps for lubrication, pollution to the ground is avoided, and the environment is safe.

Owner:柏玉斌

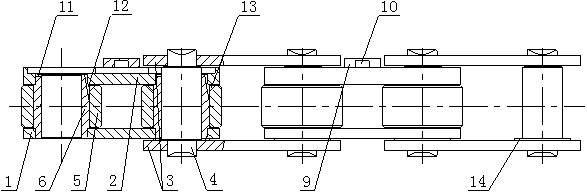

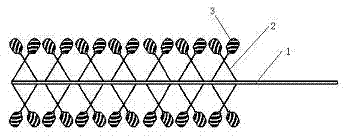

Conveying chain

InactiveCN102530476AExtended service lifeFully lubricatedConveyorsBiochemical engineeringLubrication

The invention discloses a conveying chain. The conveying chain comprises a first inner chain plate, a second inner chain plate, outer chain plates, a pin shaft, a roller and a sleeve. The first inner chain plate and the second inner chain plate are arranged at the two ends of the roller. One outer chain plate is arranged at each of the outer ends of the first inner chain plate and the second inner chain plate respectively. The roller, the first inner chain plate, the second inner chain plate and the two outer chain plates are connected together by the pin shaft. The sleeve is arranged between the pin shaft and the first inner chain plate, and between the second inner chain plate and the roller. The second inner chain plate is thicker than the first inner chain plate. Communicated oil storing slots are arranged between the two holes of the second inner chain plate. A cover plate is fixed on the second inner chain plate by a fixing pin. An oil filling slot is arranged on one surface of the cover plate. One end of the sleeve, close to the second inner chain plate, is provided with a notch. A slot forming an included angle with the axial direction of the sleeve is arranged at the position on the sleeve, corresponding to the notch. A large chamfering is arranged at one end of the second inner chain plate, where the inner diameter of the roller closes to. According to the conveying chain disclosed by the invention, long-time lubrication is realized after oil filling in one time, and the sleeve, the roller and the pin shaft are ensured to be fully lubricated.

Owner:SUZHOU UNIVERSAL GRP TECH CO LTD

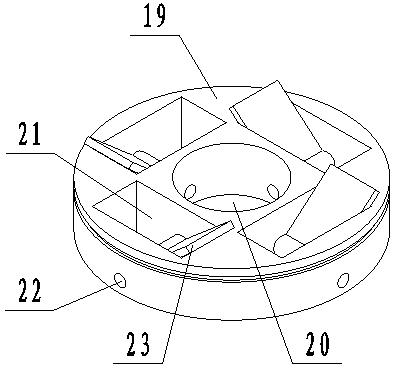

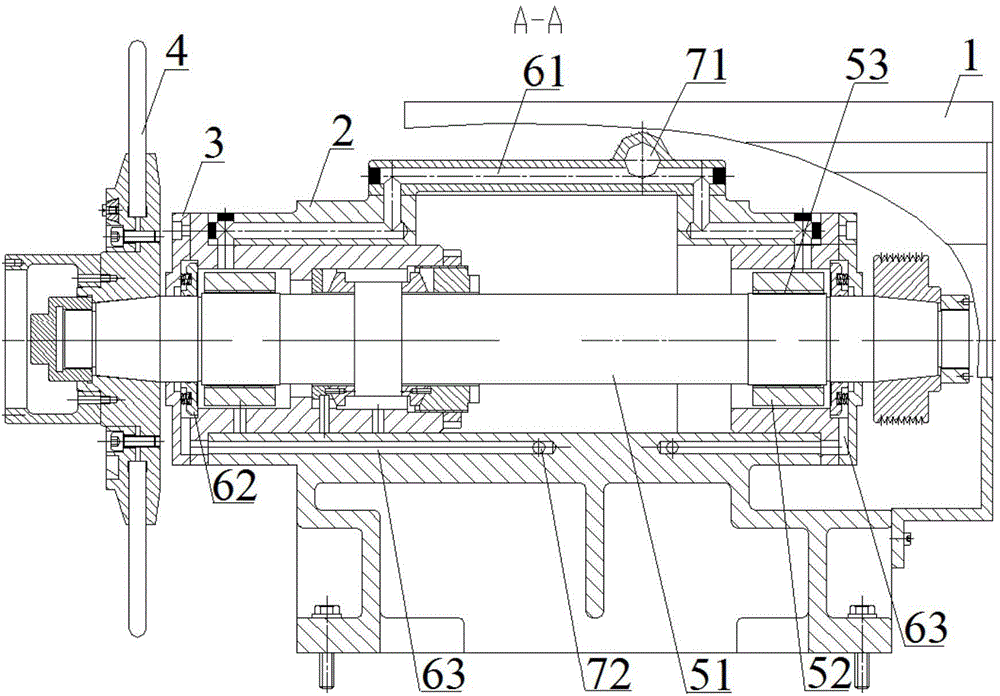

Monorail crane speed reducer lubricated through positive and negative rotation

ActiveCN103075500AExtended service lifeSimple structureToothed gearingsGear lubrication/coolingLow speedReducer

The invention discloses a monorail crane speed reducer lubricated through positive and negative rotation, which belongs to the technical field of lubrication of speed reducers. The invention provides a monorail crane speed reducer lubricated through positive and negative rotation, which is simple in structure and has a good lubricating effect. According to the adopted technical scheme, the bottom of a low-speed output shaft is sleeved on the upper part of a first gear shaft, and a bidirectional vane wheel is arranged between the low-speed output shaft and the first gear shaft; an upper end bearing is arranged between the low-speed output shaft and a shaft outlet cover; an oil path pipe is arranged inside the shaft body of the low-speed output shaft, and leads towards the upper side of the upper end bearing from a lower cabin of a box body; and the structure of the bidirectional vane wheel is as follows: the center of a vane wheel body is provided with a central through hole; a plurality of vane holes are uniformly formed around the central through hole; and a vane is arranged at the bottom of each vane hole through a vane shaft. According to the monorail crane speed reducer, during multi-stage gear transmission, lubricating oil enters the oil path pipe from the insides of the vane holes of the bidirectional vane wheel, and flows towards the upper side of the upper end bearing to lubricate the upper end bearing and a bearing below the upper end bearing.

Owner:长治宏瀚机械制造有限公司

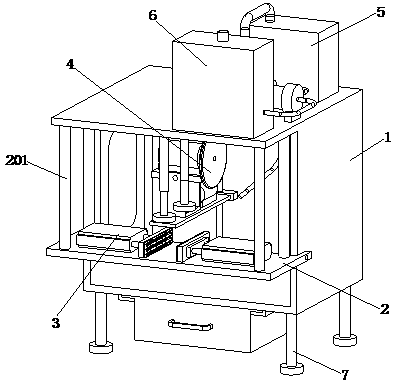

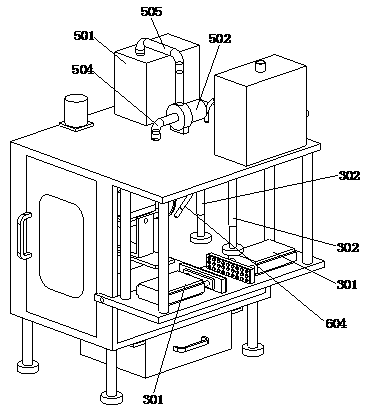

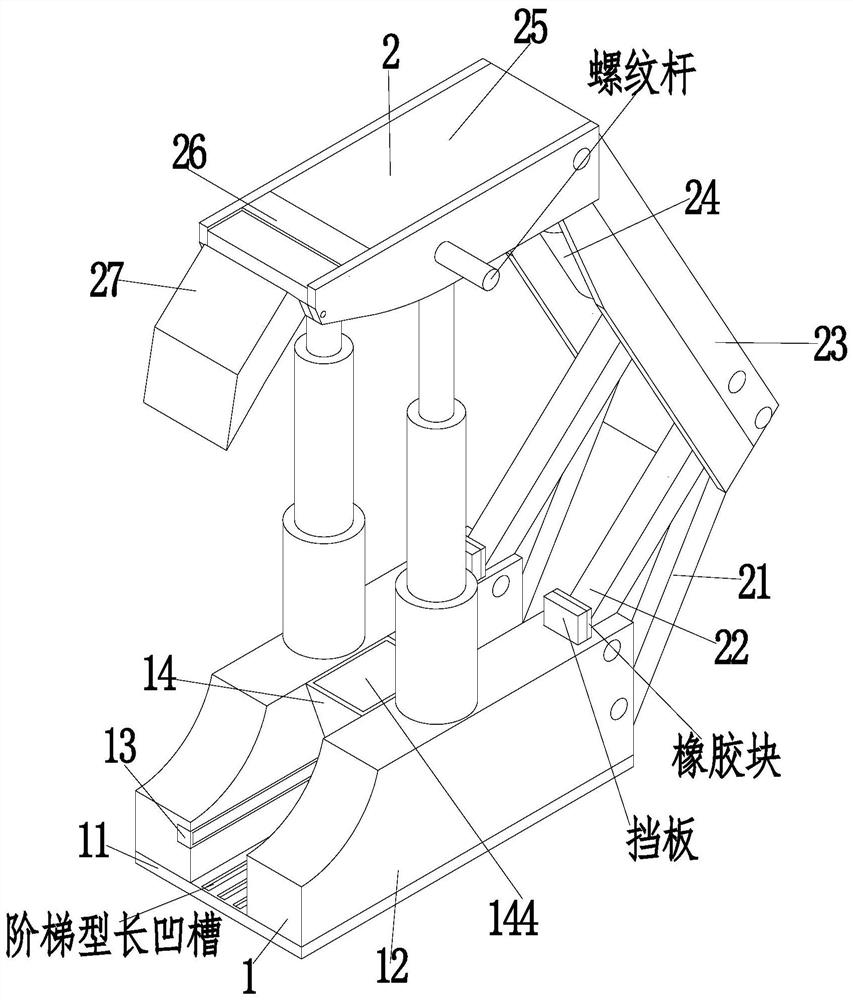

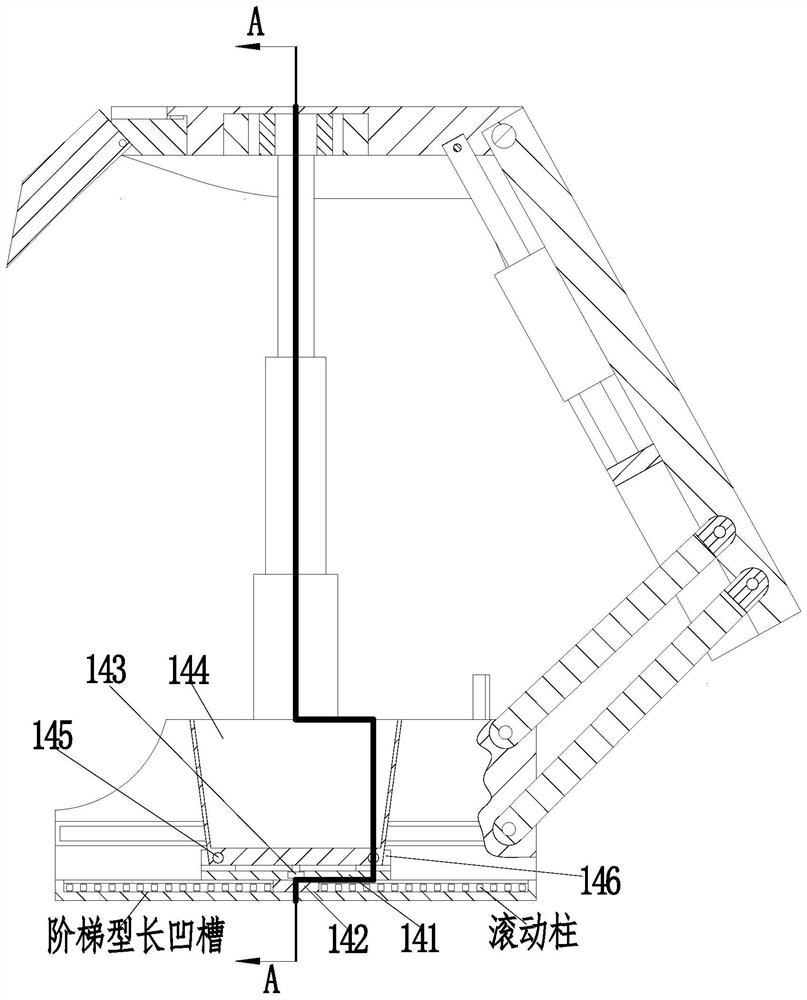

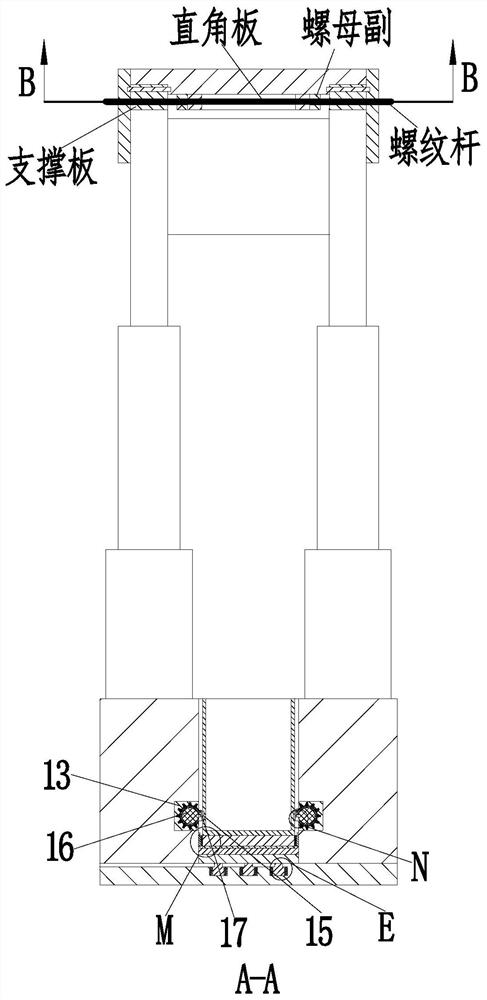

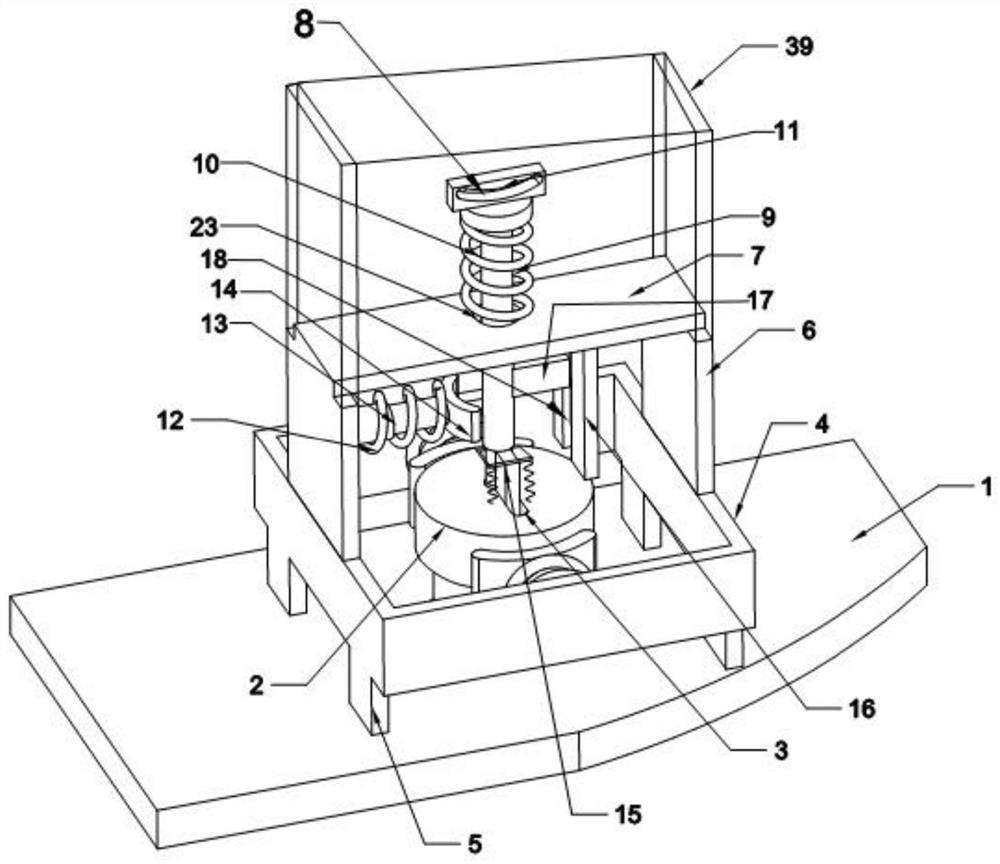

Chamfering device of hardware die

InactiveCN110328541AAvoid shakingTo achieve the purpose of lubricationFeeding apparatusDriving apparatusEngineeringWaste recycling

The invention discloses a chamfering device of a hardware die, and belongs to the technical field of hardware dies. The chamfering device comprises a shell, a bearing plate, a limiting component, a chamfering component, a waste recycling component, a lubricating component and four supporting legs, wherein the shell is of a cavity structure, the four supporting legs are distributed at the bottom end of the shell in a rectangular mode, the two ends of the bearing plate are in threaded connection with the side wall of the shell correspondingly, four supporting columns are distributed on the bearing plate in a rectangular manner, the top ends of the four supporting columns are fixedly connected with the top end of the shell, the limiting component is arranged on the bearing plate, the chamfering component is arranged in the shell, and the waste recycling component and the lubricating component are both arranged at the top end of the shell. According to the chamfering device, the chamfer angle can not be adjusted according to actual conditions, the chamfering efficiency is influenced, so that the abrasion of a cutter head is relatively high, and the service life of the cutter head is reduced.

