Patents

Literature

70results about How to "Small amount of thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low pressure casting aluminium alloy for cylinder cap of minicar engine

The present invention relates to a minicar engine cylinder cap low-pressure casting aluminium alloy, and its main chemical components are Si, Cu and Mg, in particular Cu and Mg control is better, and its harmful impurity element control is serious, and after said alloy is undergone the processes of modification treatment by means of modification agent and (T6) heat treatment, its tensile strength QbMPa is greater than or equal to 300, HB is about 110, and said alloy has enough strength and rigidity and good size stability, and said alloy can meet the requirements for miniature car engine cylinder cap low-pressure casting process and mechanical working process.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

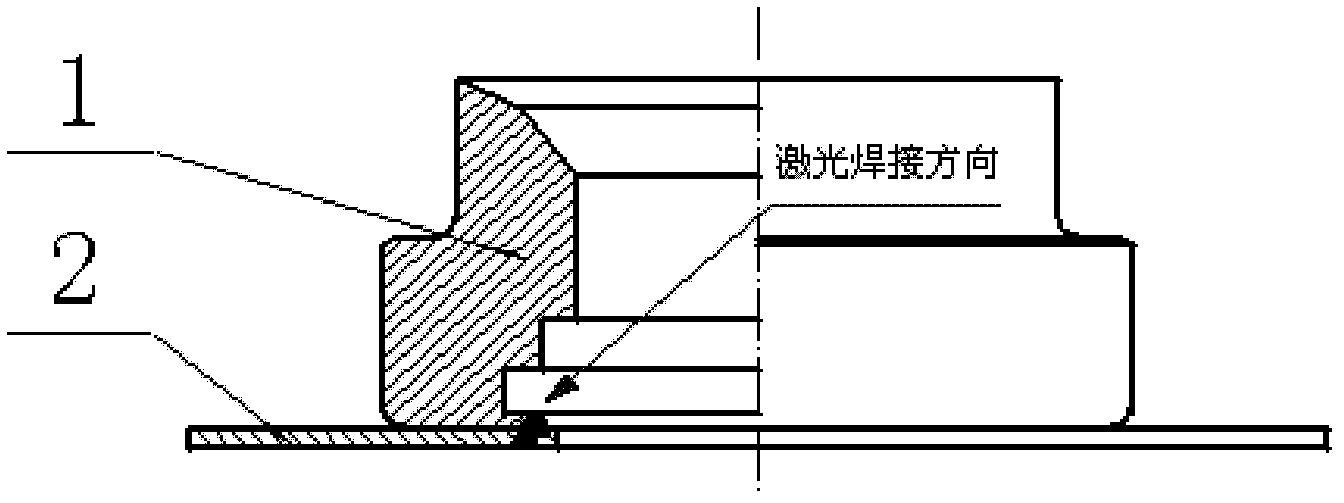

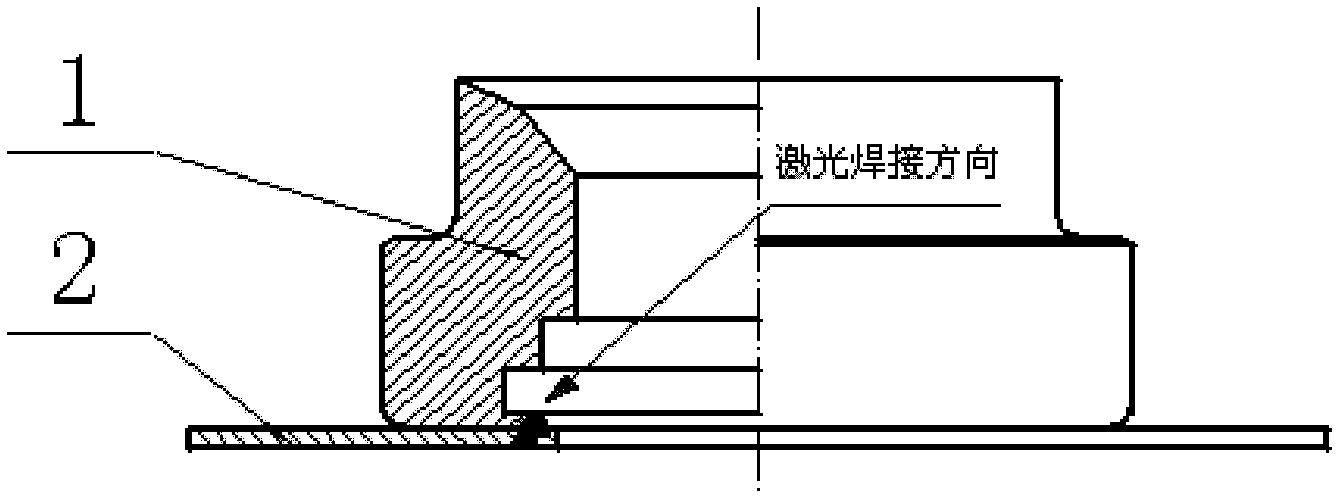

Pulsed laser welding method for high-pressure sealed valve body component

InactiveCN102653034AIncrease productivityHigh precisionLaser beam welding apparatusPeak valueHigh pressure

The invention discloses a pulsed laser welding method for a high-pressure sealed valve body component and aims at providing a processing method for forming a continuous compact weld bead, which has the advantages of stable quality, higher efficiency, appropriate fusion depth of a joint after welding, regular weld joint, bright joint, uniform melting and mutually overlapped laser spots. The method disclosed by the invention is realized through the following technical scheme comprising the following steps of: (a) removing oxides on the surface of a weld and washing a joint part by a washing agent; (b) enabling a valve seat to be tightly close to a sealing gasket through a clamp, clamping on a three-jaw chuck, tilting a rotating table for 45 degrees and melting an angle joint of the valve body component; and (c) setting single pulse energy according to the characteristics of material and enabling a pulse waveform to be steep at the front and gentle at the back, thereby rapidly increasing laser energy to a peak value, rapidly heating, improving absorbability, then slowly lowering the temperature, maintaining the temperature for heating continuously, avoiding violent splashing, simultaneously increasing the fusion depth, melting the angle joint into a whole, matching with reasonable welding speed and pulse frequency, and enabling the laser spots to be mutually overlapped for forming the continuous compact weld bead.

