Cylindrical grinder easy to assemble and maintain

A technology of cylindrical grinding and housing, which is applied in the field of machine tools, can solve the problems of thermal expansion and deformation of the metal spindle and bearing bush, difficult adjustment of the gap between the spindle and bearing bush, aging of rubber seals, etc., and achieves small thermal deformation, easy assembly and maintenance, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

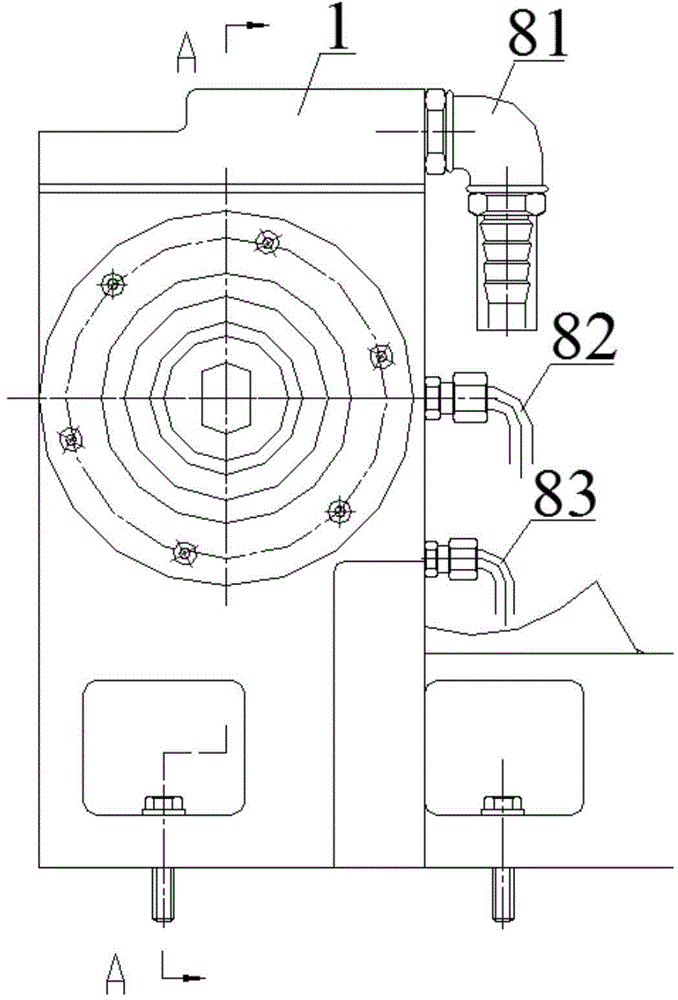

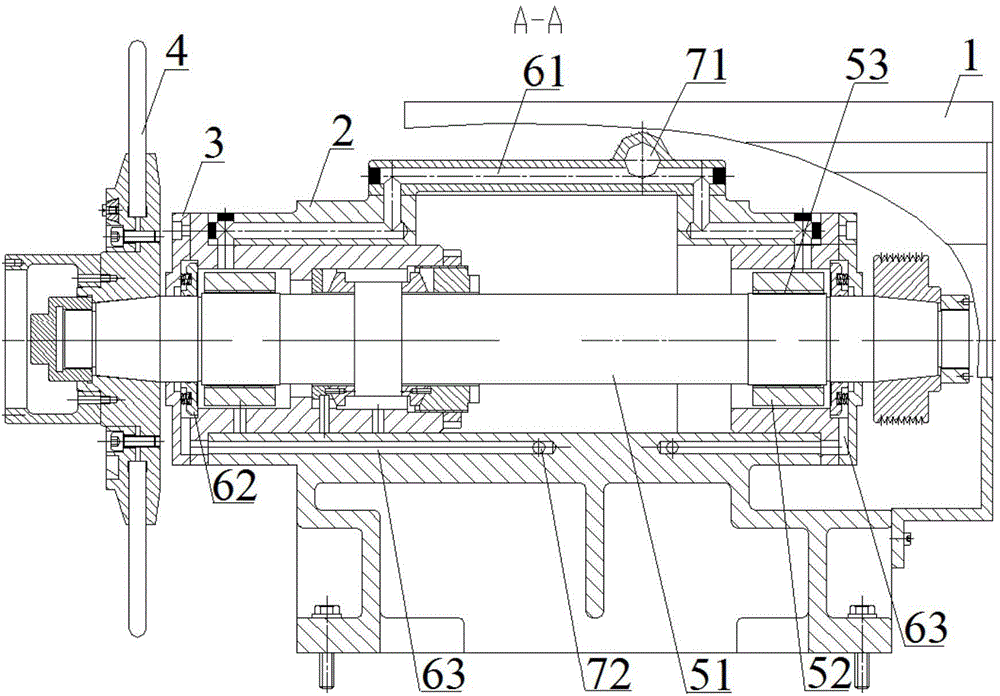

[0033]In conjunction with the accompanying drawings, a cylindrical grinder that is easy to assemble and maintain in this embodiment (the cylindrical grinder especially refers to a fully automatic CNC cylindrical grinder) includes a sleeve 1, a housing 2, a cover plate 3, a grinding wheel 4 and a sliding For the bearing, the housing 2 is arranged inside the sleeve 1 , and the two ends of the housing 2 are reliably sealed by the cover plate 3 . The sliding bearing runs through the casing 2 transversely, and the sliding bearing includes a main shaft 51 and a bearing bush 52 , and one end of the main shaft 51 is connected with a high-speed rotating grinding wheel 4 . In this embodiment, on the main shaft 51 of the sliding bearing, specifically, the contact portion between the main shaft 51 and the bearing bush 52 is sprayed with a ceramic coating 53 with a thickness of 1mm, and the advantage of the surface finish and high hardness of the ceramic itself is used to reduce the contact...

Embodiment 2

[0041] A kind of cylindrical mill that is easy to assemble and maintain in this embodiment is basically the same as Embodiment 1, and its difference is that: the thickness of the ceramic coating 53 in this embodiment is 0.8mm, the hardness is 90HV, and the surface roughness is 0.05 μm.

Embodiment 3

[0043] A kind of cylindrical mill that is easy to assemble and maintain in this embodiment is basically the same as Embodiment 1, and its difference is: the thickness of ceramic coating 53 in this embodiment is 1.5mm, hardness is 75HV, and surface roughness is 0.1 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com