Owner:李义飞

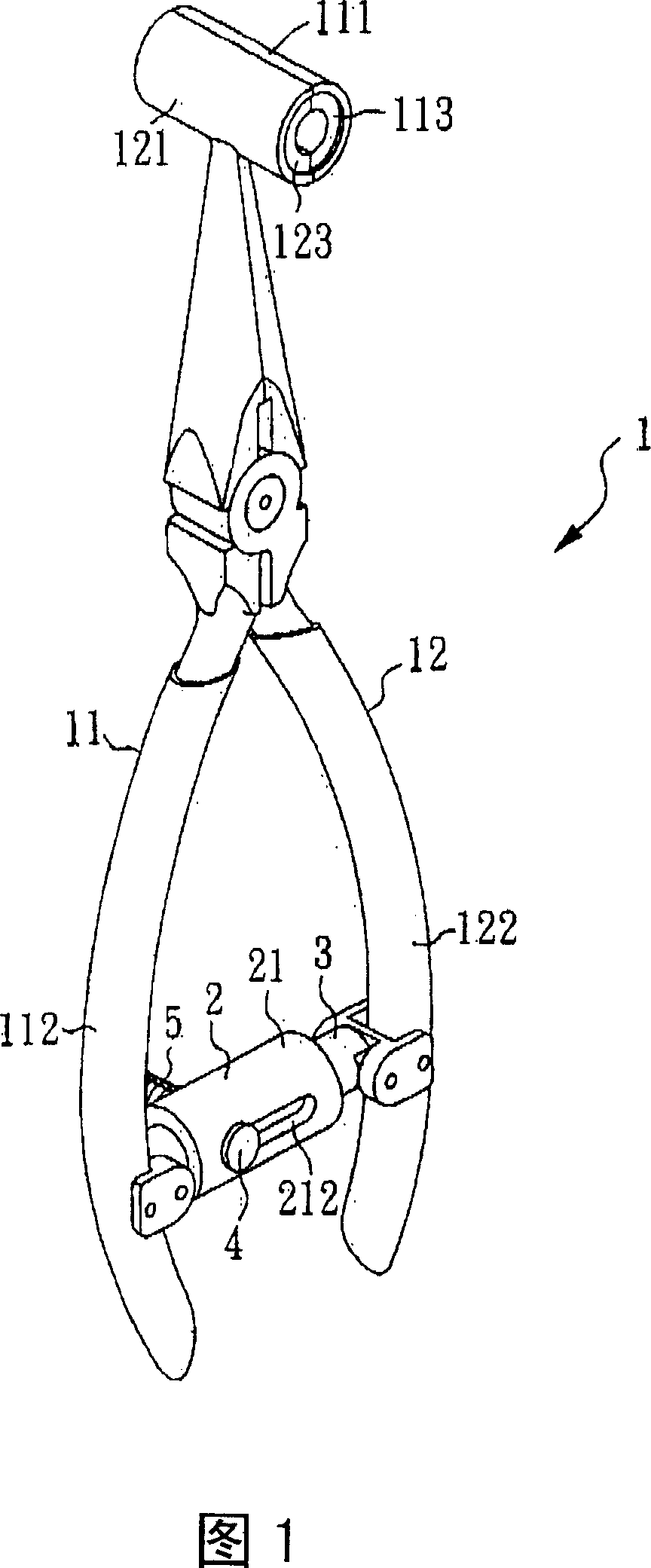

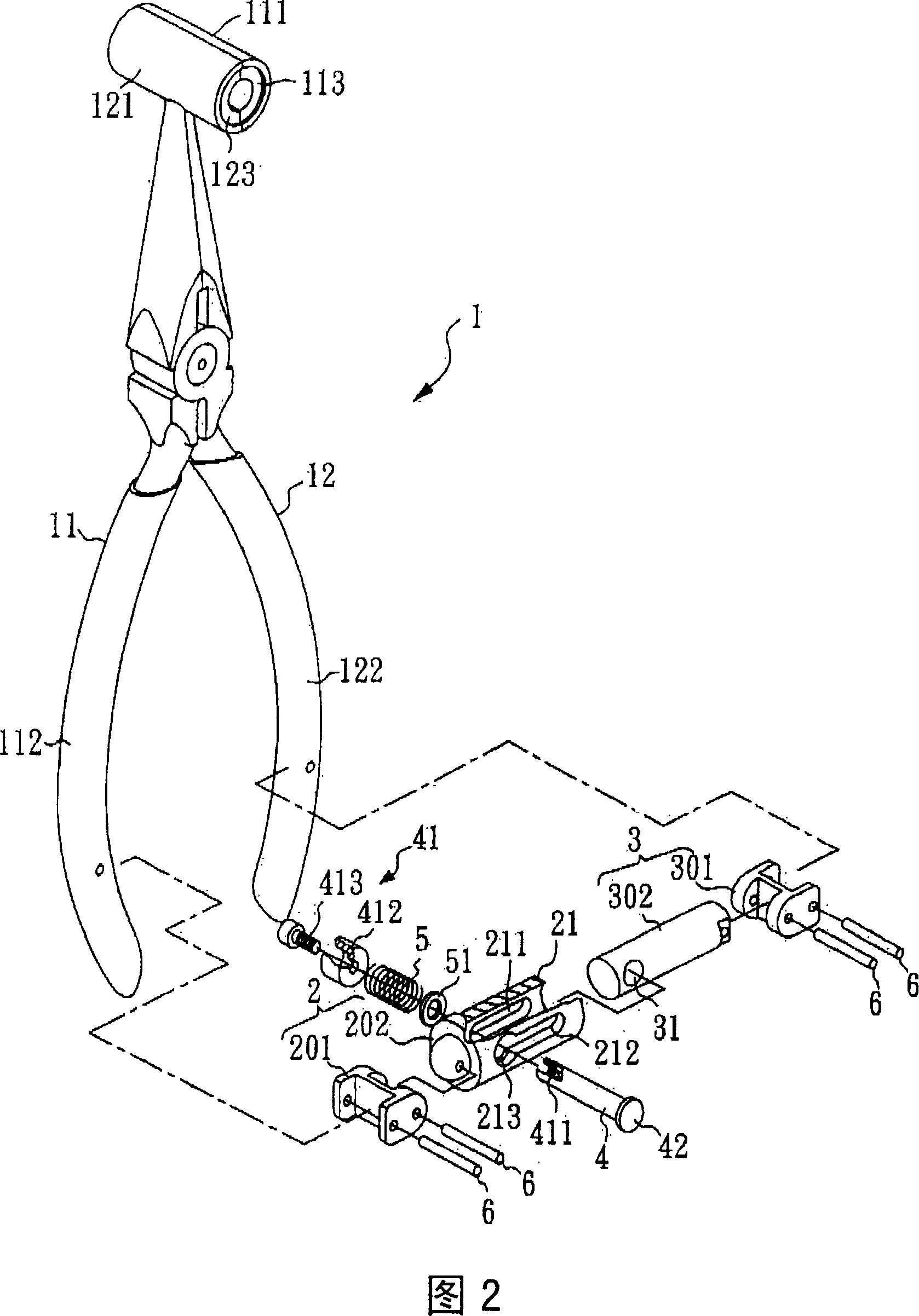

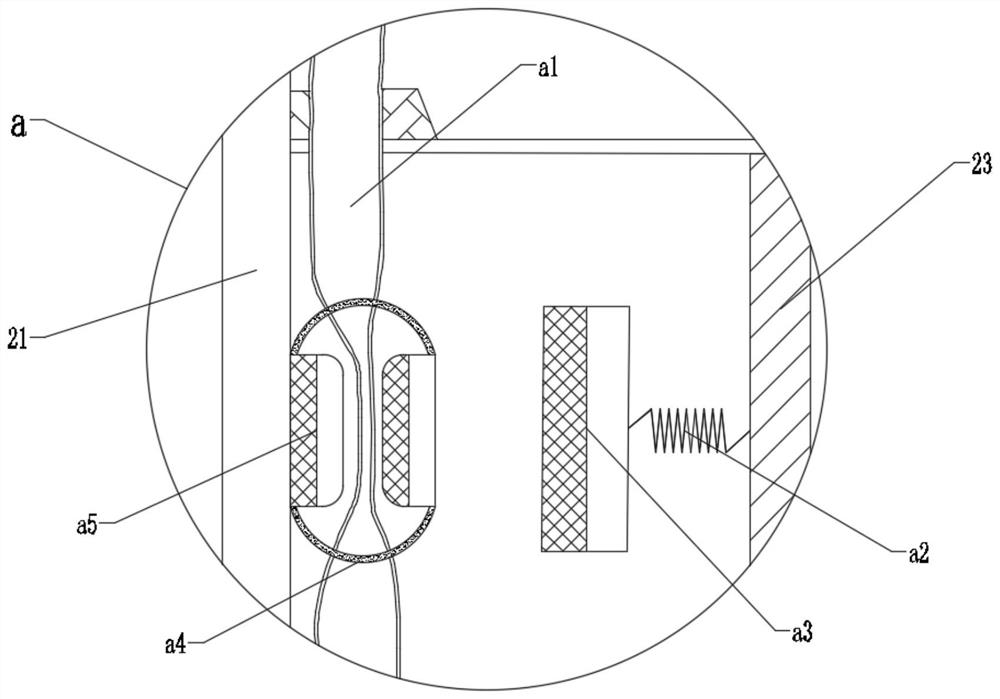

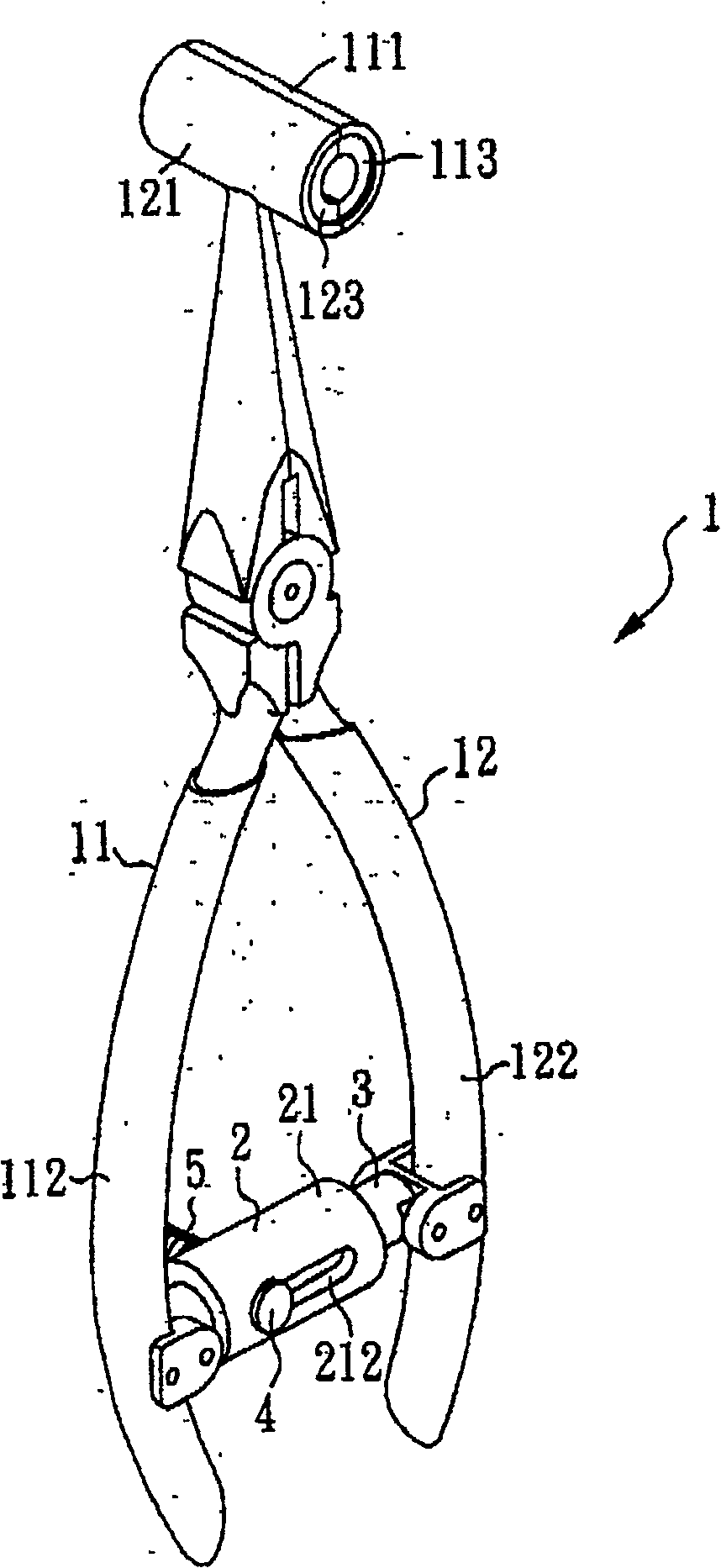

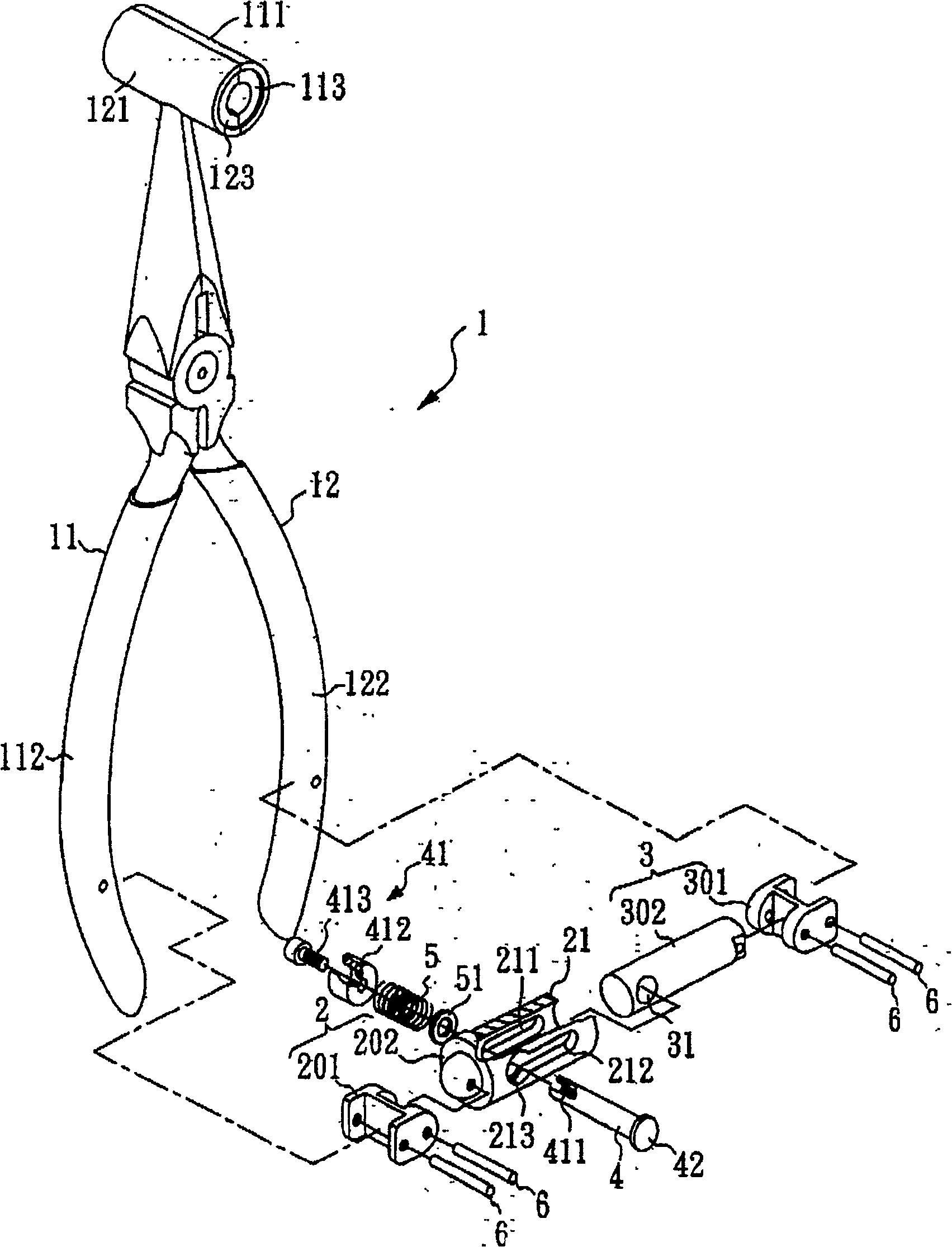

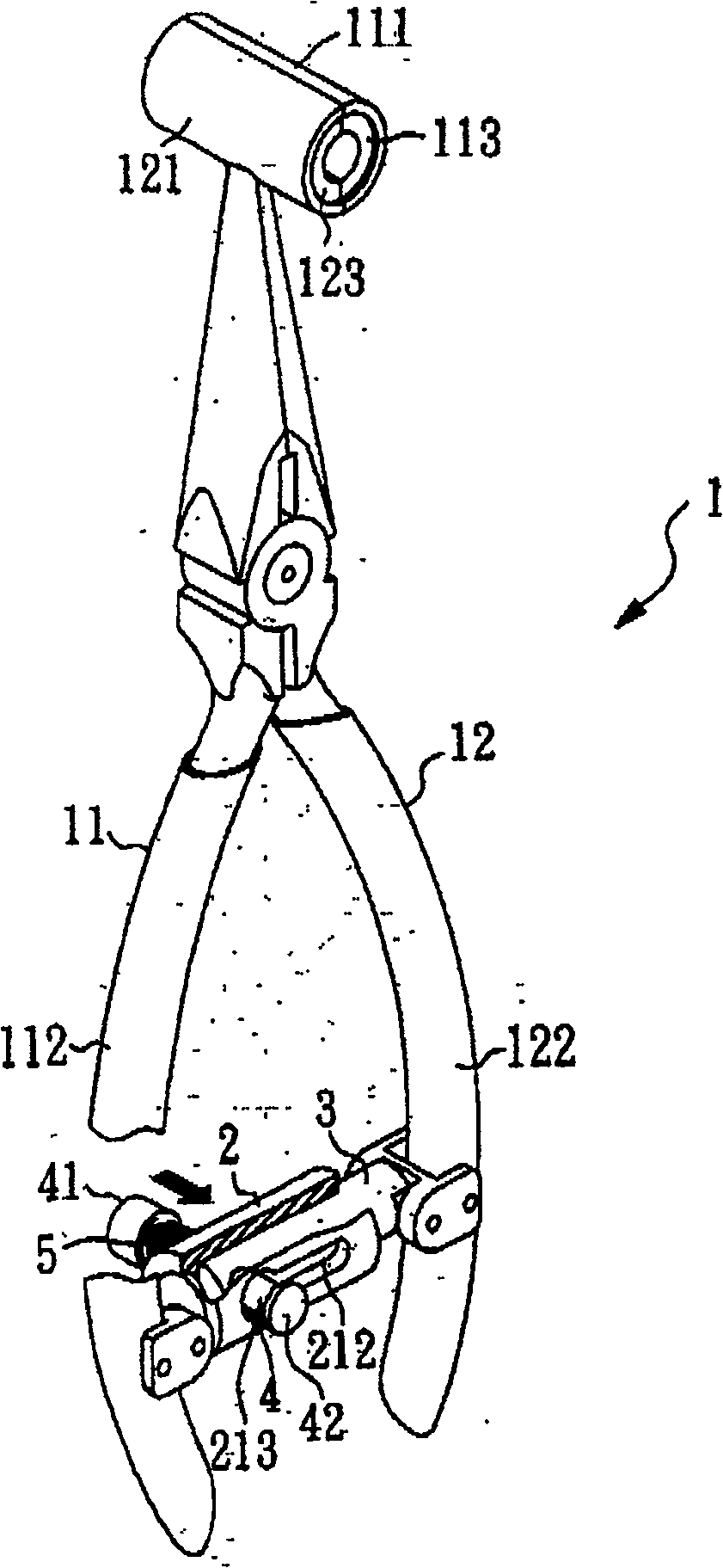

Self-locking mechanism

The invention discloses a self-locking accessory mechanism, which comprises the following parts: cylinder component, long axis component, movement shaft and spring component, wherein the cylinder component possesses mutual corresponding upper chute and lower chute; the long axis component is cased in the cylinder component, which pierces the expanding flute through-out hole corresponding to lower chute; the movement shaft pierces lower chute, through-out hole and upper chute, which consists of upper expanding part and lower expanding part; the lower expanding part corresponds to expanding flute; the spring component is cased on the movement shaft with top between upper expanding part and cylinder component, which provides elastic stress to move the movement shaft to be fixed in the expanding flute corresponding to lower expanding part.

Owner:KINPO ELECTRONICS CHINA

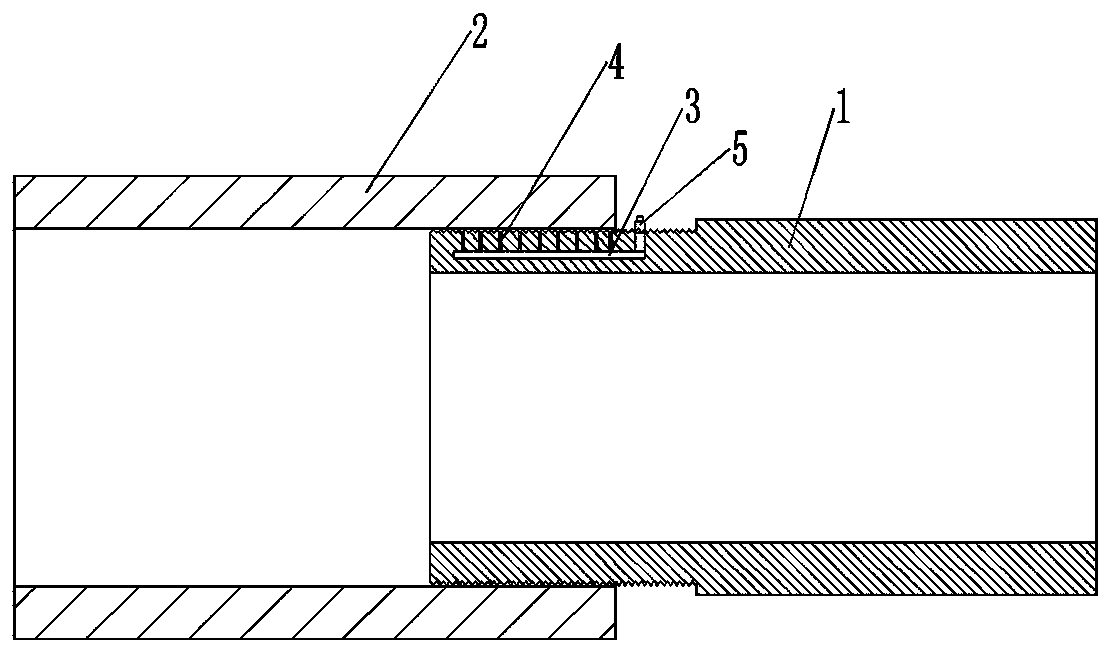

Cylindrical grinder easy to assemble and maintain

ActiveCN104690613AHigh precisionHigh surface finishGrinding machine componentsRevolution surface grinding machinesCeramic coatingThermal expansion

The invention discloses a cylindrical grinder easy to assemble and maintain and belongs to the technical field of machine tools. The cylindrical grinder comprises a sleeve, a shell, a cover plate, a grinding wheel and a sliding bearing, the shell is arranged inside the sleeve, two ends of the shell are sealed through the cover plate, the sliding bearing transversely penetrates the shell, and one end of the sliding bearing is connected with the grinding wheel; a ceramic coating is arranged on the sliding bearing and at the contact position of a spindle and a bearing bush, a return oil pipeline is arranged inside the shell and is communicated with a lubricating oil tank on the outer portion of the sleeve, and lubricating oil is circulated in the return oil pipeline in zero-pressure circulation. The ceramic coating is sprayed at the friction position of the spindle and the bearing bush, so that problems about thermal expansion deformation and abrasion of the metal spindle are solved by the aid of outstanding performance of ceramic; meanwhile, according to self structural features of the cylindrical grinder, a brand new oil leakage prevention pipeline is designed for the cylindrical grinder, zero-pressure circulation lubrication of the lubricating oil in an oil cavity is realized, long-term operation is achieved without disassembling the grinder for maintenance, and maintenance cost is greatly lowered.