Owner:成都泛华航空仪表电器有限公司

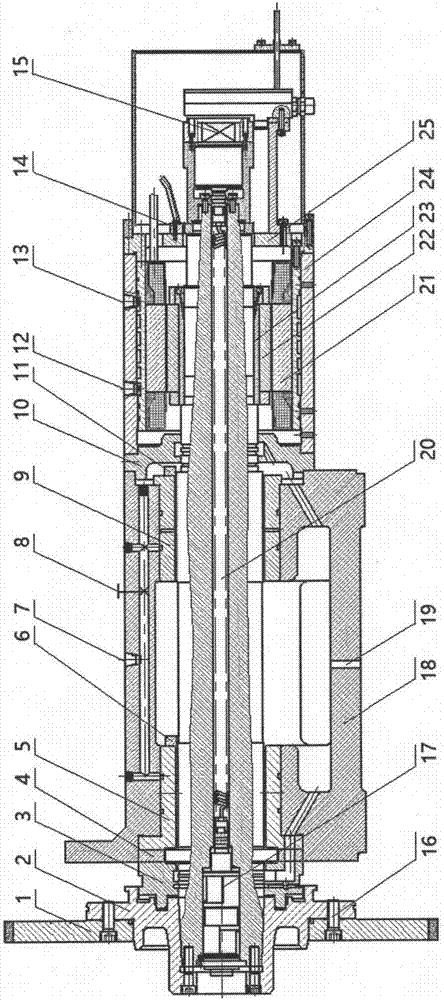

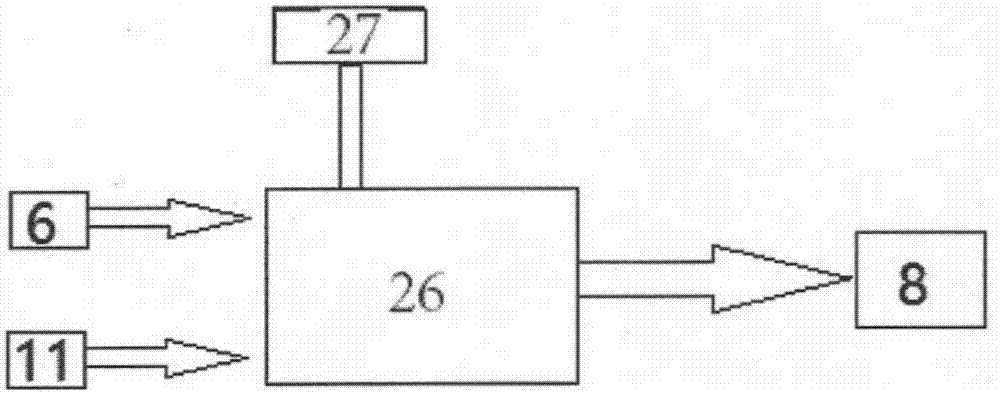

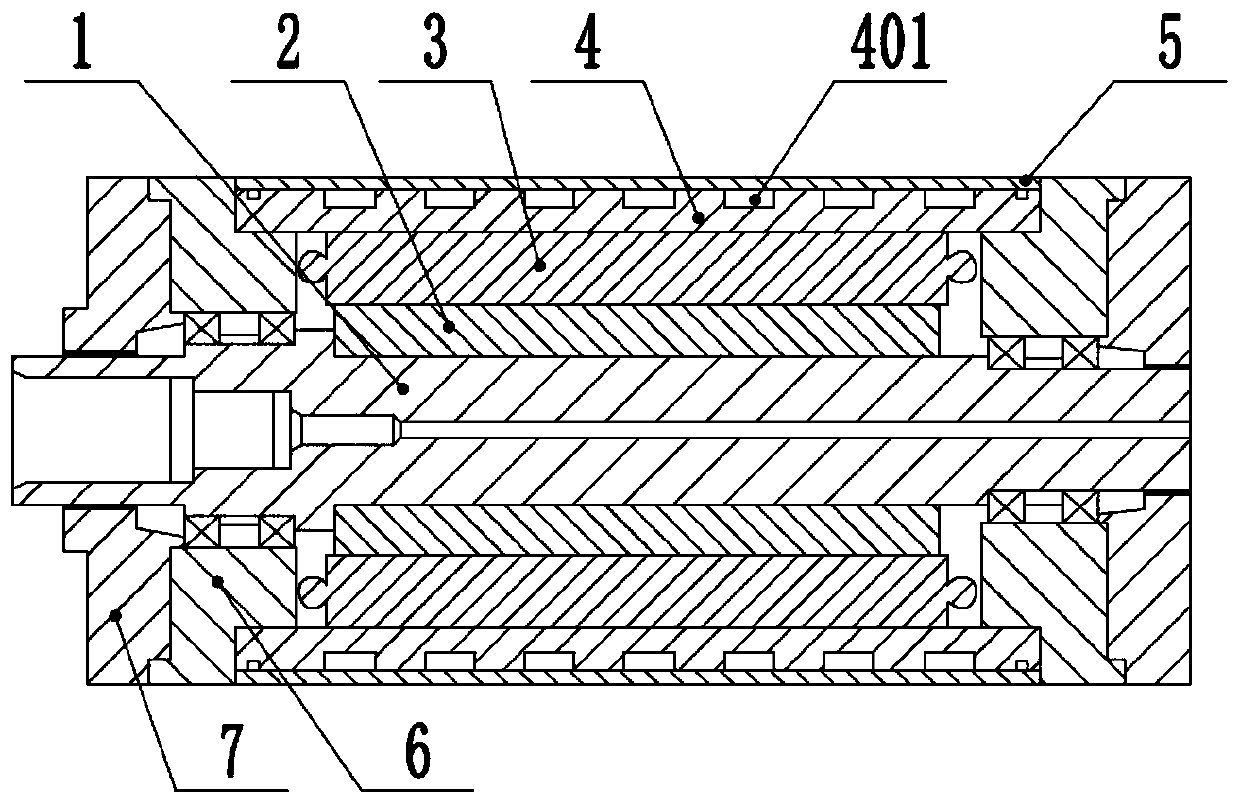

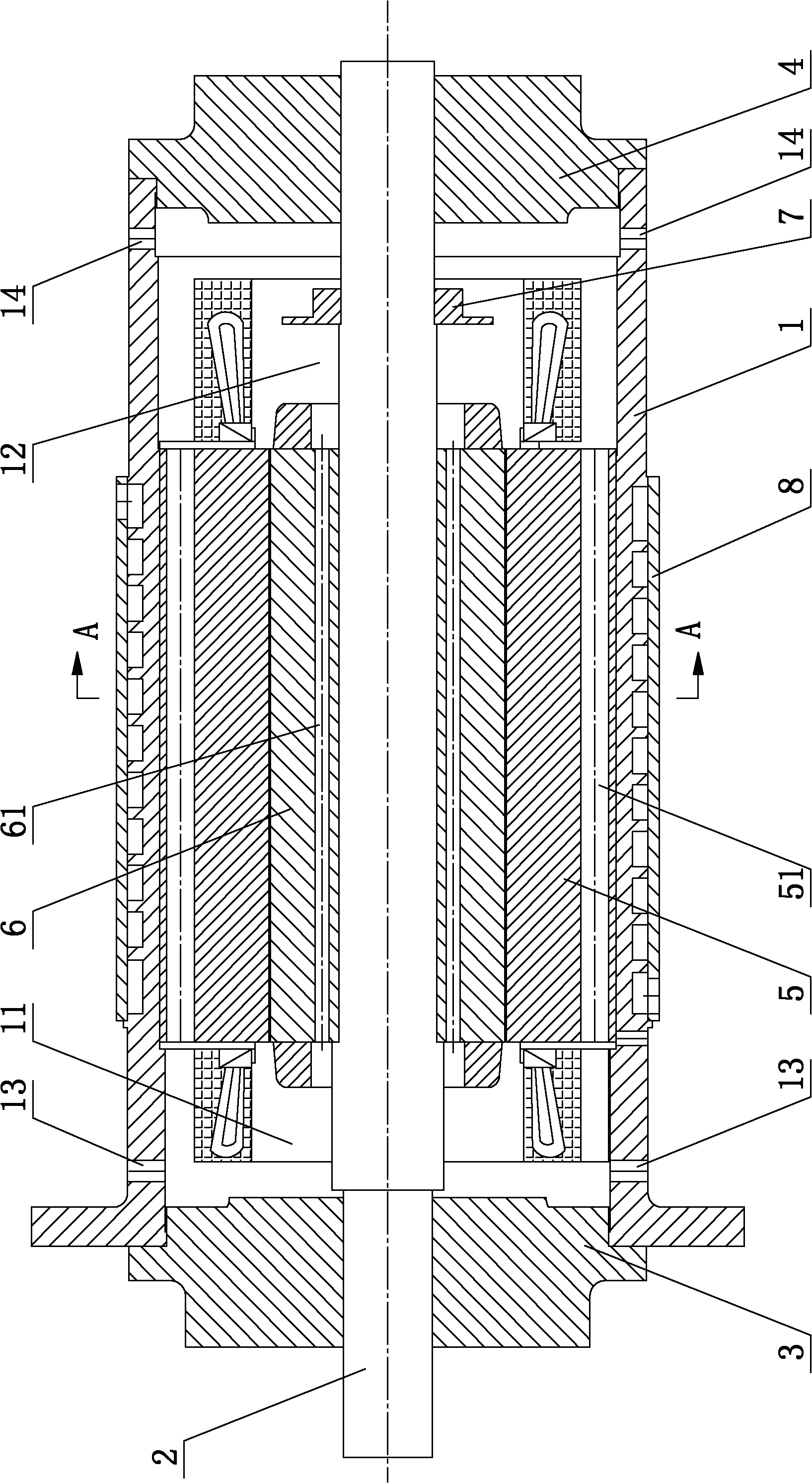

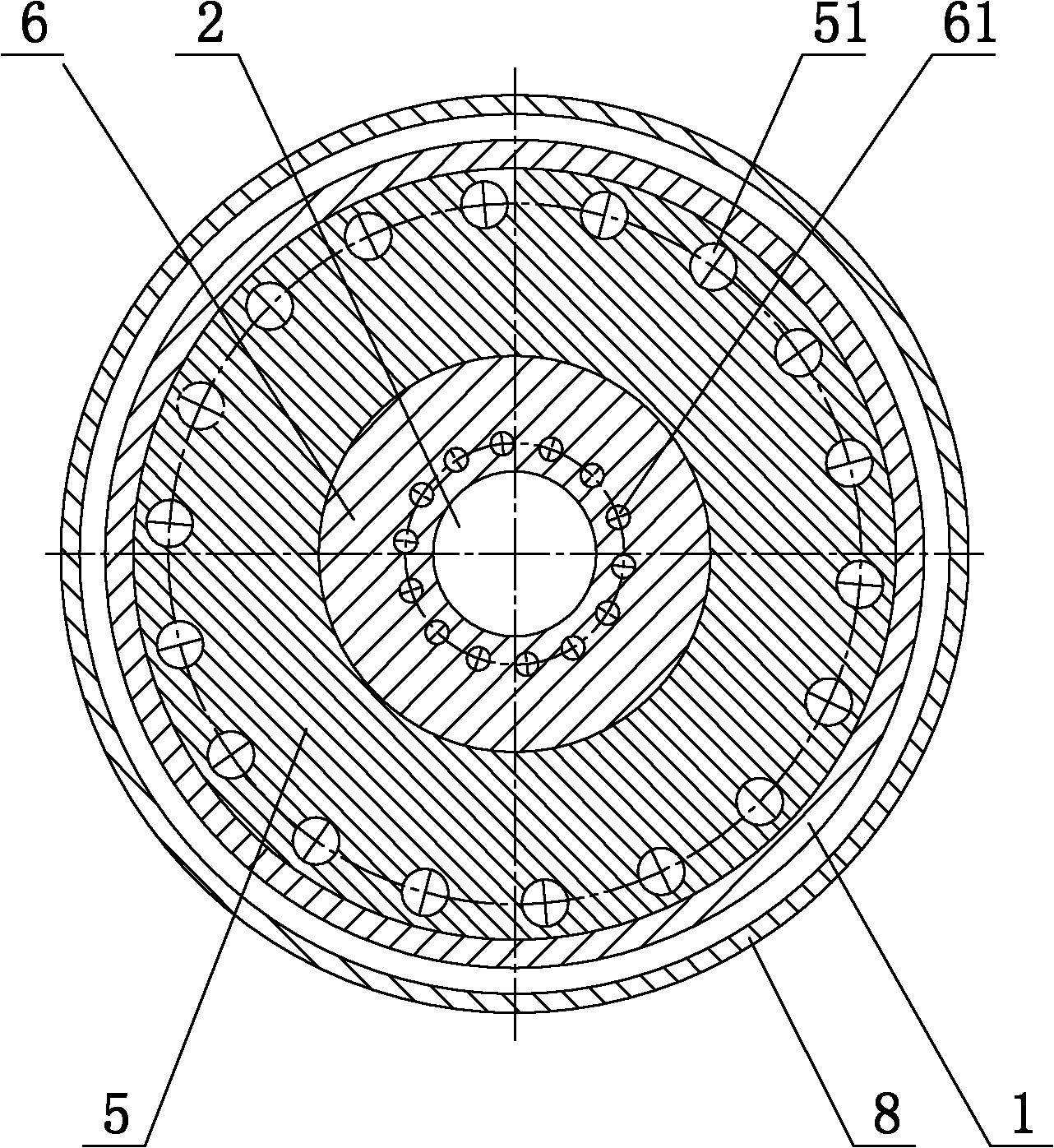

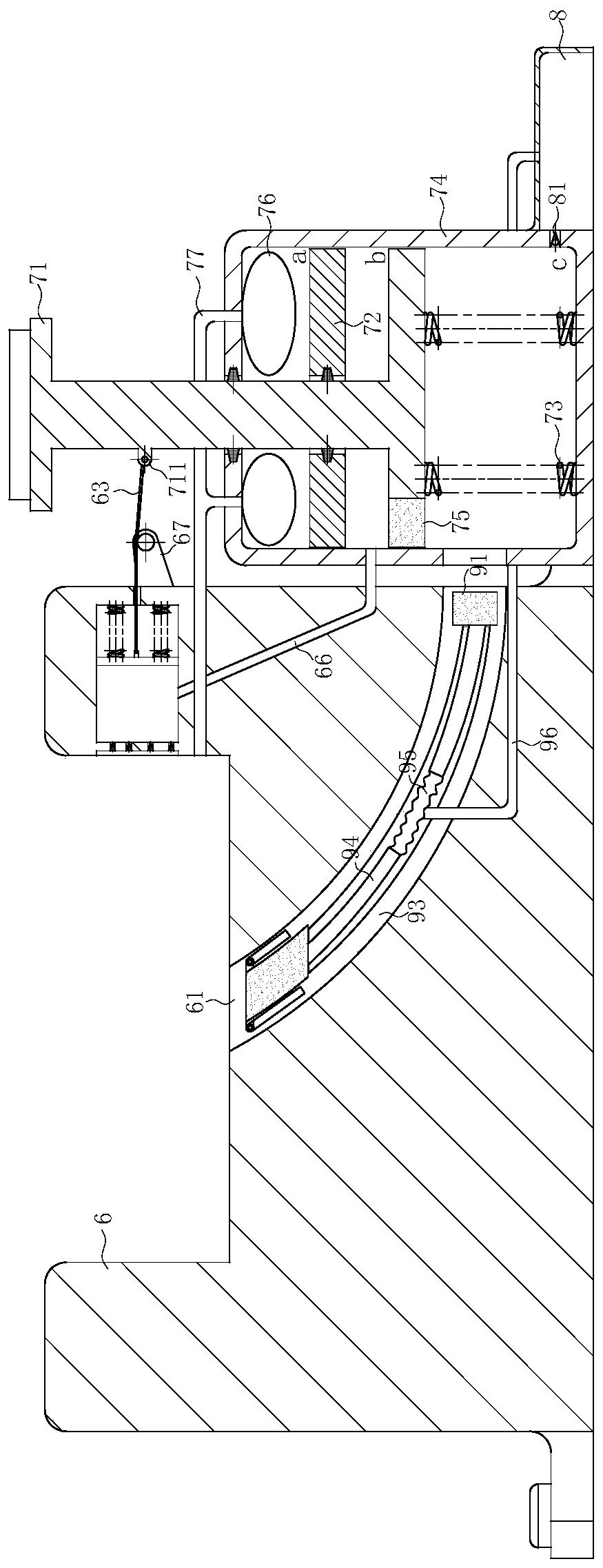

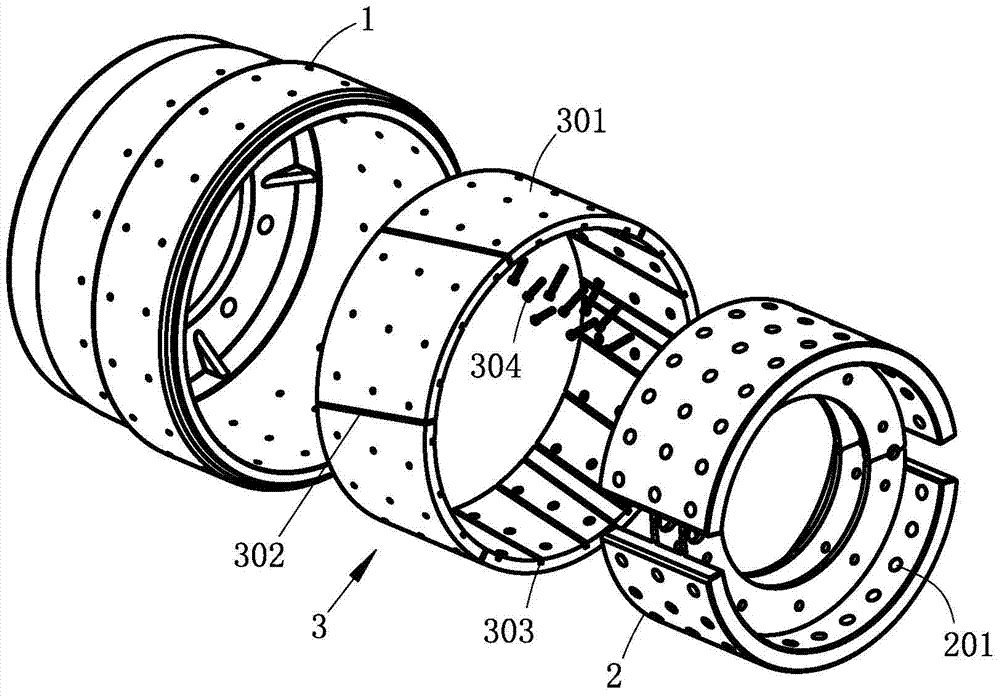

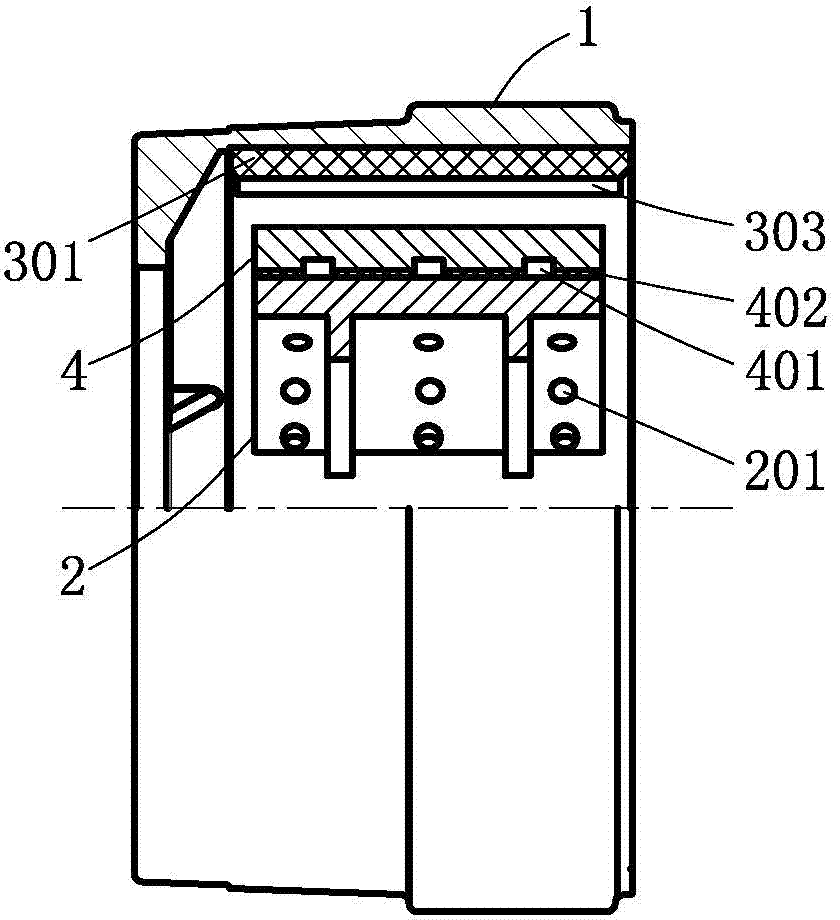

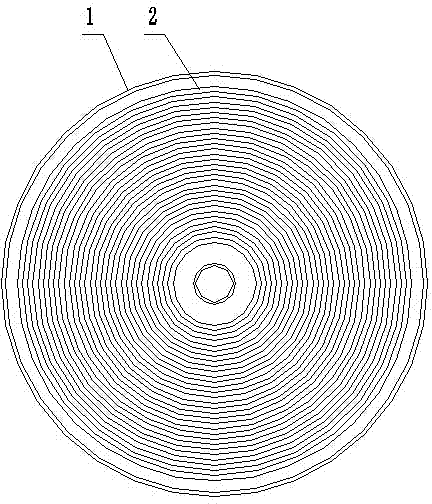

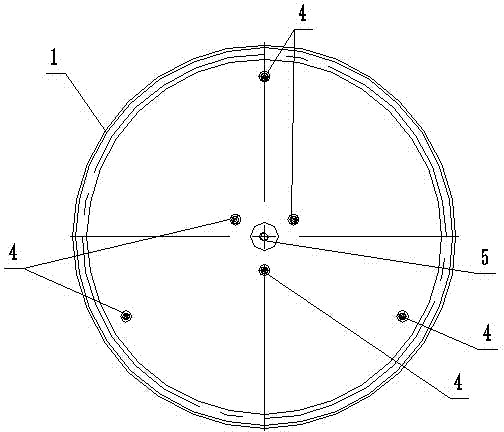

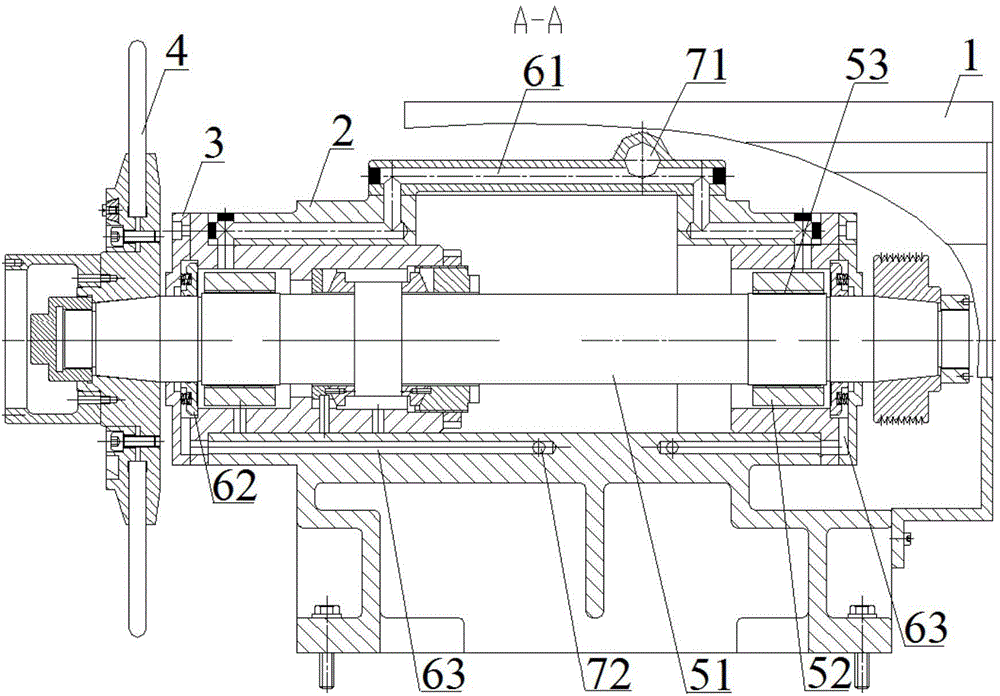

High-speed high-precision built-in dynamic and static piezoelectric main shaft

ActiveCN106984836ASmall amount of thermal deformationImprove output accuracyLarge fixed membersMaintainance and safety accessoriesNumerical controlElectricity

The invention relates to a high-speed high-precision built-in dynamic and static piezoelectric main shaft. The high-speed high-precision built-in dynamic and static piezoelectric main shaft is characterized in that the main shaft comprises a box body, a front bearing and a rear bearing are arranged in the box body through a front bearing end cover and a rear bearing end cover correspondingly, and the front bearing and the rear bearing jointly bear a main shaft body internally provided with an online dynamic balancing head; the box body is provided with an oil inlet and an oil outlet, the oil inlet communicates with the oil outlet through an oil way, the oil way is divided into two parts, and one part enters the front bearing and the rear bearing through the oil inlet to suspend the main shaft body in a gap between the front bearing and the rear bearing to form pure liquid lubrication; and the other part is fed to the front bearing and the front bearing end cover to make the main shaft body achieve axial positioning, and a grinding wheel is arranged on the front bearing end cover through a flange disc. The high-speed high precision built-in dynamic and static piezoelectric main shaft is simple in structure, good in dynamic performance, large in rotation number of the main shaft, high in rotation precision and small in heat deformation and can be widely applied to grinding wheel electric main shafts of precise grinding machines, main shafts of numerical control machining centers and precise lathes and the like.

Owner:DONGHUA UNIV

Pressure casting aluminium aluminium alloy for cylinder of minicar engine

InactiveCN1483847AGood casting process performanceHigh leak inspection pass rateChemical compositionPressure casting

The present invention relates to a mnicar engine cylinder pressure casting aluminium alloy, and its chemical component composition includes (wt%) Cu 1.5-3.0%, Si 10.0-12.0%, Mg 0.15-0.35%, the rest is al and the other is impurity. Said alloy tensile strength Qb is greater than or equal to 300MP. Said alloy has enough strength and rigidity and good size stability. Said alloy can meet the requirements for minicar engine cylinder body high-pressure casting process and mechanical working process.

Owner:重庆长安汽车有限责任公司

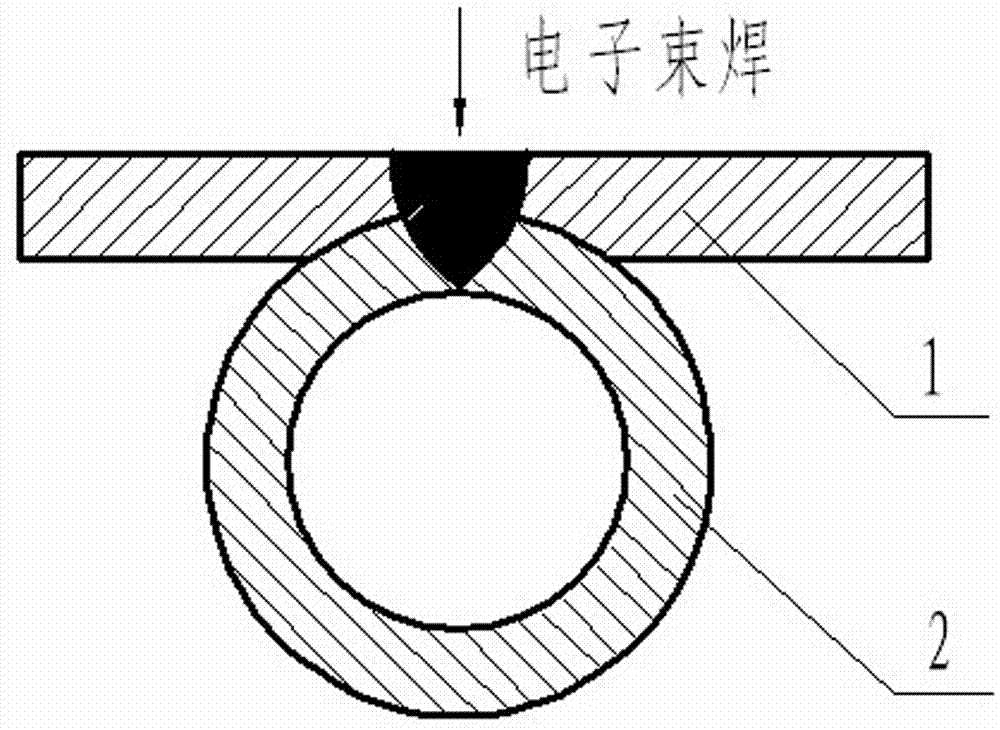

Method for welding thin-walled cylinder with magnet sleeved inside in seal housing component

ActiveCN103537788ASimple and fast operationQuality improvementElectron beam welding apparatusSteam pressureEngineering

The invention provides a method for welding a thin-walled cylinder with a magnet sleeved inside in a seal housing component. The welding efficiency of the aluminum alloy thin-walled seal housing component can be obviously improved through the method, quality is stable, a connector is bright, fusion is even, and continuous and compact welding beads can be formed. According to the technical scheme, the method comprises the following steps that the butt joint positions of inner and outer housing welding joints are closely attached through a clamp, and annular welding joint pulse electron beam tack welding is carried out on the circumferential seam crossing of an assembled component; a deflection distance occurring to an electron beam caused by Lorentz force is compensated by an electron beam deflection angle; the total heat input amount of the electron beam is controlled with the impulse waveform of the pulse electron beam, the impulse waveform is steep in the front and gentle in the back, and welding is carried out through heat generated when beam flow ascends and descends; under the condition that small pulse power is set and steam pressure is reduced, a pulse back edge is prolonged by 3-5s, slow reduction is carried out, the focal position of the electron beam is adjusted to be within the range 0.55mm below the surface of a workpiece, the surface of a connector to be welded is melted and integrally welded, and the continuous welding beads are formed.

