Radial piston used in hydraulic motor

A technology of hydraulic motor and radial column is applied in the fields of hydraulic piston pump motor accessories and radial piston for hydraulic motor, which can solve the problems of early wear and stuck of the piston, and achieve the effect of not losing volumetric efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

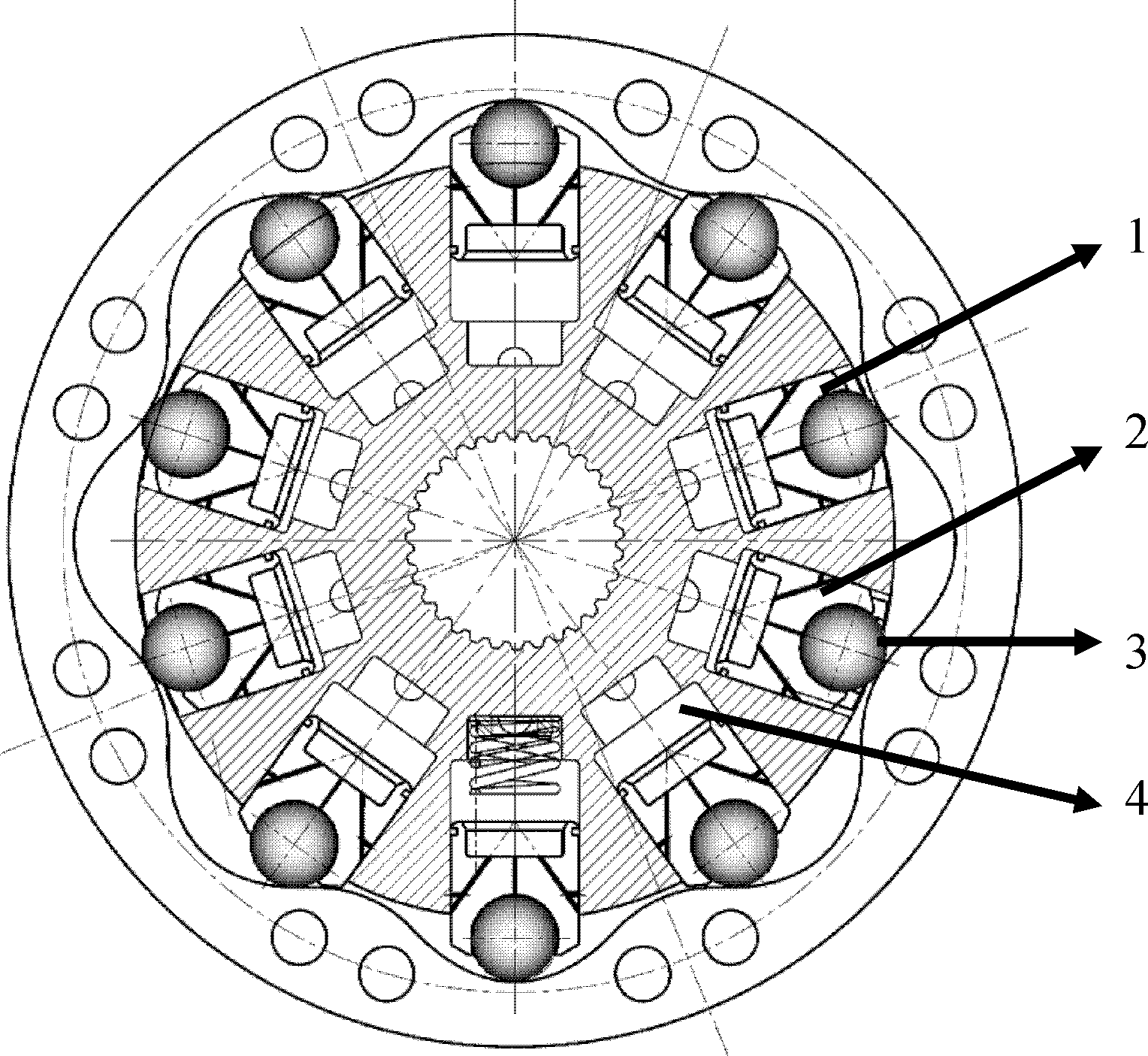

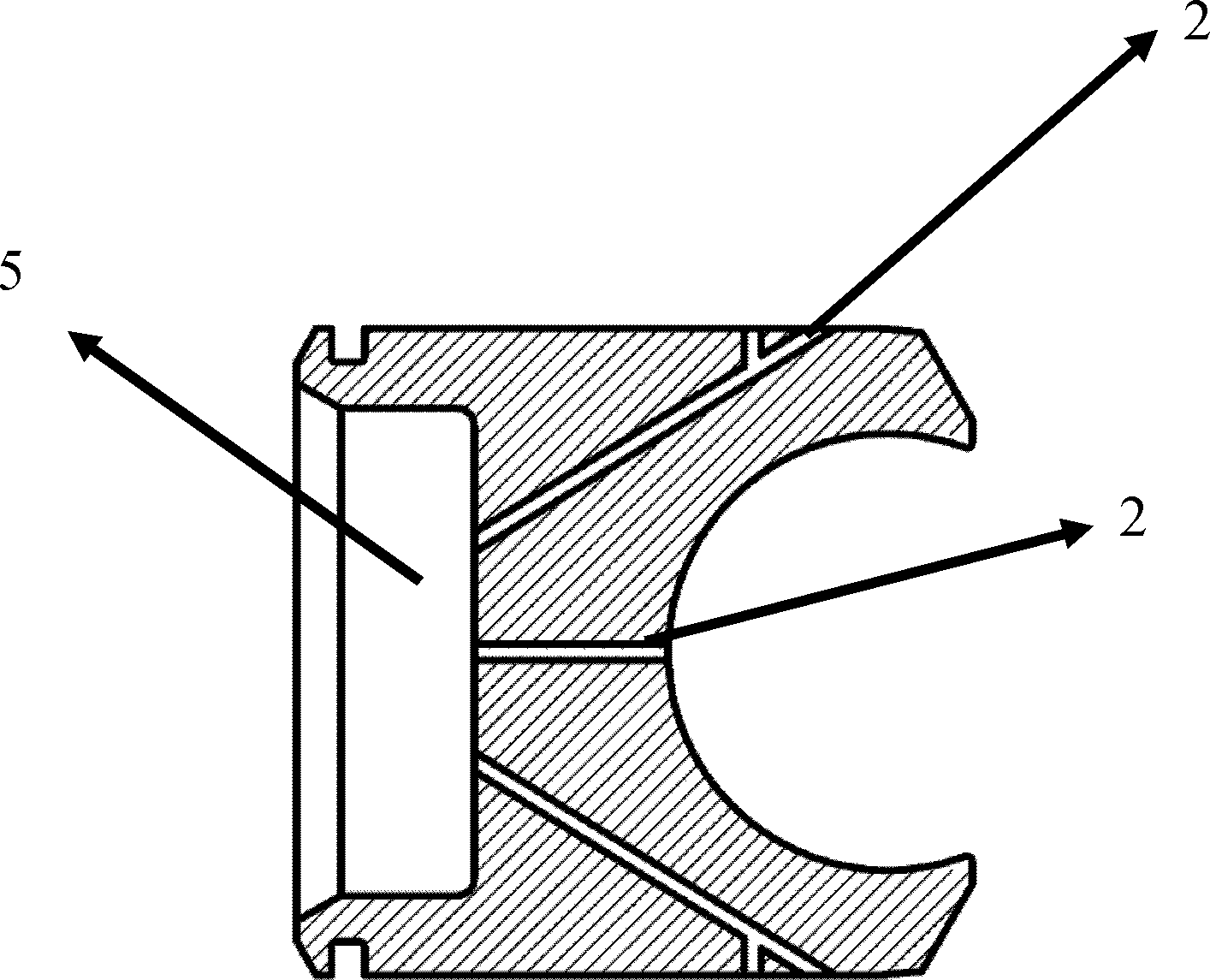

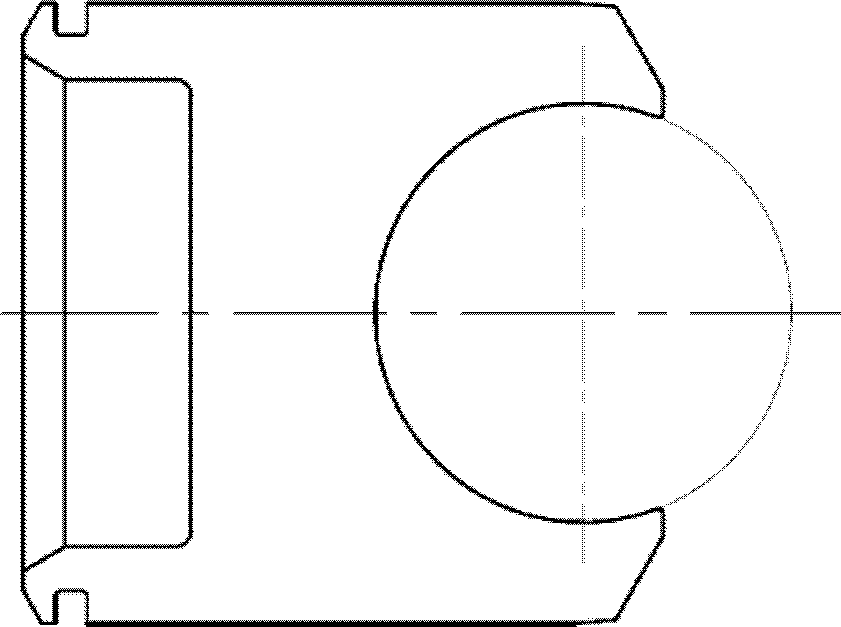

[0012] Such as Figure 1-3 As shown, the radial plunger for the hydraulic motor of the present invention has a plurality of lubricating holes 2 on the stressed friction surface of the radial plunger 1, and each lubricating hole 2 is connected to the high-pressure chamber 5, especially at the center The radial plunger 1 at the bottom of the roller 3 is provided with a lubricating hole 2 leading into the high-pressure chamber 5 . The invention introduces lubricating oil into the hole, and performs low-pressure lubrication through long hole throttling.

[0013] In this embodiment, in order to ensure the volumetric efficiency during the working process of the hydraulic pump assembly, a lubricating groove is opened in the middle of the radial plunger supported by the rollers, which can also enhance the lubrication of the rollers.

[0014] When the inner curve r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com