Owner:MAANSHAN HENGLIDA MACHINE BLADE +1

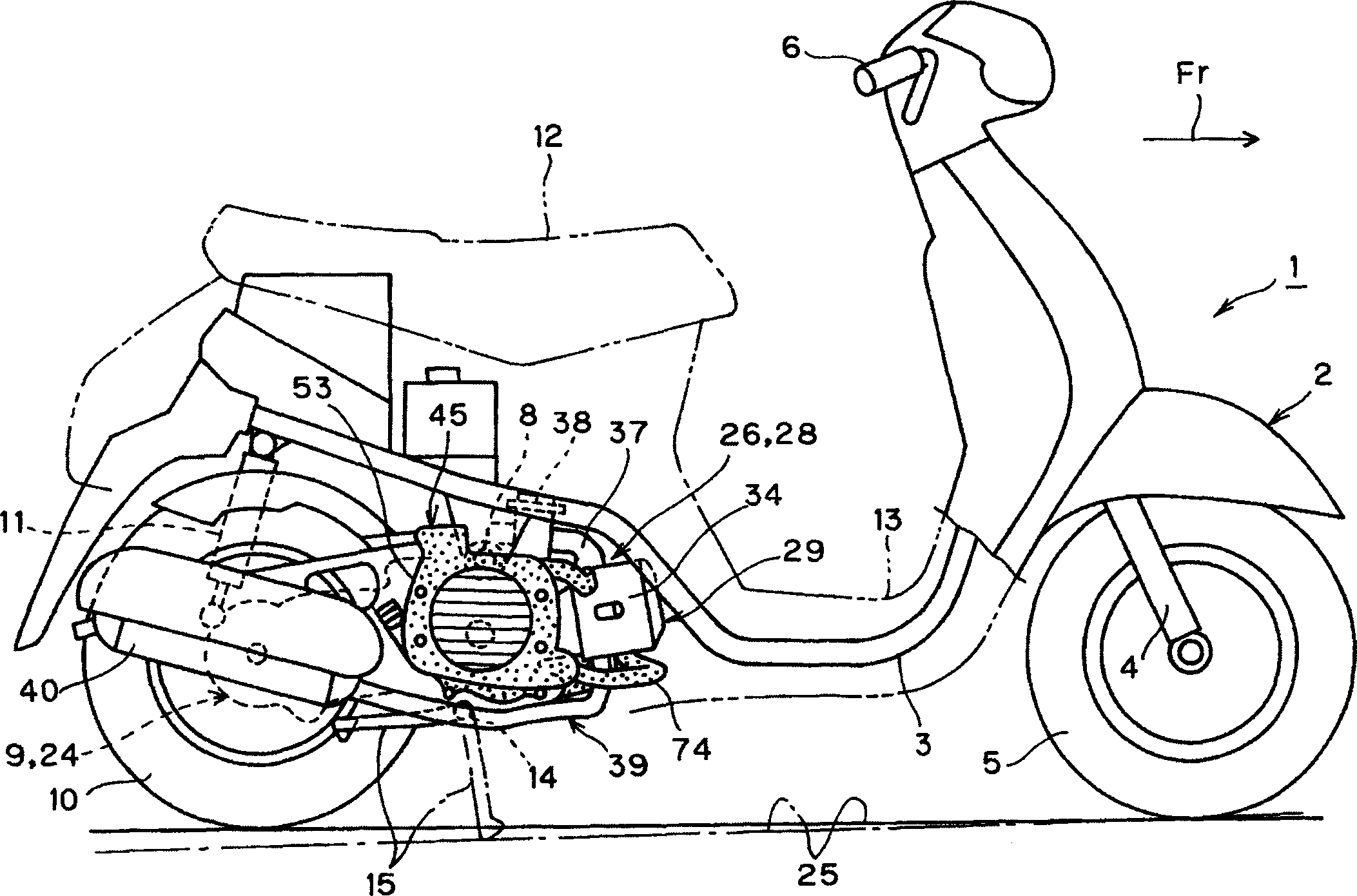

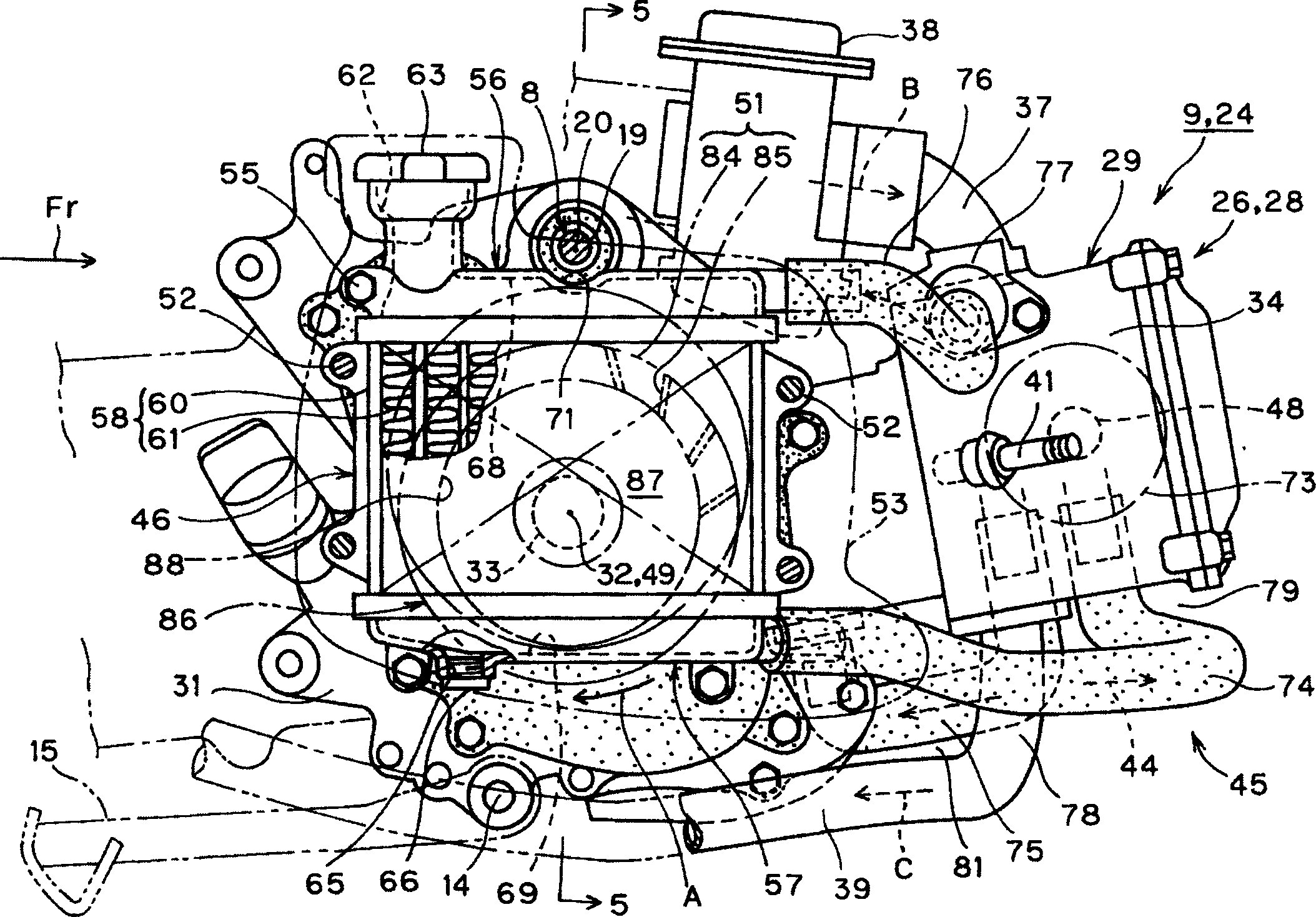

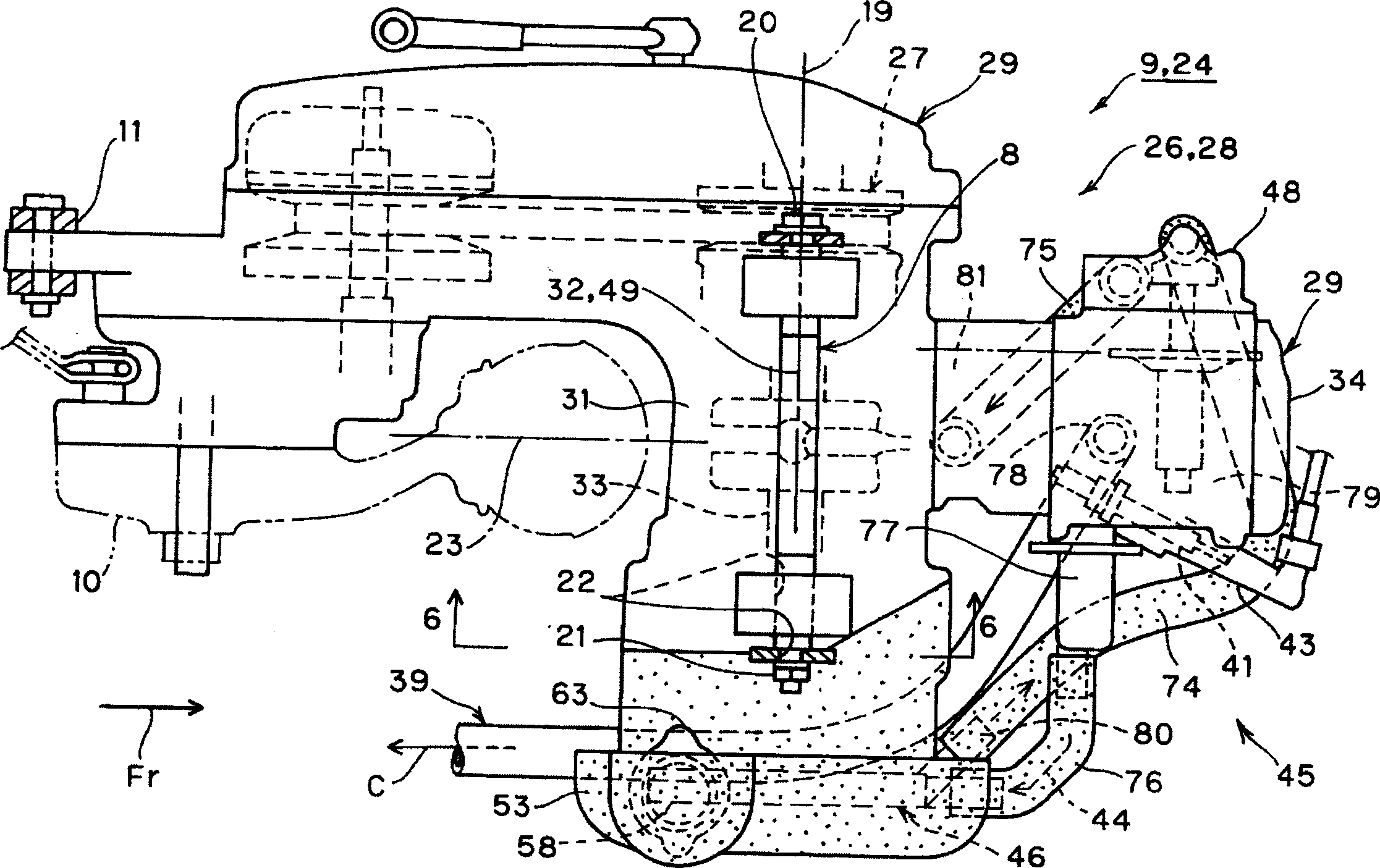

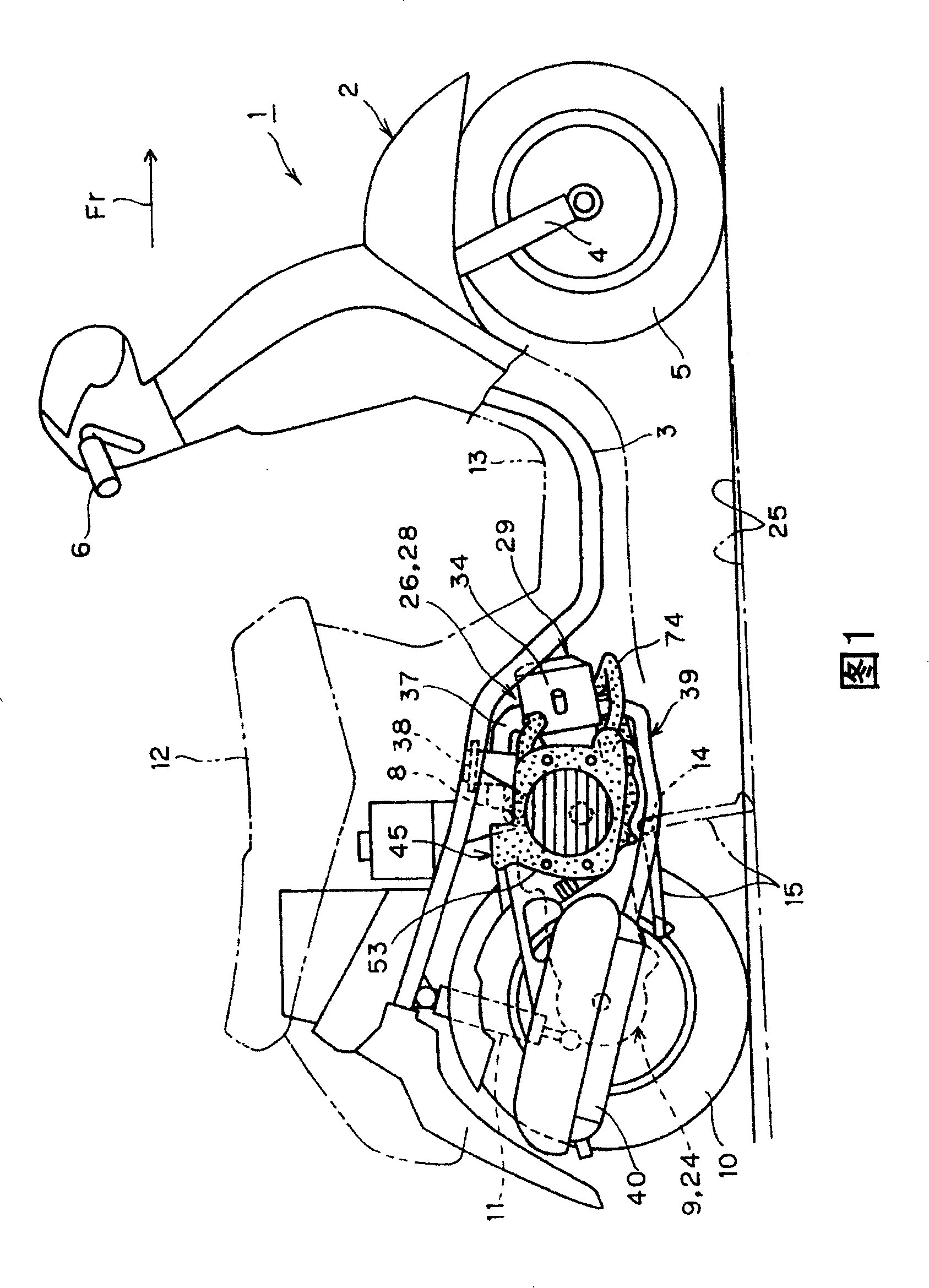

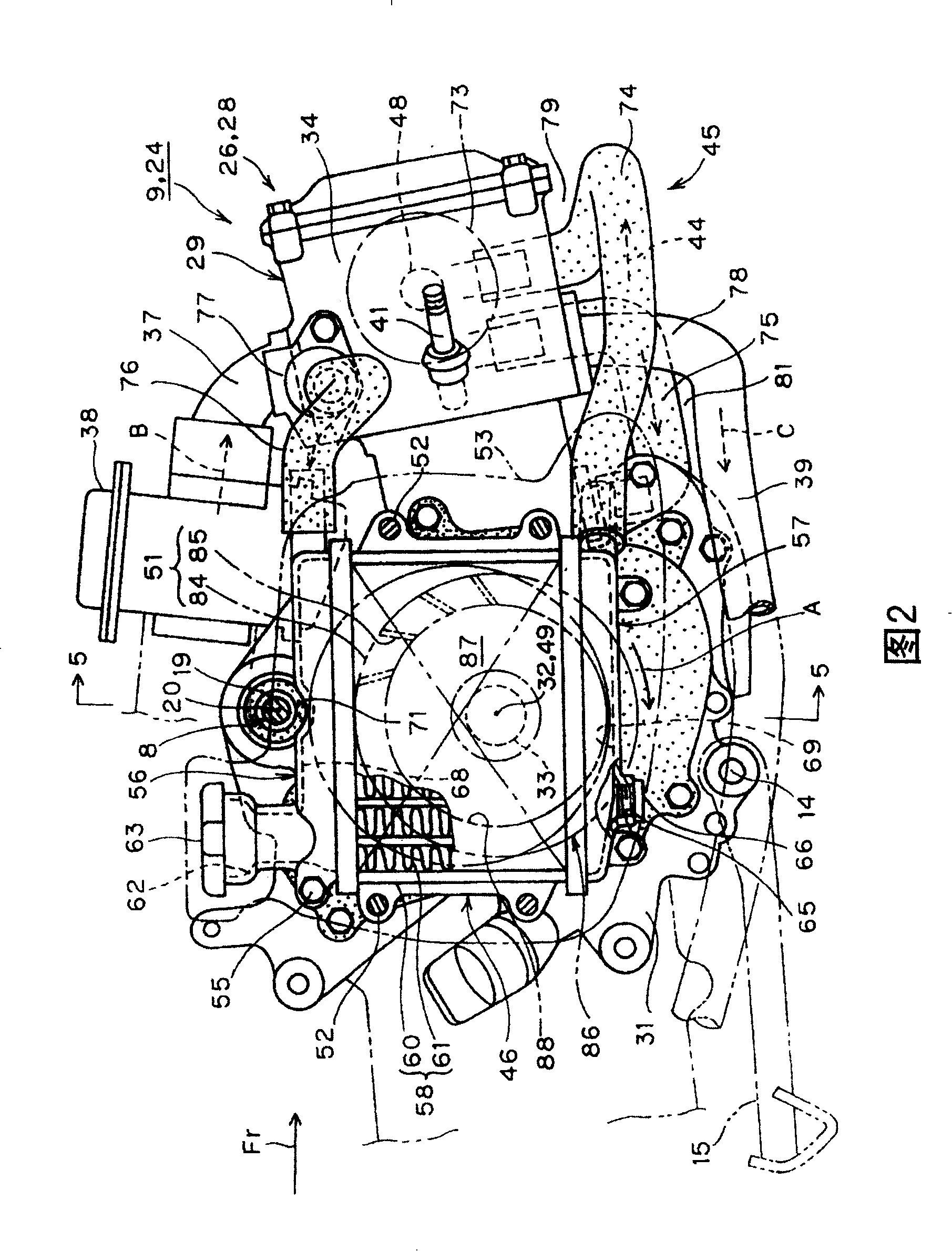

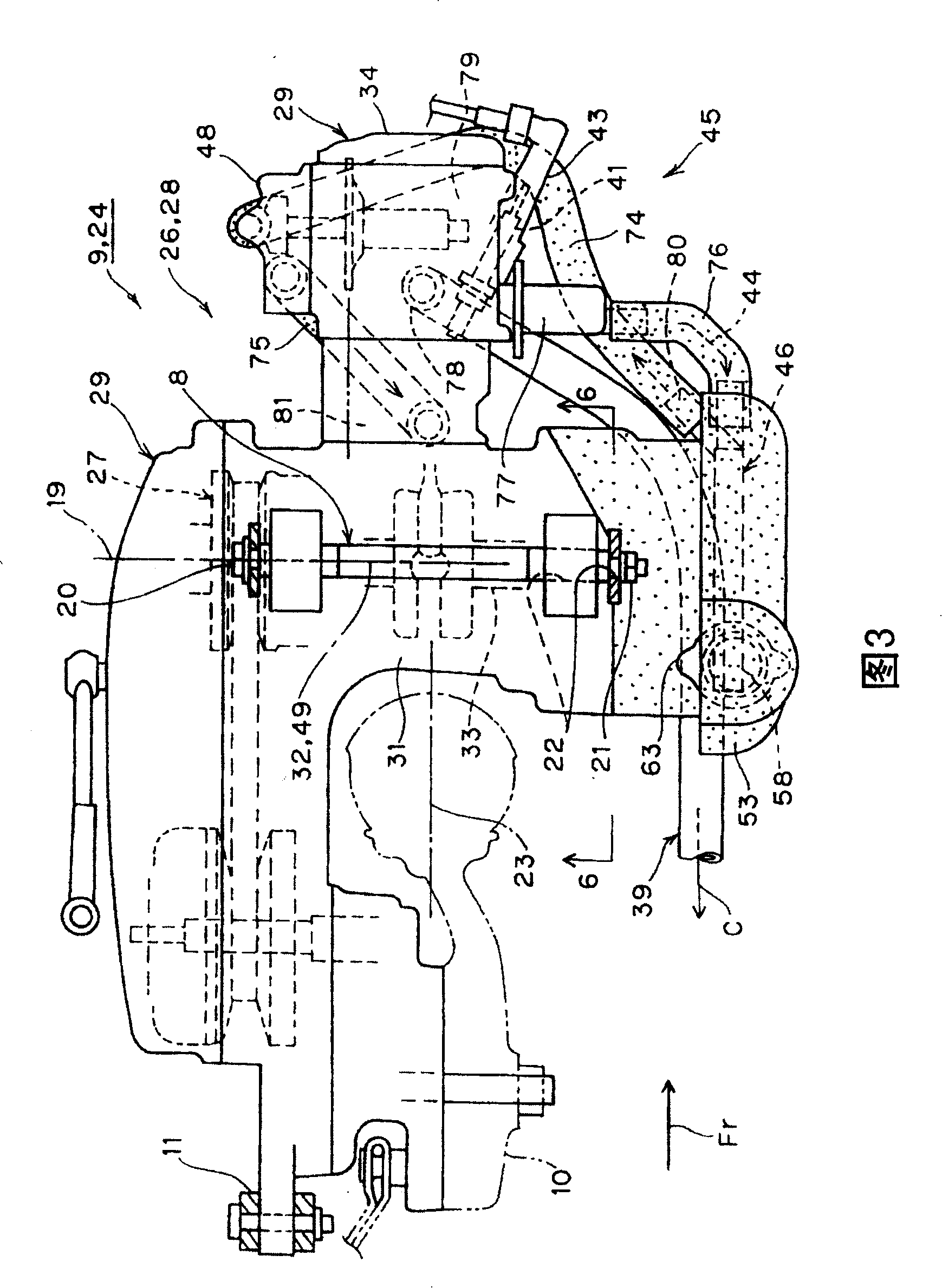

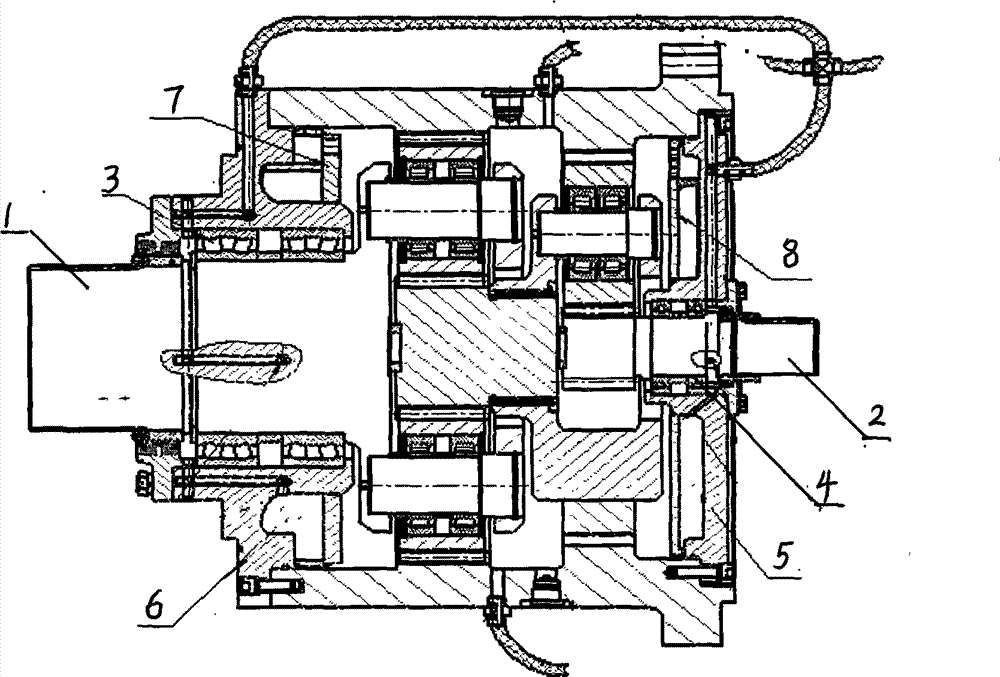

Riding vehicle

ActiveCN1608936APrevent mutual barriersEasy to implementCycle equipmentsMotorcyclesExternal combustion engineWater jacket

The purpose of this invention is to facilitate respective works for assembling, maintaining and inspecting regarding constituent parts of a vehicle. A front wheel 5 which is supported by the front section of the vehicle body 2, a driving unit 24 the front section side of which is pivoted by a pivot 8 extending in the width direction of the vehicle body 2 so that the rear section side may be rockable in the vertical direction, and a rear wheel 10 which is supported by the rear section of the driving unit 24 are provided. The driving unit 24 is equipped with an internal combustion engine 28 for running-driving, a radiator 46 which cools a cooling water 44 for cooling the internal combustion engine 28, and a cooling water tube 76 which communicates the radiator 46 and a water jacket 47 which is formed on the internal combustion engine 28 with each other. When the vehicle body 2 is seen from the side surface, the pivot 8 is arranged above the middle section in the longitudinal direction of the radiator 46, and the whole of the cooling water tubes 74 and 76 are arranged on the front side of the pivot 8.