Owner:四川泛华航空仪表电器有限公司

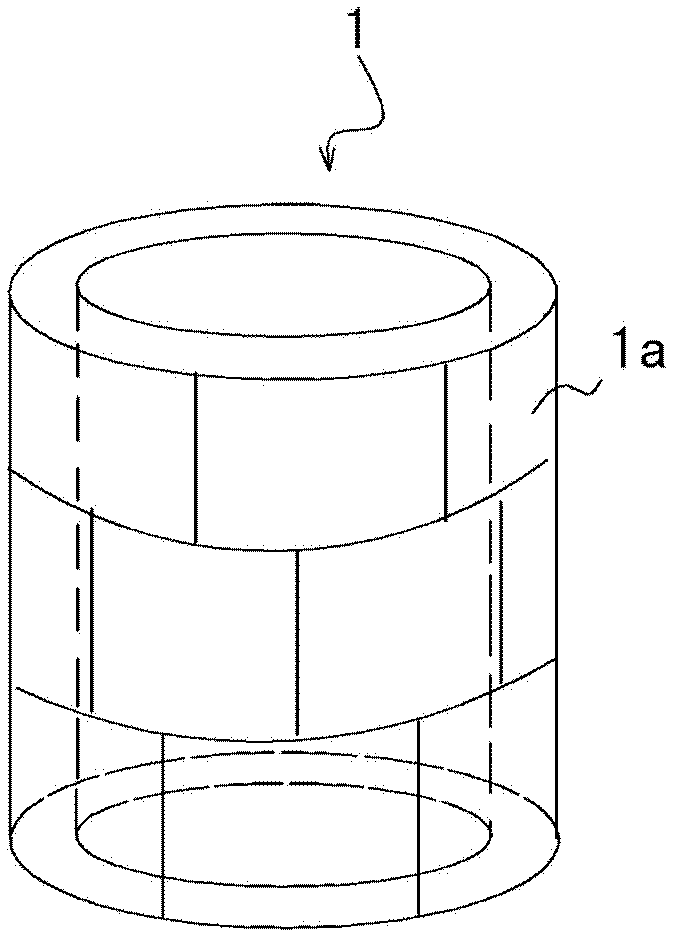

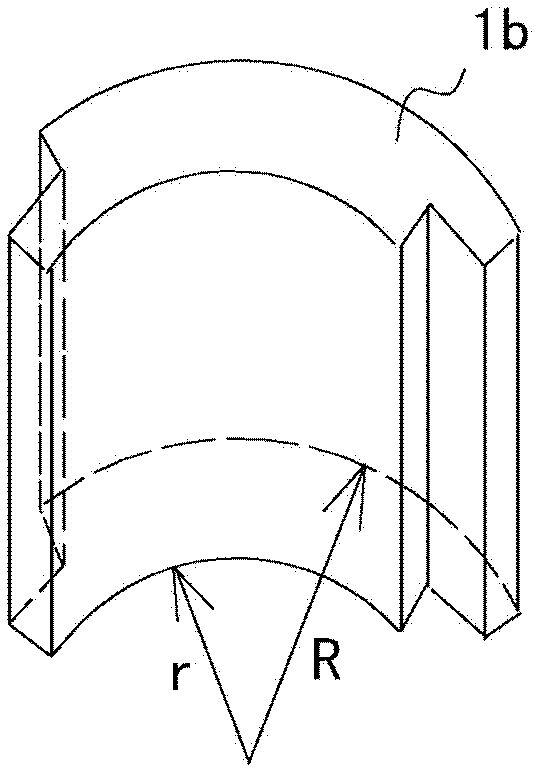

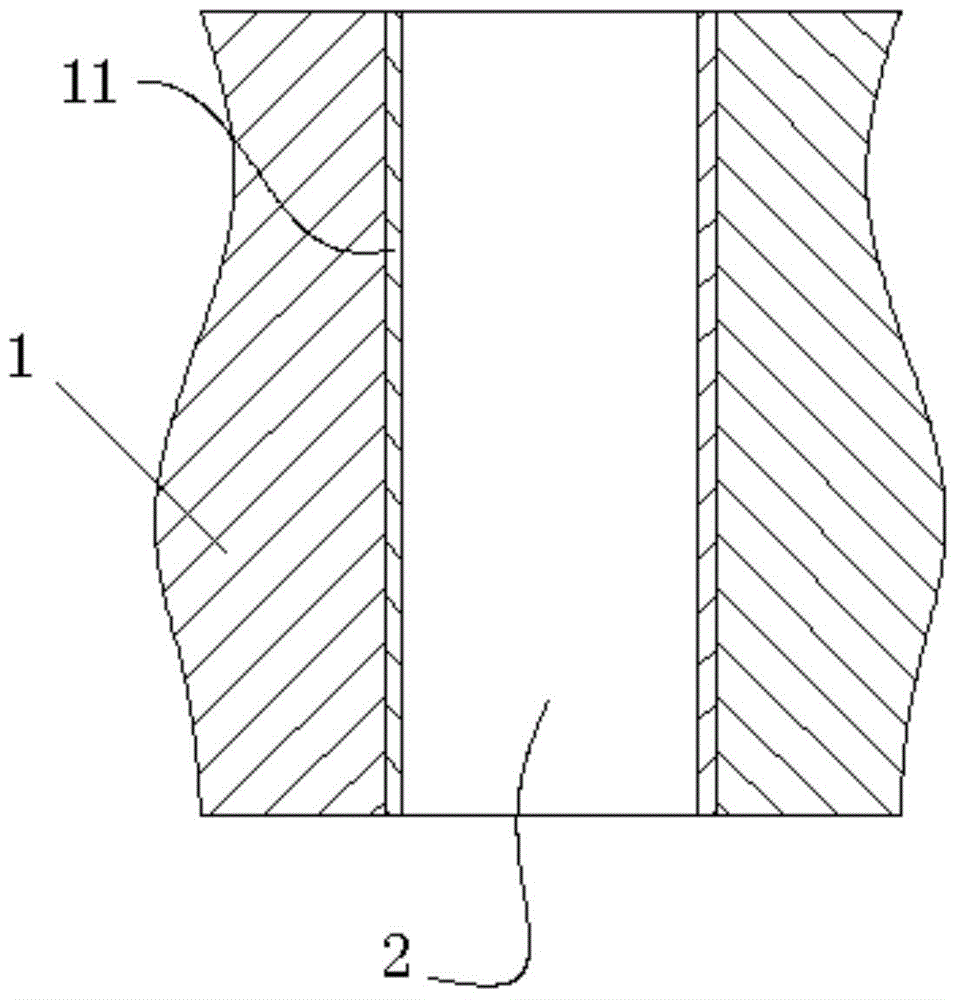

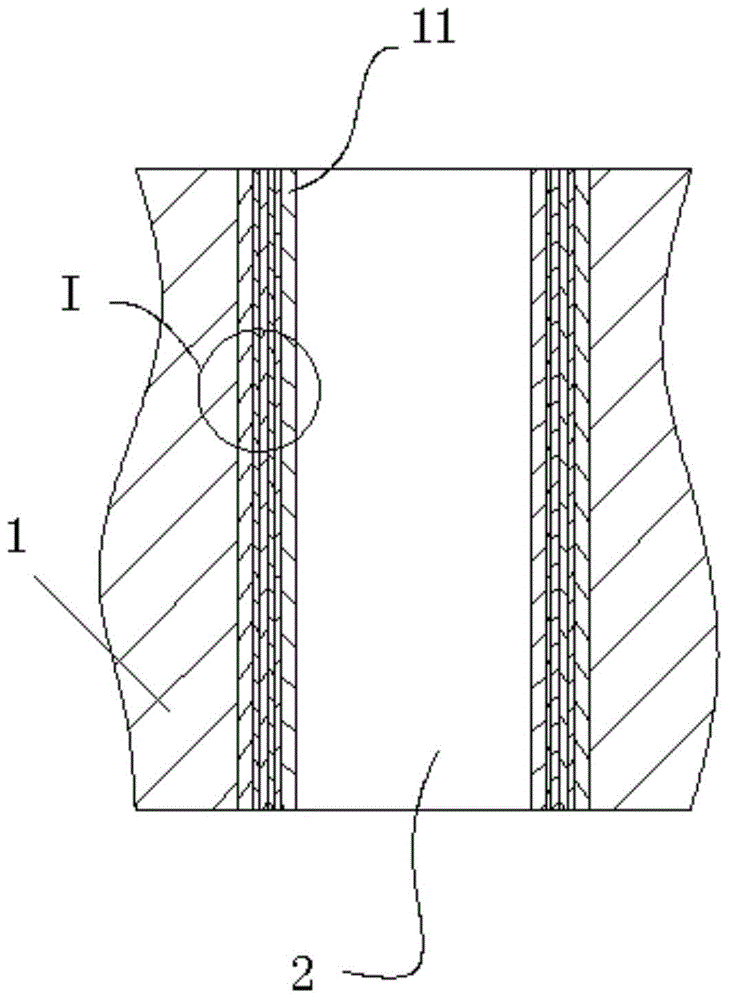

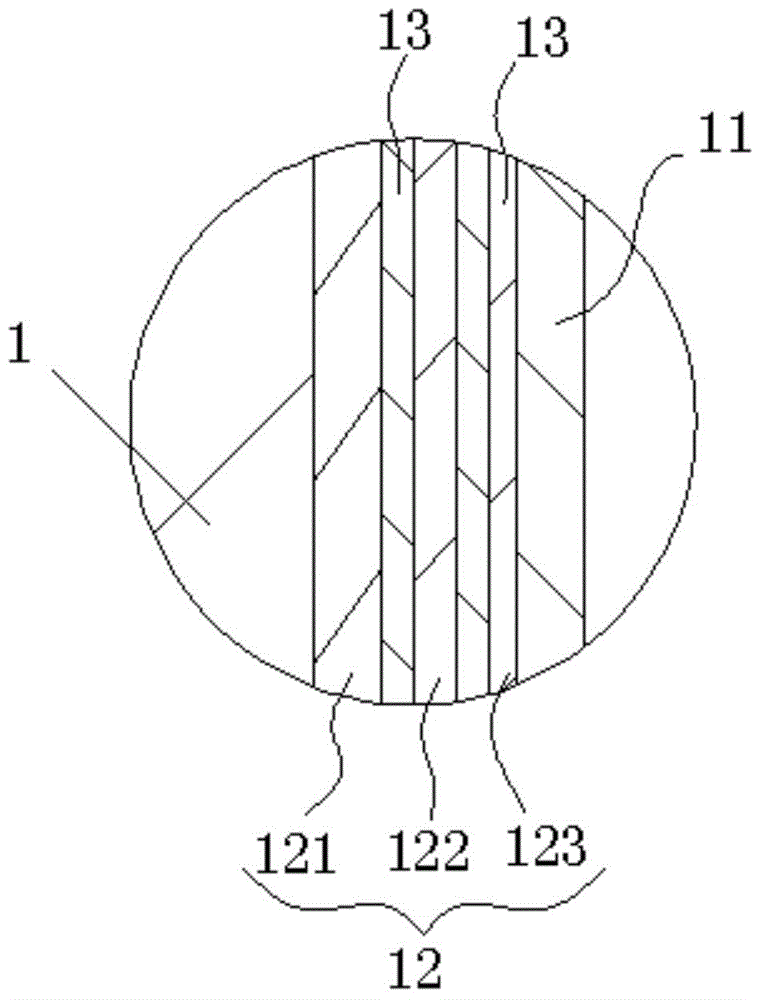

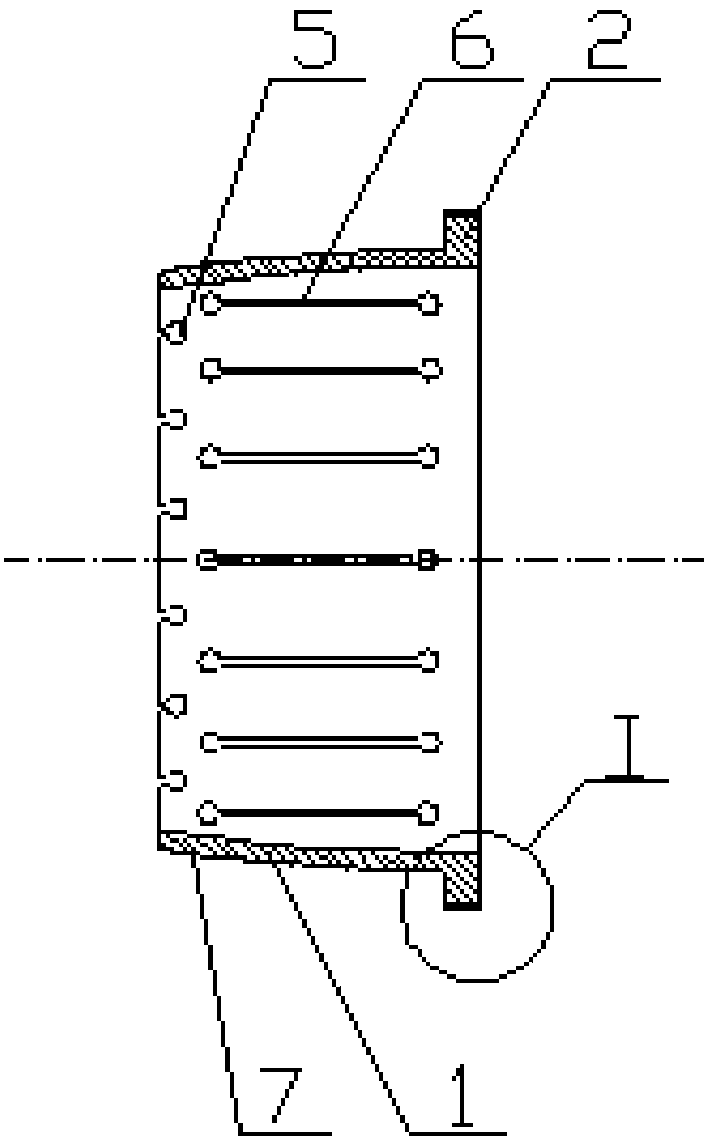

Insulation cylinder used in laser crystal growth process

InactiveCN102206870ASmall amount of thermal deformationReduced increase in production costsAfter-treatment apparatusThermal deformationEngineering

The invention discloses an insulation cylinder used in a laser crystal growth process. The invention is characterized in that the insulation cylinder is in a split structure, i.e. the whole insulation cylinder is split into unit components which can be mutually spliced to form a cylindrical body. The invention can effectively avoid thermal deformation due to different thermal expansion systems, thereby ensuring the reliability of the production process.

Owner:安徽环巢光电科技有限公司

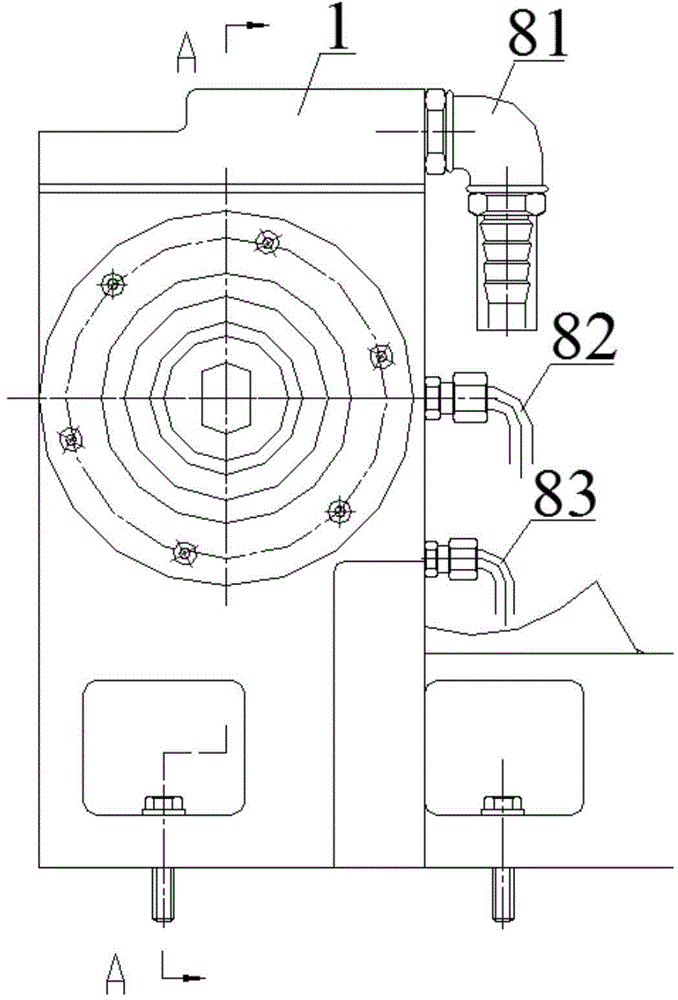

Electric spindle

PendingCN109865848AImprove machining accuracyLight in massMaintainance and safety accessoriesFiberCarbon fibers

The invention discloses an electric spindle. The electric spindle comprises a spindle core, a motor rotor, a motor stator, a cooling jacket and a shell which are coaxially arranged, the exterior of the spindle core is sleeved with the motor rotor, the exterior of the motor rotor is sleeved with the motor stator, the motor rotor and the motor stator are rotatably connected, the exterior of the motor stator is sleeved with the cooling jacket, the exterior of the cooling jacket is sleeved with the shell, a cooling channel is arranged between the cooling jacket and the shell and communicates withexternal cooling liquid, and the shell is made of a carbon fiber material. According to the electric spindle, the shell is made of the carbon fiber material, a shell made of metal in the prior art isreplaced, carbon fibers have the good heat dissipation performance, the heat dissipation capability of the shell can be improved through the carbon fiber material, and then the heat dissipation performance of the spindle core is improved; the thermal deformation amount in the heating process is small, and the machining precision of the electric spindle can be improved; and meanwhile, the mass of the electric spindle can be decreased by adopting the shell made of the carbon fibers, and then carrying, loading and unloading are convenient.

Owner:宁波天控五轴数控技术有限公司 +1

Improved engine cylinder block and manufacturing technique thereof

ActiveCN105986919AImprove manufacturing precisionExtended service lifeCylinder headsCylindersCombustionThermal deformation

The invention relates to an improved engine cylinder block and a manufacturing technique thereof. The improved engine cylinder block includes a cylinder block body; air cylinder holes are formed in the cylinder block body; and the inner wall of each air cylinder hole is provided with an abrasion resisting layer, and the abrasion resisting layer is of a cast iron coating. The manufacturing technique of the improved engine cylinder block includes: casting an engine cylinder block workblank and machining a locating basis, machining the air cylinder holes, performing stable heat treatment, performing texturing treatment, performing cleaning, performing coating, and boring holes. The beneficial effects of the improved engine cylinder block are that the inner walls of the air cylinder holes are provided with the abrasion resisting layers, the problem that the coefficients of thermal expansion of the air cylinder holes and a lining are different during combustion due to different materials in the prior art can be solved, the thermal deformation of the air cylinder holes of the engine can be effectively reduced, the manufacturing accuracy of the engine cylinder block can be improved, and the service life can be prolonged; AND the improved engine cylinder block is simple in manufacturing technique, is safe and reliable, and has wide prospect.

Owner:代卫东

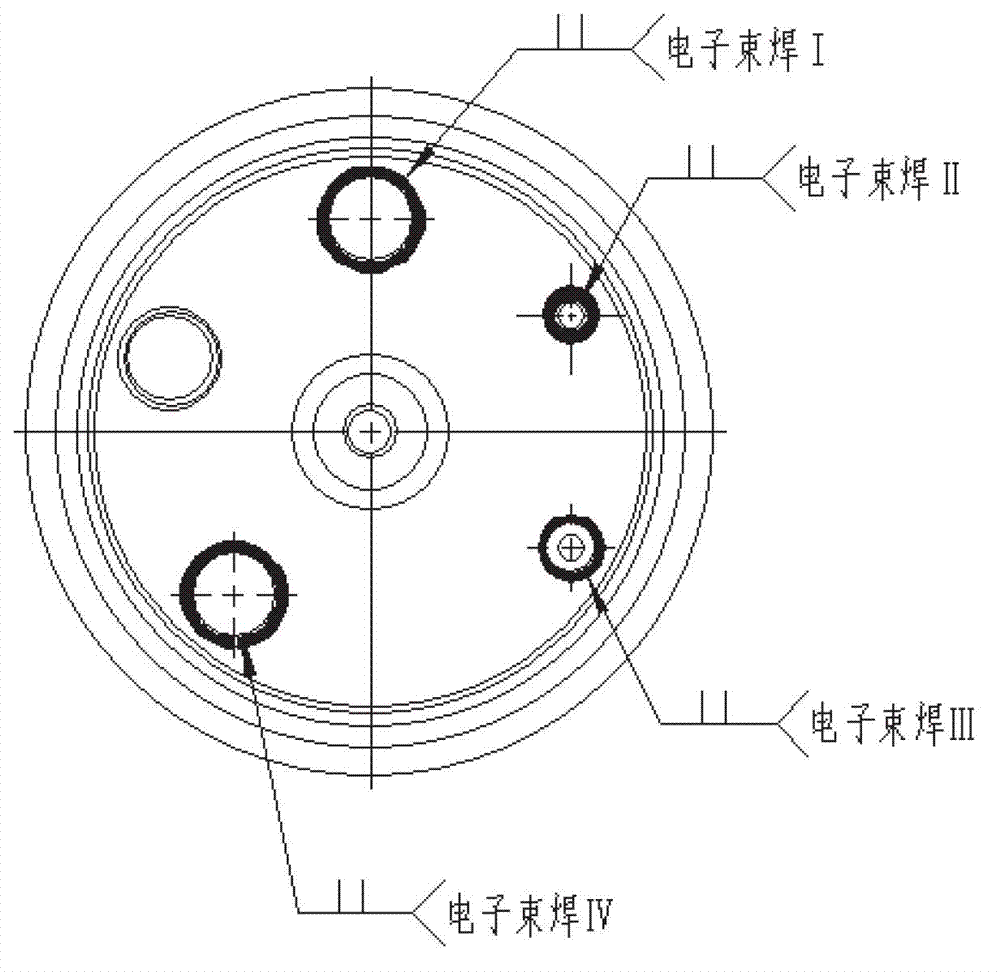

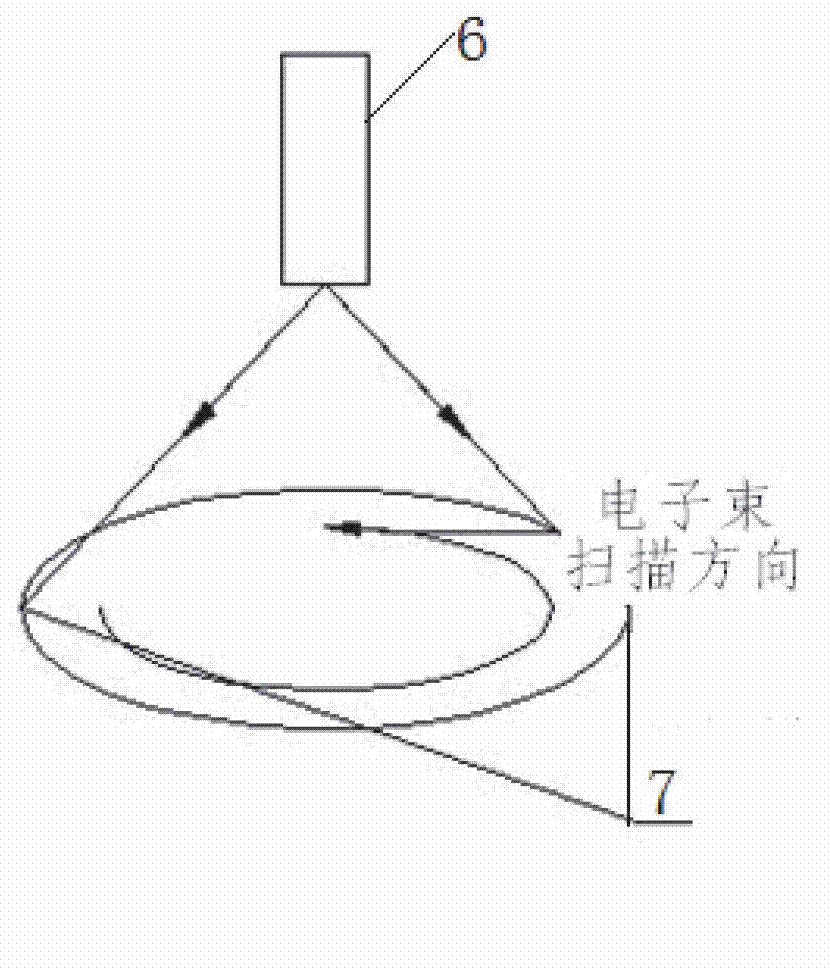

Method for welding eccentric circumferential seams by using electron beam scanning

ActiveCN102962578ADesensitizationQuality improvementElectron beam welding apparatusPeak valueBeam scanning

The invention discloses a method for welding eccentric circumferential seams by using electron beam scanning. The purpose of the invention is to provide the method for welding eccentric circumferential seams, which is easy to control and has stable quality and high efficiency. The method is implemented by the following technical scheme: the oxide of the surfaces of the workpiecesparts to be welded on workpieces is first removed, and organic cleaning agent is used for cleaning the parts of the an eccentric circumferential seams; the workpieces to be welded, which have the eccentric circumferential seams, are assembled together and clamped on a three-jaw chuck; the scanning program of an electron beam welder is set to drive an electron beam in an electron gun to oscillate and revolve within a certain deflection angle range, so that a surface heat source is generated, electron scanning process parameters are set, i.e., the energy of the electron beam is rapidly increased to a peak value, the beam rise time is set as 1s to 2s, the beam welding and scanning time for keeping heating is set as 25s to 30s, the fall time is set as 10s to 12s, the scanning frequency is 400Hz to 600Hz, and under the process parameters, the scanning track of the electron beam is controlled and the workpieces scanned by the electron beam are heated, melted and welded at the seams.

Owner:四川泛华航空仪表电器有限公司

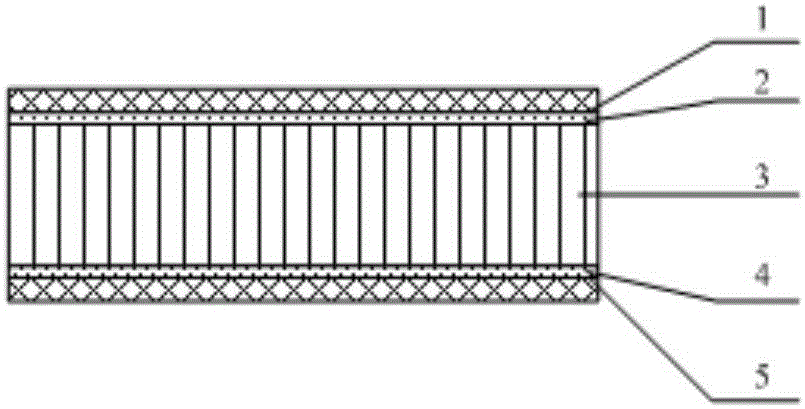

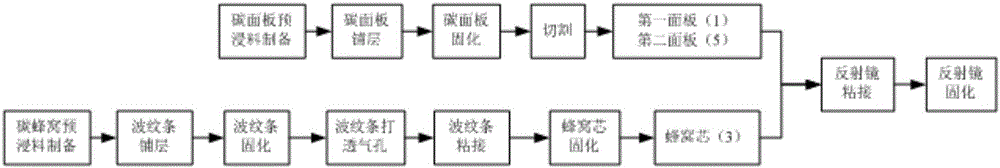

Full-carbon fiber composite material reflecting mirror substrate and preparation method thereof

ActiveCN106739192AWell matched thermal expansionDesignableLaminationLamination apparatusHoneycombThermal expansion

The invention discloses a full-carbon fiber composite material reflecting mirror substrate and a preparation method thereof. The full-carbon fiber composite material reflecting mirror substrate comprises a first panel, a first adhesive film, a honeycomb core, a second adhesive film and a second panel, wherein the first panel is adhered to one side of the first adhesive film; the second panel is adhered to one side of the second adhesive film; and the other side of the first adhesive film and the other side of the second adhesive film are adhered to two sides of the honeycomb core. By designing the first panel, the honeycomb core and the second panel, properties of a carbon fiber composite material are effectively utilized and the problems of a traditional reflecting mirror that the weight is great, the coefficient of thermal expansion is high and the thermal performance is not matched are solved; and layering angles and sequences of the honeycomb core are designed so that the specific modulus of the reflecting mirror is improved and the defect that the honeycomb vertical performances of the traditional reflecting mirror are poor is overcome.