Owner:YAMAHA MOTOR CO LTD

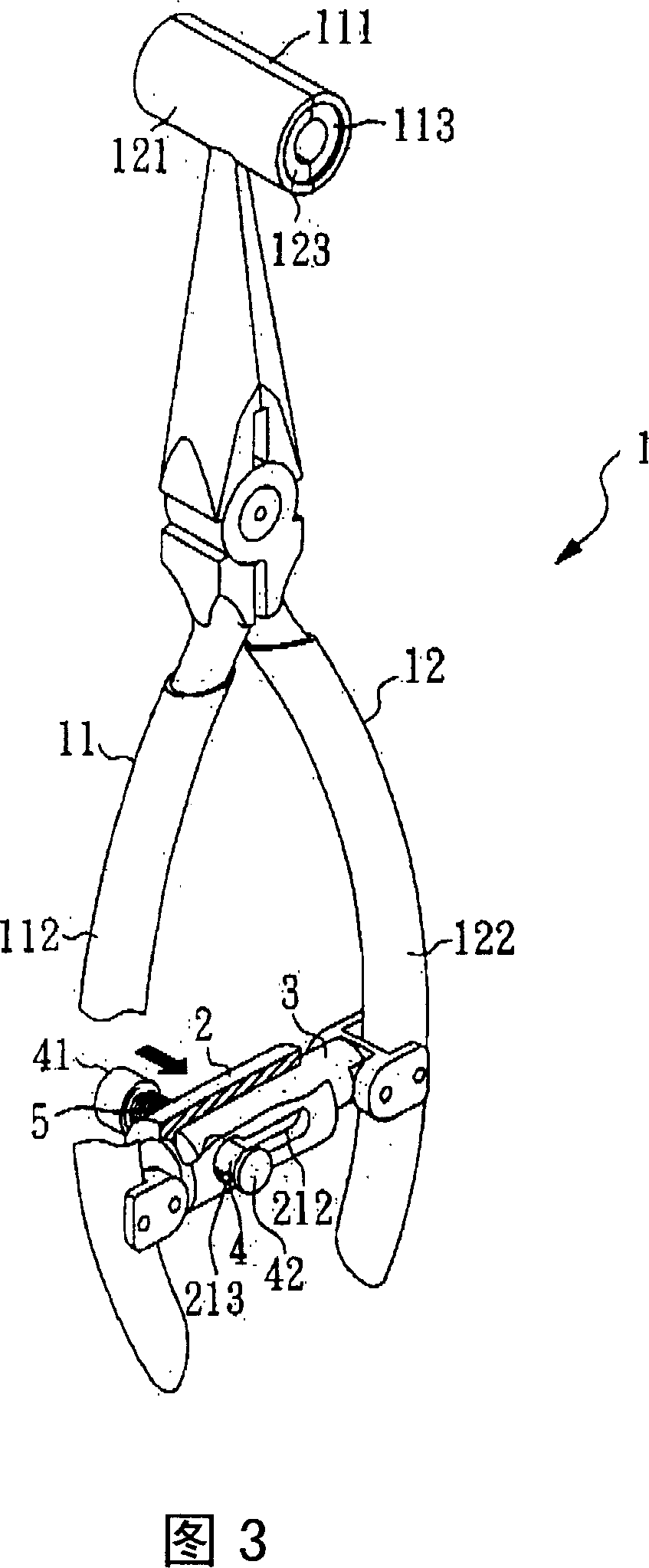

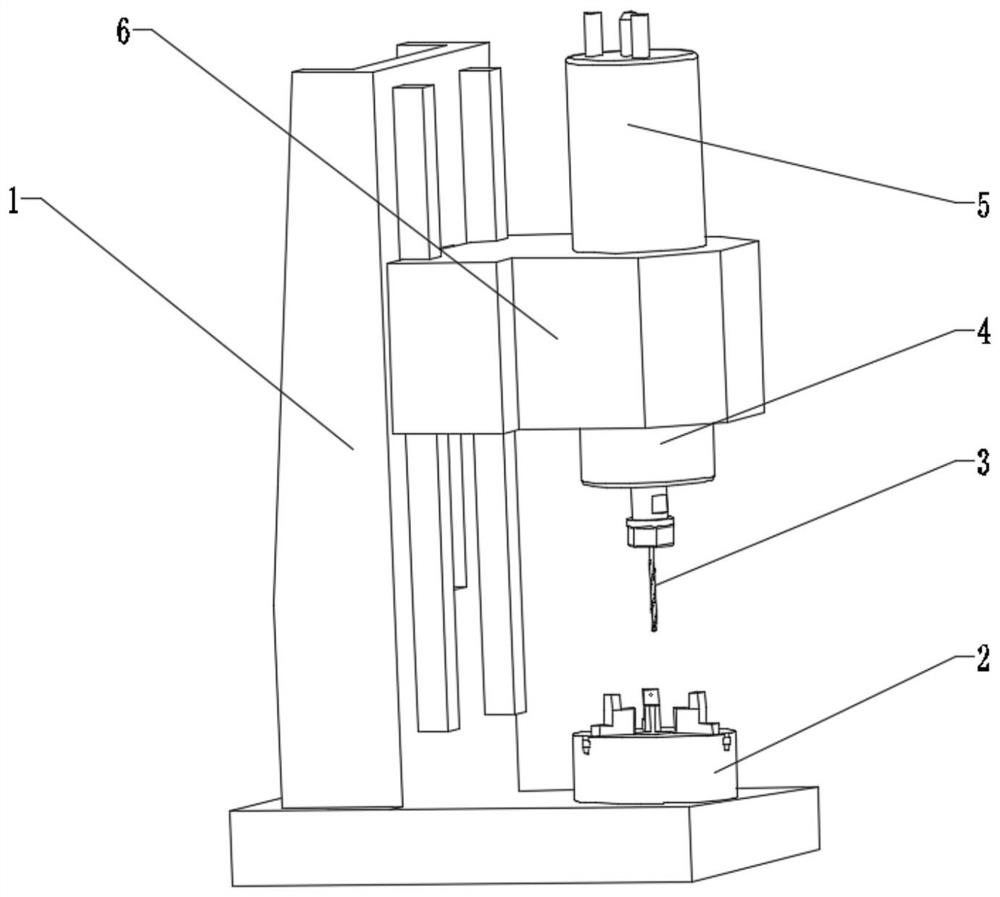

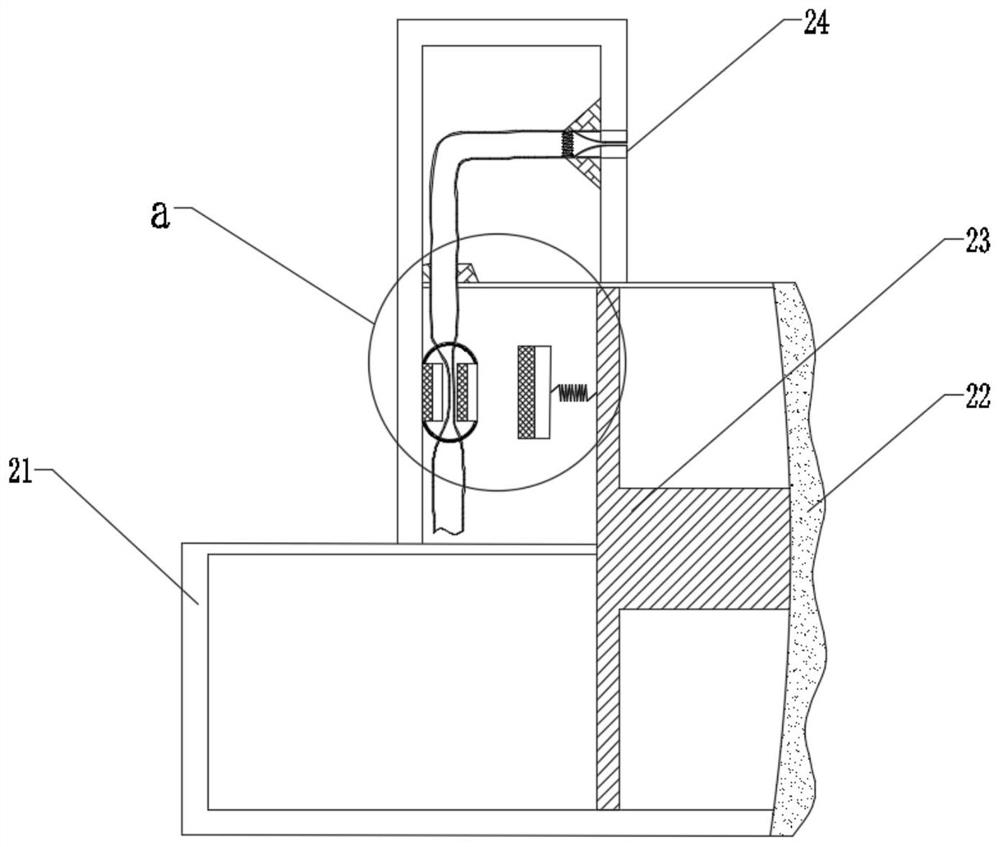

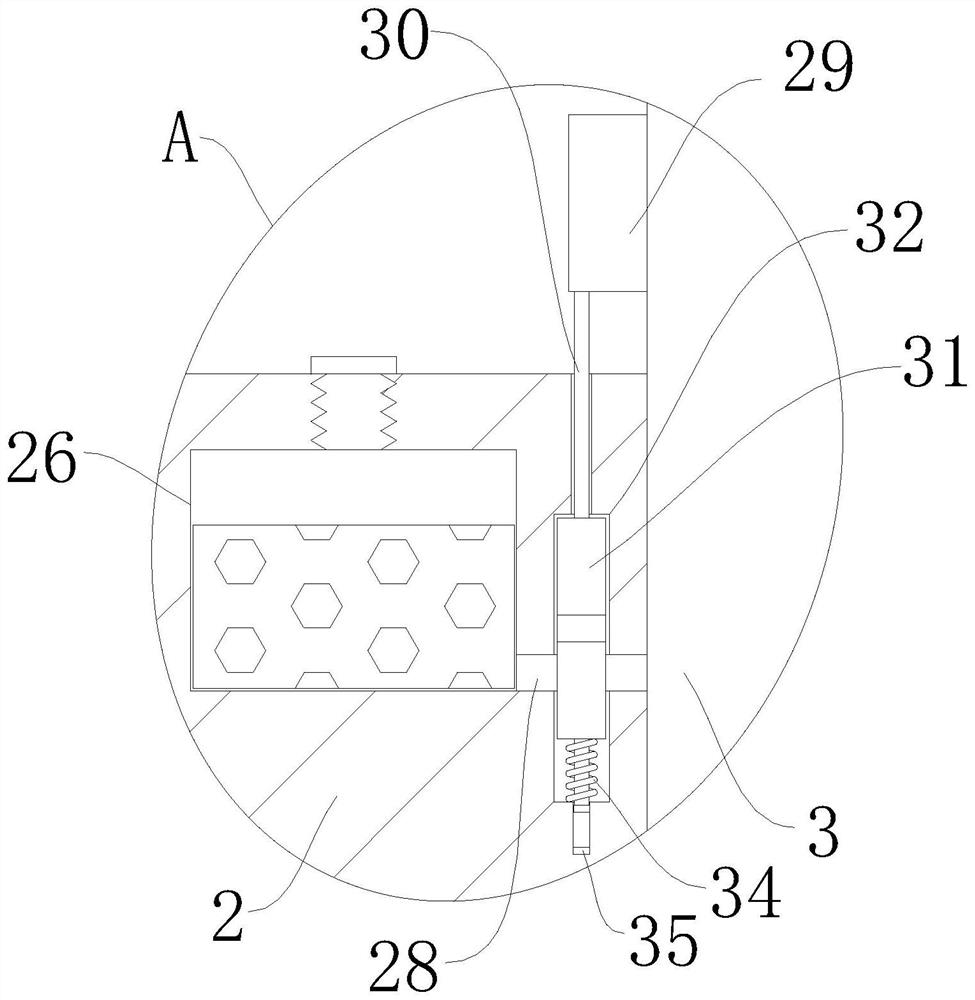

Metal punching machining equipment

InactiveCN113369521APrevent looseningAvoid drilling offsetMaintainance and safety accessoriesBoring/drilling machinesPunchingMetal machining

The invention discloses metal punching machining equipment. The equipment structurally comprises a punching equipment main rack and a clamp lifting device, the bottom of the right side of the punching equipment main rack is fixedly connected with the bottom of a clamp, a drill bit is installed over the clamp, a lubricant releasing device is fixedly connected to the top of the drill bit, the top of the lubricant releasing device is fixedly connected with a driving device, the exteriors of the lubricant releasing device and the driving device are both fixedly connected with a lifting device, the clamp comprises a clamp shell, a high-temperature-resistant clamp head and a fixing frame, the fixing frame is fixedly connected into the clamp shell, and the tail end of the right side of the fixing frame is fixedly connected with the high-temperature-resistant clamp head. The equipment relates to the technical field of metal processing, the high-temperature-resistant clamp head is arranged, so that the situation that due to heat expansion and cold contraction caused by high temperature, a clamp is loosened can be avoided, drilling deviation is prevented, and therefore the drilling accuracy is guaranteed.

Owner:朱荣焕

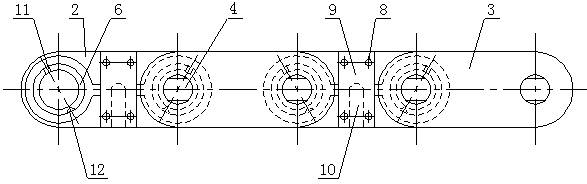

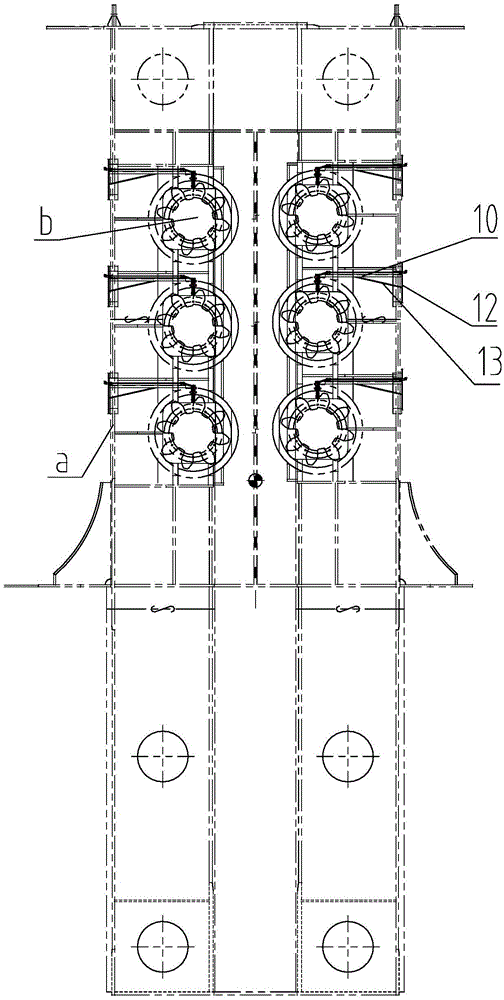

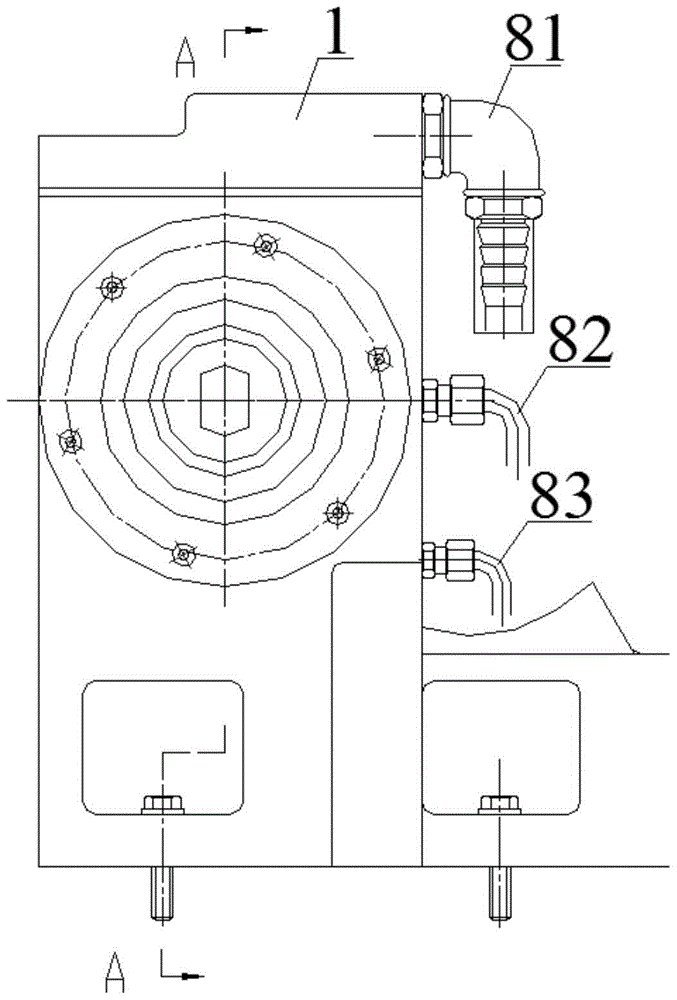

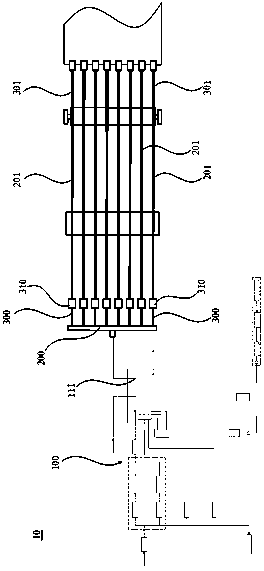

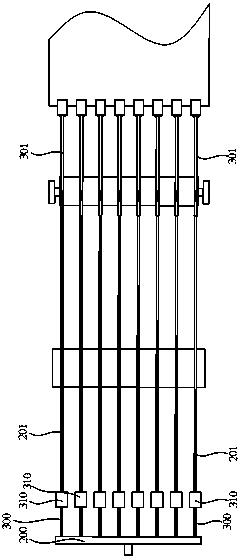

Self-lubricating felt of gear-rack jacking system

ActiveCN105465584ASimple structureEasy to manufactureLifting framesEngine lubricationDistributorLubrication

The invention discloses a self-lubricating felt of a gear-rack jacking system and belongs to the field of gear-rack jacking systems. The self-lubricating felt comprises: an electric lubrication pump, a distributor and a plurality of self-lubricating assemblies; an oil outlet of the electric lubrication pump communicates with an oil inlet of the distributor; a plurality of oil outlets of the distributor communicate with the plurality of self-lubricating assemblies, respectively; each self-lubricating assembly comprises: an oil inlet connector, a first oil inlet pipe, a three-way pipe, a second oil inlet pipe, a third oil inlet pipe, a first oil leading pipe, a fixed plate and a felt brush, and one end of the oil inlet connector communicates with one oil outlet of the distributor, while the other end of the oil inlet connector is connected with a first end of the first oil inlet pipe. The self-lubricating felt is capable of achieving the purpose of lubrication instead of artificial application, and therefore, high safety and high lubrication efficiency in a lubrication process are realized; further, the self-lubricating felt is simple in structure, easy to manufacture and relatively low in cost; as a result, lubrication costs are reduced.

Owner:WUHAN MARINE MACHINERY PLANT

Riding vehicle

ActiveCN100395154CImprove responsivenessCan suppress smallLiquid coolingCycle equipmentsEngineeringInternal combustion engine

Owner:YAMAHA MOTOR CO LTD

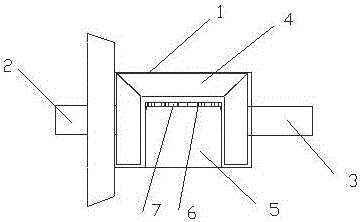

A main shaft structure of automatic lubricating and cooling gear shaping machine

ActiveCN103302317BAvoid wear and tearImprove cooling effectMaintainance and safety accessoriesReciprocating motionThermal deformation

An automatic lubricating and cooling type gear shaping machine spindle structure, which includes a main shaft, a main shaft sleeve is arranged outside the main shaft, the main shaft sleeve is embedded in the body of the tool holder, and an oil inlet and an oil outlet are respectively arranged on the upper end of the main shaft sleeve. A spiral oil groove is provided, and the outer circle of the main shaft sleeve is provided with multiple annular cooling grooves, and the lower end of the annular cooling groove communicates with the spiral oil groove. In the present invention, two spiral oil grooves are processed in the main shaft sleeve, and oil is brought into the friction zone by the reciprocating motion of the main shaft to form a lubricating oil film to achieve the purpose of lubrication and prevent the main shaft from being damaged; the outer circle of the main shaft sleeve is covered with annular cooling grooves, cooling The lower end of the groove communicates with the lubricating oil groove, and there is only one opening between the annular cooling grooves, and the openings between adjacent cooling grooves are symmetrically distributed. The heat is taken away to ensure the sufficient cooling of the main shaft sleeve, so that the thermal deformation of the main shaft sleeve is very small and prevent the main shaft from grinding to death.

Owner:宜昌长机科技有限责任公司

Multifunctional threaded pipeline

PendingCN110360390ATo achieve the purpose of lubricationEasy to disassembleNon-disconnectible pipe-jointsScrew threaded jointsThreaded pipeEngineering

The invention provides a multifunctional threaded pipeline which comprises a first pipe body with an external screw thread, and a second pipe body with an internal screw thread. The second pipe body and the first pipe body are connected in a screwing way through the internal screw thread and the external screw thread; a main glue injection channel is built in the threaded pipe wall of the first pipe body; a branch glue injection pipeline is arranged on the threaded pipe wall of the first pipe body; and one end of the main glue injection channel communicates with the outside. The multifunctional threaded pipeline has the beneficial effects that (1) the device can be sealed by adopting a high-pressure sealant filling manner regularly without the need for disassembling the pipeline; and (2) when the connected pipeline does not need to be sealed, lubricating oil is injected into the main glue injection channel, so that two rusted pipelines can be disassembled and separated.

Owner:JIANGSU JUZHENG MASCH CO LTD

A cylindrical grinder that is easy to assemble and maintain

ActiveCN104690613BHigh precisionHigh surface finishGrinding machine componentsRevolution surface grinding machinesCeramic coatingThermal expansion

The invention discloses a cylindrical grinder easy to assemble and maintain and belongs to the technical field of machine tools. The cylindrical grinder comprises a sleeve, a shell, a cover plate, a grinding wheel and a sliding bearing, the shell is arranged inside the sleeve, two ends of the shell are sealed through the cover plate, the sliding bearing transversely penetrates the shell, and one end of the sliding bearing is connected with the grinding wheel; a ceramic coating is arranged on the sliding bearing and at the contact position of a spindle and a bearing bush, a return oil pipeline is arranged inside the shell and is communicated with a lubricating oil tank on the outer portion of the sleeve, and lubricating oil is circulated in the return oil pipeline in zero-pressure circulation. The ceramic coating is sprayed at the friction position of the spindle and the bearing bush, so that problems about thermal expansion deformation and abrasion of the metal spindle are solved by the aid of outstanding performance of ceramic; meanwhile, according to self structural features of the cylindrical grinder, a brand new oil leakage prevention pipeline is designed for the cylindrical grinder, zero-pressure circulation lubrication of the lubricating oil in an oil cavity is realized, long-term operation is achieved without disassembling the grinder for maintenance, and maintenance cost is greatly lowered.

Owner:MAANSHAN HENGLIDA MACHINE BLADE +1

A fast polishing device

The invention relates to a quick polishing device, which is used for grinding cylinders and comprises a main rod, grinding branches and grinding heads. The grinding branches are obliquely formed on the main rod in an axially staggered manner, and the grinding heads are disposed at ends of the grinding branches and are grinding head bodies capable of rotating along the grinding branches. The grinding branches are structurally designed into staggered oblique forms, accordingly, staggered oil storage pits are formed in an inner cavity of a cylinder liner conveniently, and the purpose of lubricating when a piston moves left and right is achieved. In addition, rotating sleeves are disposed on the grinding heads, accordingly, grinding grooves formed when the grinding heads are used for grinding are crescent, and the service lives of the grinding heads are prolonged. Furthermore, as the grooves are disposed on the grinding heads, the grinding heads are sharp when used for grinding. Besides, due to the reasonable structure and the crescent oil storage pits which are formed on the surface of the cylinder liner after the cylinder liner is ground, the quality of the cylinder liner is remarkably improved, and service performances of the cylinder liner are enhanced.

Owner:RUGAO JIANGHAI TECHN SCHOOL

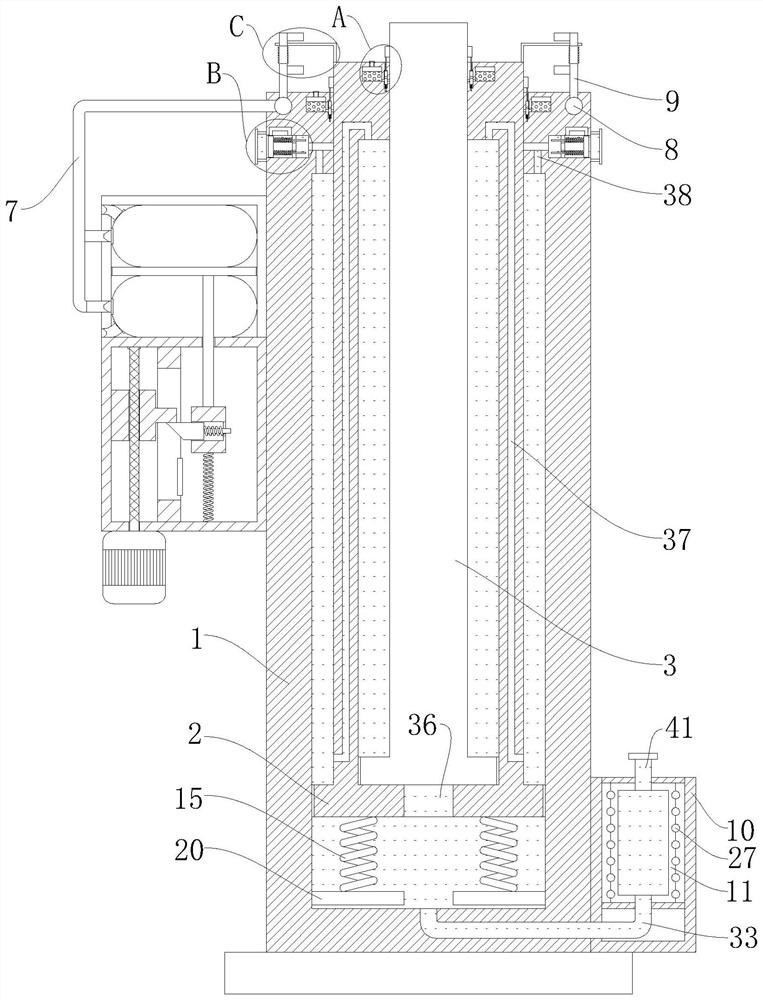

Enhanced hydraulic support

PendingCN113187526AImprove efficiencyEasy dischargeMining devicesProps/chocksStructural engineeringMechanical engineering

The invention relates to an enhanced hydraulic support which comprises a base, a beam body and stand columns; the beam body is connected with the right end face of the base in a rotating connection mode; the stand columns are symmetrically and fixedly installed on the front side and the rear side of the upper end face of the base; the upper end faces of the stand columns are connected with the beam body in a rotating connection mode; the base comprises a bottom plate, a fixed block, a sliding rail, a material conveying groove, a first magnet, a sliding block and a second magnet; and the beam body comprises a first connecting rod, a second connecting rod, a shield beam, a balance jack, a top beam, a telescopic beam and a side protection plate. According to the enhanced hydraulic support, through the base, gangue produced in coal mining operation is quickly stored, so as to reduce discharge of the gangue so as to improve the efficiency of the hydraulic support in the coal mining operation; and by means of the stand columns in the beam body, when one stand column breaks down, the hydraulic support can still be used, and coal mining operation is prevented from being affected.

Owner:武汉荣拓智能设备有限公司

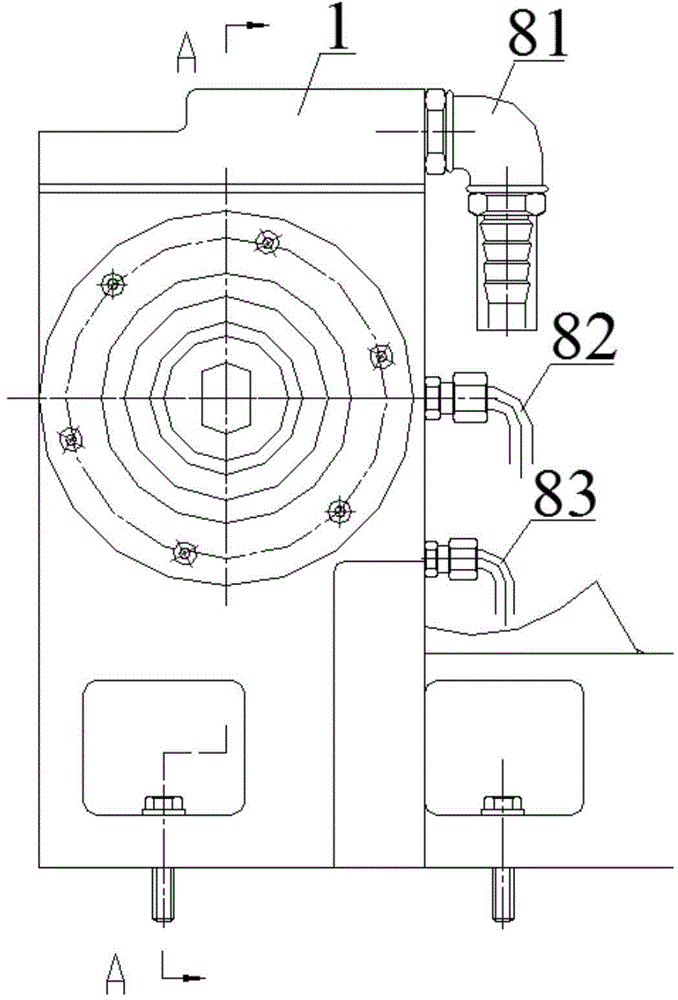

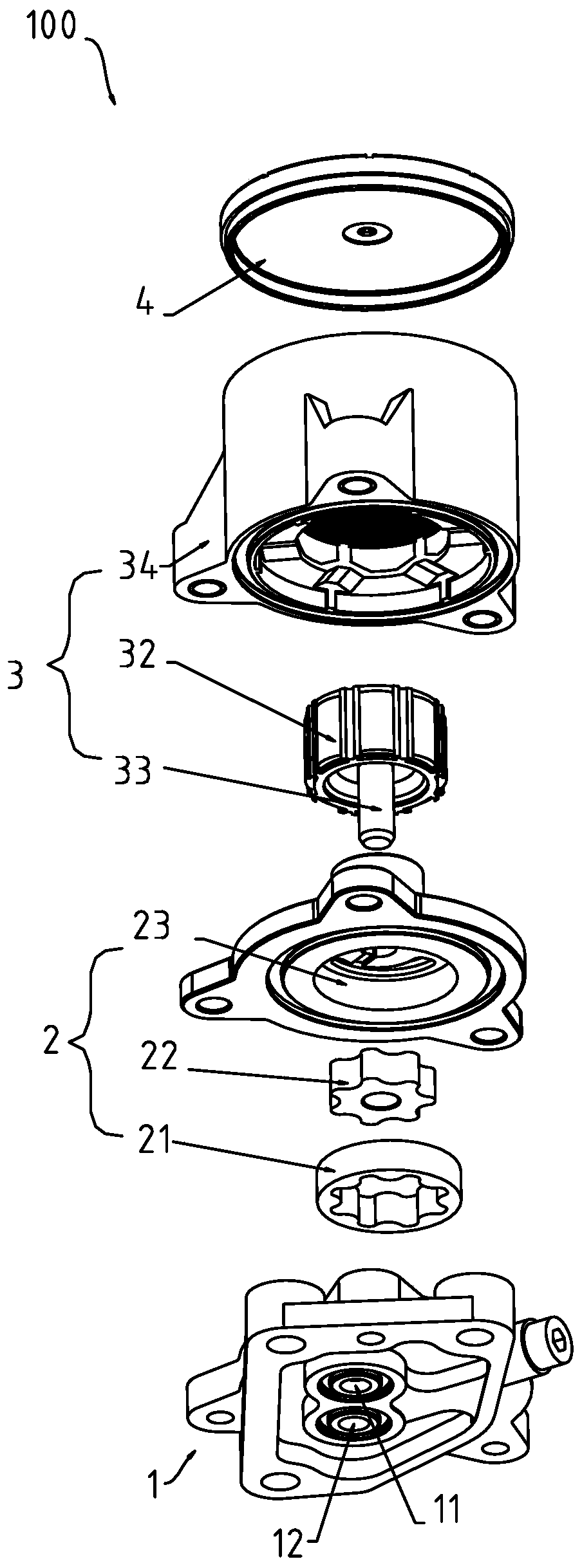

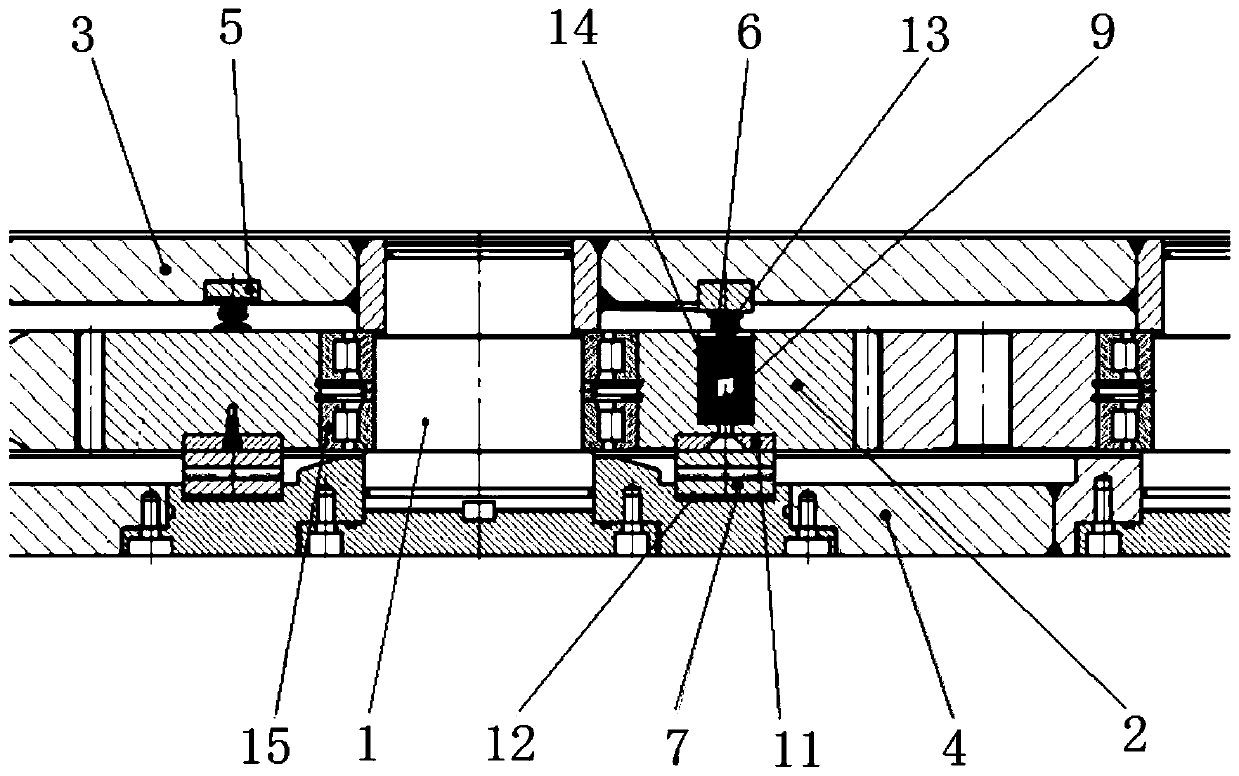

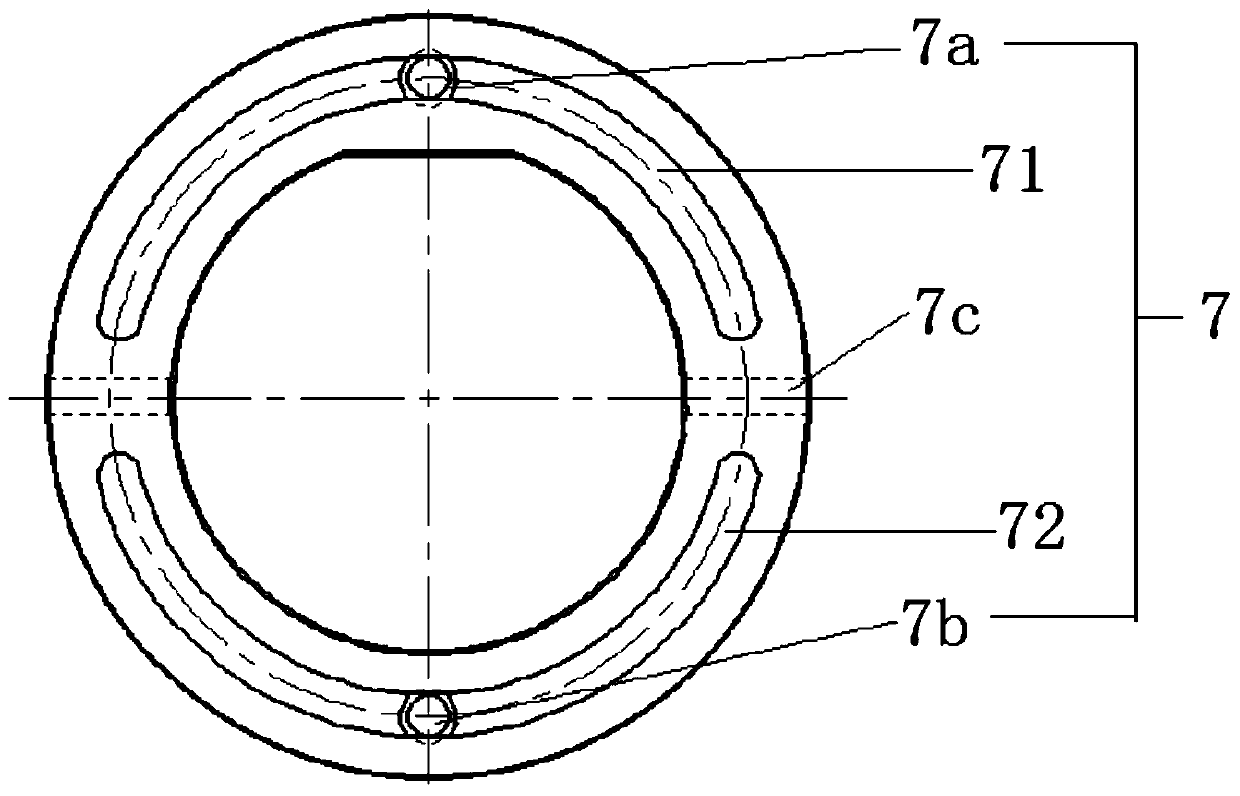

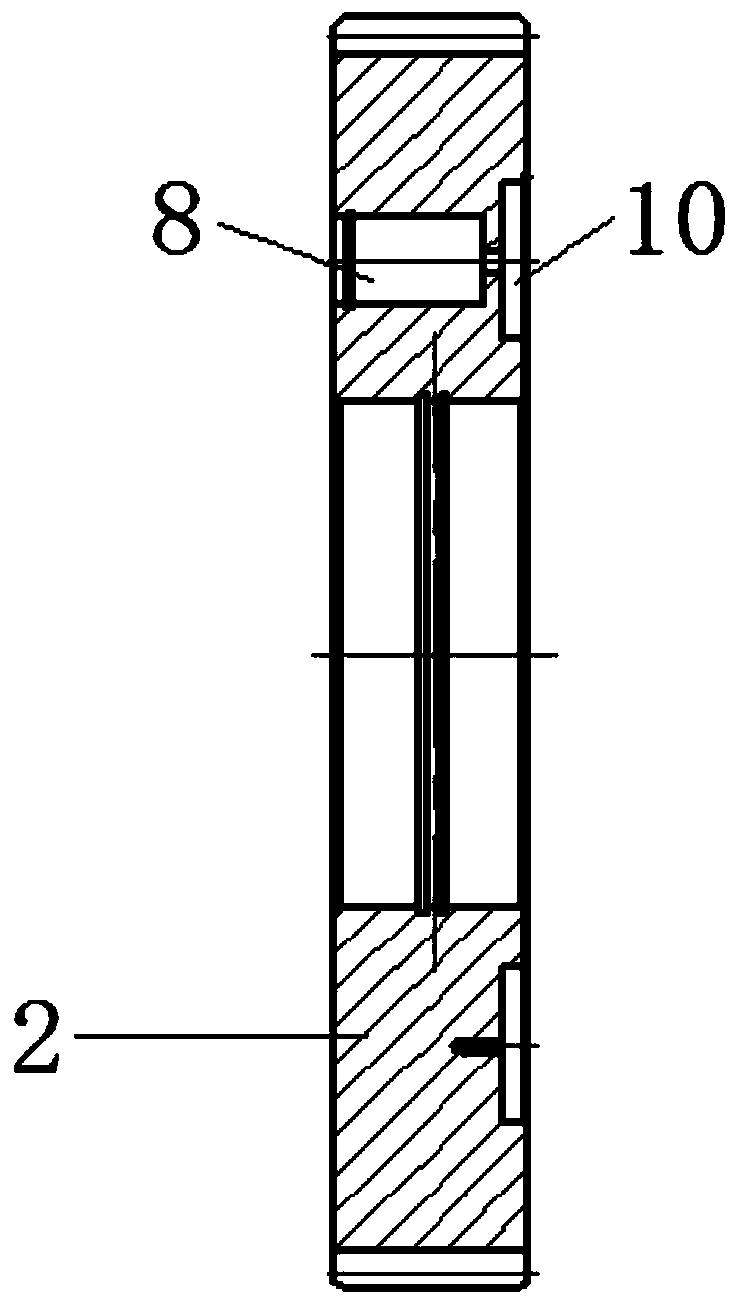

Bearing for fluid pump

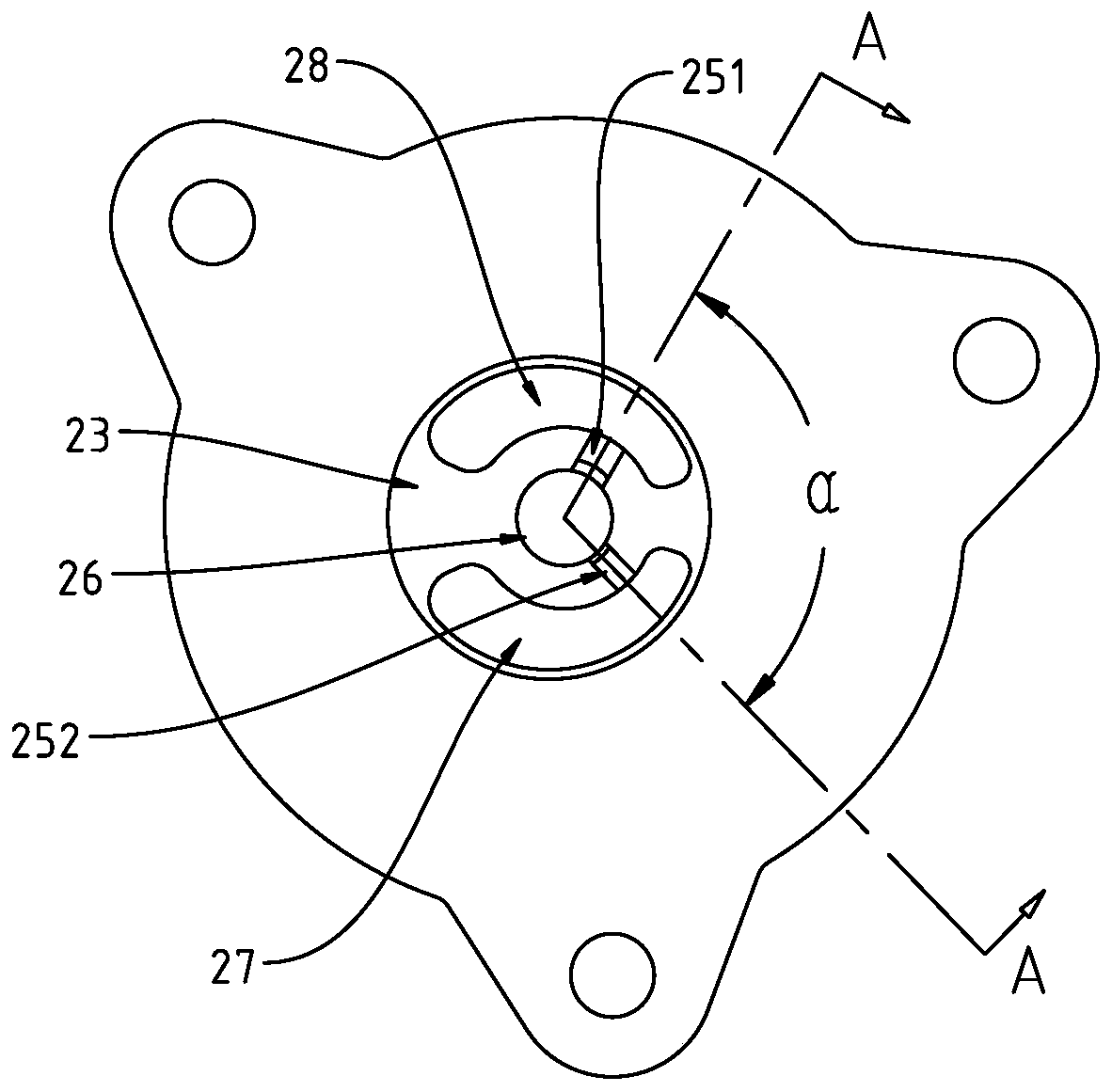

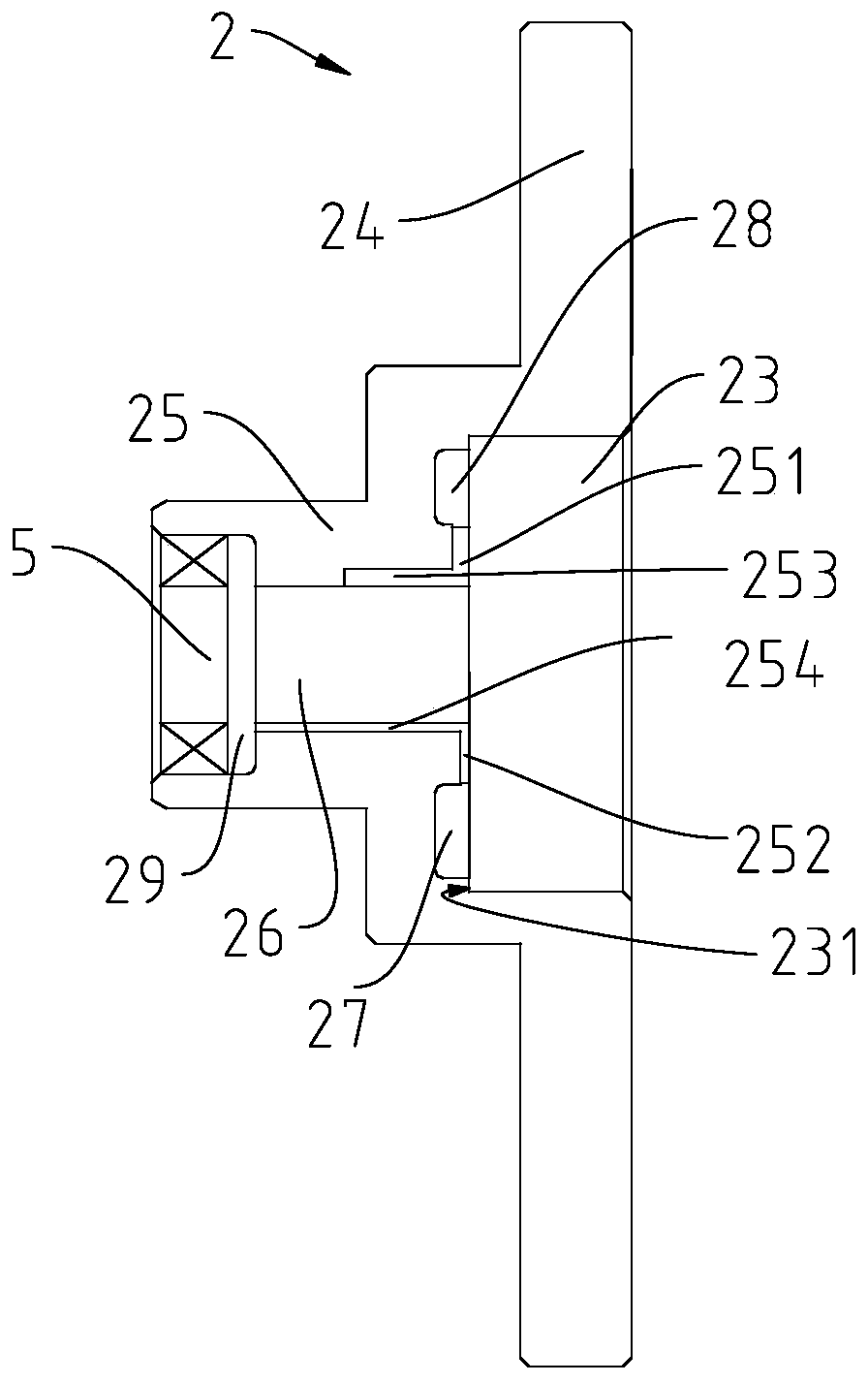

PendingCN110425222ATo achieve the purpose of lubricationAvoid wear and tearShaftsBearing componentsPositive pressureBiomedical engineering