Owner:BEIJING AEROSPACE HEZHONG TECH DEV +1

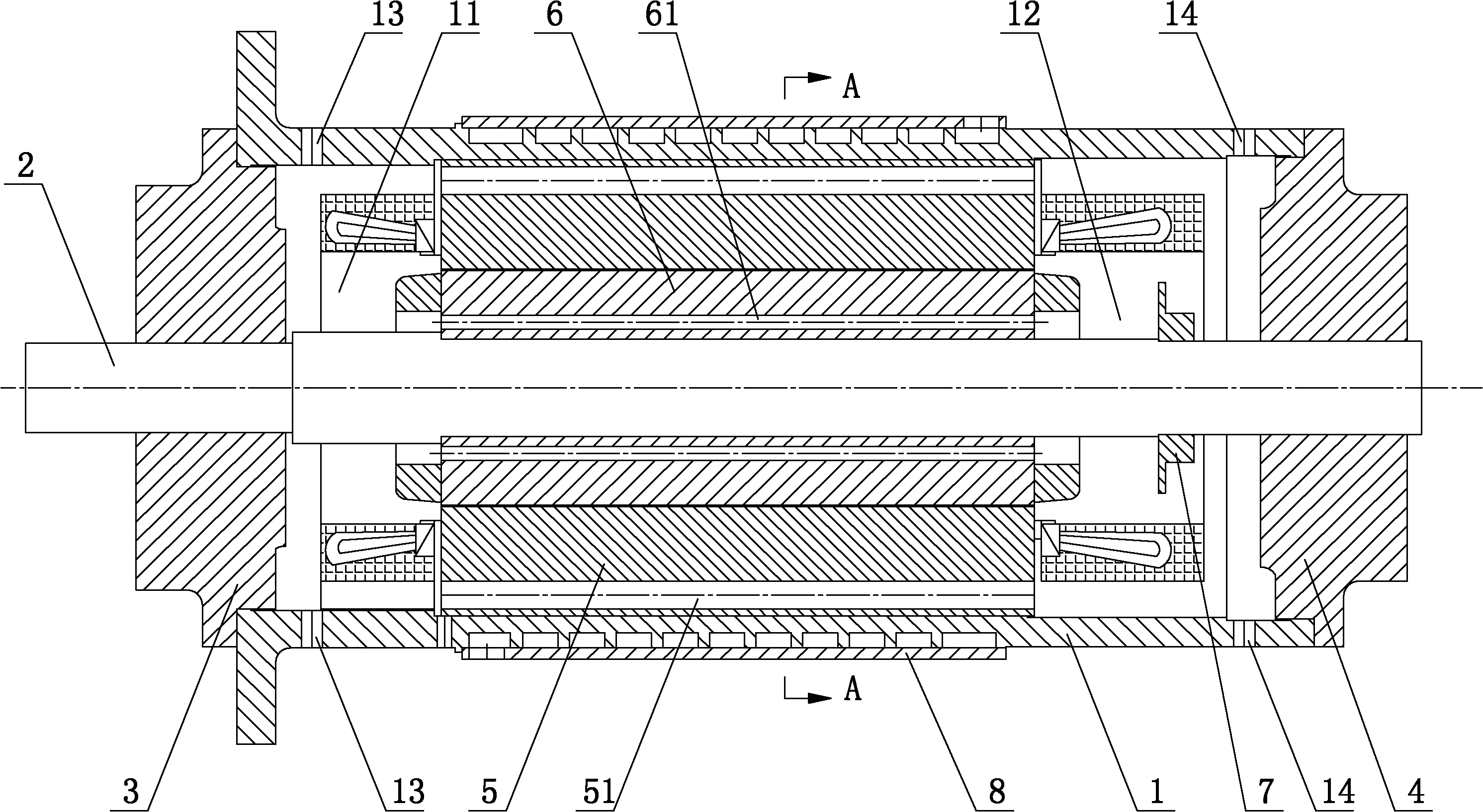

High-speed motor with rotor cooling structure

InactiveCN101841211AReduce heatSmall amount of thermal deformationMagnetic circuit rotating partsMagnetic circuit stationary partsImpellerFlange

The invention discloses a high-speed motor with a rotor cooling structure, comprising a motor shell, a main shaft of the motor, a front flange component, a rear flange component, a motor stator and a motor rotor. The motor stator is sleeved in the motor shell; the motor rotor is sleeved in the motor stator; the front flange component is assembled at the front end of the motor shell to form into a front end cavity; the rear flange component is assembled at the rear end of the motor shell to form into a rear end cavity; the main shaft of the motor is sleeved in the motor rotor, and the front end and the rear end of the main shaft are respectively supported on the front flange component and the rear flange component; the motor rotor is provided with an air vent hole which communicates the front end cavity with the rear end cavity; the motor stator is provided with an air return hole which communicates the front end cavity with the rear end cavity; and the front end cavity or the rear end cavity on the main shaft of the motor is internally provided with an impeller. The high-speed motor with the rotor cooling structure can be used for cooling the motor rotor, and has high rotation precision, long service life, simple structure and convenient installation.

Owner:FOSPOVA +1

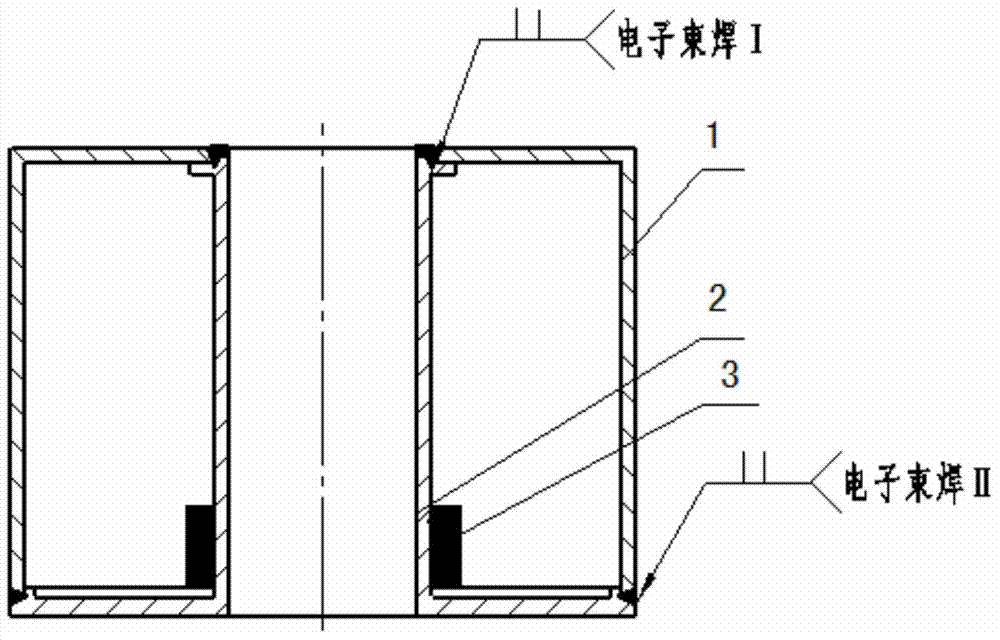

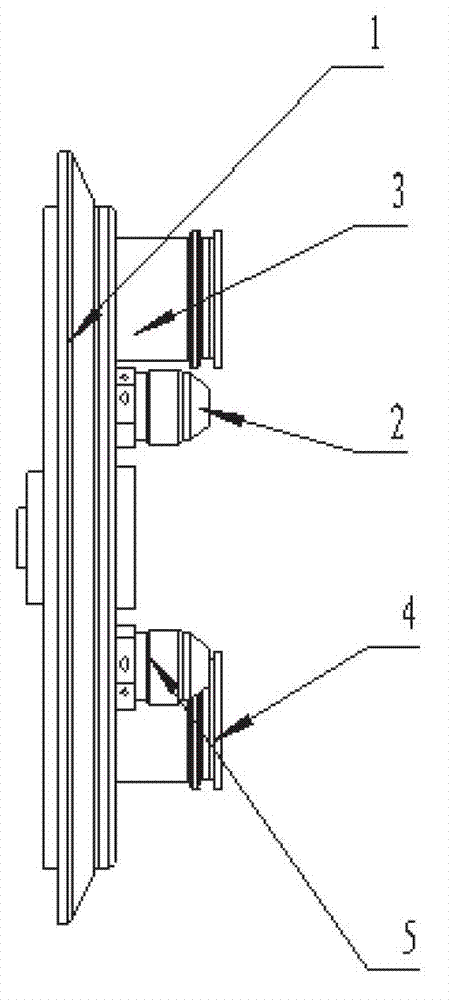

Non-penetrating welding method of feed components through electron beams

ActiveCN104227218AIncrease the active areaDispersed Power DensityElectron beam welding apparatusWeld seamThermal deformation

The invention discloses a non-penetrating welding method of feed components through electron beams. According to the non-penetrating welding method, the needed technological process is simple, efficiency is high, deformation is little, welding seams are regular, welding precision is high, and the product percent of pass can be 100%. The non-penetrating welding method is realized through the technical scheme that in the welding process, scanning waveforms of the electron beams are set to be oval, the scanning amplitude in the X direction is set to be 2 mm to 3 mm, the scanning amplitude in the Y direction is set to be 4 mm to 6 mm, the scanning frequency is set to be 80 Hz to 100 Hz, the acceleration voltage is set to be 50 kV to 60 kV, the beam current is set to be 10 mA to 15 mA, the focus current is set to be 800 mA to 900 mA, any one set of specific values of is selected from the process parameters, the beam slope is set to be in an isosceles trapezoid shape, ascending time and descending time of the electron beams are both set to be 3s to 5s, and the welding seams are welded in a deflection scanning mode; the electron beams penetrate through feed pieces on a sleeve pipe to weld the feed pieces and the sleeve pipe under the feed pieces together. The non-penetrating welding method solves the problems that a conventional welding process is complex, thermal deformation is serious, and burning through and open solder are likely to happen.

Owner:四川泛华航空仪表电器有限公司

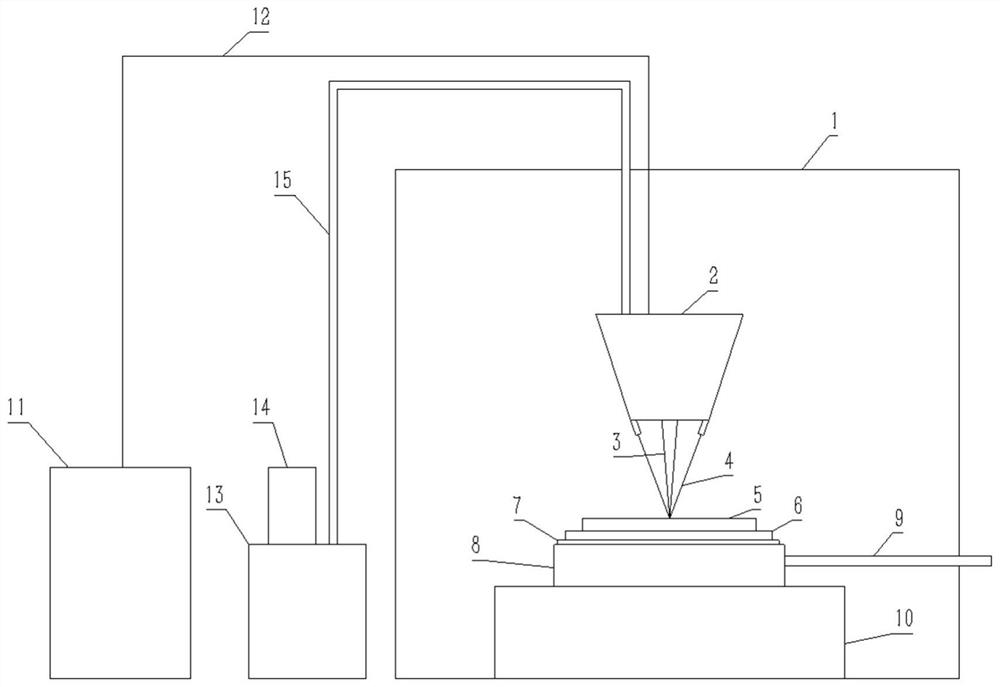

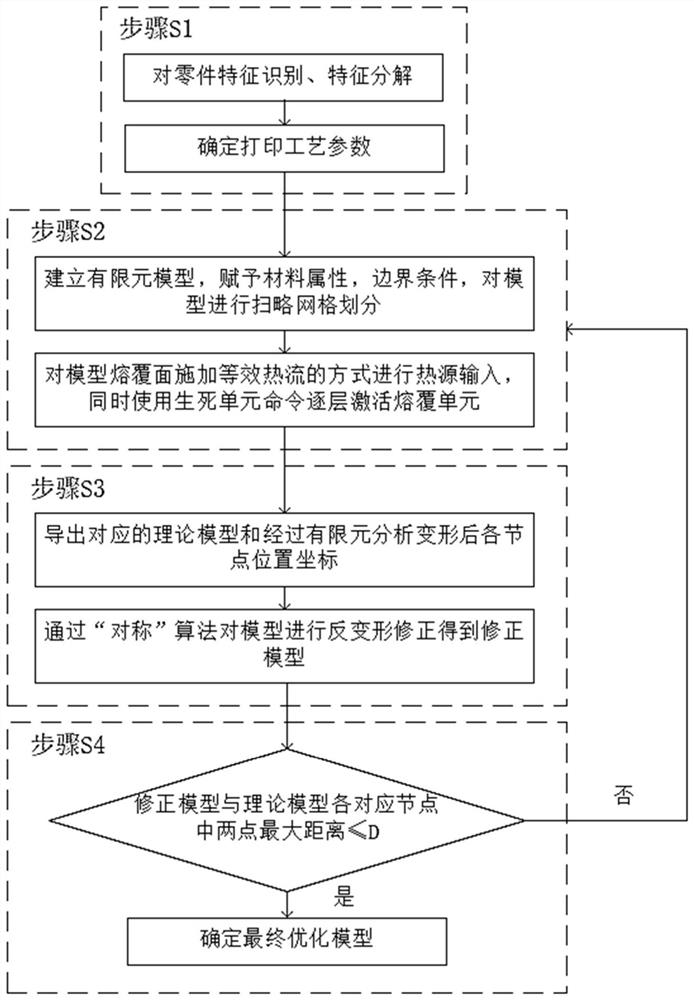

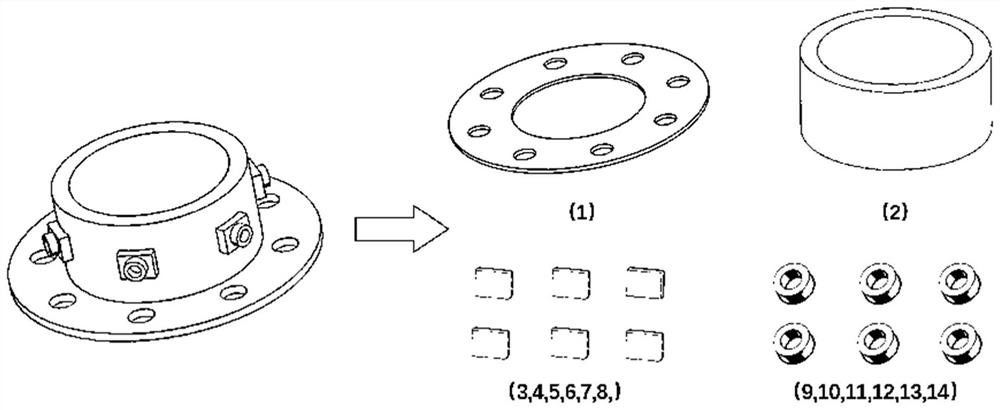

Additive and subtractive composite manufacturing part deformation prediction and control method and equipment

ActiveCN113158368ASimple calculationCalculation speedGeometric CADIncreasing energy efficiencyHeat flowProcess engineering

The invention discloses an additive and subtractive composite manufacturing part deformation prediction and control method and equipment. The method comprises conducting feature recognition and feature decomposition on a target part model, and determining printing parameters; performing finite element thermal coupling analysis of equivalent loading on the model; performing model reversible deformation optimization design according to a simulation result; and determining an optimized final part structure model in an iteration mode. According to the method, a method of combining unit-by-unit activation and Gaussian moving heat source commonly adopted at present is converted into surface heat flow loading of layer-by-layer life and death unit activation in an energy equivalent mode. In the simulation process, birth and death units are used for simulation, all the units are killed firstly, namely, the rigidity is changed into 0, and then the rigidity is activated to be changed into a'birth 'state. Compared with other current life-death unit analog simulation additive manufacturing methods, the method has the advantages that the calculation process can be simplified, the calculation speed can be increased, overall simulation of large parts can be achieved, and an overall temperature field-stress field-displacement field can be obtained quickly.

Owner:XI AN JIAOTONG UNIV +1

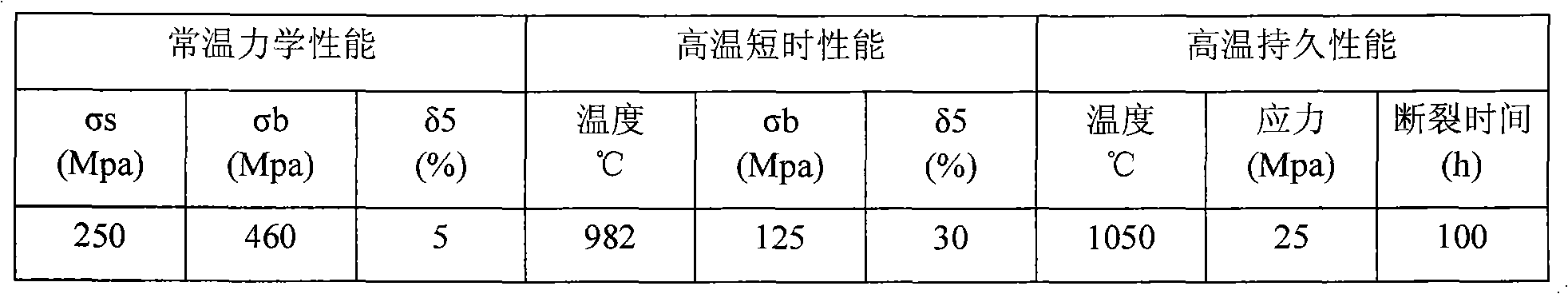

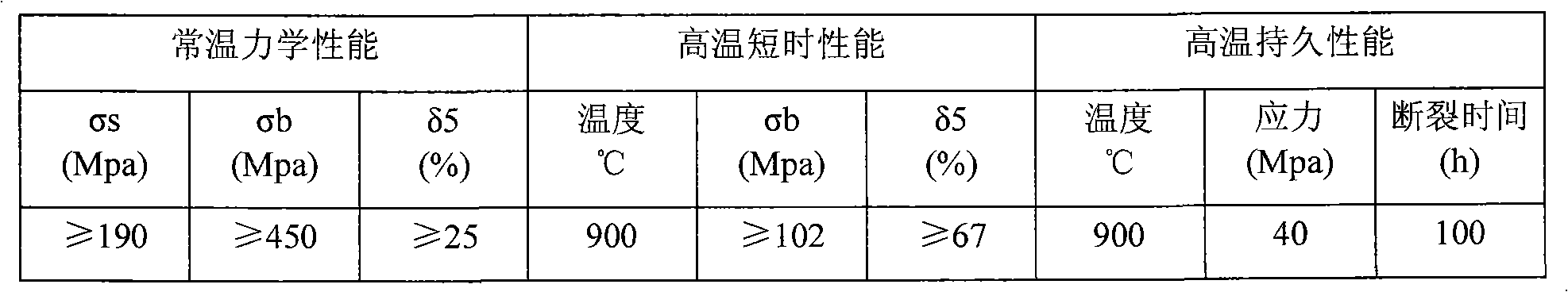

Cast special Ni-based high temperature alloy

The invention relates to metallurgical industry, and provides a cast special Ni-based high temperature alloy, which comprises the following chemical components in percentage by weight: 0.40 to 0.60 percent of C, 1.00 to 1.75 percent of Si, 0.80 to 1.50 percent of Mn, less than 0.03 percent of P, less than 0.03 percent of S, 27.00 to 31.00 percent of Cr, 47.00 to 50.00 percent of Ni, 3.00 to 6.00 percent of W, 2.00 to 3.00 percent of Co, and the balance of Fe and trace impurities. By changing a metallographic structure, the cast special Ni-based high temperature alloy improves heat resistance and high temperature performance of steel, and can effectively reduce heat deformation and improve service life, and is mainly used for manufacturing radiation tubes, pipe fittings, fittings and the like of high temperature devices in the petrochemical industry, the metallurgical industry and other industries.