The invention provides a bearing for a fluid pump. When the fluid pump works, a positive pressure region (28) for pumping fluid and a negative pressure region (27) for allowing the fluid to flow intoare formed in the fluid pump, a fluid supply groove (253) extending in the axial direction and a fluid backflow groove (254) are formed in the hole wall of a shaft hole (26) of the bearing (25) correspondingly, wherein the fluid supply groove (253) communicates with the positive pressure region (28), the fluid backflow groove (254) communicates with the negative pressure region (27), and the fluidsupply groove (253) is in a blind groove shape. According to the bearing, the holding force of an oil seal can be reduced, or the oil seal can be directly omitted, so that the manufacturing cost of an oil pump is reduced.

Owner:常州嵘驰发动机技术有限公司

Lubrication type speed reducer structure suitable for large gradient

InactiveCN103836169ASolve lubrication problemsSimple structureGear lubrication/coolingOil canReducer

The invention discloses a lubrication type speed reducer structure suitable for a large gradient. The lubrication type speed reducer structure suitable for the large gradient comprises a speed reducer output shaft and a speed reducer input shaft. The end of the inner side of an input bearing block and the end of the inner side of an output bearing block are correspondingly fixedly provided with a front oil storage baffle and a rear oil storage baffle respectively in a welded mode, and the front oil storage baffle and the rear oil storage baffle correspond to the input bearing block and the output bearing block respectively to form oil storage cavities. The edge of one side of the front oil storage baffle and the edge of one side of the rear oil storage baffle are provided with a plurality of oil inlet holes, and the edge of the other side of the front oil storage baffle and the edge of the other side of the rear oil storage baffle are provided with a plurality of oil passing holes. The positions, located at the oil inlet holes, of the front oil storage baffle and the rear oil storage baffle are fixedly provided with oil isolating rings in a welded mode. According to the lubrication type speed reducer structure, lubricating oil can be isolated into the oil storage cavities, the oil backflow velocity can be reduced during large-gradient work, bearings located at high positions can be still in contact with the lubricating oil, and the purpose of lubricating can be achieved.

Owner:SHENYANG NORTH MINING MACHINERY

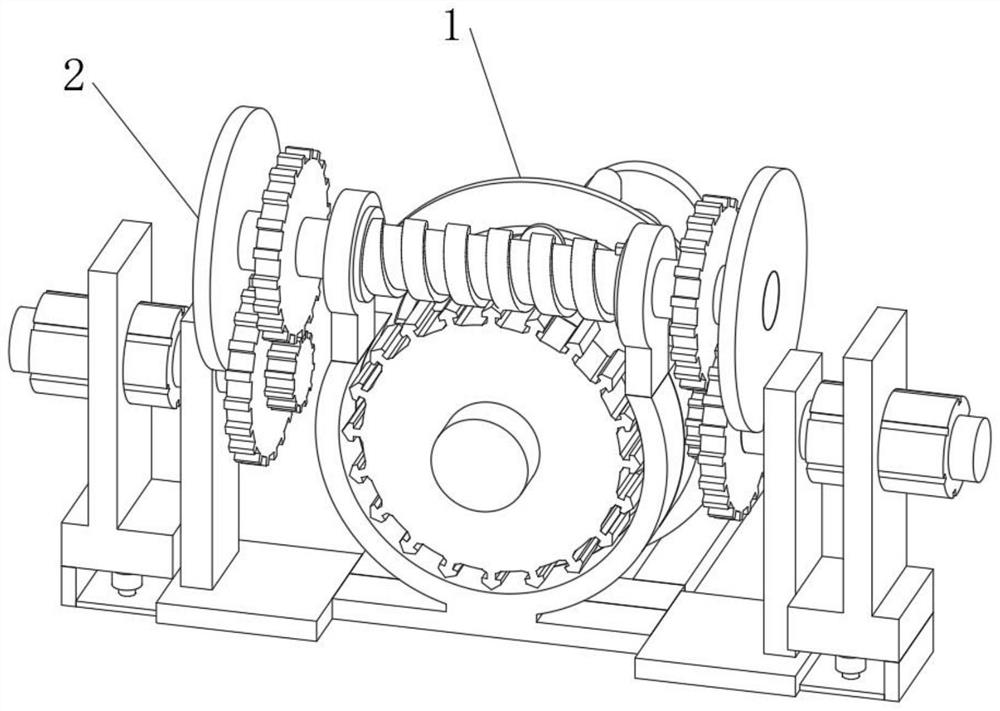

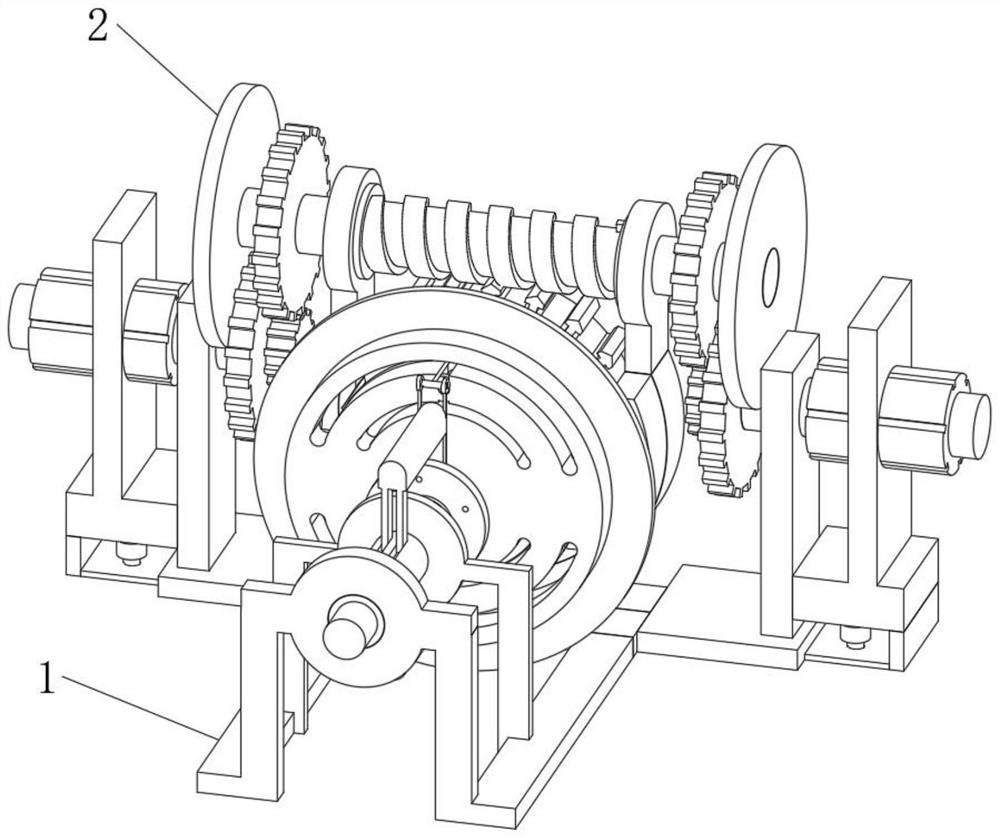

High-precision worm and gear transmission mechanism

PendingCN114776769ARealize regulatory control workAchieving assembly fit workGear lubrication/coolingToothed gearingsEngineeringTransmission equipment

The invention relates to the technical field of transmission equipment, and discloses a high-precision worm gear and worm transmission mechanism which comprises a worm gear pushing and guiding connecting structure and a worm connecting and driving structure, and the worm connecting and driving structure is connected to the front end of the center of the worm gear pushing and guiding connecting structure in an engaged mode. The worm wheel pushing and guiding connecting structure comprises a pushing and guiding transferring part and a first supporting rack, the pushing and guiding transferring part is arranged at the center position of the worm wheel pushing and guiding connecting structure, and the rear end of the pushing and guiding transferring part is connected with the first supporting rack in a sleeved mode. The bottom end of the first supporting rack is fixedly connected with a bottom supporting plate, and the center position of the bottom supporting plate is fixedly connected with the second supporting rack. Through the arrangement of the worm gear pushing and guiding connecting structure and the worm connecting and driving structure, high-precision worm gear and worm transmission work is achieved, and the purpose of better driving treatment is achieved.

Owner:江苏迈仕传动科技有限公司

Glassed steel differential housing

InactiveCN106838274AReduce the chance of bringing dandruffHigh temperature resistance and good water permeabilityGear lubrication/coolingDifferential gearingsEngineeringMechanical engineering

The invention discloses a glassed steel differential housing. The glassed steel differential housing comprises a shell, wherein a driving gear and a driven gear are separately arranged at the two sides of the shell; the driving gear is linked with the driven gear through side gears; a lug is arranged in the shell through welding; a top cover with through holes is arranged at the top of the lug; and the top cover is clamped with the lug. Compared with the prior art, the glassed steel differential housing has the advantages that by increasing the design of the lug, a clearance in the glassed steel differential housing is reduced, so that the flock and chip bringing-in rate is reduced; at the same time, when filled with lubricating oil, the cavity in the lug can perform the function of a container, and the lubricating oil is filled into the lug and tossed out from the through holes of the top cover with continuous rotating, so that a lubricating purpose is achieved; and besides, the high temperature resistance and the water permeability are great.

Owner:无锡上工搪化工设备有限公司

Vehicle door locking mechanism facilitating operation

InactiveCN112780113AAvoid time-consuming and labor-intensive disadvantagesTo achieve the purpose of lubricationVehicle locksControl engineeringCar door

The invention relates to the technical field of vehicle door locks, in particular to a vehicle door locking mechanism facilitating operation, and solves the problems that in the prior art, a vehicle door lock is stuck after being used for a long time and when a vehicle door lacks lubricating oil, the whole lock generally needs to be disassembled when a car key is broken in a lock hole, professional unlocking personnel needs to take out the broken key, time and labor are wasted, and the maintenance cost is increased. The vehicle door locking mechanism facilitating operation comprises a vehicle door, a rotating groove is formed in the vehicle door, a lock cylinder is arranged at the inner side of the rotating groove, and the lock cylinder is rotatably connected with the inner wall of the rotating groove through a ball. According to the vehicle door locking mechanism, a push rod is adopted to drive a reverse push block to take out the key broken in the lock cylinder, the operation is rapid and effective, and the defect that in the prior art, the whole door lock needs to be disassembled, and time and labor are wasted is overcome.

Owner:林俊钦

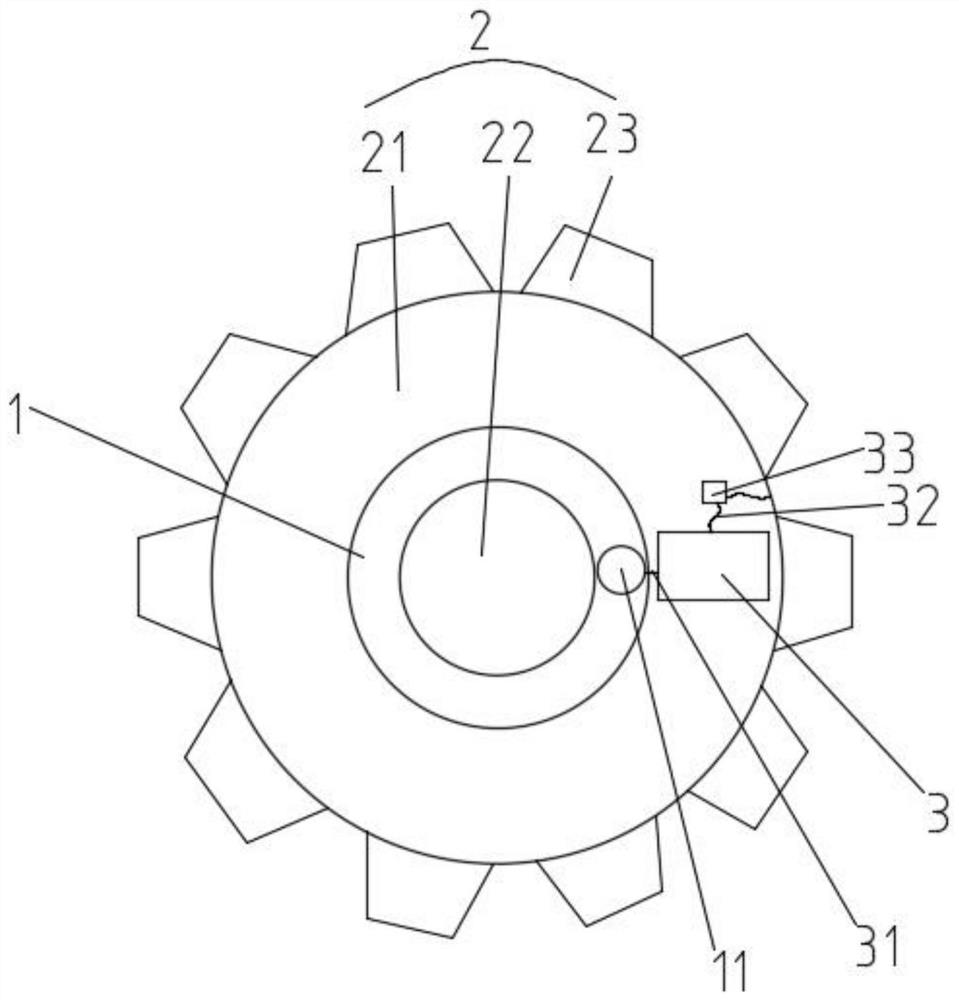

Low-friction lubricating gear

InactiveCN112824709ATo achieve the purpose of lubricationReduce frictionGear lubrication/coolingPortable liftingGear wheelEngineering

The invention relates to a low-friction lubricating gear. The low-friction lubricating gear comprises a gear column and a gear body connected with the gear column; the gear body comprises a gear disc, a shaft hole and outer teeth; the shaft hole is located in the middle of the gear disc; the outer teeth are located on the periphery of the gear disc; an oil storage cavity is formed in the gear disc; one end of the oil storage cavity communicates with an oil injection hole in the gear column through an oil passage I; the other end of the oil storage cavity communicates with an oil outlet in a tooth groove of the outer tooth through an oil passage II; and a temperature variable-diameter check valve is arranged in the oil passage II. According to the low-friction lubricating gear, through the oil storage cavity in the gear disc and the temperature variable-diameter check valve in the oil passage, when the temperature of a gear is too high, oil in the oil storage cavity enters the oil outlet in the tooth groove of the outer tooth through the check valve, so that the purpose of gear lubrication is achieved; and meanwhile, through copper plating treatment on the surface of the gear body, the roughness of the tooth surface is improved, and the friction force during gear operation is reduced.

Owner:高邮市精标齿轮制造有限公司

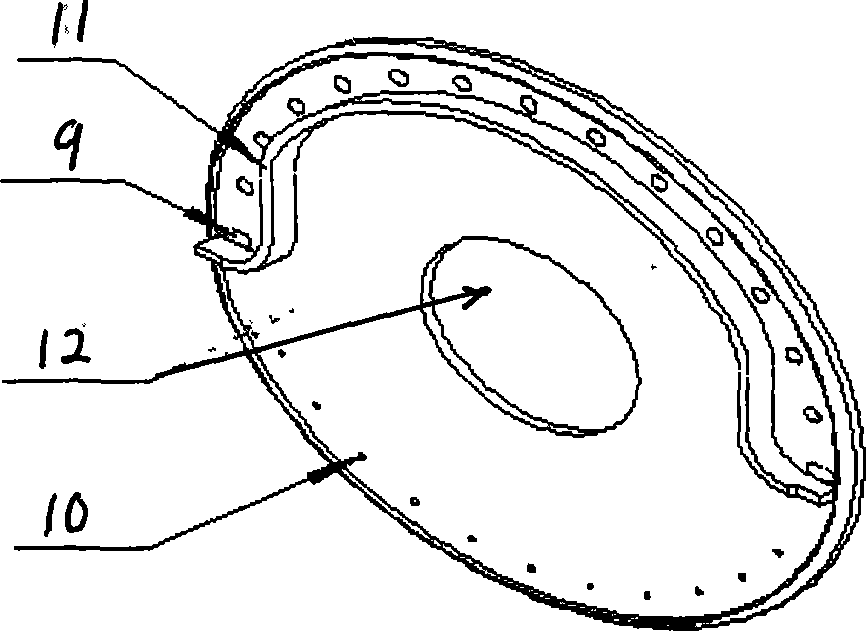

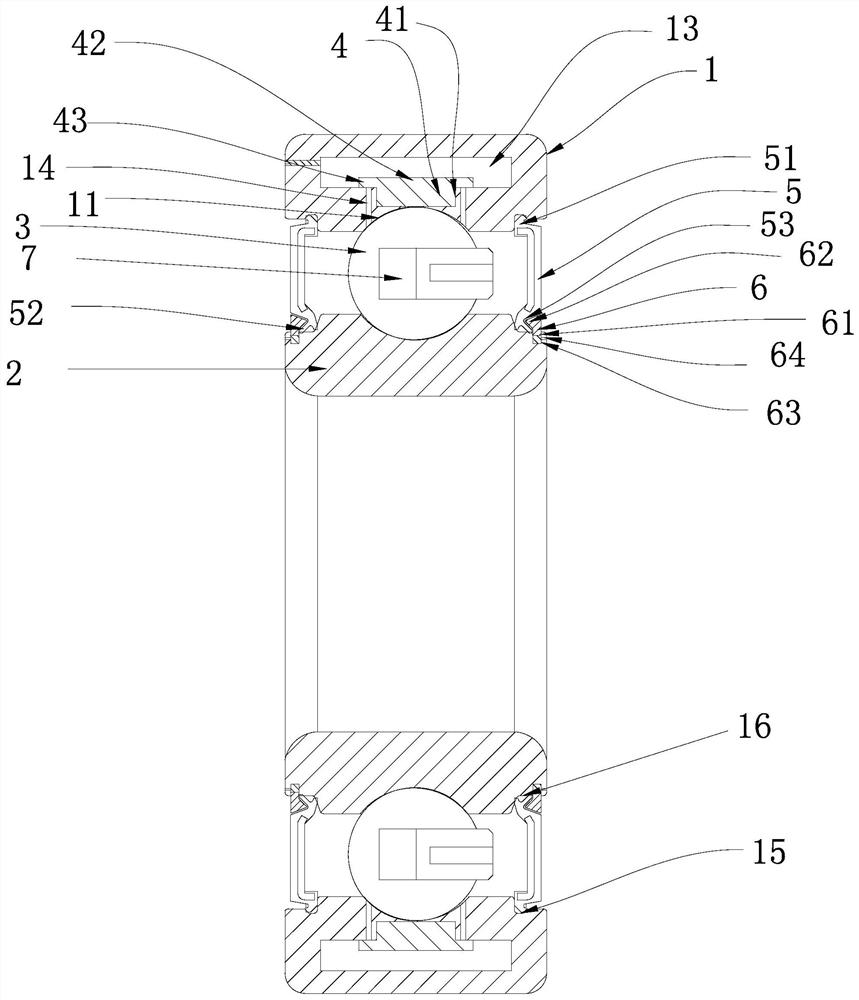

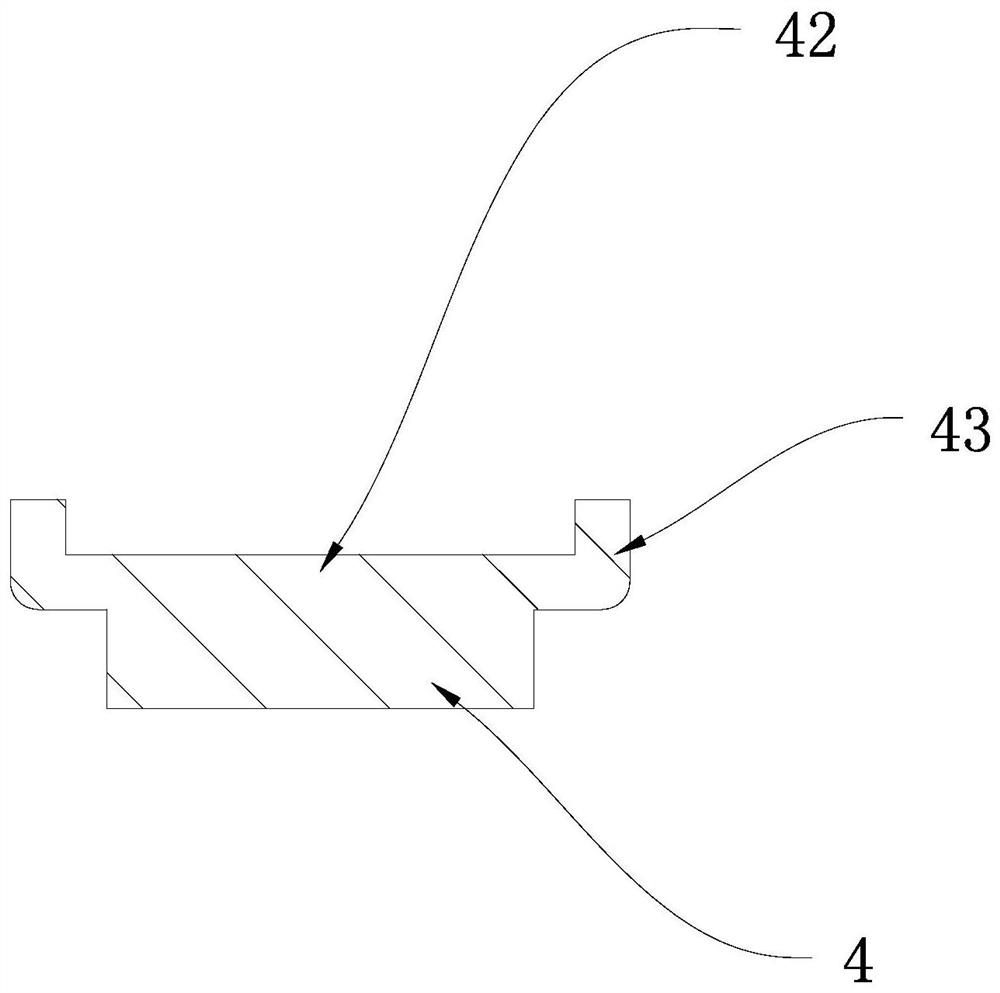

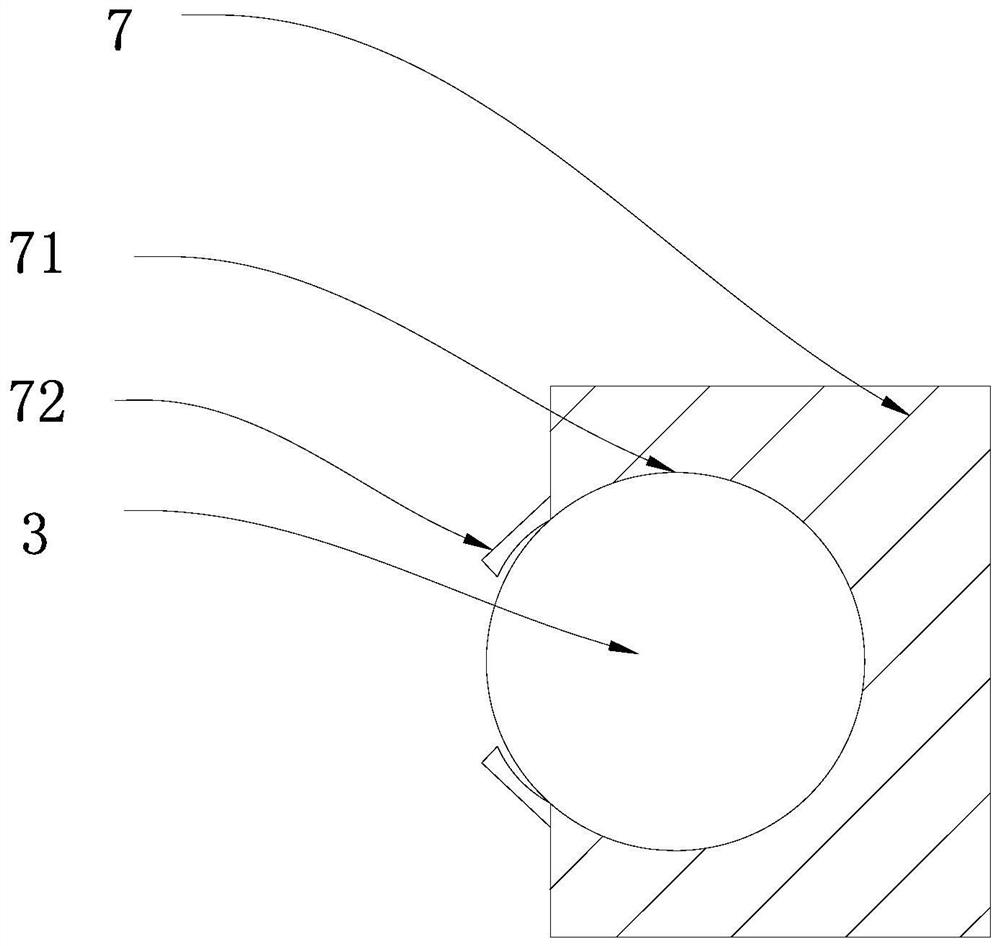

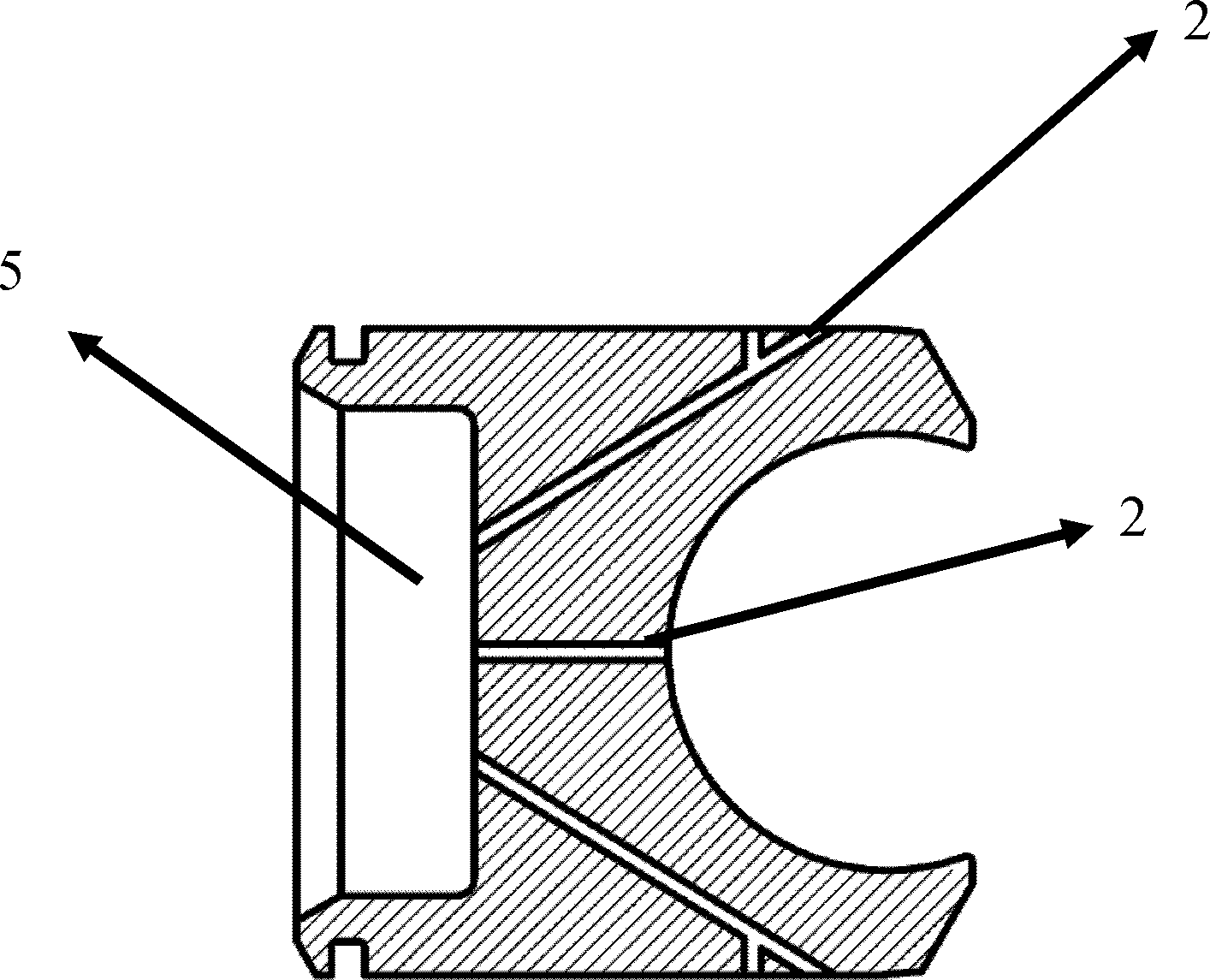

High-sealing oil supplementing bearing special for silicone oil clutch

The invention discloses a high-sealing oil supplementing bearing special for a silicone oil clutch. The high-sealing oil supplementing bearing comprises an outer ring, an inner ring and rollers, wherein a roller path allowing the rollers to roll is formed in the inner circumferential wall of the outer ring and the outer circumferential wall of the inner ring, a rolling cavity is formed between the outer ring and the inner ring, and two sealing parts used for sealing the rolling cavity are arranged between the outer ring and the inner ring; and the two sealing parts are arranged at the two sides of the rollers, an oil supplementing cavity is formed in the outer ring in a hollow manner, the oil supplementing cavity is filled with solid grease, an oil discharging hole for conveying grease is further formed in the outer ring, one end of the oil discharging hole is communicated with the oil supplementing cavity, and the other end of the oil discharging hole is communicated with the roller path on the outer ring; and a blocking part used for dredging the oil discharging hole when the bearing operates and blocking the oil discharging hole when the bearing stops operating is arranged in the oil supplementing cavity. According to the high-sealing oil supplementing bearing, the problems that in the prior art, because the grease in the bearing rolling cavity is used up, the rollers rotate in a dry manner, and the bearing sealing parts are prone to disengaging from the rollers are solved.

Owner:C&U CO LTD +3

Self-locking mechanism

The invention discloses a self-locking accessory mechanism, which comprises the following parts: cylinder component, long axis component, movement shaft and spring component, wherein the cylinder component possesses mutual corresponding upper chute and lower chute; the long axis component is cased in the cylinder component, which pierces the expanding flute through-out hole corresponding to lower chute; the movement shaft pierces lower chute, through-out hole and upper chute, which consists of upper expanding part and lower expanding part; the lower expanding part corresponds to expanding flute; the spring component is cased on the movement shaft with top between upper expanding part and cylinder component, which provides elastic stress to move the movement shaft to be fixed in the expanding flute corresponding to lower expanding part.

Owner:KINPO ELECTRONICS CHINA

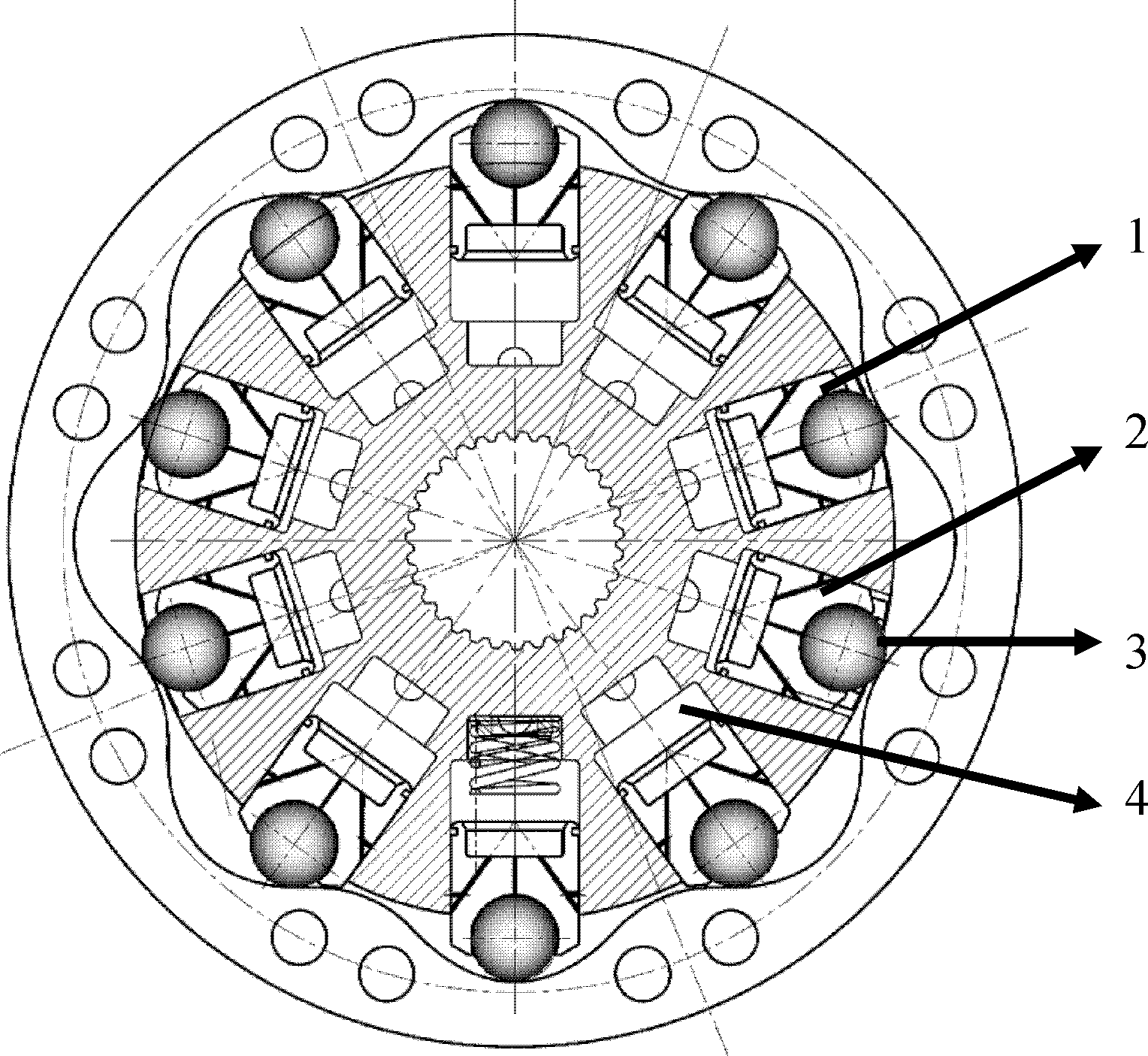

Radial piston used in hydraulic motor

InactiveCN102758720ANo loss of volumetric efficiencyAdjustable structurePlungersTrunk pistonsLubricationEngineering

The invention discloses a radial piston used in a hydraulic motor. The radial piston is characterized in that a plurality of lubricating holes (2) are provided on a stressed friction surface of the radial piston (1). According to the invention, the structure of a traditional piston is adjusted. The lubricating holes communicating with a high pressure cavity are arranged at the stressed friction surface of the radial piston which is vulnerable to severe abrasion. Through long-hole throttling, high pressure oil is delivered to lubricating points. Therefore, the lubrication of stressed radial piston stressed friction surface is improved, and the lubrication on a central roller is more sufficient.

Owner:无锡市汉力士液压泵制品有限公司

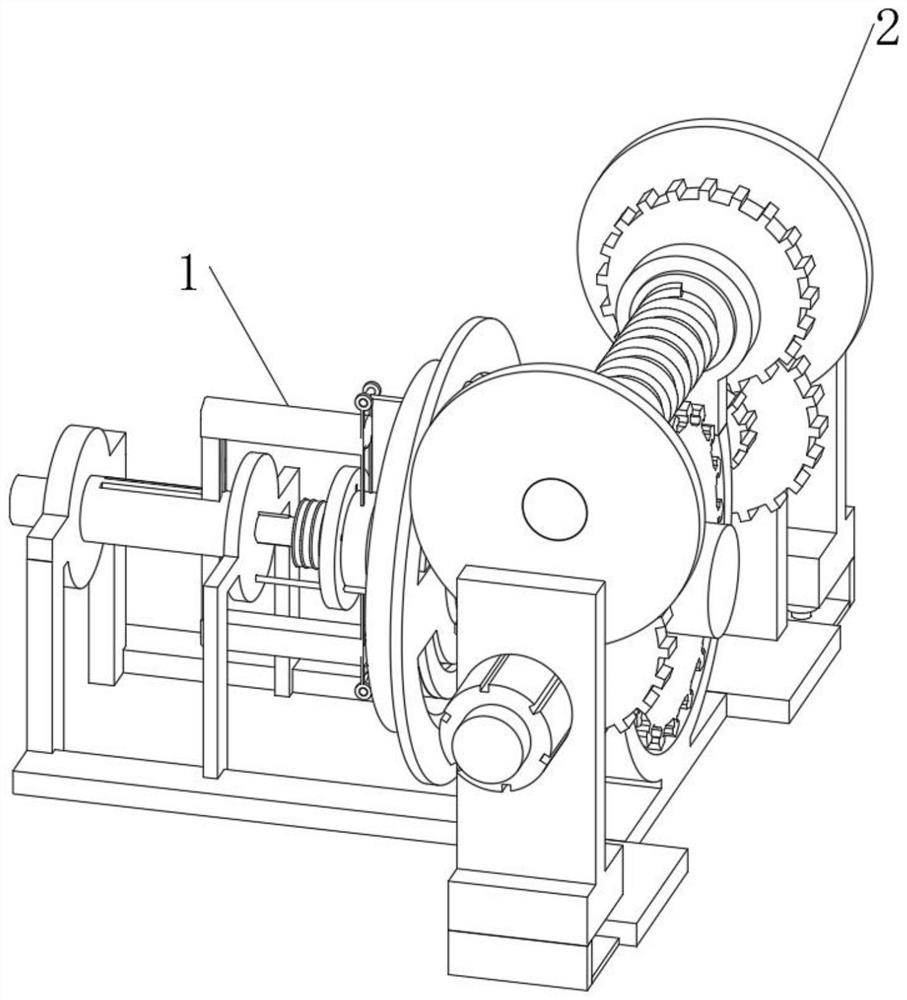

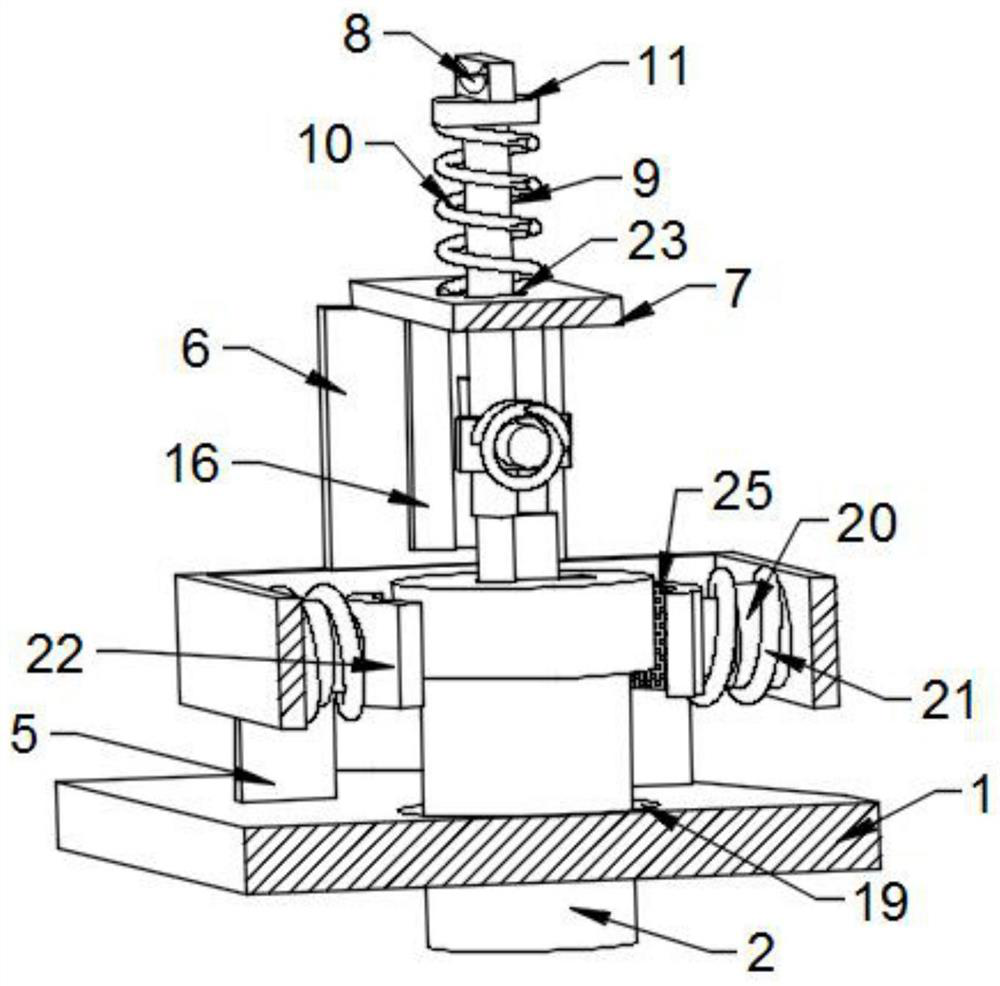

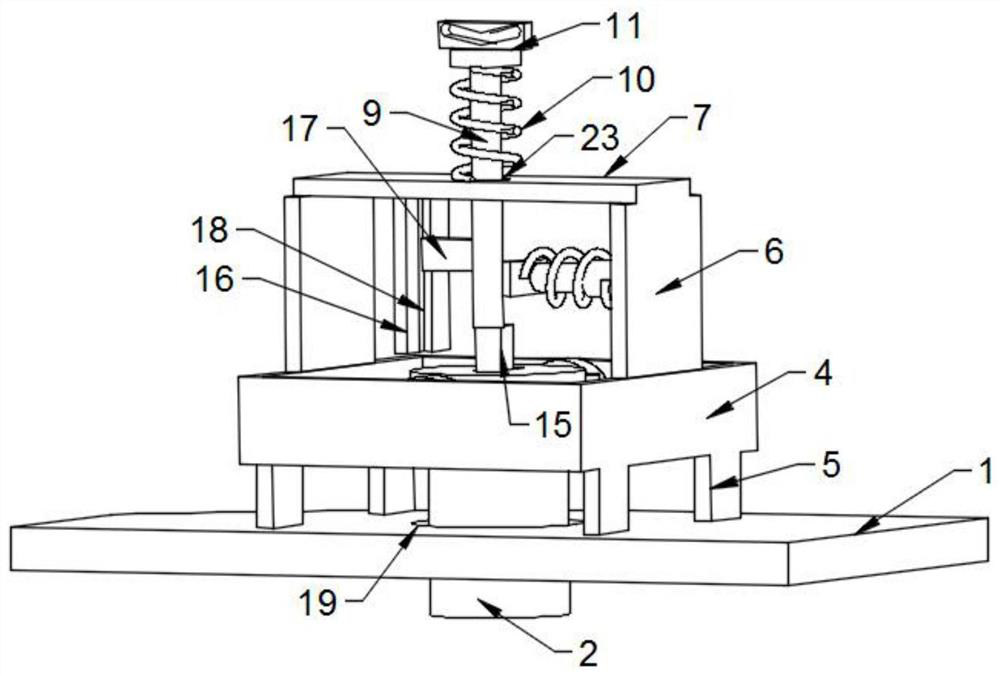

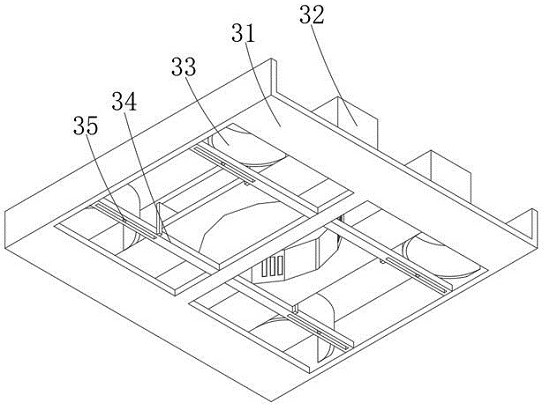

Gear train self-lubricating device

ActiveCN109854730ATo achieve the purpose of lubricationSimple structureGear lubrication/coolingEngineeringOil distribution

The invention discloses a gear train self-lubricating device. The gear train self-lubricating device comprises a gear shaft, a gear, a first shell, a second shell, a swash plate, a plunger and an oildistribution disk. The gear shaft is rotatably sleeved with the gear. The first shell and the second shell are arranged on the two sides of the gear correspondingly. The swash plate is arranged on theinner wall of the first shell. The thickness of the swash plate gradually changes in the circumferential direction. The gear is provided with a plunger hole in the axial direction. The plunger is located in the plunger hole and supported through an elastic part. When the gear rotates, the top end of the plunger abuts against the swash plate. The oil distribution disk is arranged on the inner wallof the second shell, communicates with the bottom end of the plunger hole and is used for filling oil into the plunger hole or discharging lubricating oil in the plunger hole. According to the gear train self-lubricating device provided by the invention, the lubricating oil is transferred from one side of the oil distribution disk to the other side of the oil distribution disk along with rotationof the gear to achieve the lubricating effect. There is no need to additionally pump in pressure. The gear train self-lubricating device is simple in structure and wide in application range, and thesize of equipment is reduced.