Owner:黄石山力大通热工设备有限公司

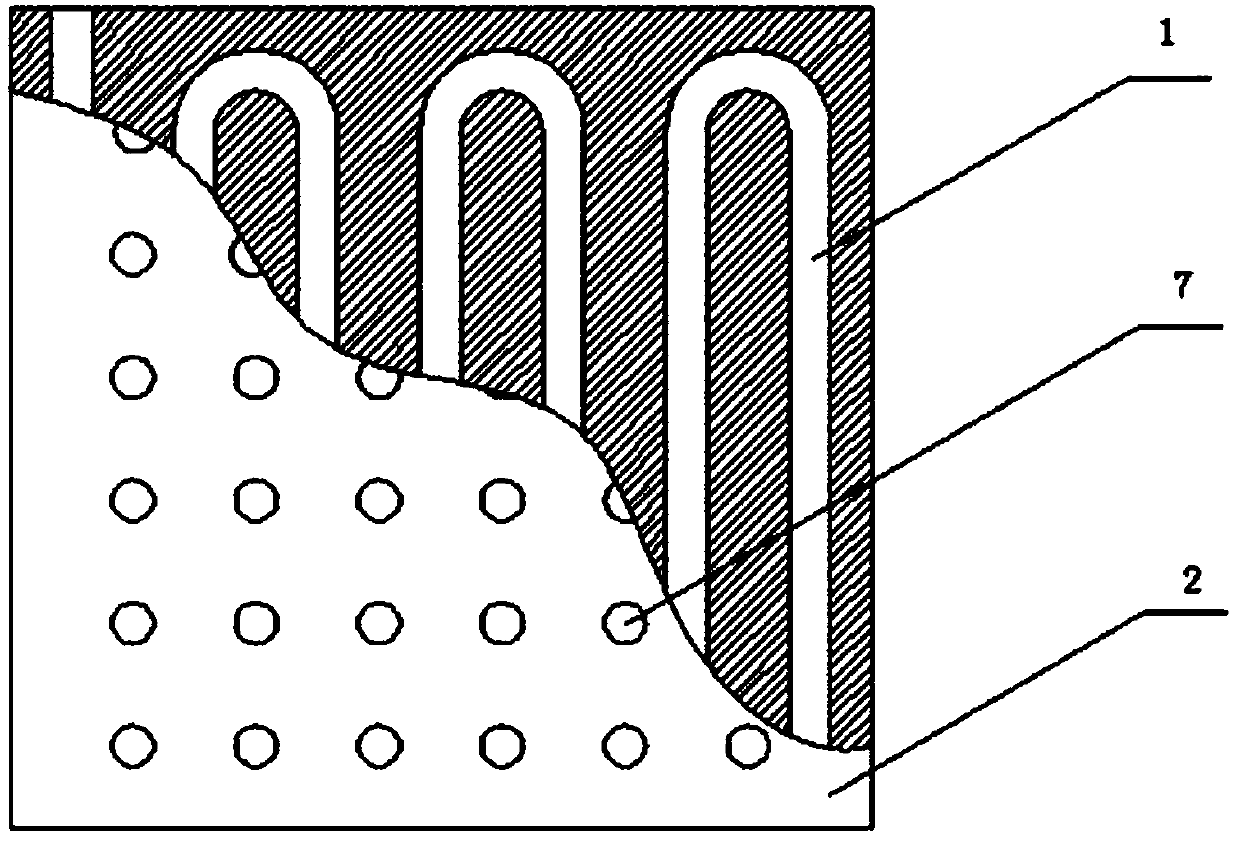

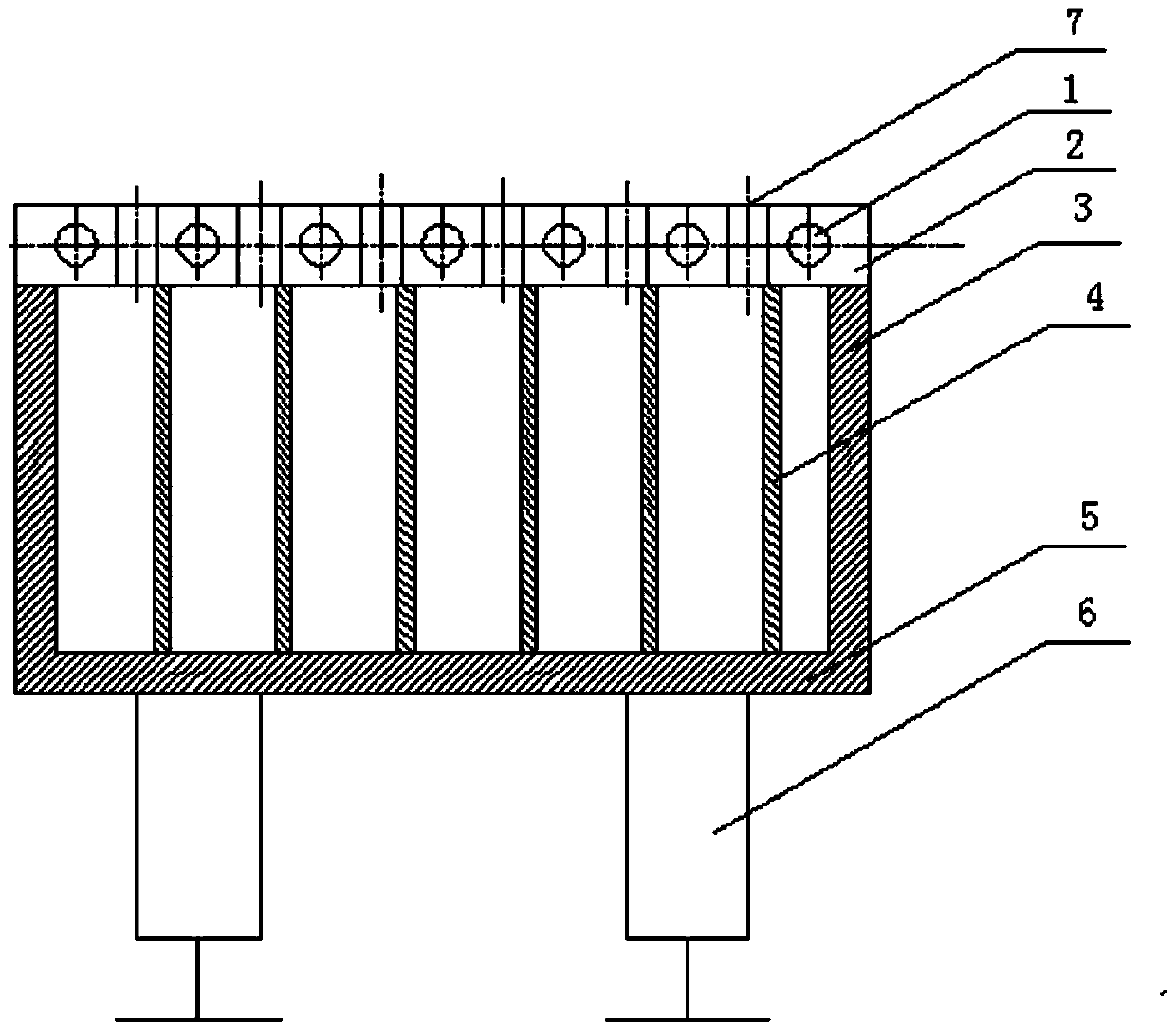

Optical experiment platform capable of achieving active and uniform heat conduction and preparation method thereof

InactiveCN104199166AInhibitionDoes not affect structural stiffnessMountingsEngineeringHeat distribution

The invention provides an optical experiment platform capable of achieving active and uniform heat conduction and a preparation method thereof. The optical experiment platform capable of achieving active and uniform heat conduction comprises a panel, threaded holes and U-shaped passages, wherein the U-shaped passages are sealed inside the panel and filled with inorganic heat superconducting materials, the panel is provided with the threaded holes, and the threaded holes and the U-shaped passages are distributed alternately. The optical experiment platform capable of achieving active and uniform heat conduction has the advantages that the inorganic heat superconducting materials are extremely high in heat conductivity, heat can be diffused to the whole platform rapidly after the platform is heated locally, and the heat can be transferred from a hot end to a cold end only in several seconds; since the inorganic heat superconducting materials are uniform in heat distribution, stability of the platform is improved while heat deformation is decreased; influence on accuracy degree of an optical path in an optical experiment is small, and high experiment accuracy and good reliability are guaranteed, so that success rate of the optical experiment is increased greatly.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

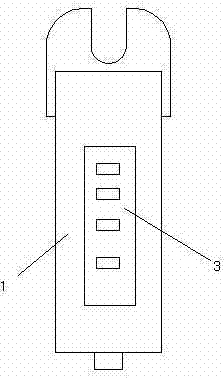

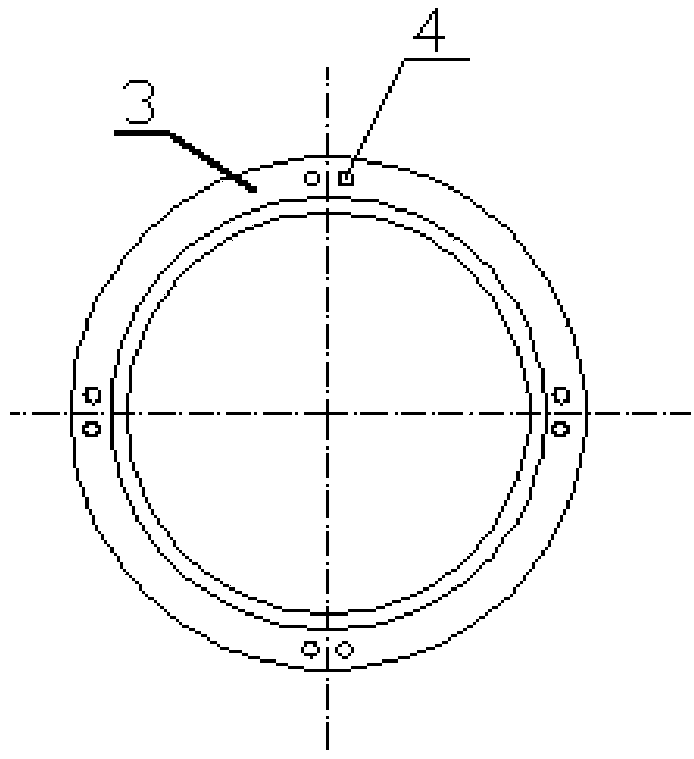

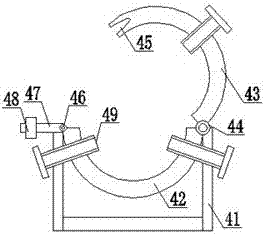

Handheld automatic welding head for welding closely-spaced small-diameter metal pipes

ActiveCN103862212ASave operating spaceBreak the single limitWelding/cutting auxillary devicesElectrode holder supportersGear wheelDrive shaft

The invention discloses a handheld automatic welding head for welding closely-spaced small-diameter metal pipes. The handheld automatic welding head comprises a shell , wherein a servo motor, a transmission part and a welding part are arranged inside the shell; the servo motor is used for driving the welding part to run through the transmission part. An open gear is driven to rotate in a limited space by matching the motor with the transmission part to realize 360-degree welding of U-shaped pipes, so that the essence of the gear transmission is effectively utilized. In combination with shaft transmission, the operating space is saved to the maximum extent while the welding operation is finished. A driven gear is driven by using the motor, and is used for changing the transmission direction, so that the limitation of single welding direction is broken. By adopting the transmission shaft, the open gear can rotate continuously to the opening for welding, so that 360-degree welding is realized, and smooth implementation of various types of movements is ensured.

Owner:郑州科慧科技股份有限公司

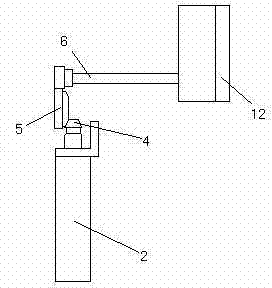

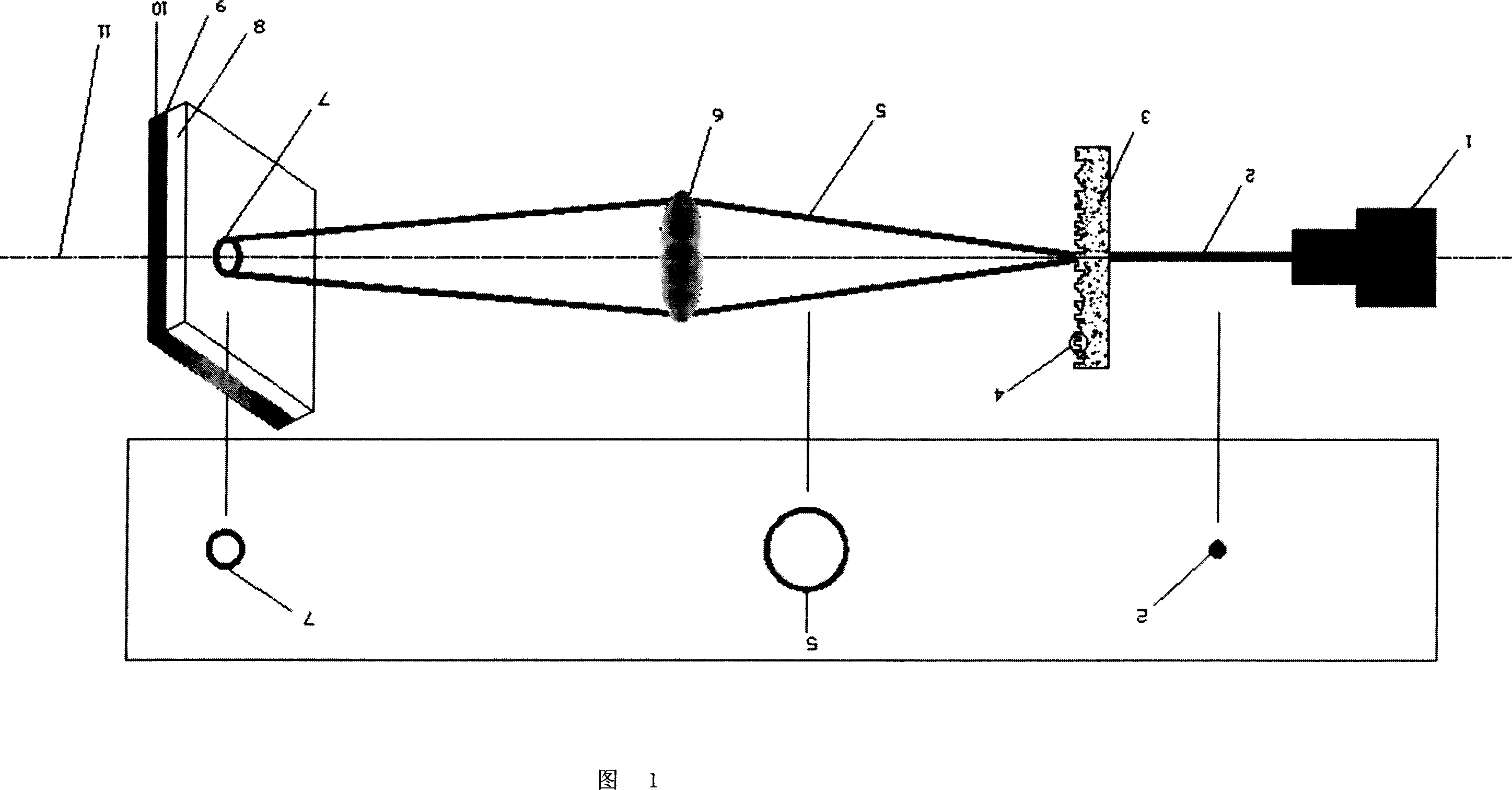

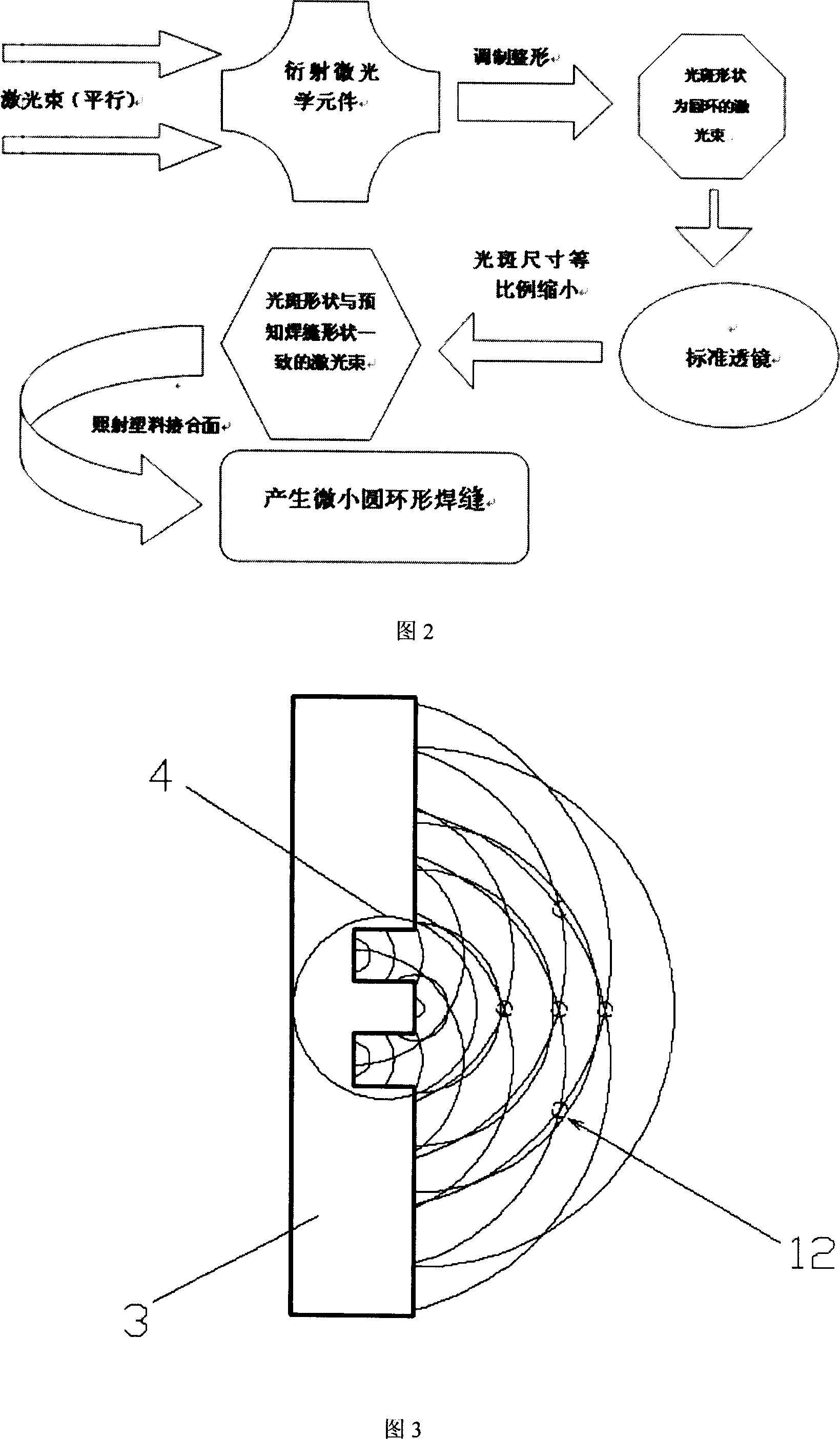

Laser plastic micro-welding method

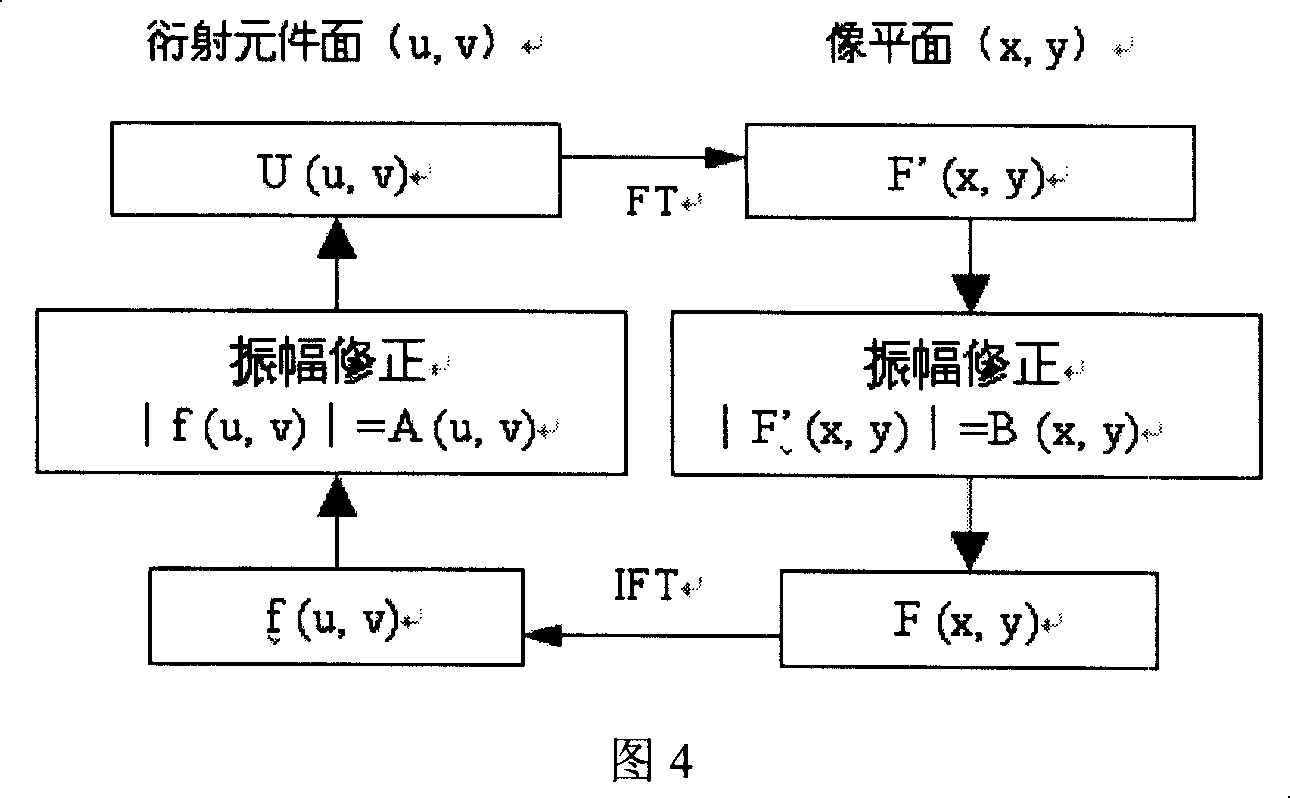

InactiveCN101100107ASmall amount of thermal deformationImprove welding strengthDiffraction gratingsPhotomechanical exposure apparatusWeld seamReactive-ion etching

The present invention relates to laser welding technology, and is especially laser micro welding process for plastic. Micro optical diffraction element is designed based on the weld seam shape and laser wavelength by means of proper algorithm, and formed on transparent chip material through reaction ion etching, UV photo etching or direct laser beam writing. Laser beam is made to pass through the micro optical diffraction element and one standard lens to form laser spot in the shape same as the weld seam for irradiating the joint of two plastic workpieces to complete the laser micro welding. The laser micro welding process for plastic has short processing time, no need of shifting laser beam and welded parts, small heat deformation and other advantages, and is suitable for batch production.

Owner:JIANGSU UNIV

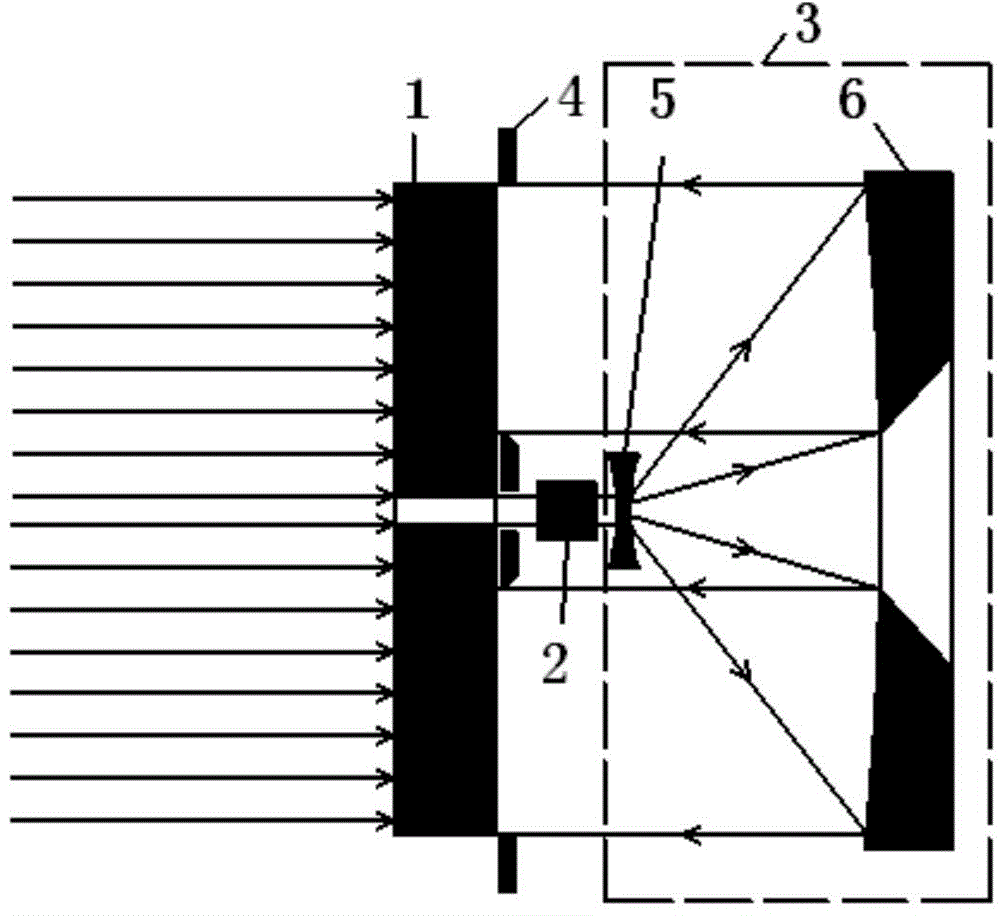

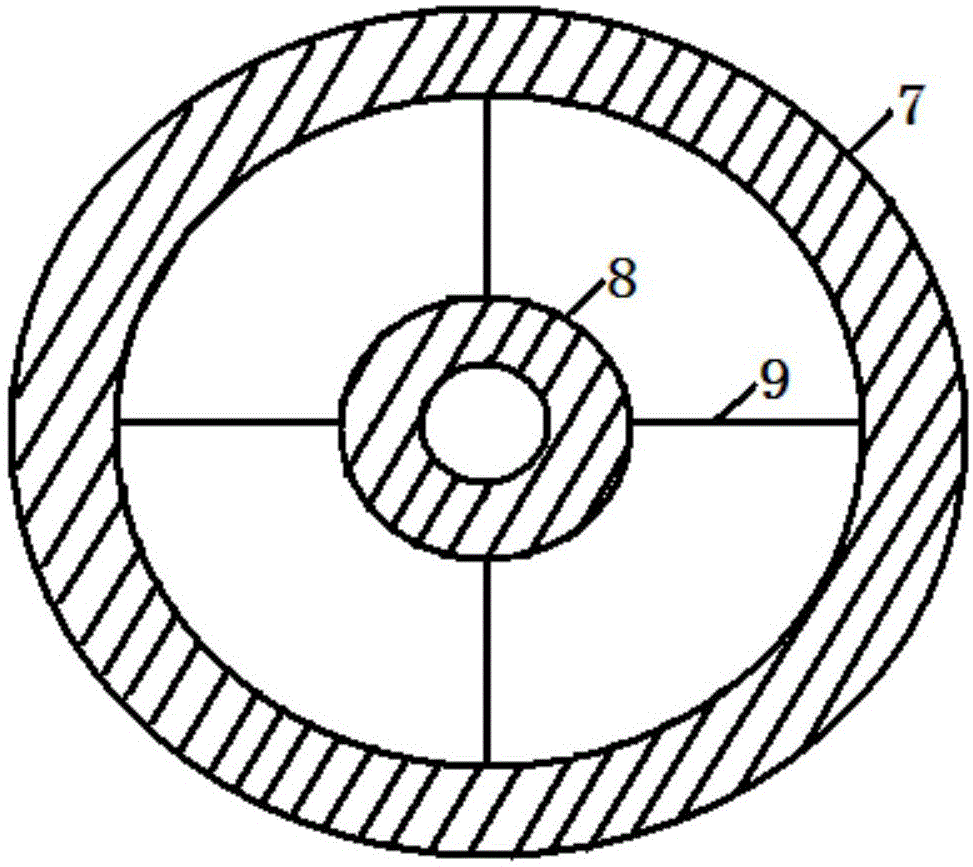

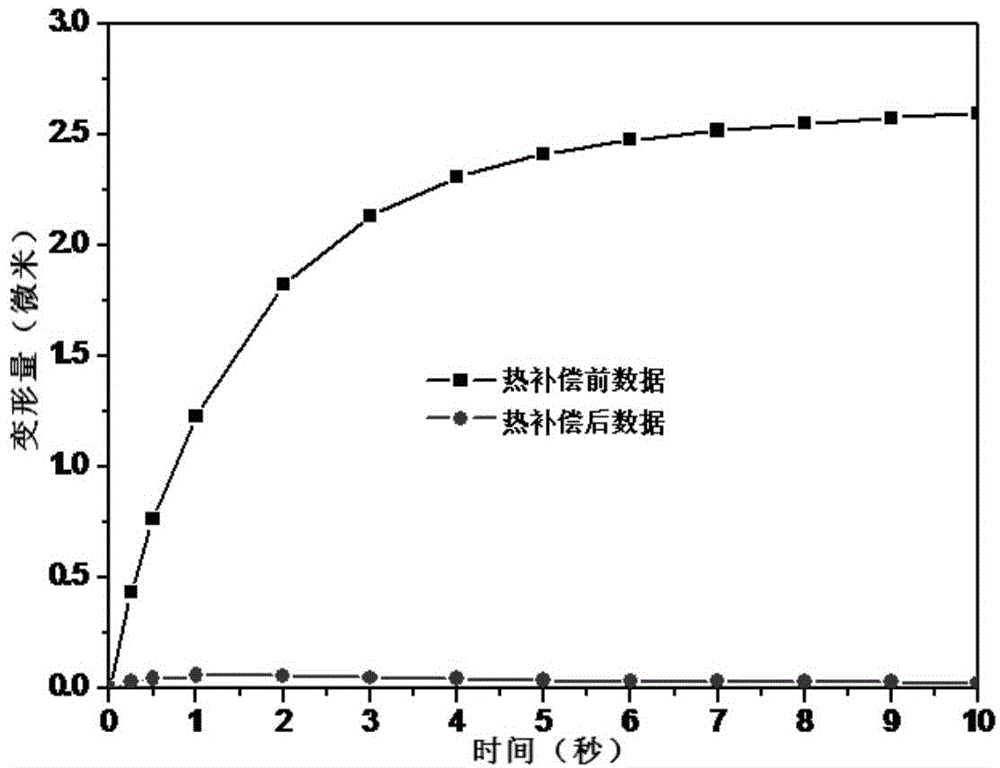

Light heating compensating lens and application method thereof

ActiveCN104953458ASmall amount of thermal deformationEvenly distributedLaser detailsLight energyLight spot

The invention aims to provide a light heating compensating lens and an application method thereof. The light heating compensating lens includes a lens body, a laser attenuator, a laser beam expanding system and a diaphragm. During a heat compensation process, a part of laser passes through the center of the lens body with a central hole and then the laser attenuator for adjustment of heat compensation energy, the laser beam expanding system composed of a concave lens and a concave mirror for adjustment of diameter of heat compensation light beams, and the diaphragm for adjustment of a heat compensation heating range. The laser then goes to the back face of a mirror coated with a highly absorbing film for heat compensation. According to the invention, light energy of a laser can be utilized for realizing the uniform heat compensation of a laser endoscope and heat deformation of a light spot of the laser endoscope can be reduced to a value which is 1 / 40 of an original one.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

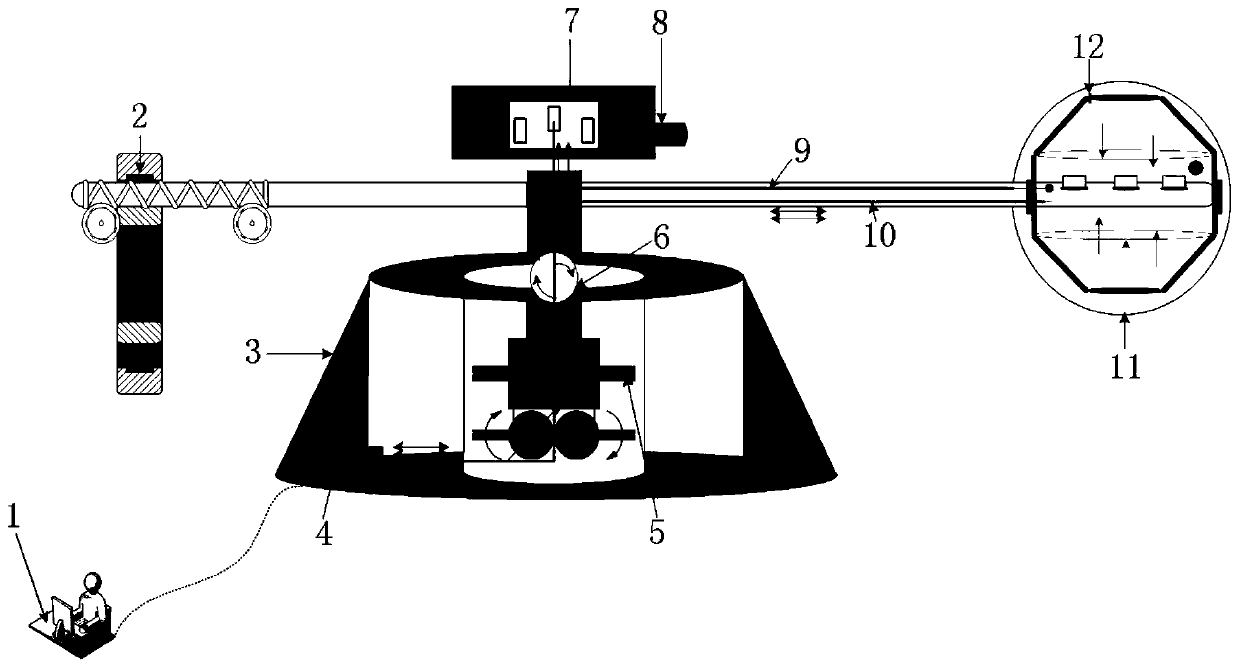

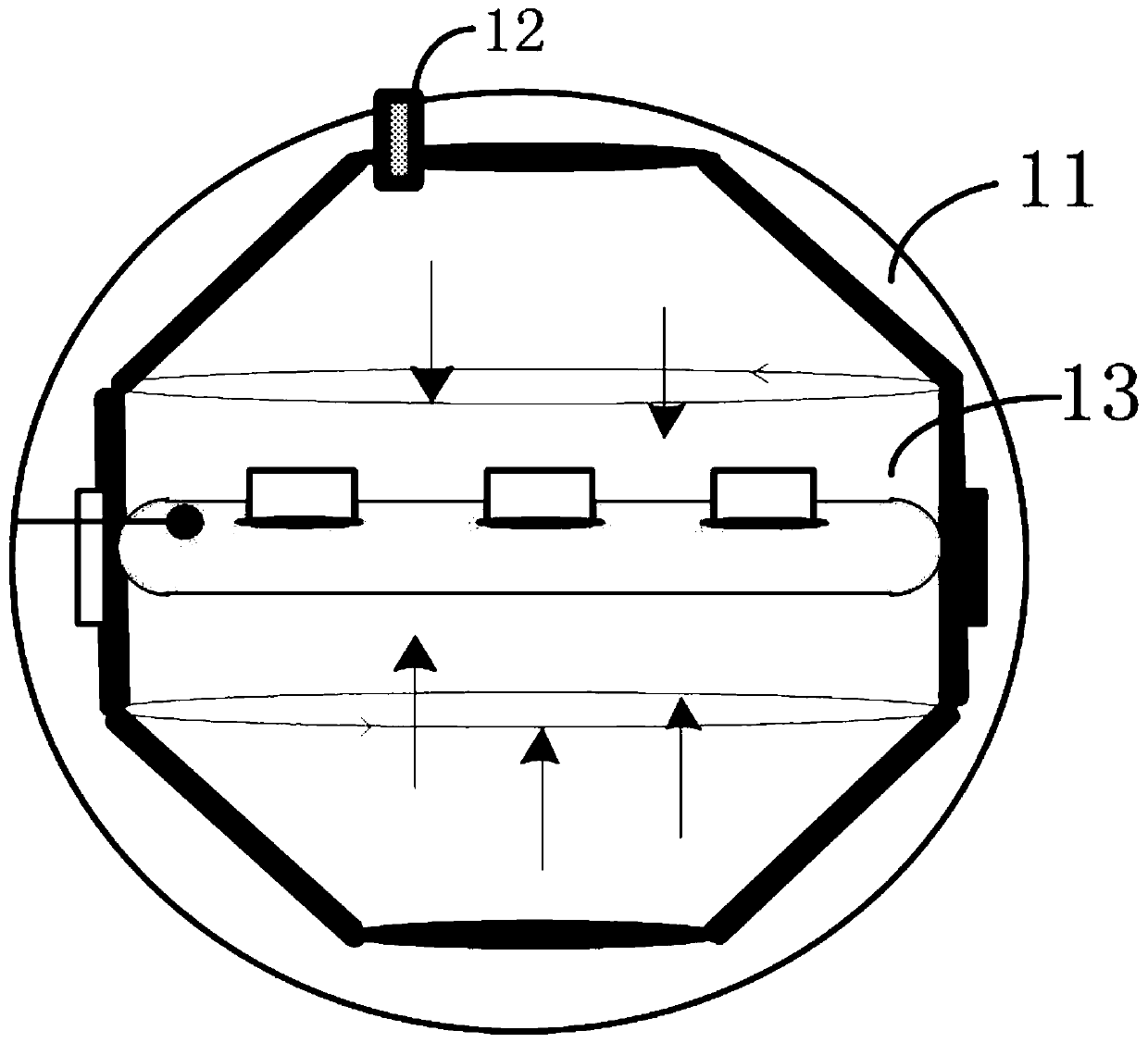

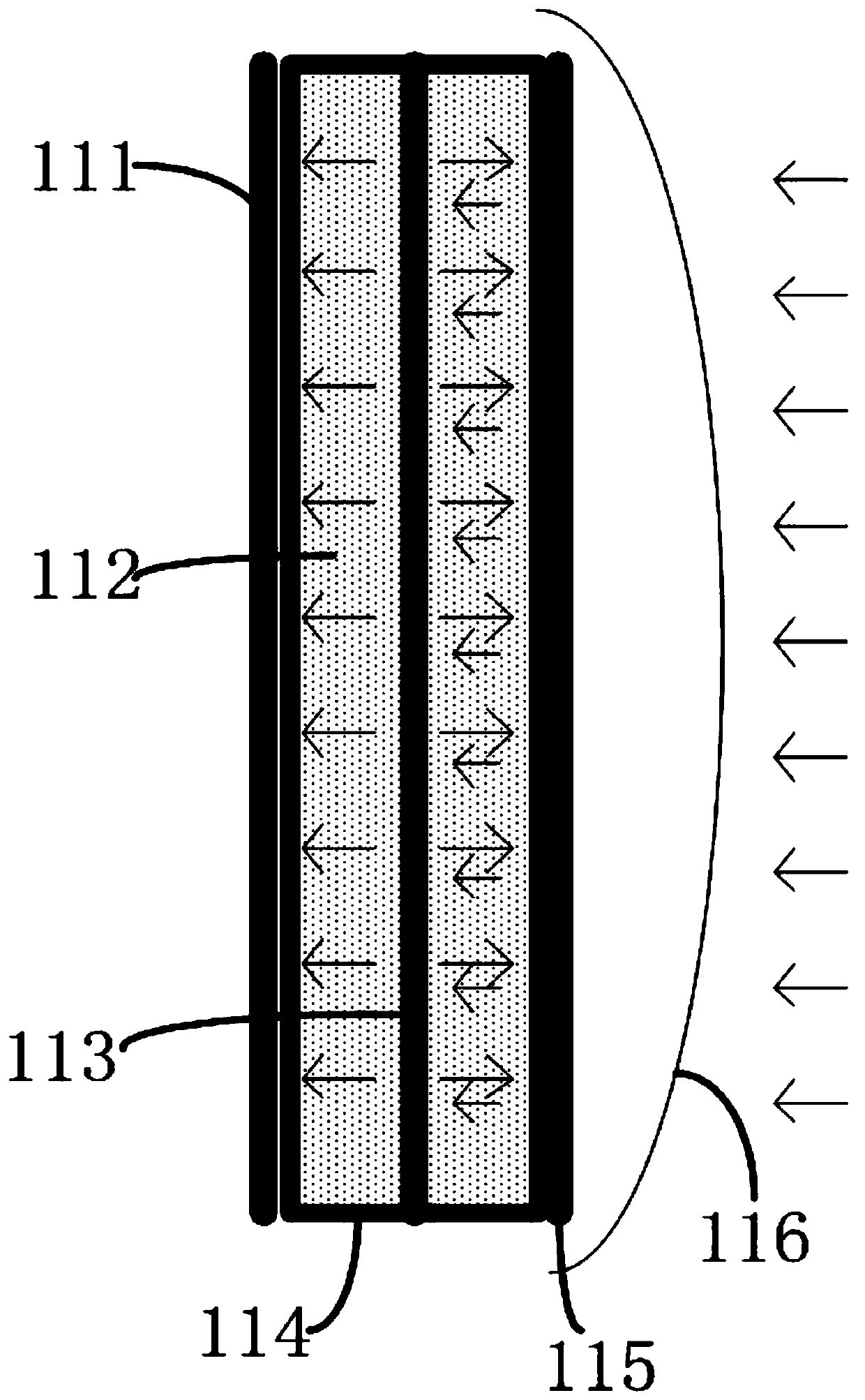

Temperature-centrifugation composite environment assessment test device and test method

PendingCN111442944AHigh strengthSmall amount of thermal deformationStructural/machines measurementStructural engineeringMechanical engineering

The invention discloses a temperature-centrifugation composite environment assessment test device and a test method. The test device comprises a centrifuge test system, a thermal loading unit and a data monitoring processing unit; the centrifuge test system comprises a centrifuge and a fairing; and the thermal loading unit is integrally mounted at the far end of a big arm of the centrifuge, the fairing is mounted outside the thermal loading unit in a sleeving manner, a vacuum environment is arranged inside the fairing, and a test piece is arranged in the thermal loading unit. According to thedevice and the method, vacuum, high temperature, centrifugal load and load history under action scenes such as space isotope heat source product ground emission, space attitude adjustment, space detection, landing and the like can be accurately simulated; a complete data testing system is arranged, multiple parameters such as the temperature, the strain, the vacuum degree and the product state canbe detected in an integrated mode in the testing process, and the product response situation of a tested product under the temperature-centrifugation composite environment can be accurately obtained.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