Owner:山西煤矿机械制造股份有限公司

Sealed multi-stage hydraulic cylinder

PendingCN114321092AImprove ash removal effectTo achieve the purpose of blowingFluid-pressure actuatorsEngine lubricationHydraulic cylinderReciprocating motion

The invention relates to the technical field of hydraulic cylinders, in particular to a sealed multi-stage hydraulic cylinder which comprises a hydraulic cylinder body, a first telescopic rod is slidably connected to an inner cavity of the hydraulic cylinder body, a second telescopic rod is slidably connected to an inner cavity of the first telescopic rod, and a round pipe is installed in the top of the hydraulic cylinder body. A plurality of air blowing pipes are evenly installed at the top of the round pipe, telescopic pipes are fixedly installed at the top ends of all the sets of air blowing pipes, L-shaped plates are connected to the pipe walls of all the sets of telescopic pipes in a sleeving mode, a reciprocating lead screw is driven by a motor to rotate, up-down reciprocating motion of a movable block can be achieved, and a U-shaped frame is driven to move up and down through cooperation of an inclined block and a first spring; and therefore, dust can be blown away from the first telescopic rod and the second telescopic rod which are retracted in sequence all the time, the situation that the first telescopic rod and the second telescopic rod are abraded due to residual dust during retraction can be effectively avoided, and the service life of the device can be effectively prolonged.

Owner:汪志宏

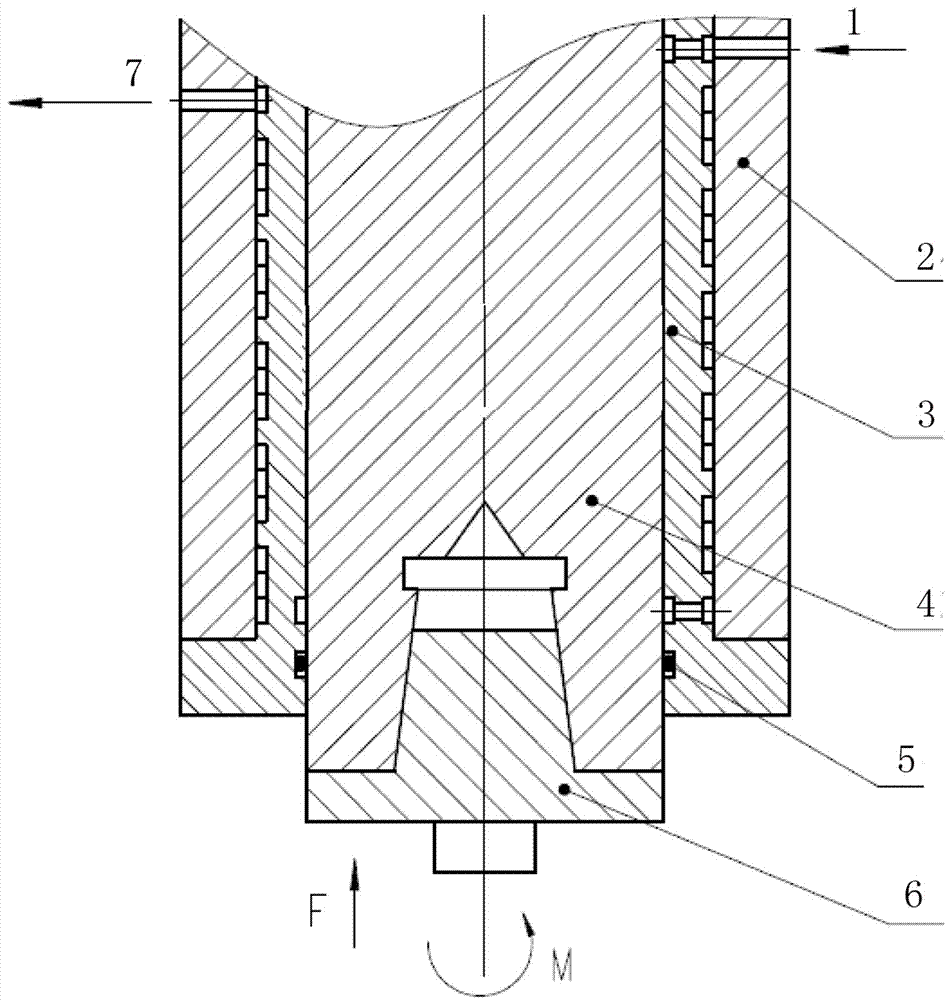

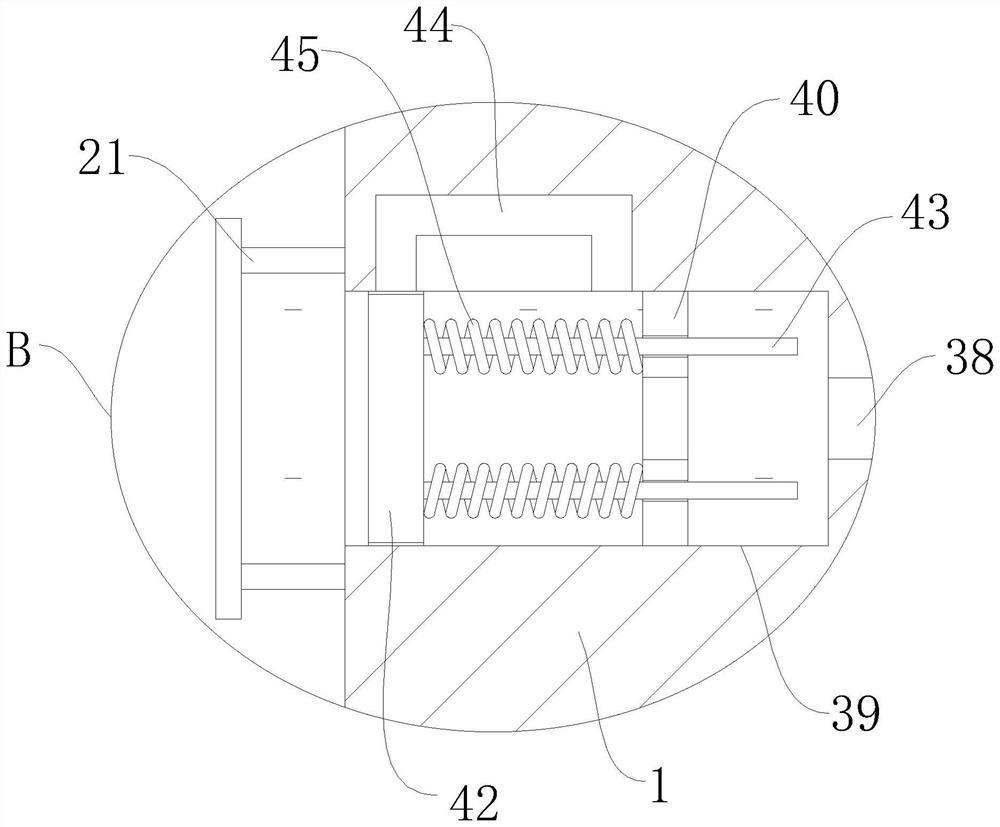

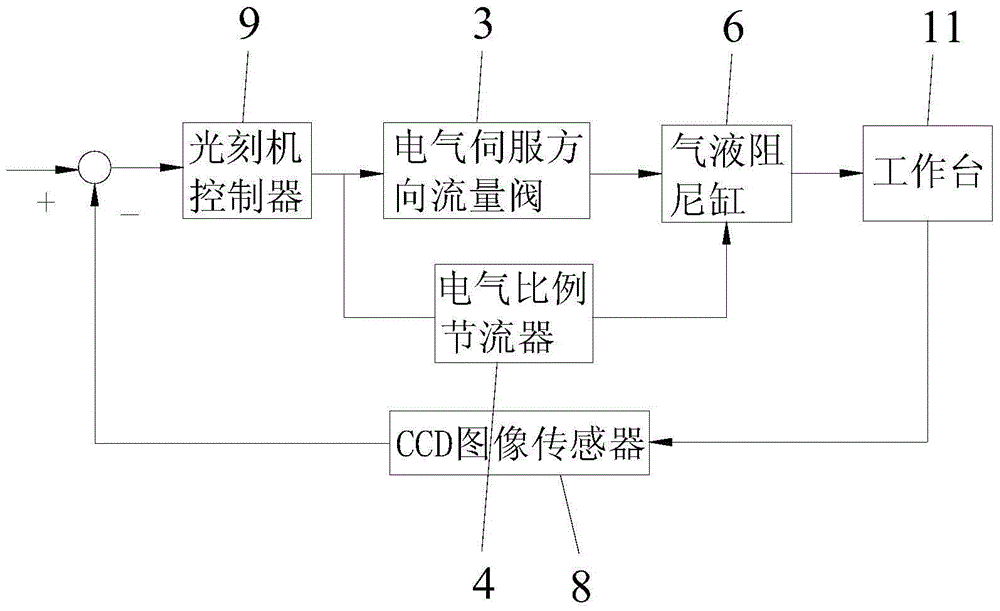

Electrical servo alignment control system and control method for lithography machine

ActiveCN104460240BEliminate frictionEliminate the effects of thermal deformationPhotomechanical exposure apparatusMicrolithography exposure apparatusHydraulic cylinderControl system

The invention discloses an electrical servo position alignment control system and an electrical servo position alignment control method of a photoetching machine. The control system comprises a pneumatic triple element connected with an air source, an electrical servo direction flow valve, an electrical proportion flow regulator, an air-hydraulic damping cylinder formed by a servo cylinder and a hydraulic cylinder through series connection, a static-pressure air-floatation guide rail of a support workbench, a CCD (Charge Coupled Device) image sensor located above the workbench, and a photoetching machine controller, wherein the pneumatic triple element is connected with the electrical servo direction flow valve and the static-pressure air-floatation guide rail by two pipelines respectively, the electrical servo direction flow valve is connected with the servo cylinder, the electrical proportion flow regulator is connected with the hydraulic cylinder, a push rod of the hydraulic cylinder is connected to the workbench, and the photoetching machine controller is connected with the electrical servo direction flow valve, the electrical proportion flow regulator and the CCD image sensor. According to the electrical servo position alignment control system and the electrical servo position alignment control method of the photoetching machine, the homeostatic control precision of the system can be improved, and the position of the workbench can be accurately controlled.

Owner:ZHISHENG SCI & TECH GUANGZHOU

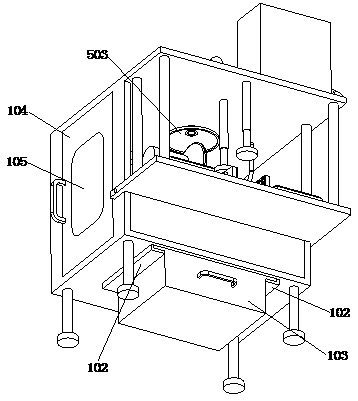

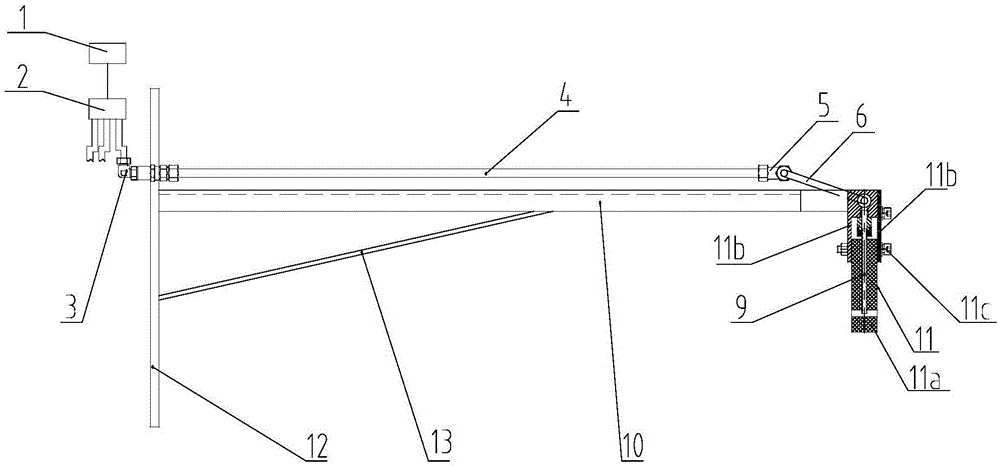

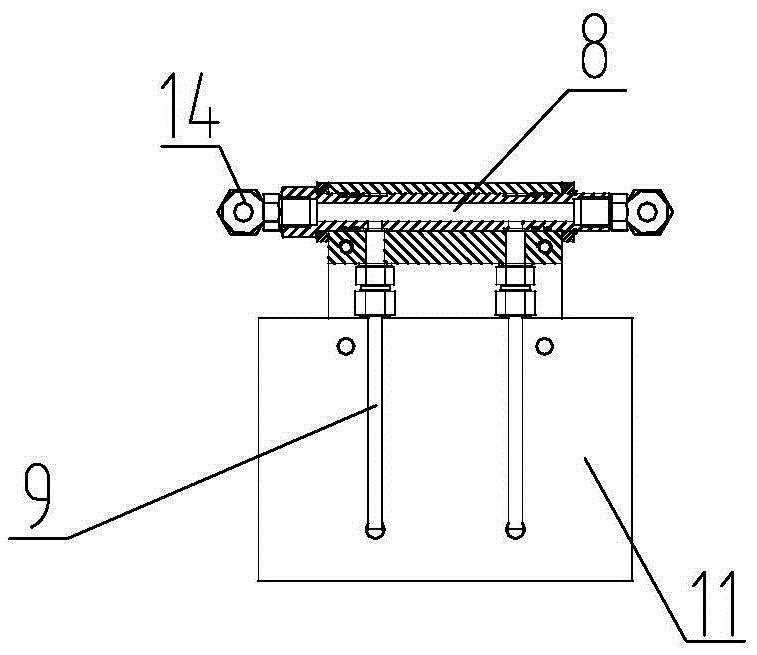

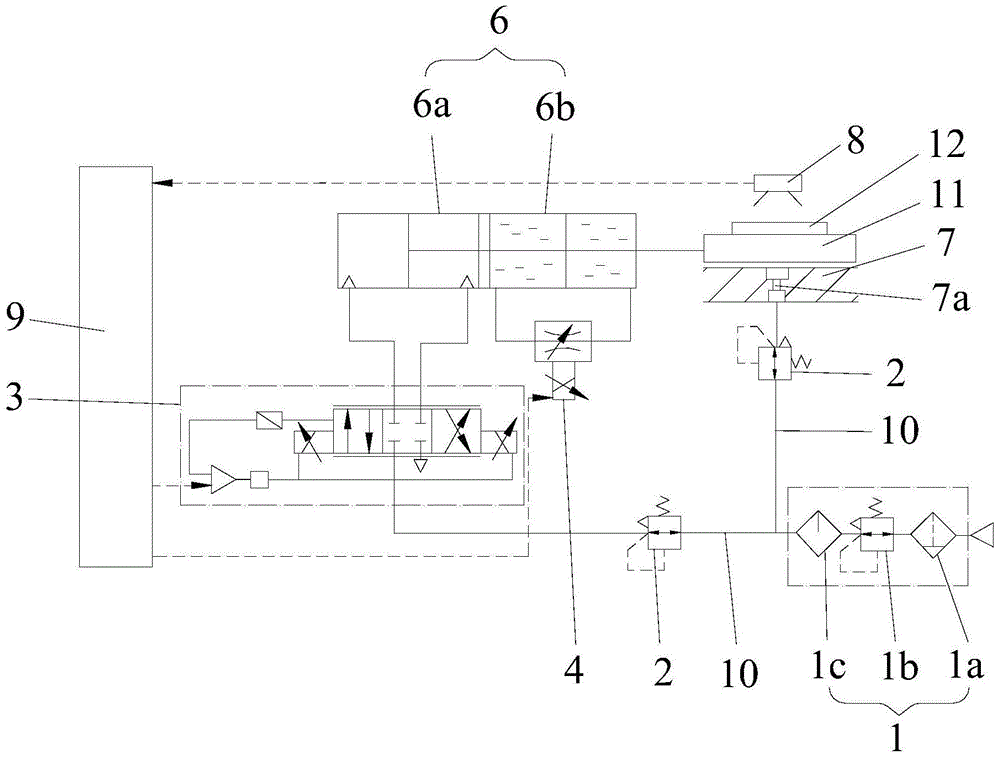

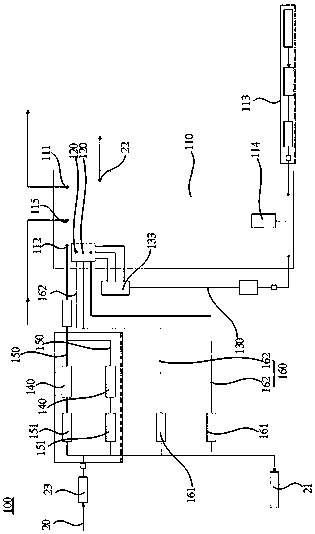

Micro quantity lubrication system and method of manufacturing bent pipe with micro quantity lubrication system

ActiveCN110434239ATo achieve the purpose of lubricationAvoid wastingShaping toolsEngineeringLubrication

The invention relates to a micro quantity lubrication system and a method of manufacturing bent pipe with the micro quantity lubrication system. The micro quantity lubrication system comprises a microlubricating oil mist supply device, a shunt valve and a plurality of oil pipe. The micro lubricating oil mist supply device comprises atomizing chamber, an atomizer, an oil supply channel and pressure regulating valve. Gas is injected into the atomizing chamber, and the amount of the gas is adjusted by the pressure regulating valve to adjust the pressure in the atomizing chamber. The lubricatingoil mist sprays to the atomizing chamber through a spray port of the oil mist, and then the lubricating oil mist is output to the shunt valve through an oil mist output port; and the lubricating oil mist after shunting sprays through the oil pipe to the core rod of a pipe bending machine, and then sprays from the oil hole at the end of the core rod to lubricate the bend of the copper pipe. The micro quantity lubrication system is more economical in lubricating oil, and can use less lubricating oil to achieve the purpose of lubrication, so as to avoid waste and reduce cost.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD

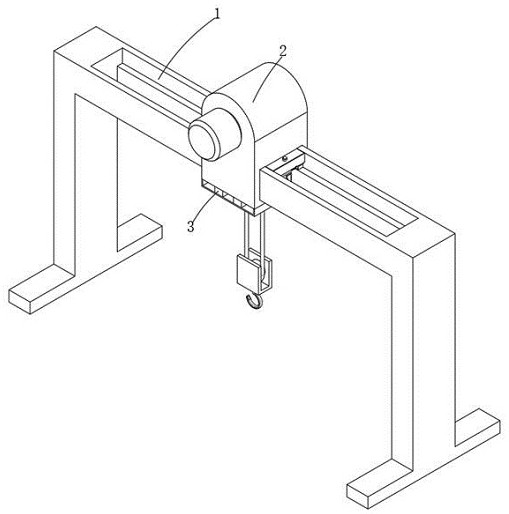

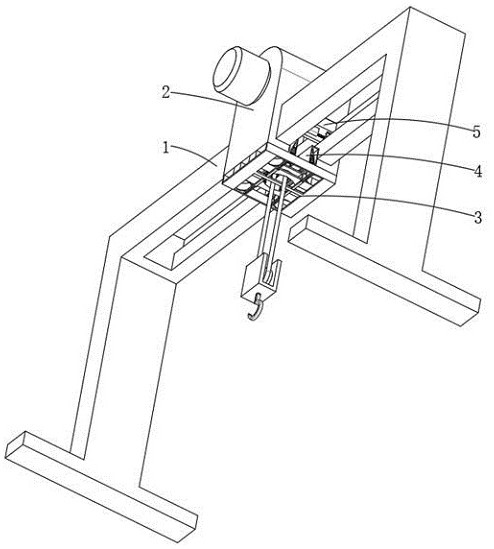

Self-adaptive positioning device for crane

InactiveCN114275685AAvoid wear and tearExtended service lifeCleaning using toolsTrolley cranesSlide plateWire rope

The invention discloses a self-adaptive positioning device for a crane, and relates to the technical field of crane equipment. The crane comprises a crane body, a lifting appliance device is slidably mounted at the top of the crane body, a positioning device is arranged at the bottom of the lifting appliance device and comprises a U-shaped groove frame, the U-shaped groove frame is fixed to the bottom of the lifting appliance device, and arc groove sliding plates are slidably mounted on the left side and the right side of the bottom of the inner wall of the U-shaped groove frame correspondingly; the opposite sides of the arc groove sliding plates on the left side and the right side are elastically connected with the inner wall of the U-shaped groove frame through elastic plates, and protruding columns are fixed to the bottoms of the elastic plates. The arc chute sliding plate is matched with the elastic plate, so that the arc chute sliding plate buffers the steel wire rope of the lifting appliance device through the elastic plate, the problems that the steel wire rope shakes to be separated from the center of the fixing frame and is abraded are solved, and the service life of the steel wire rope of the lifting appliance device is prolonged.

Owner:HENAN INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com