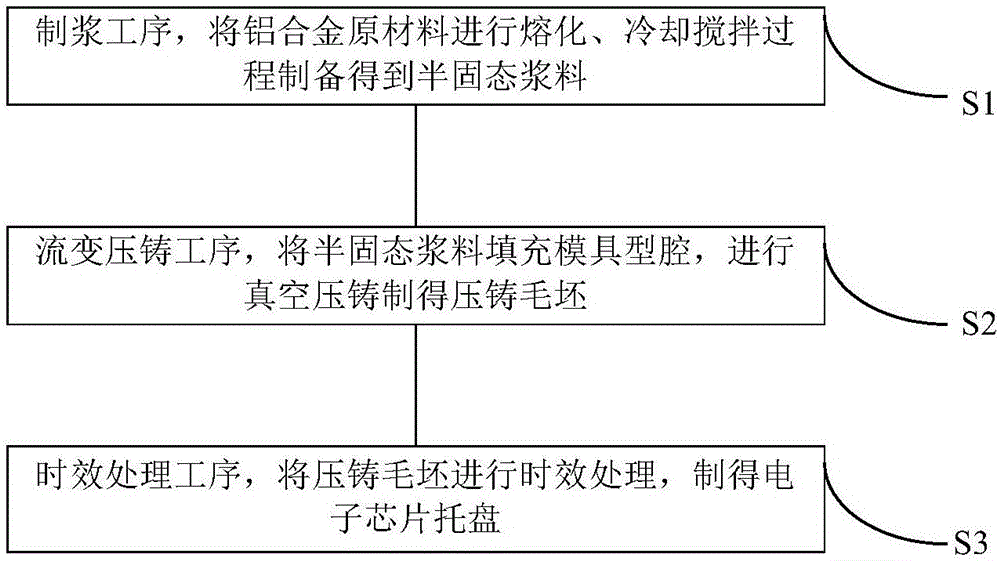

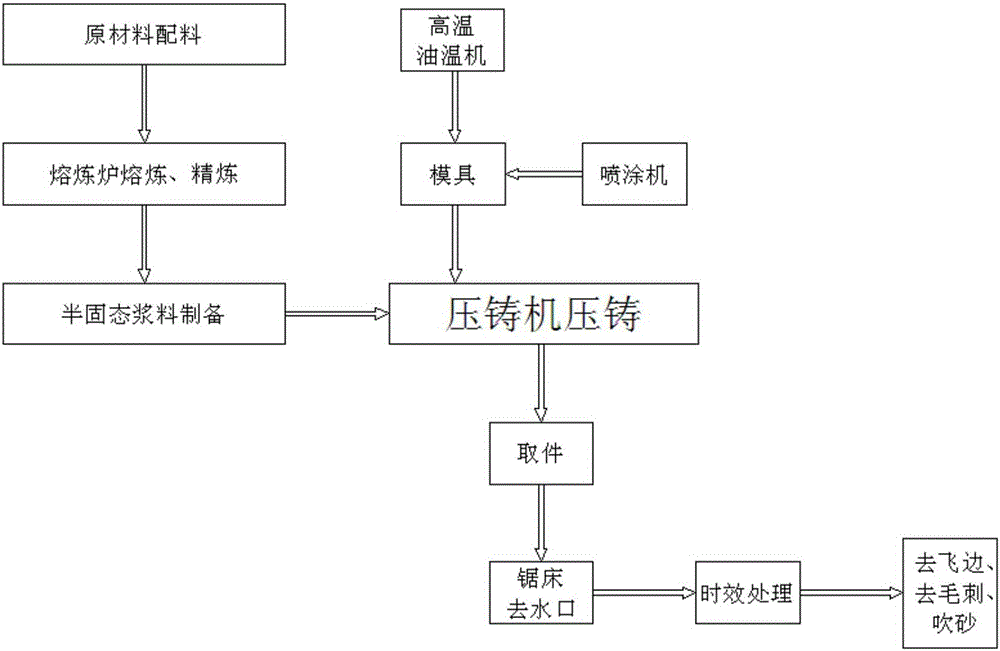

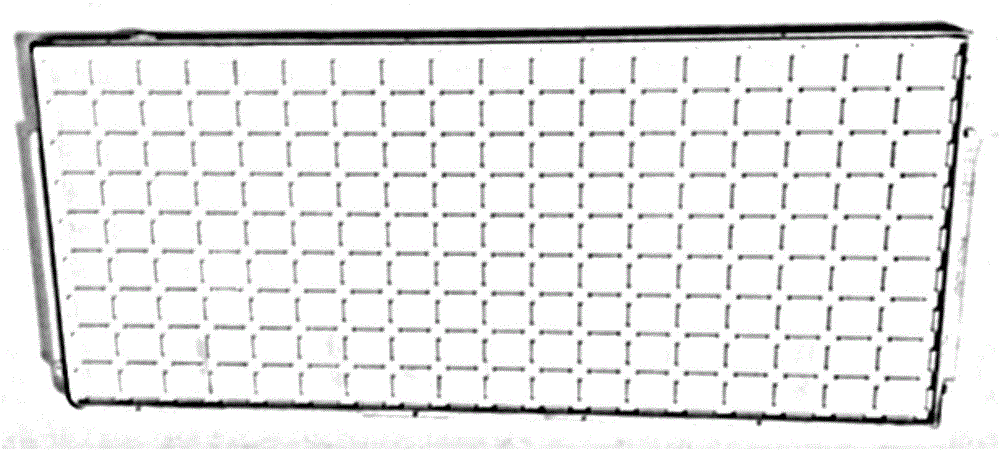

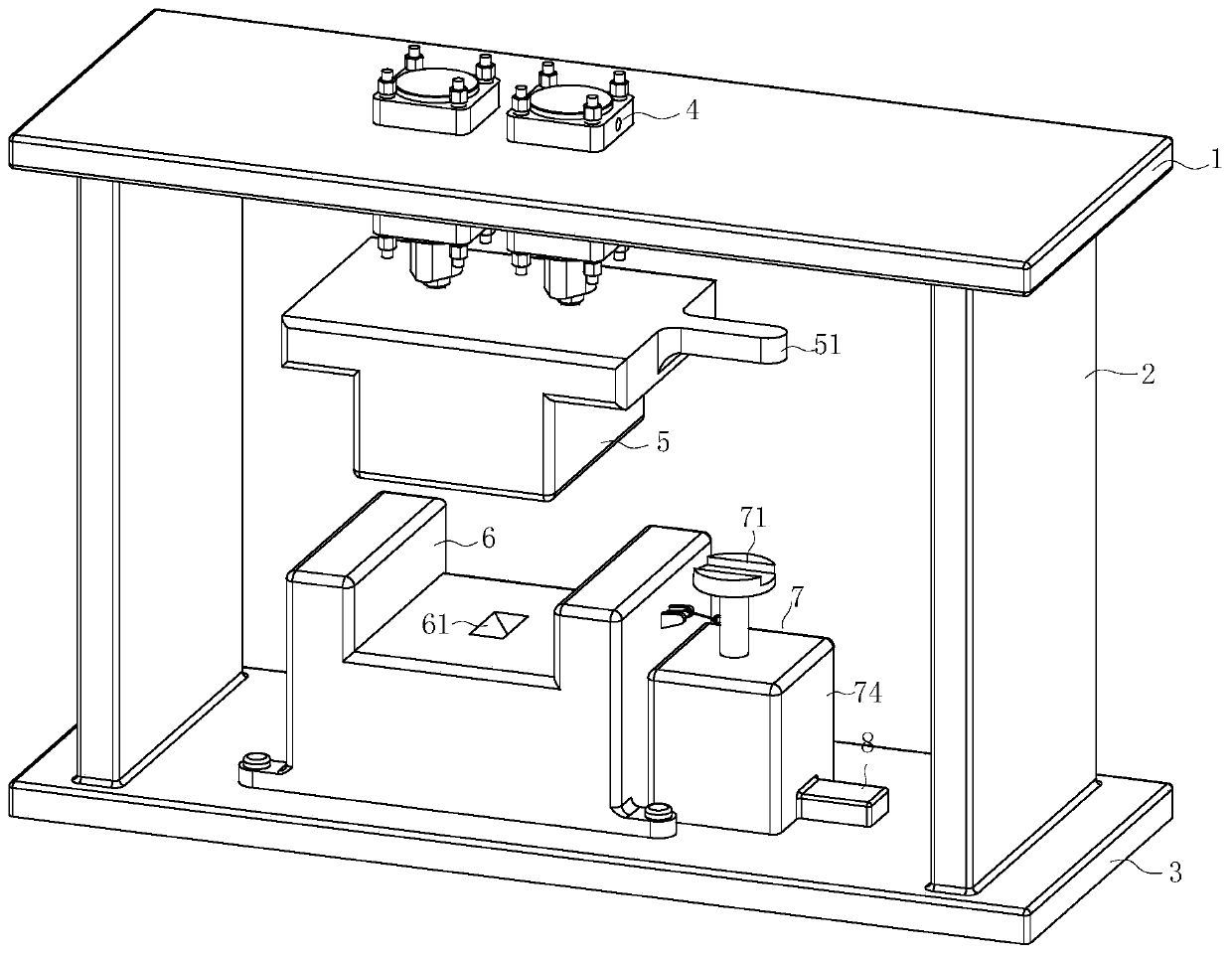

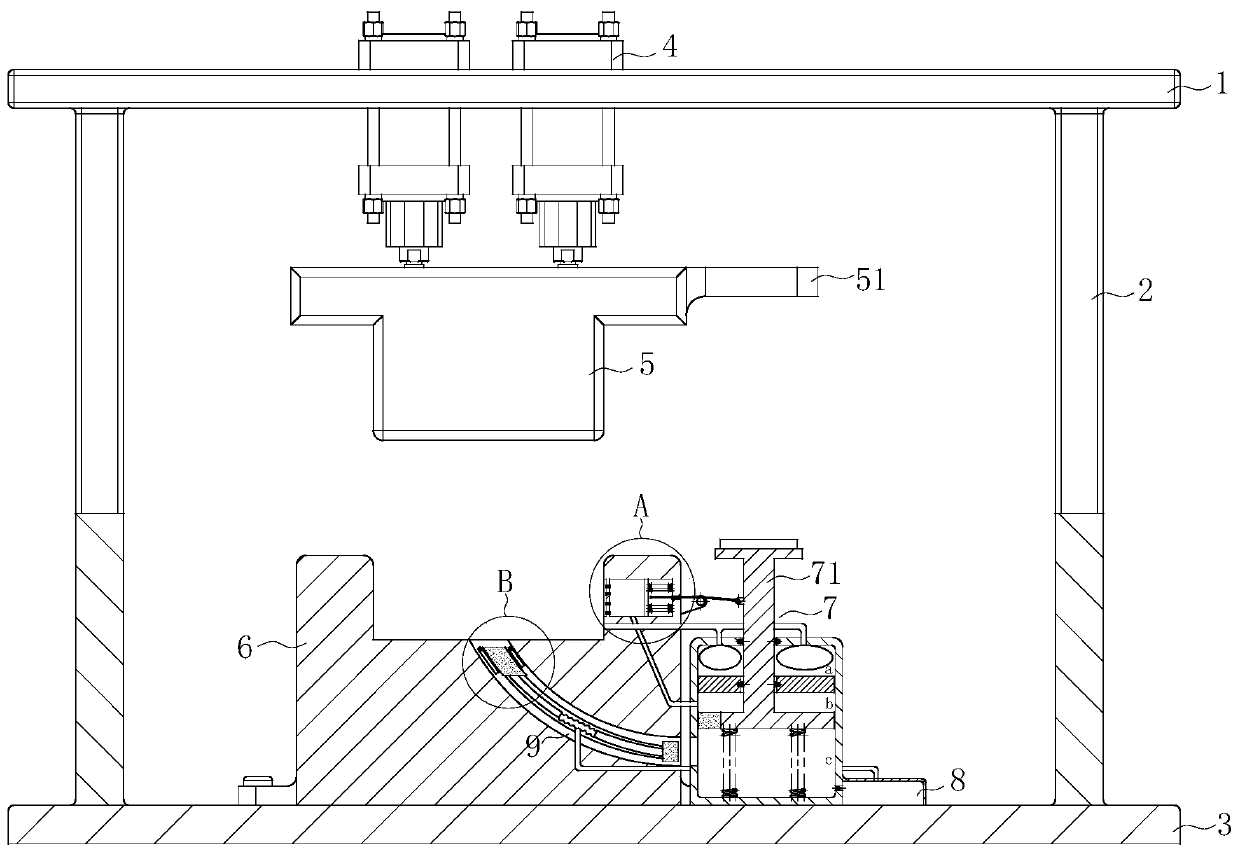

Aluminum alloy electronic chip tray and preparation process thereof

ActiveCN107520419AMeet the design requirementsMeet high-end needsSemiconductor/solid-state device manufacturingSemi solidDie casting

The invention provides a preparation process of an aluminum alloy electronic chip tray. The electronic chip tray is produced through a semi-solid rheo-diecasting process. The production process specifically comprises a pulping procedure, a rheo-diecasting procedure and an aging treatment procedure. Vacuum die casting is adopted as a die casting manner. The aluminum alloy electronic chip tray prepared through the preparation process has the excellent performance of an aluminum material, effectively overcomes the technical problem that an aluminum alloy material is prone to deforming when heated, is small in heat deformation and has excellent appearance quality and anti-static performance; the market application of the electronic chip tray is opened up; the application field of die castings is expanded; and the aluminum alloy electronic chip tray produced through the preparation process is further requested to be protected.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

Stamping die

PendingCN110125255AAvoid shakingImprove qualityShaping toolsMetal-working feeding devicesMagnetEngineering

The invention relates to the technical field of a stamping die, in particular to a stamping die, the stamping die comprises a cover plate, a bracket plate, a bottom plate, a first cylinder, an upper stamping block, a lower stamping holder, a pushing unit, a gas collecting box and a magnet unit, wherein the lower end of the bracket is fixedly connected with the upper surface of the bottom plate, and the upper end is fixedly connected with the lower surface of the cover plate; the pushing unit is positioned at the right side of the lower stamping base and fixedly installed on the upper surface of the bottom plate; the magnet unit is positioned in an arc-shaped groove of the lower stamping base; through the mutual cooperation of the cover plate, the bracket plate, the bottom plate, the firstcylinder, the upper stamping block, the lower stamping base, the pushing unit, the gas collecting box and the magnet unit, the stamped metal material is tightly adsorbed by the magnet so as to avoid shaking; and the quality of stamped parts is higher.

Owner:黄广顺

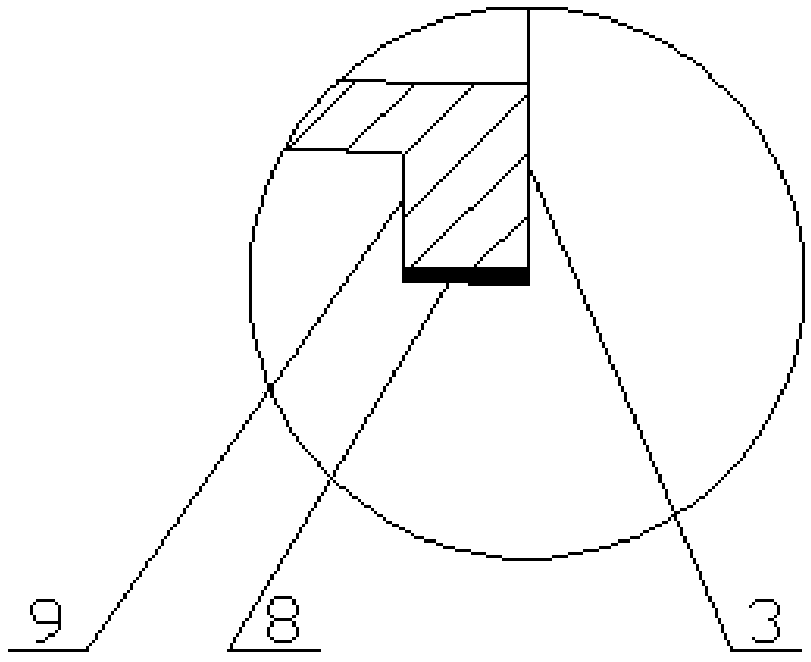

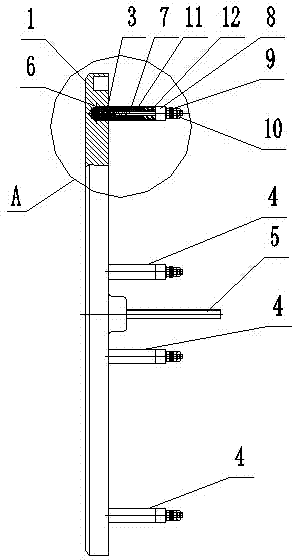

Thermal deformation coordinated missile dome attachment ring

ActiveCN107063004BReduce conductionSmall amount of thermal deformationAmmunition projectilesProjectilesThermal deformationFlange

The invention discloses a missile dome connecting ring having thermal deformation compatibility. The missile dome connecting ring having thermal deformation compatibility comprises a connecting ring lining, a connecting ring flange and the like. The connecting ring lining is fixedly connected with the connecting ring flange. The front end face of the connecting ring lining is located on the connecting ring lining. Hole-shaped stress grooves are located on the front end face of the connecting ring lining. Linear stress grooves are located on the connecting ring lining. The back end face of the connecting ring flange and the front end face of the connecting ring flange are located on the front side and the back side of the connecting ring flange correspondingly. Connecting ring threaded holes are located in the back end face of the connecting ring flange. A heat-proof coating is located on the outer surface of the connecting ring flange. The missile dome connecting ring having thermal deformation compatibility can guarantee that when a missile flies at a high mach number, a missile dome is complete in structure, solves the problem that the missile dome is damaged because of overheating and has the advantages of being simple in technology, safe and reliable.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

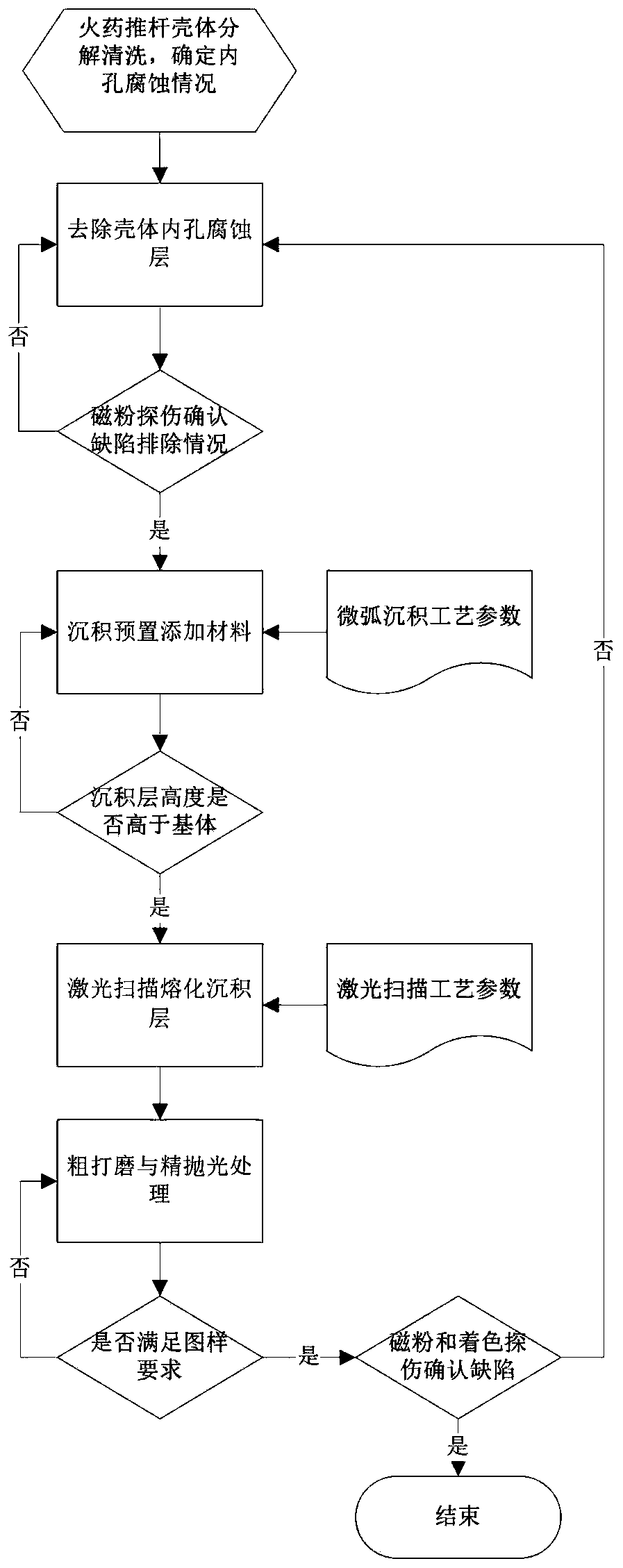

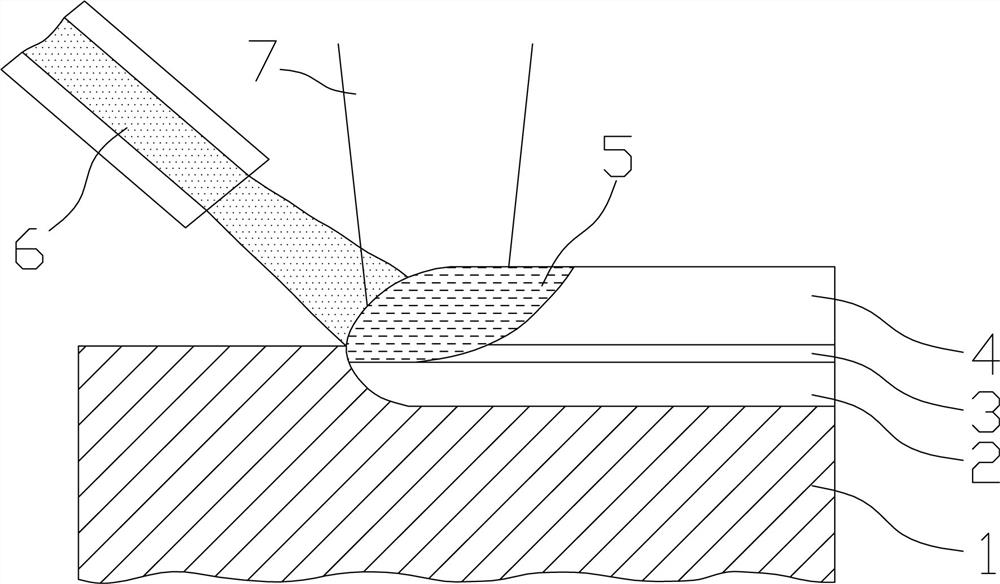

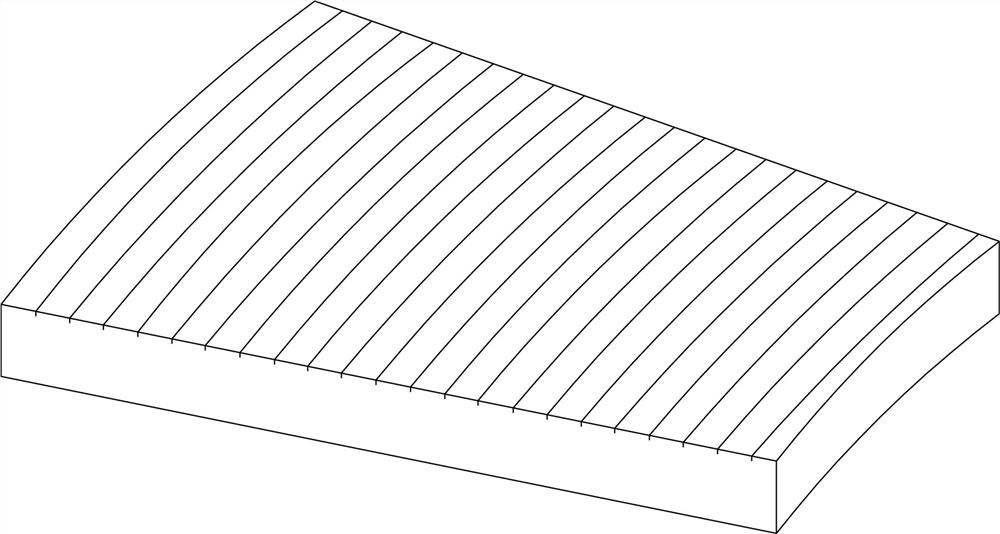

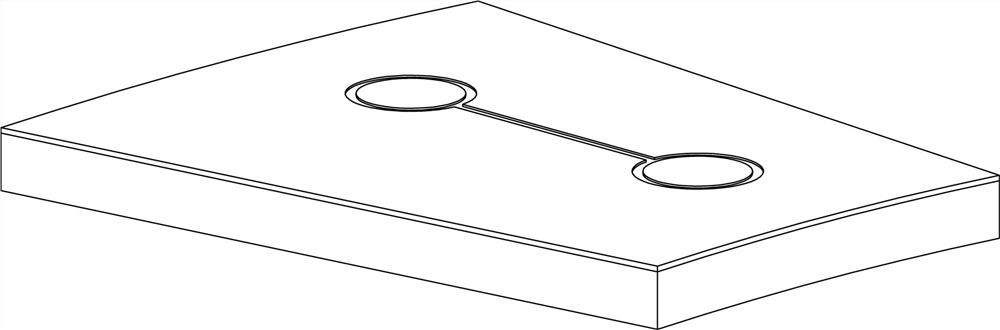

Laser composite repair method for surface corrosion of inner hole of shell

InactiveCN110468409ALittle thermal impactLess heat damageMetallic material coating processesLaser beam welding apparatusLaser scanningThermal deformation

The invention relates to a laser composite repair method for surface corrosion of an inner hole of a shell. The laser composite repair method comprises the following steps of disassembling and cleaning the surface of an inner hole of a powder push rod shell, and measuring the dimensions; determining the local corrosion part and corrosion amount of the inner hole; analyzing the powder push rod shell and evaluating the life of the powder push rod shell according to the detection results, and removing the corrosion layer of the inner hole of the shell; and adopting magnetic particle testing, andensuring that no crack defects occur after removal of the corrosion layer. By adopting preset additive materials of microarc deposition GH4169 corrosion resistant metal bars, the trouble that powder is hard to reach the repair part of the inner hole in a laser cladding feeding mode is overcome; by adopting a microarc deposition and laser scanning composite processing mod, a specific method for corrosion repair of the inner hole is formed; beneficial reference is provided for damage repair of the inner hole, and the repair method has the advantages of low heat input amount and thermal deformation amount, and less heat effect on and heat damage to metal base; and the repair quality of the inner hole of the shell can be improved obviously.

Owner:国营芜湖机械厂

Thrust pad repairing method based on laser cladding process

PendingCN112981395ALow heat inputSmall amount of thermal deformationAdditive manufacturing apparatusIncreasing energy efficiencyTinningEngineering

The invention aims at providing a thrust pad repairing method based on a laser cladding process. The deformation amount in the thrust pad repairing process is effectively controlled, the problems of hole shrinkage and shelling of a babbitt metal layer are thoroughly solved, the design size of a thrust pad is recovered, the use performance of the thrust pad is improved, the service life of the thrust pad is prolonged, and extremely high economical efficiency is achieved. The thrust pad repairing method comprises the following steps: removing an original babbitt metal layer of the thrust pad, preparing the babbitt metal layer on the surface of a steel billet through laser cladding, carrying out ultrasonic flaw detection, milling, carrying out dye penetrant inspection and grinding. According to the method, the thrust pad which fails in service is remanufactured, and the use performance of the thrust pad is recovered and improved through a new additive manufacturing method. Compared with pouring and oxyacetylene welding processes, the manufacturing process of the babbitt metal layer is greatly simplified, the steel billet preheating and tinning processes are omitted, and the quality of the babbitt metal layer, the combination condition of the babbitt metal layer and the steel billet, the deformation amount of the steel billet and the labor environment are effectively improved.

Owner:CHINA YANGTZE POWER

Drum brake

InactiveCN104728316ANo thermal deformationWith heat insulation functionBraking membersEngineeringDrum brake

The invention discloses a drum brake and belongs to the technical field of brakes. The drum brake comprises a brake drum, a friction plate and a brake shoe, wherein the friction plate is fixedly installed on the inner side of the brake drum, and a friction face is formed on the inner surface of the friction plate. The heat deformation of the brake drum is avoided, the service life of the friction plate and the maintenance period of the brake drum are prolonged, the using performance of the drum brake is improved, and the drum brake is widely produced and used.

Owner:李瑾瞳

Electric heating stove plate used in ship kitchen

InactiveCN104235898AHigh temperature resistanceSmall amount of thermal deformationDomestic stoves or rangesLighting and heating apparatusCopperGlass-ceramic

The invention discloses an electric heating stove plate used in a ship kitchen. The electric heating stove plate consists of a cast iron plate, electric heating pipes, electric heating wires installed in the electric heating pipes and multiple stove plate wiring post modules, wherein the number of the stove plate wiring post modules corresponds to the electric heating wires in the electric heating pipes. The stove plate wiring post modules consist of stainless steel pipes, leading-out rods, ceramic insulators, pressing nuts and wiring copper nuts, leading-out positions at two ends of each electric heating wire in the corresponding electric heating pipe are respectively connected with one end of the corresponding leading-out rod, the other end of each leading-out rod is sleeved with a ceramic insulator, the pressing nuts and the wiring copper nuts are installed on the leading-out rods, modified magnesium oxide filling layers are arranged around the electric heating wires in the electric heating pipes, and lead-free glass ceramics are arranged at pipe orifices of the electric heating pipes. By means of the technical scheme, the shortcomings in the prior art are overcome, and the electric heating stove plate is simple in structure, economical, environment-friendly, low in cost, convenient to replace, durable and even in heat emitting and ensures the temperature requirement when being used in a ship.

Owner:ANQING SANWEI ELECTRICAL

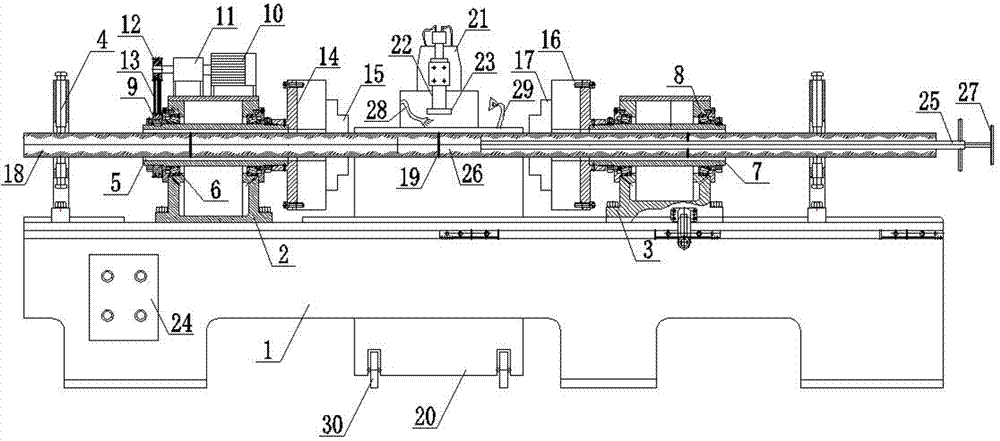

Screw pump metal stator welding whole-set equipment system

InactiveCN107309548AEasy dockingEasy to fixLaser beam welding apparatusReduction driveThermal deformation

The invention relates to a screw pump metal stator welding whole-set equipment system. A front support frame and a rear support frame are separately arranged at the front and the rear of the surface of a machining tool body; clamping positioning racks are symmetrically arranged on two sides of the machining tool body; a first sleeve and a second sleeve are movably mounted in the middles of the front support frame and the rear support frame separately in the transverse direction through a first bearing and a second bearing; a motor is mounted on the top of the front support frame; an output end of the motor is connected with a driving belt pulley through a speed reducer; a first rotating plate and a second rotating plate are separately mounted on opposite side surfaces of the front support frame and the rear support frame; a first chuck and a second chuck are separately arranged on the first rotating plate and the second rotating plate; a welding rack is arranged at a position which is close to the middle of the machining tool body; and a laser welding machine is further mounted on the top of the welding rack. By the technical scheme, the screw pump metal stator welding whole-set equipment system which is accurate in welding and positioning, high in welding speed, high in depth, small in weld joint thermal stress and small in thermal deformation can be provided.

Owner:YANCHENG SHIHONG PETROLEUM EQUIP

Cylindrical grinder easy to assemble and maintain

ActiveCN104690613AHigh precisionHigh surface finishGrinding machine componentsRevolution surface grinding machinesCeramic coatingThermal expansion

The invention discloses a cylindrical grinder easy to assemble and maintain and belongs to the technical field of machine tools. The cylindrical grinder comprises a sleeve, a shell, a cover plate, a grinding wheel and a sliding bearing, the shell is arranged inside the sleeve, two ends of the shell are sealed through the cover plate, the sliding bearing transversely penetrates the shell, and one end of the sliding bearing is connected with the grinding wheel; a ceramic coating is arranged on the sliding bearing and at the contact position of a spindle and a bearing bush, a return oil pipeline is arranged inside the shell and is communicated with a lubricating oil tank on the outer portion of the sleeve, and lubricating oil is circulated in the return oil pipeline in zero-pressure circulation. The ceramic coating is sprayed at the friction position of the spindle and the bearing bush, so that problems about thermal expansion deformation and abrasion of the metal spindle are solved by the aid of outstanding performance of ceramic; meanwhile, according to self structural features of the cylindrical grinder, a brand new oil leakage prevention pipeline is designed for the cylindrical grinder, zero-pressure circulation lubrication of the lubricating oil in an oil cavity is realized, long-term operation is achieved without disassembling the grinder for maintenance, and maintenance cost is greatly lowered.

Owner:MAANSHAN HENGLIDA MACHINE BLADE +1

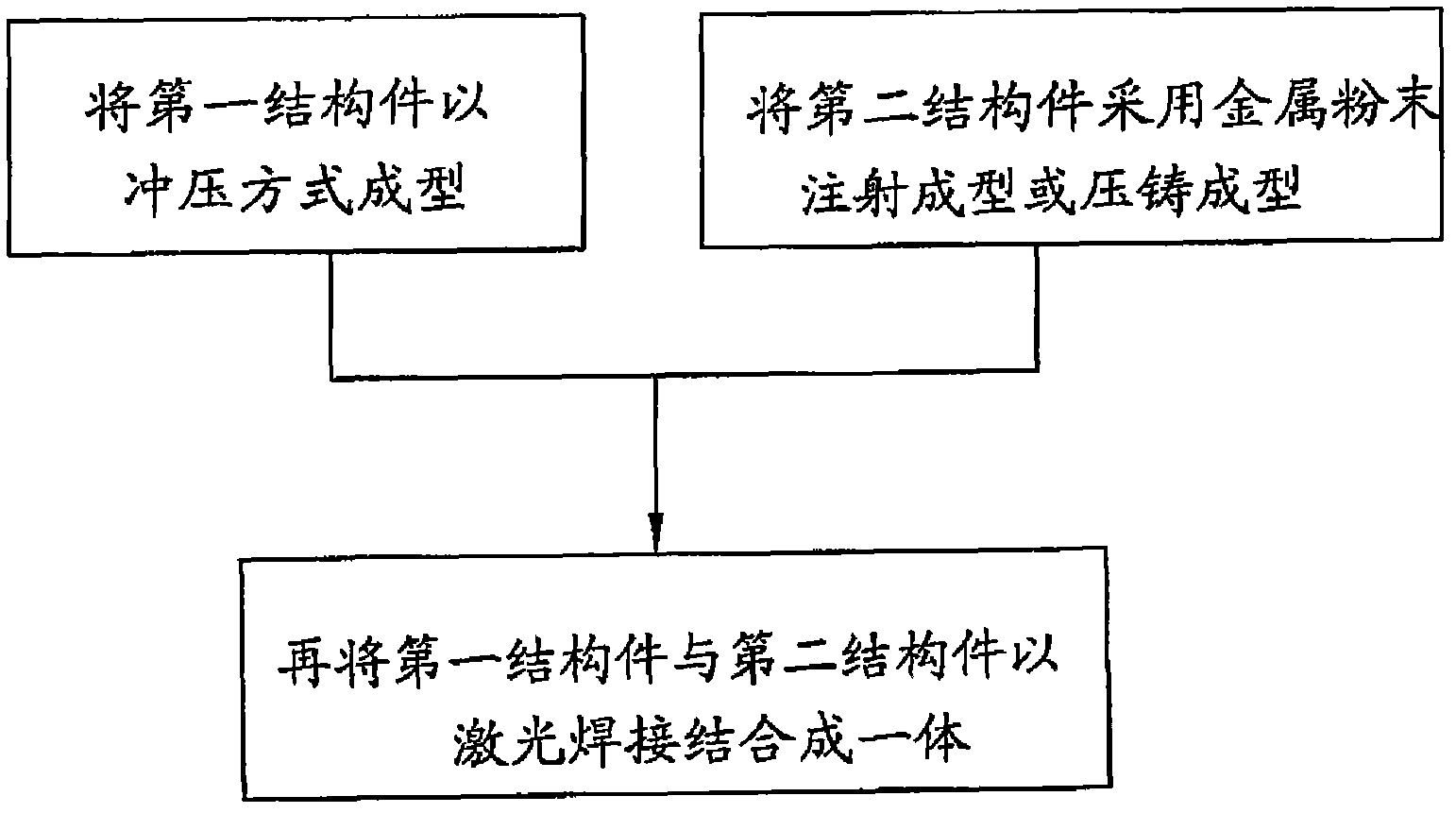

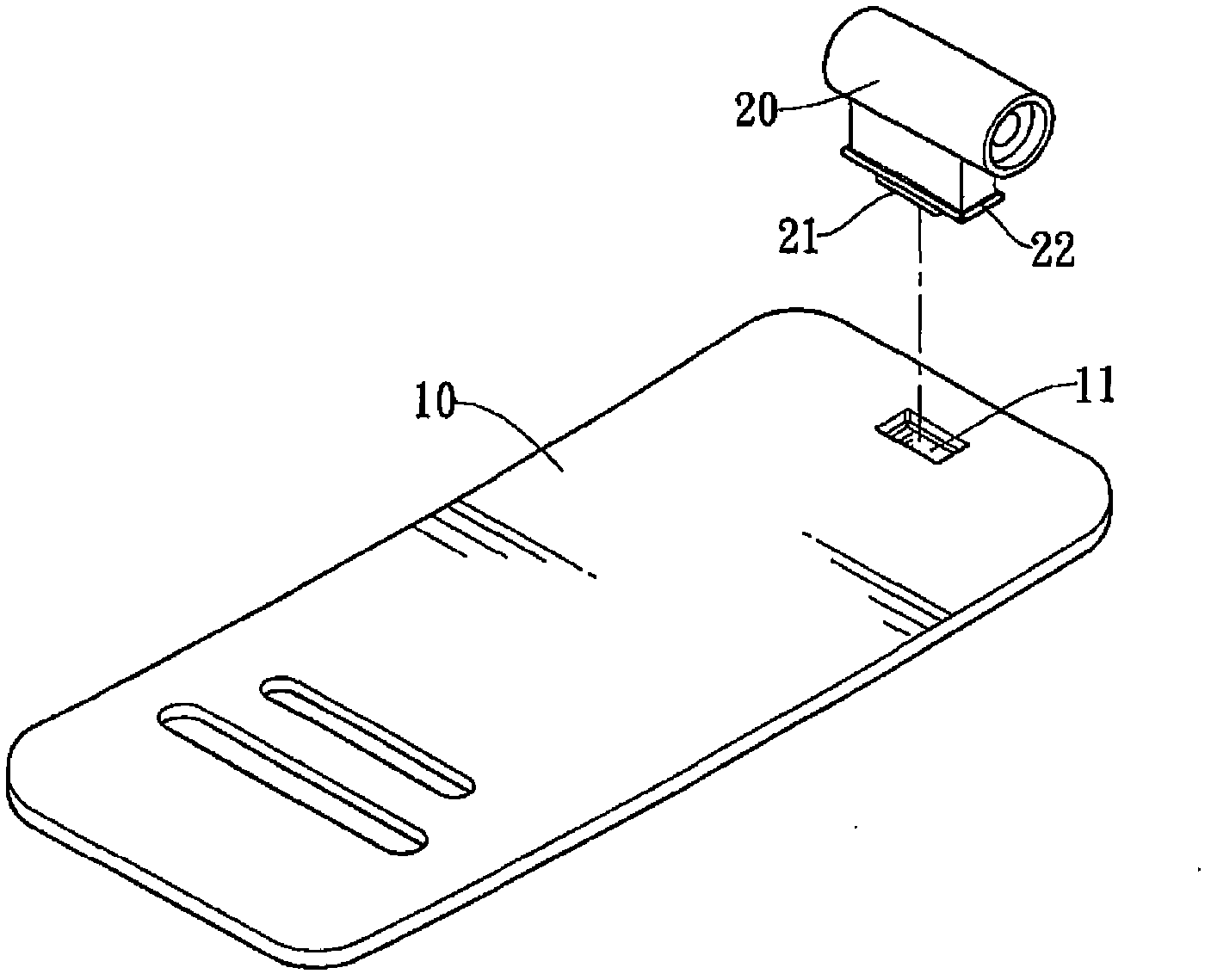

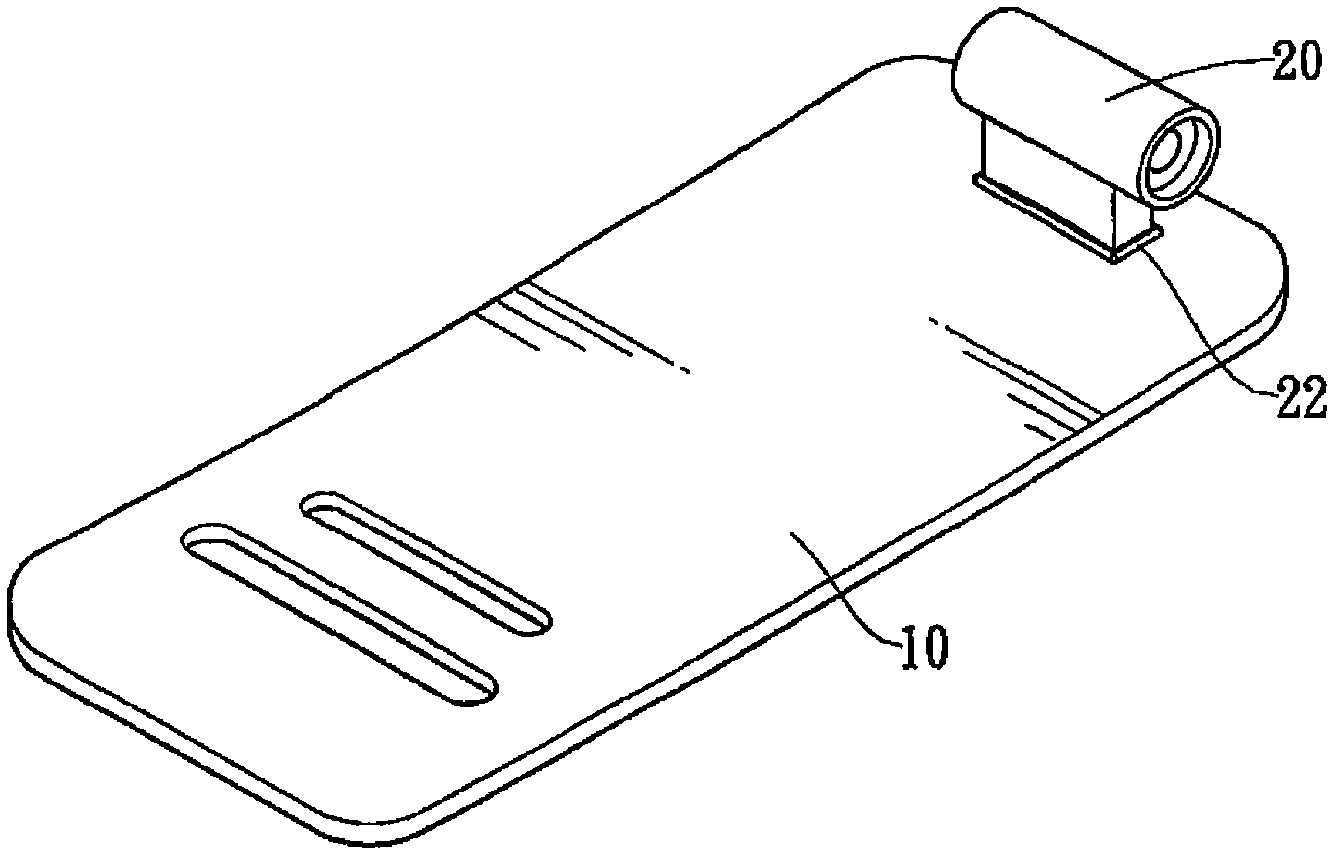

Manufacturing method of assembly part and foot stool manufactured by adopting the manufacturing method

InactiveCN102705637ASolve shrinkageImprove appearance qualityCasings/cabinets/drawers detailsStands/trestlesDie castingEngineering

The manufacturing method of assembly parts of this invention first forms a first structure member by using a pressing method, and forms a second structure member by using the metal powder injection molding or die casting method, and then joins the first structure member and the second structure member into one piece by using laser welding. The stand manufactured by using the manufacturing method includes a supporting member formed by the pressing method, and a connection member made by using the metal powder injection molding or die casting method. In this way, the stand formed in one piece by conventional methods is now made by joining two structure members so that the quality problems of shrinkage and sand holes on the surface can be solved, thus increasing the production yields and reducing the cost greatly.

Owner:JARLLYTEC CO LTD

Common Ni-based high temperature alloy for casting and forging pieces

InactiveCN101638754AChange the organizational structureIncrease the strengthening phasePipe fittingPetrochemical

The invention relates to metallurgical industry, and provides a common Ni-based high temperature alloy for casting and forging pieces, which comprises the following chemical components in percentage by weight: 0.08 to 0.18 percent of C, 0.60 to 1.60 percent of Si, 0.80 to 1.50 percent of Mn, less than 0.03 percent of P, less than 0.03 percent of S, 19.00 to 22.00 percent of Cr, 31.00 to 34.00 percent of Ni, 1.00 to 1.60 percent of Nb, 0.03 to 0.20 percent of Ti, 0.03 to 0.20 percent of Zr, and the balance of Fe and trace impurities. The common Ni-based high temperature alloy for casting and forging pieces overcomes the disadvantages of deforming, cracking and short service life of spare parts of high temperature devices made of the prior common used steel in the petrochemical industry, themetallurgical industry and the like, is characterized by strong yield strength and excellent high temperature stability, is particularly suitable for casting and forging pieces used at the high temperature of 700 to 1,000 DEG C and under high pressure, and is mainly used for manifolds, tail tubes, joints, pipe fittings, fittings, forging pieces and the like of high temperature devices in the petrochemical industry, the metallurgical industry and the like.

Owner:黄石山力大通热工设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com